That's what I was thinking. Win service rifle shows 42 gr as a max load and doesn't use magnum. Thanks for the help.I see no reason why you would have to use Magnum primers with a charge of 40 grains of powder

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

1 WEEK LEFT: This Target Haunts Me Contest

Tell us about the one that got away, the flier that ruined your group, the zero that drifted, the shot you still see when you close your eyes. Winner will receive a free scope!

Join contest

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

.375 Raptor Recipe

- Thread starter Gjb89

- Start date

Anyone have quikload or versed in GRT able to do a sanity check for a recipe I received? This is more academic to be honest, but I'll definitely give it a shot assuming it is possible and within reason. Supposedly not a compressed load

375 Raptor

Bullet 235 Speer hotcor sp

Powder H4350

Start Charge 60

Max Charge 65-67

Expected Muzzle Velocity: 2,550–2,650 fps using 12.5" barrel

Estimated Muzzle Energy: ~2,900–3,000 foot-pounds

375 Raptor

Bullet 235 Speer hotcor sp

Powder H4350

Start Charge 60

Max Charge 65-67

Expected Muzzle Velocity: 2,550–2,650 fps using 12.5" barrel

Estimated Muzzle Energy: ~2,900–3,000 foot-pounds

yeah...that sounded a bit out there. charge weight can vary based on powder type though. Right? I didn't think that much would be possible. I also know there are a lot of people on here with far more knowledge than I have and thought it couldn't hurt to ask!

lol. so I'm guessing it doesn't pass the sanity check. Got it!I don't know everything but I've never seen a charge weight of 60grs of H4350 in anything

***********************************************************************************That would be greatly appreciated. Thank you

This information is provided only as a courtesy and was used in my

rifle / pistol and worked safely.

YOU are responsible for how you use this data. Use at

your own risk.

***********************************************************************************

X-Caliber 375 Raptor 12" Barrel 1-10 / Odinworks 6.8 oz. AR15 9mm Pistol buffer /

JP Ent. Large Frame Rifle Spring / SLR .875 Sentry 8 AGB /

Wilson Combat Q-Comp Muzzle Brake .458 cal.

Powder / Bullet / Primer Velocities

38.5 gr SBR SOCOM / Maker 175 gr. TRex / CCI 34 2337 ft/s 5 shot Average Vel.

39.0 gr SBR SOCOM / Maker 175 gr. TRex / CCI 34 2450 ft/s 5 shot Average Vel.

39.5 gr SBR SOCOM / Maker 175 gr. TRex / CCI 34 2490 ft/s 5 shot Average Vel.

40.0 gr SBR SOCOM / Maker 175 gr. TRex / CCI 34 2527 ft/s 5 shot Average Vel.

41.5 gr Accurate 1680 / Maker 175 gr. TRex / CCI 34 2390 ft/s 5 shot Average Vel.

42.0 gr Accurate 1680 / Maker 175 gr. TRex / CCI 34 2420 ft/s 5 shot Average Vel.

43.0 gr Accurate 1680 / Maker 175 gr. TRex / CCI 34 2440 ft/s 5 shot Average Vel.

43.5 gr Accurate 1680 / Maker 175 gr. TRex / CCI 34 2480 ft/s 5 shot Average Vel.

42.3 gr. Vihtavuori N120 / Maker 175 gr. TRex / CCI 34 2520 ft/s 5 shot Average Vel.

42.6 gr. Vihtavuori N120 / Maker 175 gr. TRex / CCI 34 2530 ft/s 5 shot Average Vel.

43.0 gr. Vihtavuori N120 / Maker 175 gr. TRex / CCI 34 2580 ft/s 5 shot Average Vel.

Last edited:

Thanks for the info. Gives me a great starting point. Happy Thanksgiving!***********************************************************************************

This information is provided only as a courtesy and was used in my

rifle / pistol and worked safely.

YOU are responsible for how you use this data. Use at

your own risk.

***********************************************************************************

X-Caliber 375 Raptor 12" Barrel 1-10 / Odinworks 6.8 oz. AR15 9mm Pistol buffer /

JP Ent. Large Frame Rifle Spring / SLR .875 Sentry 8 AGB /

Wilson Combat Q-Comp Muzzle Brake .458 cal.

Powder / Bullet / Primer Velocities

38.5 gr SBR SOCOM / Maker 175 gr. TRex / CCI 34 2337 ft/s 5 shot Average Vel.

39.0 gr SBR SOCOM / Maker 175 gr. TRex / CCI 34 2450 ft/s 5 shot Average Vel.

39.5 gr SBR SOCOM / Maker 175 gr. TRex / CCI 34 2490 ft/s 5 shot Average Vel.

40.0 gr SBR SOCOM / Maker 175 gr. TRex / CCI 34 2527 ft/s 5 shot Average Vel.

41.5 gr Accurate 1680 / Maker 175 gr. TRex / CCI 34 2390 ft/s 5 shot Average Vel.

42.0 gr Accurate 1680 / Maker 175 gr. TRex / CCI 34 2420 ft/s 5 shot Average Vel.

43.0 gr Accurate 1680 / Maker 175 gr. TRex / CCI 34 2440 ft/s 5 shot Average Vel.

43.5 gr Accurate 1680 / Maker 175 gr. TRex / CCI 34 2480 ft/s 5 shot Average Vel.

42.3 gr. Vihtavuori N120 / Maker 175 gr. TRex / CCI 34 2520 ft/s 5 shot Average Vel.

42.6 gr. Vihtavuori N120 / Maker 175 gr. TRex / CCI 34 2530 ft/s 5 shot Average Vel.

43.0 gr. Vihtavuori N120 / Maker 175 gr. TRex / CCI 34 2580 ft/s 5 shot Average Vel.

1680 isn't the best performer. N120 worked well. I haven't had time to continue working. up the N530 loads. However, N530 is no longer being shipped to USA but I have quite a pile ofThanks for the info. Gives me a great starting point. Happy Thanksgiving!

it. Happy Thanksgiving to you as well.

I've stumbled across something that appears odd in GRT. It could be I've just never thought of it to be honest. I have some Speer Hot Cor 235 grain semi spitzer soft points. GRT does have a 375 raptor profile and the bullet I'm looking at loading. I noticed it has a seating depth of .104 which seems too short. I've read a lot of posts that suggest they never do less than the diameter of the bullet as seating depth. And of course, many on the other side of the aisle as well. I also read about concentricity issues by doing too little. I realize seating depth also impacts pressure. Seating deeper generally increasing pressure. Lastly, I know I have to operate within the AR10 mag capacity of 2.800".

After that, my long winded question is, is there a point where seating a bullet too deep causes an issue? Doesn't increasing the amount of jump to the lands cause pressure in of itself? Assuming I stay within pressure limits for the cartridge, is there a difference?

I don't believe bullets normally have a seating depth listed. So if you have a bullet that doesn't list or you can't find a seating depth, is the normal procedure to load to max length of the magazine?

After that, my long winded question is, is there a point where seating a bullet too deep causes an issue? Doesn't increasing the amount of jump to the lands cause pressure in of itself? Assuming I stay within pressure limits for the cartridge, is there a difference?

I don't believe bullets normally have a seating depth listed. So if you have a bullet that doesn't list or you can't find a seating depth, is the normal procedure to load to max length of the magazine?

Here is what I'm talking about. It appears that it takes that COAL and subtracts the case length. Then seats the bullet just enough so the bullet length plus the case length equals the COAL. It even warns of the bullets seating depth being too low. So if I push it back .1 (an arbitrary amount) the warning goes away. But, is there some kind of standard minimum seating depth that should be adhered to? An since it now has a larger jump since the COAL is 2.7, is there any issue? It doesn't sound like there is. Thanks for the help.

Just chambered my barrel that I’ve had laying around for a couple years. Didn’t really plan on supers but will play with them for the sake of science. 400gr makers and cutting edge lazers along with 390atips will be what I play with most

So I got my 375 raptor assembled. Everything seems to work fine except when I'm using my Lee dies to form brass for rounds. I'm using 358 Win brass from Starline. If I form it as usual, after cut/trim with the dies set to shell holder depth -1/4 turn, the brass gets stuck in the chamber and is very difficult to eject. I also noticed that there is no or minimal primer strike from the firing pin. I've had to push the shoulder back some increasing the depth of the sizing die, but then I have to remove the die to do the other stations and finish the round. With the shoulder bumped down, the round chambers and ejects as expected if inserted manually into the chamber and the bolt is allowed to close. If it strips it from the mag, the bolt fails to go into battery completely. If I charge it again, assuming the BCG isn't stuck, it'll work normally after that. Cycling is as expected after the first firing and after the first time it is put into battery. It seems like the first time the bolt closes on newly formed brass it is fixing whatever minimal problem there is.

I'd prefer not to have my BCG cramming the brass into it's final form. Any thoughts on where to look? Could it be the dies? I've also read it could be a stiff extractor spring. I have a known good BCG from a .308. Going to swap that tomorrow with new brass and test that. Additional ideas would be appreciated.

I only managed to get through the x-caliber break-in today, but on the two 5 round mags I used at the end, which were reloaded a few times, everything worked perfectly.

Thanks,

James

I'd prefer not to have my BCG cramming the brass into it's final form. Any thoughts on where to look? Could it be the dies? I've also read it could be a stiff extractor spring. I have a known good BCG from a .308. Going to swap that tomorrow with new brass and test that. Additional ideas would be appreciated.

I only managed to get through the x-caliber break-in today, but on the two 5 round mags I used at the end, which were reloaded a few times, everything worked perfectly.

Thanks,

James

My thoughts on what to check.So I got my 375 raptor assembled. Everything seems to work fine except when I'm using my Lee dies to form brass for rounds. I'm using 358 Win brass from Starline. If I form it as usual, after cut/trim with the dies set to shell holder depth -1/4 turn, the brass gets stuck in the chamber and is very difficult to eject. I also noticed that there is no or minimal primer strike from the firing pin. I've had to push the shoulder back some increasing the depth of the sizing die, but then I have to remove the die to do the other stations and finish the round. With the shoulder bumped down, the round chambers and ejects as expected if inserted manually into the chamber and the bolt is allowed to close. If it strips it from the mag, the bolt fails to go into battery completely. If I charge it again, assuming the BCG isn't stuck, it'll work normally after that. Cycling is as expected after the first firing and after the first time it is put into battery. It seems like the first time the bolt closes on newly formed brass it is fixing whatever minimal problem there is.

I'd prefer not to have my BCG cramming the brass into it's final form. Any thoughts on where to look? Could it be the dies? I've also read it could be a stiff extractor spring. I have a known good BCG from a .308. Going to swap that tomorrow with new brass and test that. Additional ideas would be appreciated.

I only managed to get through the x-caliber break-in today, but on the two 5 round mags I used at the end, which were reloaded a few times, everything worked perfectly.

Thanks,

James

-Check barrel with headspace gauge

-Check cases with case gauge

-Buy brass/ammo from BlackCollarMunitions and see if it works. I haven't tried there stuff yet, but it looks like they finally have it available.

I have to run my starline 358 cases through my CH4D die and then through the LEE die. Not sure why, could be tolerances combined with brass springback or something. I haven't tried with my extra LEE dies sets I got recently to see if they have the same issue.

Regarding bullet seating depth, I believe the old data showed 2.710" for the 235gr speer.

Regarding powder for that bullet, I used the data for the 250gr SGK to find where to start. It lists both 10x and AA2200.

BTW, don't expect to get the velocities listed on the old raptor site data. My velocities are 50-75fps slower.

I don't see any type of gauges available specifically for 375 raptor. So, I went and bought a Hornady headspace gauge to be able to measure the shoulder. I did notice that I have to crank the LEE FS die as far down as I can to be able to get it to match fired brass.My thoughts on what to check.

-Check barrel with headspace gauge

-Check cases with case gauge

-Buy brass/ammo from BlackCollarMunitions and see if it works. I haven't tried there stuff yet, but it looks like they finally have it available.

I have to run my starline 358 cases through my CH4D die and then through the LEE die. Not sure why, could be tolerances combined with brass springback or something. I haven't tried with my extra LEE dies sets I got recently to see if they have the same issue.

Regarding bullet seating depth, I believe the old data showed 2.710" for the 235gr speer.

Regarding powder for that bullet, I used the data for the 250gr SGK to find where to start. It lists both 10x and AA2200.

BTW, don't expect to get the velocities listed on the old raptor site data. My velocities are 50-75fps slower.

I was thinking about purchasing one of the CH4D dies as well, but it sounds like you have a similar issue with cases using theirs as well.

Do you just use one FS die after the other?

I noticed a lot of the overhype from that page. I'm actually enjoying the 375 Raptor, but it's not going to get to where they say it can be unless you really push your cartridge loads.

I got my headspace gauge from PT&G. Case gauge from Medesha Firearms on ebay.

According to the old raptor website, the CH4D dies used a larger neck outside diameter. This was for sizing thicker military brass. My dies left no neck tension on the once-fired brass I was using.

For new brass, I cut brass with mini saw, expand neck with expander die, trim to spec, one pass through CH4D die, then one pass through lee. I use a Lyman turret press so I can switch dies very easy.

IIRC, I can also just use a filed-down shellholder with my lee dies and skip the CH4D die.

For my brass that is once-fired, I think I just run it through the lee die with a normal shellholder.

Converting brass is a bit of a pain. I will try to get some factory raptor brass while it's available.

Regarding the old website velocity numbers, I think 1200-R was the key to some of that. I think it burns like 10x but since it's a ball powder, you can add more. But yeah, their numbers seem a bit high.

Beyond 300yds, most normal bullets may not expand as much. However. You only need the .375 to expand 30% to match a .308 expanded 50%. And there is more mass behind the .375.

I decided on a 308 as my practice/old faithful gun, and the raptor as my wildcat shenanigans gun.

According to the old raptor website, the CH4D dies used a larger neck outside diameter. This was for sizing thicker military brass. My dies left no neck tension on the once-fired brass I was using.

For new brass, I cut brass with mini saw, expand neck with expander die, trim to spec, one pass through CH4D die, then one pass through lee. I use a Lyman turret press so I can switch dies very easy.

IIRC, I can also just use a filed-down shellholder with my lee dies and skip the CH4D die.

For my brass that is once-fired, I think I just run it through the lee die with a normal shellholder.

Converting brass is a bit of a pain. I will try to get some factory raptor brass while it's available.

Regarding the old website velocity numbers, I think 1200-R was the key to some of that. I think it burns like 10x but since it's a ball powder, you can add more. But yeah, their numbers seem a bit high.

Beyond 300yds, most normal bullets may not expand as much. However. You only need the .375 to expand 30% to match a .308 expanded 50%. And there is more mass behind the .375.

I decided on a 308 as my practice/old faithful gun, and the raptor as my wildcat shenanigans gun.

U

Only 80% burned, very inefficient...

and 2185 fps.in a 12" barrel...if you could find a way to get all that powder in the case.

H335 would be a better choice you could actually load it.

You can not even do the starting load of 60 gr....thats over 125.8% case fill ...very compressed. The powder would flow over onto the floor, and seating the bullet? Forget about it.Anyone have quikload or versed in GRT able to do a sanity check for a recipe I received? This is more academic to be honest, but I'll definitely give it a shot assuming it is possible and within reason. Supposedly not a compressed load

375 Raptor

Bullet 235 Speer hotcor sp

Powder H4350

Start Charge 60

Max Charge 65-67

Expected Muzzle Velocity: 2,550–2,650 fps using 12.5" barrel

Estimated Muzzle Energy: ~2,900–3,000 foot-pounds

Only 80% burned, very inefficient...

and 2185 fps.in a 12" barrel...if you could find a way to get all that powder in the case.

H335 would be a better choice you could actually load it.

Here's what I got when testing out my newly build AR 10 in 375 Raptor.

These are my MAXIMUM loads, use at your own risk.

Some have Winchester WW brass and some have hybrid SS case heads.

These 2 have similar capacities, other cases I checked had less H2O capacity.

These are my MAXIMUM loads, use at your own risk.

Some have Winchester WW brass and some have hybrid SS case heads.

These 2 have similar capacities, other cases I checked had less H2O capacity.

Attachments

The 400 gr Maker didn't stabilize in the 12 twist past 40 yds...

So I machined .064" off the point and repointed only lost around 8 to 10 grs and the Berger bullet stability calculator says its now stable...we'll see.

Not to concerned about it because I don't plan on hunting with the 375 Raptor in sub mode, just messing around with this caliber is fun. Plus I have 510 whisper.

So I started on other bullets, hollow pointing 270 gr Speer, hollow pointing 235 gr and thinning the jacket for more explosive expansion on small game.

Making 165 gr out of copper.

A plastic sabot and tiny bullets?...anyone?

So I machined .064" off the point and repointed only lost around 8 to 10 grs and the Berger bullet stability calculator says its now stable...we'll see.

Not to concerned about it because I don't plan on hunting with the 375 Raptor in sub mode, just messing around with this caliber is fun. Plus I have 510 whisper.

So I started on other bullets, hollow pointing 270 gr Speer, hollow pointing 235 gr and thinning the jacket for more explosive expansion on small game.

Making 165 gr out of copper.

A plastic sabot and tiny bullets?...anyone?

Attachments

You may know more than I on this, but I am not sure how accurate those stability calculators are for subsonic.The 400 gr Maker didn't stabilize in the 12 twist past 40 yds...

So I machined .064" off the point and repointed only lost around 8 to 10 grs and the Berger bullet stability calculator says its now stable...we'll see.

Not to concerned about it because I don't plan on hunting with the 375 Raptor in sub mode, just messing around with this caliber is fun. Plus I have 510 whisper.

So I started on other bullets, hollow pointing 270 gr Speer, hollow pointing 235 gr and thinning the jacket for more explosive expansion on small game.

Making 165 gr out of copper.

A plastic sabot and tiny bullets?...anyone?

I thought I read about that issue somewhere. The round nose shape may also change things.

I do hope the 400gr makers stabilize well with my 10 twist.

I did get some 137gr hammer bullets to try on lighter game.

The round nose would require a slower twist being closer to the bore and shorter lenght by design for the same weight compared to long pointy match bullets.You may know more than I on this, but I am not sure how accurate those stability calculators are for subsonic.

I thought I read about that issue somewhere. The round nose shape may also change things.

I do hope the 400gr makers stabilize well with my 10 twist.

I did get some 137gr hammer bullets to try on lighter game.

Bullet length is a big factor in stability, the other is altitude, and temperature is a smaller factor ...12 and 10 twists, they'd be all stable at 4200 ft or above in elevation. I have that here, just gotta drive a bit farther.

So we'll see how the bullet stability calculator works with subs and around 12 to 1500 ft in elevation.

Don't have the answers so I'm doing the experimenting.

Whats nice about the Maker 400 gr is its long nose is hollow, so ya don't lose much weight to shorten it. But shortening the bullet is the best way to stablize it...or hunt at high elevations.

I believe a 10 twist will stablize the 400 maker, at least for close ranges where one is likely to use it.

Bullet tumbling increases wounding and alot of these bullets tumble after impact and a bit of penetration, as they lose gyroscopic stability, for many reasons like loss of a petal, impact with bone, off balance because of weight loss inconsistencies.

Plan on having a little fun with this project.

Some of it may be off the wall and usless, but take anything you find useful to use.

I like the idea of some lighter than normal bullets as bunny busters.

I got the 358 win to 3740 fps in a 16" AR 10, with tiny copper hollowpionts....usefulness is limited.

The 137 gr could be interesting...

Got out today and did some Maximum load testing...

Except for 2 400 gr Maker modified to 388 ...shortened to 1.742" from 1.805" and weighing in at 398.

So take 10 grains off the bullet shorten it 1/16" cause it's all hollow and repoint...now it's stable in my 12 twist.

Just as predicted by the Berger stability calculator...works for round nose subs ...in this case.

Here is the basic "Maximum loads" tested ...use at your own risk ...work up if you decide to use them. Note any difference in COAL as pressures can really rise with a small shortening of the COAL.

The 300 SMK at 2125 fps ave had noticeably more recoil.

The Speer 235 gr showed good accuracy at maximum pressure. The 300 gr Sierra was less accurate around 1.3"

The H335 showed good SDs in velocity for a run of the mill AR 10.

AA 1680 appears to be good for the 388 gr Maker 18.5 gr 1090 fps.

Developing the data.

Except for 2 400 gr Maker modified to 388 ...shortened to 1.742" from 1.805" and weighing in at 398.

So take 10 grains off the bullet shorten it 1/16" cause it's all hollow and repoint...now it's stable in my 12 twist.

Just as predicted by the Berger stability calculator...works for round nose subs ...in this case.

Here is the basic "Maximum loads" tested ...use at your own risk ...work up if you decide to use them. Note any difference in COAL as pressures can really rise with a small shortening of the COAL.

The 300 SMK at 2125 fps ave had noticeably more recoil.

The Speer 235 gr showed good accuracy at maximum pressure. The 300 gr Sierra was less accurate around 1.3"

The H335 showed good SDs in velocity for a run of the mill AR 10.

AA 1680 appears to be good for the 388 gr Maker 18.5 gr 1090 fps.

Developing the data.

Attachments

-

20250724_140914.jpg1 MB · Views: 18

20250724_140914.jpg1 MB · Views: 18 -

20250724_142255.jpg789.9 KB · Views: 17

20250724_142255.jpg789.9 KB · Views: 17 -

20250724_142844.jpg1.4 MB · Views: 14

20250724_142844.jpg1.4 MB · Views: 14 -

20250724_144412.jpg1.3 MB · Views: 17

20250724_144412.jpg1.3 MB · Views: 17 -

20250724_143959.jpg994.2 KB · Views: 20

20250724_143959.jpg994.2 KB · Views: 20 -

20250724_145745.jpg771.3 KB · Views: 19

20250724_145745.jpg771.3 KB · Views: 19 -

20250724_223229.jpg895.4 KB · Views: 20

20250724_223229.jpg895.4 KB · Views: 20 -

20250724_140423.jpg1.1 MB · Views: 16

20250724_140423.jpg1.1 MB · Views: 16 -

20250724_142855.jpg1.4 MB · Views: 18

20250724_142855.jpg1.4 MB · Views: 18

Nothing too exciting. 20ish grains of CFE Black. Looks like I can back down 1.5-2gr to get to about 1050 where I want to be with the 400gr.

I use 18.5 gr of 1680 for 1090 fps...I seat the 400 gr subs deep to take up powder space, around 2.640" to get low S/Ds.

It has the same problem as the 8.6 with respect to too much powder space for subs...the 400 gr or longer RN type should be the best for most uses.

But I have to experiment.

I have some 300 gr RN to seat deep or run backwards like a wadcutter.

Deep Hollow point the 235 gr Speer & thin the front portion of the jacket on the lathe.

Or even saw cut segments in the front of the bullet...

Or machine some out of copper solid.

Already did most of that except mess with the 300 grs

Just cut a bunch of LC & Lapua to length, only takes a few minutes in the mill. Cut 5hem about .010" over and they size down in length to print. A very easy case to make.

It has the same problem as the 8.6 with respect to too much powder space for subs...the 400 gr or longer RN type should be the best for most uses.

But I have to experiment.

I have some 300 gr RN to seat deep or run backwards like a wadcutter.

Deep Hollow point the 235 gr Speer & thin the front portion of the jacket on the lathe.

Or even saw cut segments in the front of the bullet...

Or machine some out of copper solid.

Already did most of that except mess with the 300 grs

Just cut a bunch of LC & Lapua to length, only takes a few minutes in the mill. Cut 5hem about .010" over and they size down in length to print. A very easy case to make.

Attachments

I use 18.5 gr of 1680 for 1090 fps...I seat the 400 gr subs deep to take up powder space, around 2.640" to get low S/Ds.

It has the same problem as the 8.6 with respect to too much powder space for subs...the 400 gr or longer RN type should be the best for most uses.

But I have to experiment.

I have some 300 gr RN to seat deep or run backwards like a wadcutter.

Deep Hollow point the 235 gr Speer & thin the front portion of the jacket on the lathe.

Or even saw cut segments in the front of the bullet...

Or machine some out of copper solid.

Already did most of that except mess with the 300 grs

Just cut a bunch of LC & Lapua to length, only takes a few minutes in the mill. Cut 5hem about .010" over and they size down in length to print. A very easy case to make.

I’ll try that seating depth with my CFE Black this weekend. Just waiting for a new powder cup and funnel adapters to come in. Should be here tomorrow.

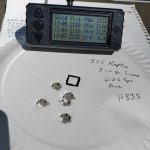

Finished shooting a bunch of sub load attempts.

Wrote down velocity, powder, velocity S/Ds, COALs for the load, group sizes at 50 yds are pictured for the various powder charges.

Bullets 235 gr Speer, 270 gr Speer, 300 gr RN, 300 gr Sierra.

AA1680 is the only one that will operate the bolt...it produced some fair groups but high S/Ds except for the 300 gr Sierra where it worked great.

TrailBoss was only accurate with the 235 gr Speer. Herco put 3 in the same hole and one down low, with 270 gr & S/D of 17.9.

RedDot had the lowest S/D of 6.0 and good accuracy with the 235 gr at 1088 fps

So as I expected the 375 Raptor is not as good of a sub round as the tiny cased 338 Spectre or the 388 ARC imp 6.5 twist for normally used bullets for caliber.

They are more accurate with sub loads but struggle with supers because they don't have much case capacity needed to drive supers faster.

The 400 gr plus should be better for sub loads in the 375 Raptor to take up powder space to get lower S/Ds. Although some here would be fine light bunny loads...notice the mostly short COALs with the light 375 cal bullets.

All things considered a fun day shooting, although hot and uncomfortable, tends to make it more tedious shooting all these loads.

Wrote down velocity, powder, velocity S/Ds, COALs for the load, group sizes at 50 yds are pictured for the various powder charges.

Bullets 235 gr Speer, 270 gr Speer, 300 gr RN, 300 gr Sierra.

AA1680 is the only one that will operate the bolt...it produced some fair groups but high S/Ds except for the 300 gr Sierra where it worked great.

TrailBoss was only accurate with the 235 gr Speer. Herco put 3 in the same hole and one down low, with 270 gr & S/D of 17.9.

RedDot had the lowest S/D of 6.0 and good accuracy with the 235 gr at 1088 fps

So as I expected the 375 Raptor is not as good of a sub round as the tiny cased 338 Spectre or the 388 ARC imp 6.5 twist for normally used bullets for caliber.

They are more accurate with sub loads but struggle with supers because they don't have much case capacity needed to drive supers faster.

The 400 gr plus should be better for sub loads in the 375 Raptor to take up powder space to get lower S/Ds. Although some here would be fine light bunny loads...notice the mostly short COALs with the light 375 cal bullets.

All things considered a fun day shooting, although hot and uncomfortable, tends to make it more tedious shooting all these loads.