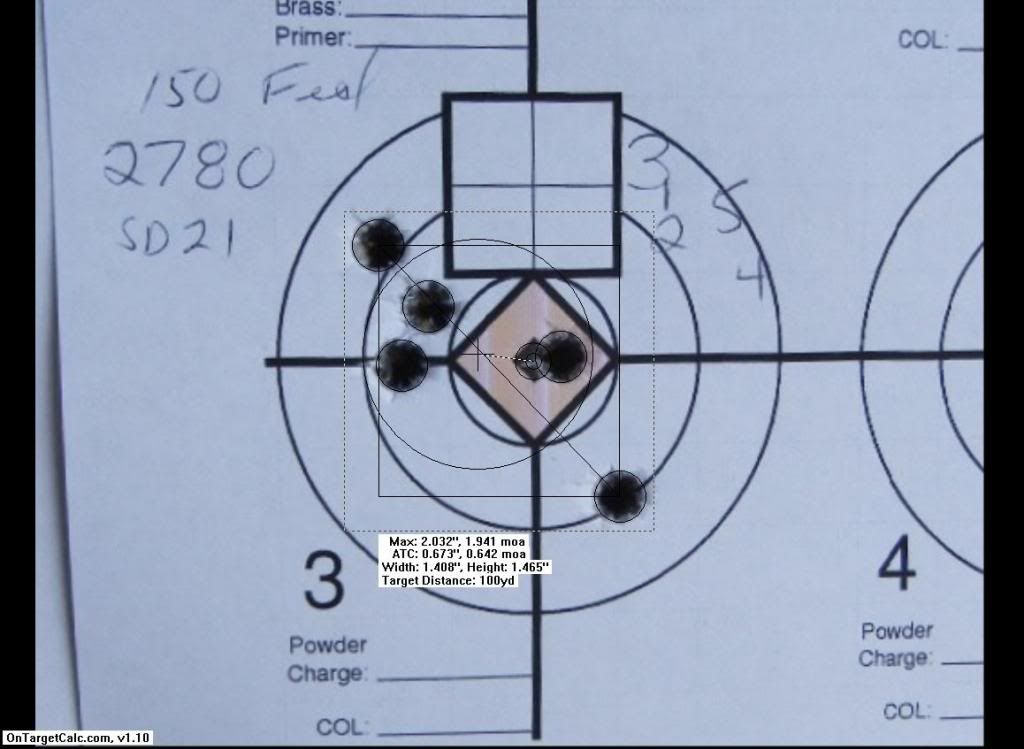

100 yards to develop a Varget and 175 Sierra MK load, easy right? Start with 5 rounds of FGMM 168's just to season the otherwise clean bore. Then a bottom of the book 42.0 grains with SMK at 2.80" COL and Federal 210 standard primers in LC LR 11 cases that were once fired, Headspace had been setback .003" from this chamber.

Great morning, wonderful conditions. Focused scope a little better, looked at the reticle, I like it and find it useful and field effective. It grows on me. Not so sure about resolution however, but I'm cannot be the judge of such things as my eyes aren't good enough. All rounds fired sitting at bench from bi-pod with a rear bag semi supported.

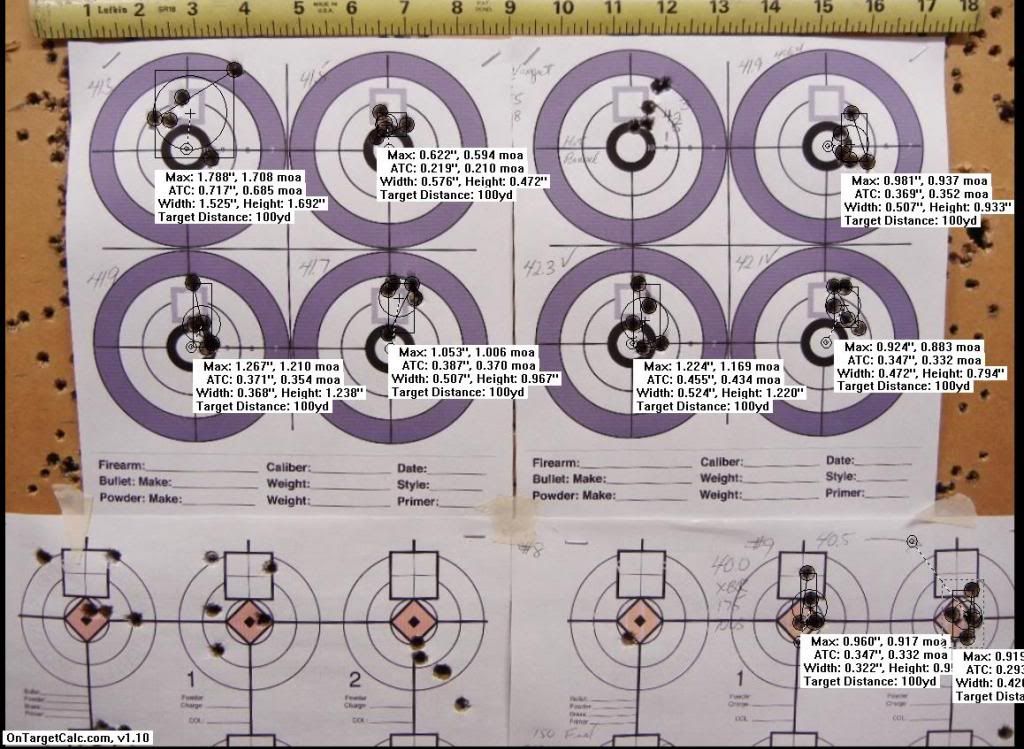

Start with clean bore and FGMM 168's (my stash) all rounds sequenced POI on the target picture below. Apparently GAP's have a known issue with staying back on the last round. Maybe it's a slow magazine follower. I am going to try a different new magazine next outing. Velocity 2644 SD 13 .896 MOA

Load #1, 42.0 grs Varget SMK 175 F 210 std, LC LR 11 1 X cases; 2nd and 4th rounds failed to feed, no lock back. Velocity 2558 SB 12 best 3 .274 (3,4 & 5) bore changing conditions from FGMM, this load shot better than it's number.

Load #2 42.4 grs; Basically same POI as prior and tight shooter, but 1 fail to feed and didn't lock back. Vel = 2573 SD 16, .6 for 4, and .858 all 5.

Load #3 42.8 grs; 1 fail to eject, 3 fails to feed failed to lock back... .633 for 4, 1.4 for all 5 rounds. Vel = 2600 SD 24

Load #4 43.1 grs; 2 fail to feed both no round picked up but bolt closed, no lock back, Vel = 2615 SD 9

.590 for 4 all 5 going .825 MOA.

Load #5 43.4 grs; This is the only load that ran 100% in every way, accidental I'm sure! best 4 .644 and all 5 at .780. Vel = 2628 SD 4

Load #6 43.7 grs; Best shooter worst function... a dilemma for sure... .459 for 4, and .595 all 5, Vel = 2656 SD 10. 100% fail to feed, 1 fail to eject and of course no lock back.

Load #7 44.0 grs; First round blew or technically pierced the primer... I was done Vel = 2688, primer piece inside bolt, removed at cleaning upon arrival home.

Great morning, wonderful conditions. Focused scope a little better, looked at the reticle, I like it and find it useful and field effective. It grows on me. Not so sure about resolution however, but I'm cannot be the judge of such things as my eyes aren't good enough. All rounds fired sitting at bench from bi-pod with a rear bag semi supported.

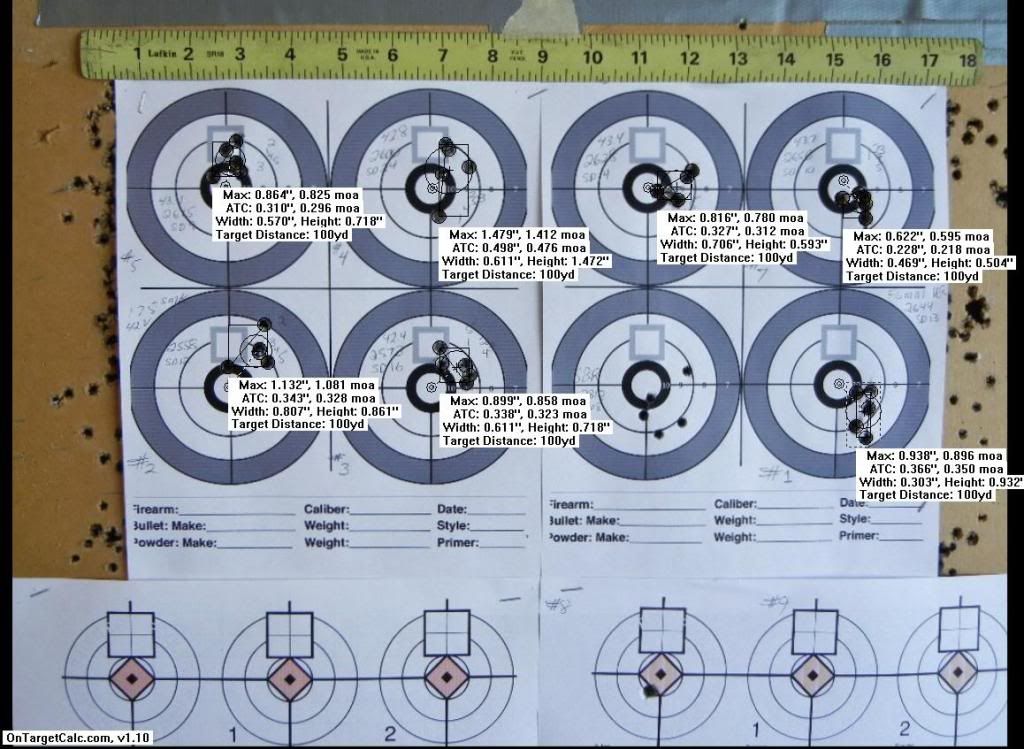

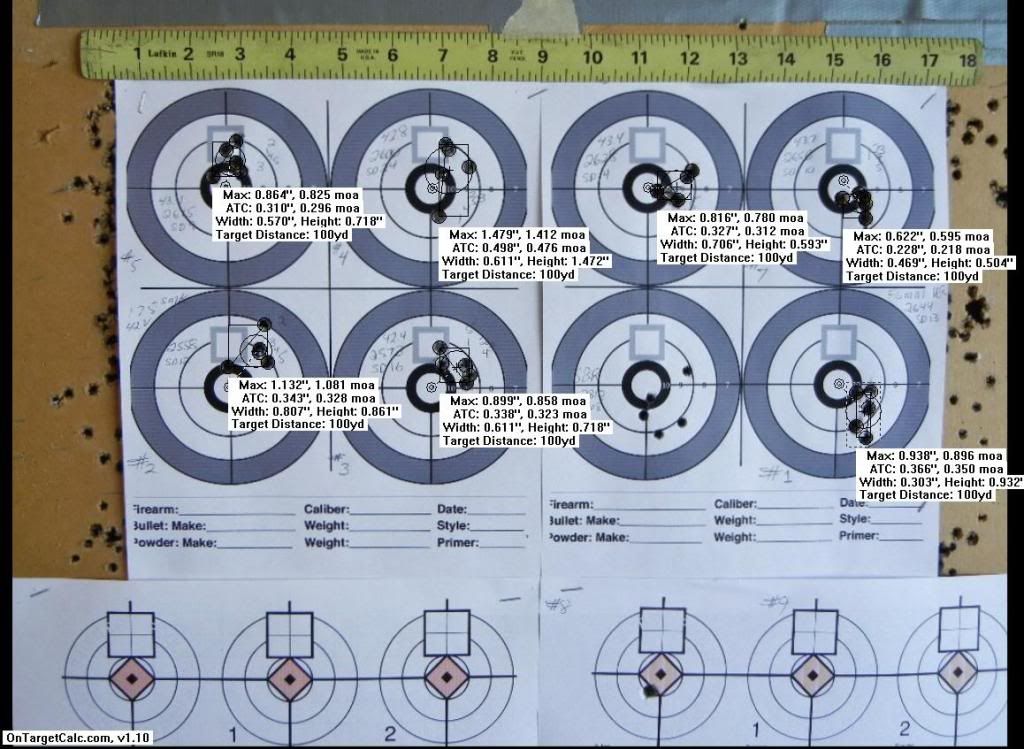

Start with clean bore and FGMM 168's (my stash) all rounds sequenced POI on the target picture below. Apparently GAP's have a known issue with staying back on the last round. Maybe it's a slow magazine follower. I am going to try a different new magazine next outing. Velocity 2644 SD 13 .896 MOA

Load #1, 42.0 grs Varget SMK 175 F 210 std, LC LR 11 1 X cases; 2nd and 4th rounds failed to feed, no lock back. Velocity 2558 SB 12 best 3 .274 (3,4 & 5) bore changing conditions from FGMM, this load shot better than it's number.

Load #2 42.4 grs; Basically same POI as prior and tight shooter, but 1 fail to feed and didn't lock back. Vel = 2573 SD 16, .6 for 4, and .858 all 5.

Load #3 42.8 grs; 1 fail to eject, 3 fails to feed failed to lock back... .633 for 4, 1.4 for all 5 rounds. Vel = 2600 SD 24

Load #4 43.1 grs; 2 fail to feed both no round picked up but bolt closed, no lock back, Vel = 2615 SD 9

.590 for 4 all 5 going .825 MOA.

Load #5 43.4 grs; This is the only load that ran 100% in every way, accidental I'm sure! best 4 .644 and all 5 at .780. Vel = 2628 SD 4

Load #6 43.7 grs; Best shooter worst function... a dilemma for sure... .459 for 4, and .595 all 5, Vel = 2656 SD 10. 100% fail to feed, 1 fail to eject and of course no lock back.

Load #7 44.0 grs; First round blew or technically pierced the primer... I was done Vel = 2688, primer piece inside bolt, removed at cleaning upon arrival home.

Last edited: