Remington offers this manual at no charge if you provide the serial number

Part No. 3518 Rev. 704

Thanks for the info.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Remington offers this manual at no charge if you provide the serial number

Part No. 3518 Rev. 704

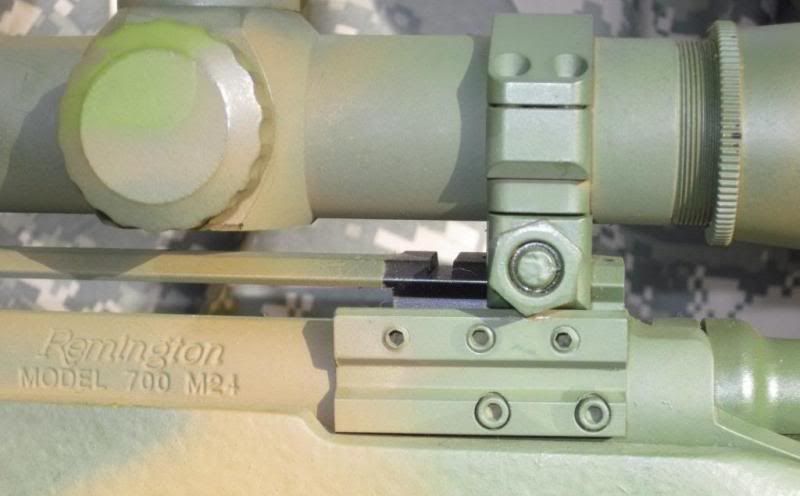

I'm not sure what that piece, just forward of the bolt handle is?

REF: m24 sws - Taringa!

Note: 1st time posting a pic. If I've violated any rules, please tell me via PM and I'll fix it and won't do it again.

Ok guys, I approached twomanattack about the possibility of making some flash hiders for the M24. He's making some awesome reproduction M40A1 scope mounts and is working the final legalities for modifying Remington triggers to M24 specs. I'm hoping that between this thread and the M24 Rebuild thread that it may gain some interest. I know I'm like everyone else, cost is a factor and if it's to much then it's just not worth it.

If you have an original flash hider and are willing to loan it out to twomanattack pm him or I.

One thing to keep in mind on this endeavor, while the basic flash hider is the same for both type of front sight bases the Remington sight base takes a thinner lock ring while the OK Webber base uses a thicker one.

The lock ring slips on first and has a notch to clear the front sight base then the flash hider is slid on and the lock ring tightened up to the back of the sight base.

So you may want to have a consensus on which lock ring to have made or do some of both before you start production.

Heres some measurements of the flash hider. I will get some of the front base later on.

Ok guys, I approached twomanattack about the possibility of making some flash hiders for the M24. He's making some awesome reproduction M40A1 scope mounts and is working the final legalities for modifying Remington triggers to M24 specs. I'm hoping that between this thread and the M24 Rebuild thread that it may gain some interest. I know I'm like everyone else, cost is a factor and if it's to much then it's just not worth it.

If you have an original flash hider and are willing to loan it out to twomanattack pm him or I.

What is that piece for?

Evidently they were using what they had. The older EMA (laser filter) isn't in production any more and hasn't been for many years. Yes the threads are similar but they aren't the exact same. I tried using one of the plastic filters on my M3A and when I tightened the lock ring the threads jumped. No good positive lockup. On the other hand, I used the plastic filter on my M14 EBR-RI with the Mark 4 3.5-10 Variable and it locked up fine.

Here is the new Laser Filter Unit for the M110 SASS. Aluminum body (NSN 1240-01-537-6986 same as the older plastic model) and fits much better than the plastic ones.

That ema you have there is a newer version for the m110 which differs from the m24 ema, you guys need to watch the market boards, an original sold on eBay a few weeks ago.

For instance, there's a Dakota M24 floormetal on gunbroker.

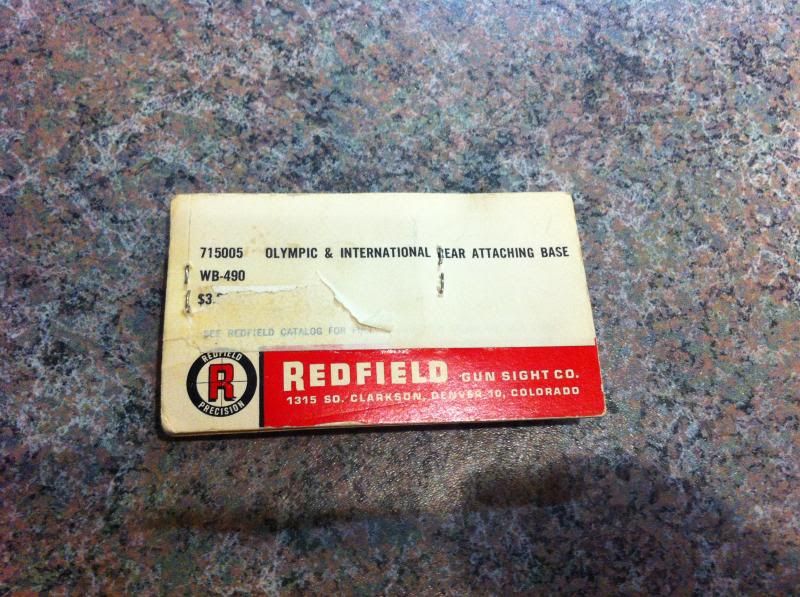

Outback did reproduce the part. It was delivered to my door, finished ready to mount, for a total of $60. I am very happy it. My issued M24 would have had an OK Weber base, but it was taken off long before I was issued the rifle. I looked for a few months for an original WB490. I had a few near misses, but couldn't find one. Mike Lau would have made me one when I sent my rifle to him. If I had it to do over I may have taken that route, but I am pleased with the product produced by Outback Gun Parts. They were very easy to deal with. I am sure they would make any changes needed. They used this thread to design the one they made for me.

These bottom 4 pictures here are of my rifles.

Ok guys, I approached twomanattack about the possibility of making some flash hiders for the M24. He's making some awesome reproduction M40A1 scope mounts and is working the final legalities for modifying Remington triggers to M24 specs. I'm hoping that between this thread and the M24 Rebuild thread that it may gain some interest. I know I'm like everyone else, cost is a factor and if it's to much then it's just not worth it.

If you have an original flash hider and are willing to loan it out to twomanattack pm him or I.

I am reading this for the first time. I think everyone here knows I am a Marine 8541 and have very little experience with army issued gear.

I am interested in reproducing the part for the masses, however it may not be cost effective. Although I have not received the part yet, it looks like a simple part to reverse engineer and produce. Unfortunatly, the cost of engineering is very high. We take a real live engineer from his project and pay him real $$$ to engineer the part to be perfect, purchase material, pay the programer to program the mill, sometimes build a fixture then pay a machinist to set up and babysit while the part runs. That process costs us $$$ before we sell even 1 part.

I have a sample flash hider in route. I will take a look at it and check the patents on it. Then I will update this post. Hopefully the sample part gets to me soon. I hope I can help everyone out. Unless we sell the item in quanity they will be very expensive. For example, the Unertl scope base we made still have not paid for themselves and although we raised the cost $15 and made some changes, we still have not broke even on the bases. If we sold 400 of them we could make some $$$ but we probably will never sell them in those quanities. These projects are just for our personal use. As of now we still have not covered the costs on the Simrad caps or Unertl mounts. With that said, I must remind people that I am a US MARINE and my business partner rates a Trident we dont have any projects going that include US ARMY issue weapons systems. I will look at the part and try to throw a number at it. The more people that commit to buy the less it will cost everyone. We could engineer it and have it built overseas it would be cheap but SORRY GUYS we wont do that.

Thanks Twomanattack!

Totally understand how big a project all this ends up being!

I personally am not going for a flashhider at the moment but on behalf of others that are interested I'm glad you are looking into it and I think we all understand that it takes time! Thankyou for looking at this and also doing the Unertl rings on top of your other work!!

I am the SPECIAL projects manager. When my partner and I want a personal item that is obsolete, we make it. I don't have a need for the M24 stuff, but it seems like a cool part that people need. I posted in the group buy section trying to guage interest. I see some of these selling for about $140 and up. So I guess I will have to keep the price below $200 to make it pay for itself. We will see how many people want them and take it from there.

FYI, the flash hider was made by Rock Island Armory not the AMU.

We took a look at what its going to take to build this. We have several hurdles to over come, it may not be cost effective to continue on this project. We would have to buy the proper broach and knurling tool. The broach is a very expensive tool. Unless someone wants to donate that tool or let us borrow it, we would have to buy it. Just that is going to put us over the $200 each build cost. The machine time is realistically 4-6 hours each piece. The build cost will be more than $200 each even if I absorb the Engineering cost. The problem with that is, I don't own a M24 and don't have a need for a flash hider. In order to make this project pay for it self, we would have to sell a minimum of 30 pieces at about $300 each. Right now I have a commitment for 10. So when 20 more people commit, we can move forward. Lets hear your thoughts. I hate to give up, but I just cant see it go further .

Pardon my asking, sorry if it be a stupid Q, but where can a guy get the correct stamps like the magnaflux marks and other spec marks needed for an M24? I think other than the lettering codes this is the oval stamp, the triangle, the circle magnaflux stamps etc. I've been told these are very hard to find. What is the cost of getting something like these custom made. I would hope all the letter codes are generic and readily available however I'm hearing that the circle letter or oval marks are Remington factory specific and are not available to anyone outside of Remington arms.

Specifically the REP, triangle J, circle M stamps for puting on the bbl and other parts.

I guess any machinist can make a punch tool. I think the stamps on Remington rifles are actually 'roll stamp'. Can be pricey to make though... Laser engraving can be another option. They can make a vector file from any picture, the laser can even replicate depth.

Not sure if theres liability issues by replicating proofing marks?