Trying to find my jam point so I can start testing seating depths.

The loctite method didn't work for me. Could barely close the bolt! And I don't own the Hornady tool.

So what I decided to do was start with the loctite measurements and seat the bullet deeper until the cartridge did not "stick" in the chamber.

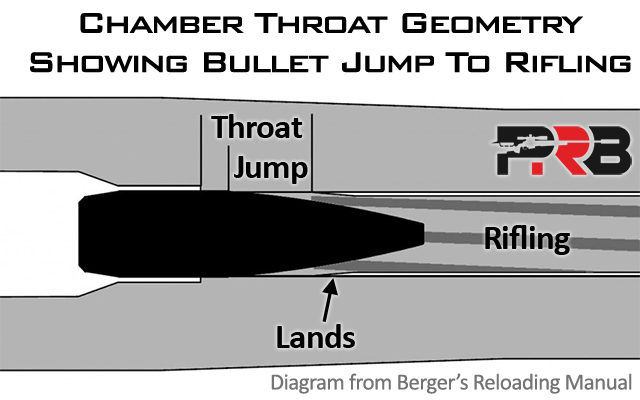

Basically I would push the rd into the chamber with my finger and then tip the rifle up. If the rd stuck, I'd remove it and seat it deeper until it fell out freely.

My thoughts process was if it was stuck, it was in the lands. Once it fell out on its own, it wasn't.

Loctite measurements were 2.335 base to ogive.

"Finger method " was 2.292 BTO

" was 2.292 BTO

Is this method complet horse shit???

Am I just wasting time, or does this seem reasonable?

147gr ELD

Lapua SRP case trimmed to 1.910

Sized shoulder to 1.554 from 1.557 fire formed

Tikka t3 varmint 6.5CM 26 in barrel

The loctite method didn't work for me. Could barely close the bolt! And I don't own the Hornady tool.

So what I decided to do was start with the loctite measurements and seat the bullet deeper until the cartridge did not "stick" in the chamber.

Basically I would push the rd into the chamber with my finger and then tip the rifle up. If the rd stuck, I'd remove it and seat it deeper until it fell out freely.

My thoughts process was if it was stuck, it was in the lands. Once it fell out on its own, it wasn't.

Loctite measurements were 2.335 base to ogive.

"Finger method

Is this method complet horse shit???

Am I just wasting time, or does this seem reasonable?

147gr ELD

Lapua SRP case trimmed to 1.910

Sized shoulder to 1.554 from 1.557 fire formed

Tikka t3 varmint 6.5CM 26 in barrel