Do you run a 1-8 twist for the 230 atip and 245 berger or 1-9? I'm moving into a 1-8 twist and didn't know if there was issues with the 230 atipToday...about an hour ago actually....

300PRC

29.5" barrel

245gr EOL's

76.0gr of RL-26

2887 fps no pressure signs ******* caveat ******

Lapua Brass

Elevation 954ft

So....the reason my speeds are slower than the were...and no pressure signs are the following:

I didn't clean my brass...I brushed out the necks with a 30cal nylon brush just to get the big carbon out.

I annealed with Aztec Code 168 on an Amp Annealer *** on neck turned brass at 13.5Thou ***

I full length resized with a LE WIlson bushing die...and I forget exactly which bushing...but very little neck sizing.

I Mandrel each one back out to 2 thou below bullet size.

I Coat my bullets with HBN

This coupled with my seating depth...I've reduced pressure for the sake of consistency. If I skip one of these steps and go same powder load...it will show pressure signs....The HBN really slicks up the bullets and drops your MV...but it makes verticals at ELR ranges really nice.

So....when you read loads on the Internet...even if they are true and real...there are a lot more things going on that you need to be aware of.

Signed,

B2

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

300 PRC update

- Thread starter DAVETOOLEY

- Start date

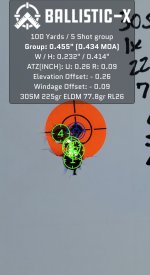

I just got an AMP and have been annealing and turning some brass.I do believe that Berger is conservative with their numbers....and hence why they tried to educate people with the No BS BC series. The .413 is at a certain condition at a certain range.....with a certain barrel...and a certain velocity. Me using a 29.5" barrel and getting a little more giddy up behind the bullets....increases the BC. Now....I also tip my bullets and HBN coat them...I'm currently at around a .455 G7.

I've shot a lot of 230 A-Tips...and many hundred 250's. While I really like the A-Tips...they have a tendency to explodicate at the absolute worst time. If I'm shooting an ELR match and one explodes and I miss....probably not that big a deal since my odds of hitting that 2000+ yard steel aren't certain....but when you shoot 1 mile paper...and 1 miss is a DQ....then it just pisses you off.

I originally started shooting the 245 EOLs because they were $50/100 or so...while the A-Tips where like $80/100.....the price difference was large enough for me to give them a try. Then I found I shot consistent with the Bergers and while I was going to tip them...thus more work....I really liked them. It seems a 1-9tw likes the 245 Berger more than the 250 A-Tip...

I still have hundreds of A-Tips...but I have a lot of 245 EOL's I will shoot first.....until the new 245-ish Berger comes out soon...then I'll test them out. I was hoping the Bergers were 'close enough' for me not to fret over when shooting ELR....and they've exceeded my expectations.....I've had matches where I shoot a sub 2" vertical at a mile...but blow my wind calls....and last week I shot 3 groups with 2" horizontals....but had something going wonky with the rear bag and my vertical dispersion was too much to keep all 5 on paper. One day I'll get both at the same time and it will be magical.

So...the A-Tip is one sexy looking bullet. They are great....it's just that the low probability of one flying apart...seems to catch me and others at exactly the wrong time. Not much Hornady can do about that....it is what it is. The bergers have been consistently great for me....I'll measure the snot out of stuff...and they are great from lot to lot.

Both are great bullets....but like I said...I originally shot the A-Tips...and wanted to convert to something not so price heavy...and ended up finding something I like more.

As a note, I was advised(as posted on the amp site) to update the software for proper annealing code for 300PRC. did all that.

ADG 1x Fired: Aztec code result was 147with #31 pilot but not neck turned. Bought the brass fired, but I do have a few news to try after I see how things turn out with this set.

Do you find there is a reddish oxide on the inside of the cases with the annealer? Also I think they mention not using dry lube with AMP. so I've switched back to wax lube and remove excess with Qitp. I will be neck turning them next and loading them. All the 6ARC I've champhered, annealed Turned and honed look machine turned and seated super smooth

I still have to iron out final details on which mandrel and bushing to use to move the brass as little as possible and I also need a WFT trimmer, but I have plenty to shoot for now and have some 230 Bergers and A tips to try next. I haven't had any pressure signs the the H225s yet, just faint ejector marks and slightly cratered/flattened primers. I've blown primers in the past, backed off from there etc.

Thanks again for the info/post.

@RocketmandbAnother range report - this time with RL 33.

I did groups at 82.5, 83. 83.5, 84, and 84.5 grains of RL 33. None were particularly impressive .

The best from a spread perspective was 83 gr, which had a 19 ES and 7.9 SD with an average of 2862 fps. I might play around a little more around this load, but I'm not going to do too much more with this powder.

For anyone interested, here are the average fps of each load:

82.5: 2837

83.0: 2862

83.5: 2875

84.0: 2897

84.5: 2917

EDIT: I started getting mild compression loading at 84.0, and a little more at 84.5, which is why I stopped there.

What projectile was this with?

@Rocketmandb

What projectile was this with?

This goes way back, and I think it was before I started using Berger 230s. If so, then it can only be Hornady 225s.

How do you like the 230 Bergers as opposed to the 230 A-Tips?This goes way back, and I think it was before I started using Berger 230s. If so, then it can only be Hornady 225s.

How do you like the 230 Bergers as opposed to the 230 A-Tips?

I generally like Berger hybrids because they are

1) Easier to tune for seating depth

2) Cheaper

A-Tips get you better BC and right now seem to be more available. But there's a reason why I'm always on the hunt for Bergers and I have 500+ A Tips sitting on the shelf.

Berger’s have never let me downI generally like Berger hybrids because they are

1) Easier to tune for seating depth

2) Cheaper

A-Tips get you better BC and right now seem to be more available. But there's a reason why I'm always on the hunt for Bergers and I have 500+ A Tips sitting on the shelf.

Hornady and A-tips have.

Do you use the OTM hybrids or the non OTM?Berger’s have never let me down

Hornady and A-tips have.

OTM, regular and LRHT in 6.5, 7 and 338.Do you use the OTM hybrids or the non OTM?

I swore I would never shoot Hornaday again but been very happy and impressed with the 230 a-tips. 2700 to 2800 no issues with any blow ups or anything. Going to try the 250 in a 1-8 twistBerger’s have never let me down

Hornady and A-tips have.

Do you use the OTM hybrids or the non OTM?I generally like Berger hybrids because they are

1) Easier to tune for seating depth

2) Cheaper

A-Tips get you better BC and right now seem to be more available. But there's a reason why I'm always on the hunt for Bergers and I have 500+ A Tips sitting on the shelf.

When they work it’s great, it’s when they suddenly start not working that I’m tired of.I swore I would never shoot Hornaday again but been very happy and impressed with the 230 a-tips. 2700 to 2800 no issues with any blow ups or anything. Going to try the 250 in a 1-8 twist

Very true. Only shot 150 of them not a lot but with the 180 eldm only took 1 hahaWhen they work it’s great, it’s when they suddenly start not working that I’m tired of.

This goes way back, and I think it was before I started using Berger 230s. If so, then it can only be Hornady 225s.

@Rocketmandb & @Schw15I swore I would never shoot Hornaday again but been very happy and impressed with the 230 a-tips. 2700 to 2800 no issues with any blow ups or anything. Going to try the 250 in a 1-8 twist

Unfortunately, RL 33 & 250 A-Tips are the slowest powder/heaviest bullet combo I’ve been able to gather. I really wanted the 245 EOL’s. I have a 1:8 27” barrel.

I know these aren’t the best components according to this group, but I’m hopeful that I can pull a consistent, accurate load out and stretch it out to 2,000 yds.

This is what other members on FB groups have reported with RL33 & 245 Berger’s/250 Hornady’s. Shouldnt be getting any fully compressed loads under 88 gr; shooting for ~2850 FPS and planning to work up to it.

Attachments

Last edited:

Do you use the OTM hybrids or the non OTM?

I'm using the non OTM. I haven't used the OTM, but they are really similar - just shorter with a very slight BC drop as a result. By all accounts I've read, the OTM are essentially just as good.

I had less capacity in the Lapua than the ADG and I found the ADG to be softer and quicker to stretch which required trimming quicker than the Lapua. Same excellent consistency in weight for both but I had terrible results with the first shot on the Lapua brass - don’t even try to get any results with your fireforming rounds.I’m due for some new brass. Using ADG currently with no complaints but maybe Lapua might be easier to find. Wondering if anyone has ran both and would share they’re thoughts between the two?

My AMP also thought the ADG was significantly softer FWIW.

Did you run the new AMP update for the 300PRC aztec code. I just got my machine but was advised to update which I did.I had less capacity in the Lapua than the ADG and I found the ADG to be softer and quicker to stretch which required trimming quicker than the Lapua. Same excellent consistency in weight for both but I had terrible results with the first shot on the Lapua brass - don’t even try to get any results with your fireforming rounds.

My AMP also thought the ADG was significantly softer FWIW.

I ran the 300PRC today with H225 over 7828 @2900, wind was hell, but I got some good hits out to 750.

I am going to run Berger 230s next. I was able to spot hits and splashes at 750/1k. I got elevation confirmed from 100 to 1k(22MOA) today which was my main goal.

The thing that surprises me the most is how soft shooting this thing really is. I'm sure a lot of it is the tuner brake. there is a weird sound when shooting under a pavillion the to me sounds like punting a football with a flagpole leg. I've never shot any other larger bore rifle with brake so it is just new to me. It doesn't beat you up it just sounds weird. I am also digging the Sightron scope. I was able to spot bullet trace at other shooters 500 targets which helps a lot against green grass backgrounds (not much splash).

Same excellent consistency in weight for both

Have you done anything to compare the necks? I don't have any Lapua yet as none of my back orders have come in, but I've been doing a lot of playing with the ADG and found some neck inconsistencies (minor) that I believe were causing my higher than desired seating force inconsistencies. These weren't huge (90% typically within a ~15lb range), but when I compare to the results I get with smaller caliber Lapua brass, it's way off (all within a ~5lb range). Some of that is undoubtedly due to the smaller caliber, but not all.

Last night I neck turned 100 pieces of ADG, so I'll see what that does to lower the seating force inconsistencies.

Last night I neck turned 100 pieces of ADG, so I'll see what that does to lower the seating force inconsistencies.

I posted the results of comparing 25 turned cases to 25 non-turned cases. There is a measurable difference. Results are in my mandrel thread:

Mandrel Musings

When I first got my K&M arbor press for seating, I was somewhat surprised at the spread of the values of force required to seat bullets. Knowing that neck tension plays a significant role in ES/SD, I started doing various things to try to bring seating force in line. I had been doing most my...

I just picked up an Autodod, interested to see how that affects my grouping.I posted the results of comparing 25 turned cases to 25 non-turned cases. There is a measurable difference. Results are in my mandrel thread:

Mandrel Musings

When I first got my K&M arbor press for seating, I was somewhat surprised at the spread of the values of force required to seat bullets. Knowing that neck tension plays a significant role in ES/SD, I started doing various things to try to bring seating force in line. I had been doing most my...www.snipershide.com

I just picked up an Autodod, interested to see how that affects my grouping.

LOL, I saw bunny too's post and thought: WTF is an Autodod?, but didn't take the time to google it until seeing Defender's "Wow". $2500 is probably no big deal for some, sort of like getting in line for a Promethius. I'd do it if I could or if I had enough of a boner for it, but my reloading room to-buy is pretty long already and much of it is low-dollar stuff compared to the above, and just maintenance of supplies.

Bunny: please give us a review once you have it dialed in. I'm in the camp of at least testing and comparing a range of neck prep strategies, so this should be interesting.

I just picked up an Autodod, interested to see how that affects my grouping.

For short range stuff, it likely won't help much. However, based on what I saw in my seating force comparisons, you should see a drop in SDs, which could pay dividends on the ELR side. The amount of drop depends on a ton of variables.

What are your SDs now?

We have an autodod as well as 21st century in the shop.

For PRS and/or short range steel stuff, you likely won’t benefit much from it.

Getting into enough diminishing returns if you’re shot shooting off a F class or better type front rest and a eared rear bag, you likely can’t shoot the difference. Bipod and rear squeeze bag will be hard to discern.

For PRS and/or short range steel stuff, you likely won’t benefit much from it.

Getting into enough diminishing returns if you’re shot shooting off a F class or better type front rest and a eared rear bag, you likely can’t shoot the difference. Bipod and rear squeeze bag will be hard to discern.

My own reloading experiences have shown Lapua and Peterson to be the brands of brass that I totally trust. Hornady ... not so much. No experience with ADG.Well, the big picture is a bummer, but at least you didn't have a horrible failure that led to injury. It is significant to this issue that DT's have strong actions and can take pretty high pressure. I'm not a fan of Hornady brass for reloading, but I have reloaded it for a few calibers without problems. I'd be tempted to push a few primers into your failed brass and some of the once-fired brass. If you have any virgin brass, that would be good for comparison. You might get a hint about whether your reloads were a big part of the picture or if headspace was the major factor. When I'm working up a load, I measure base-to-datum unfired and fired, after sizing, then after second firing, just to find out what's happening in the chamber. I want to get to where I size the case body and neck as little as possible and still function properly.

Do what you have to do to get some Lapua or ADG brass. Good luck trouble shooting it.

We have an autodod as well as 21st century in the shop.

For PRS and/or short range steel stuff, you likely won’t benefit much from it.

Getting into enough diminishing returns if you’re shot shooting off a F class or better type front rest and a eared rear bag, you likely can’t shoot the difference. Bipod and rear squeeze bag will be hard to discern.

(Vision of shooting a 300 PRC in PRS, with closer-in steel flopping around like a stuck pig...)

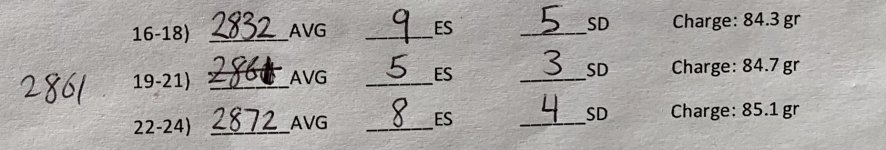

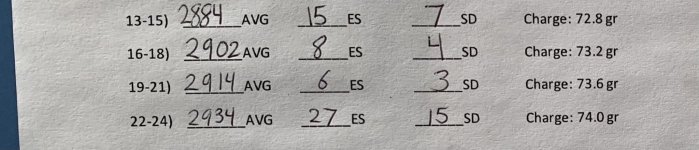

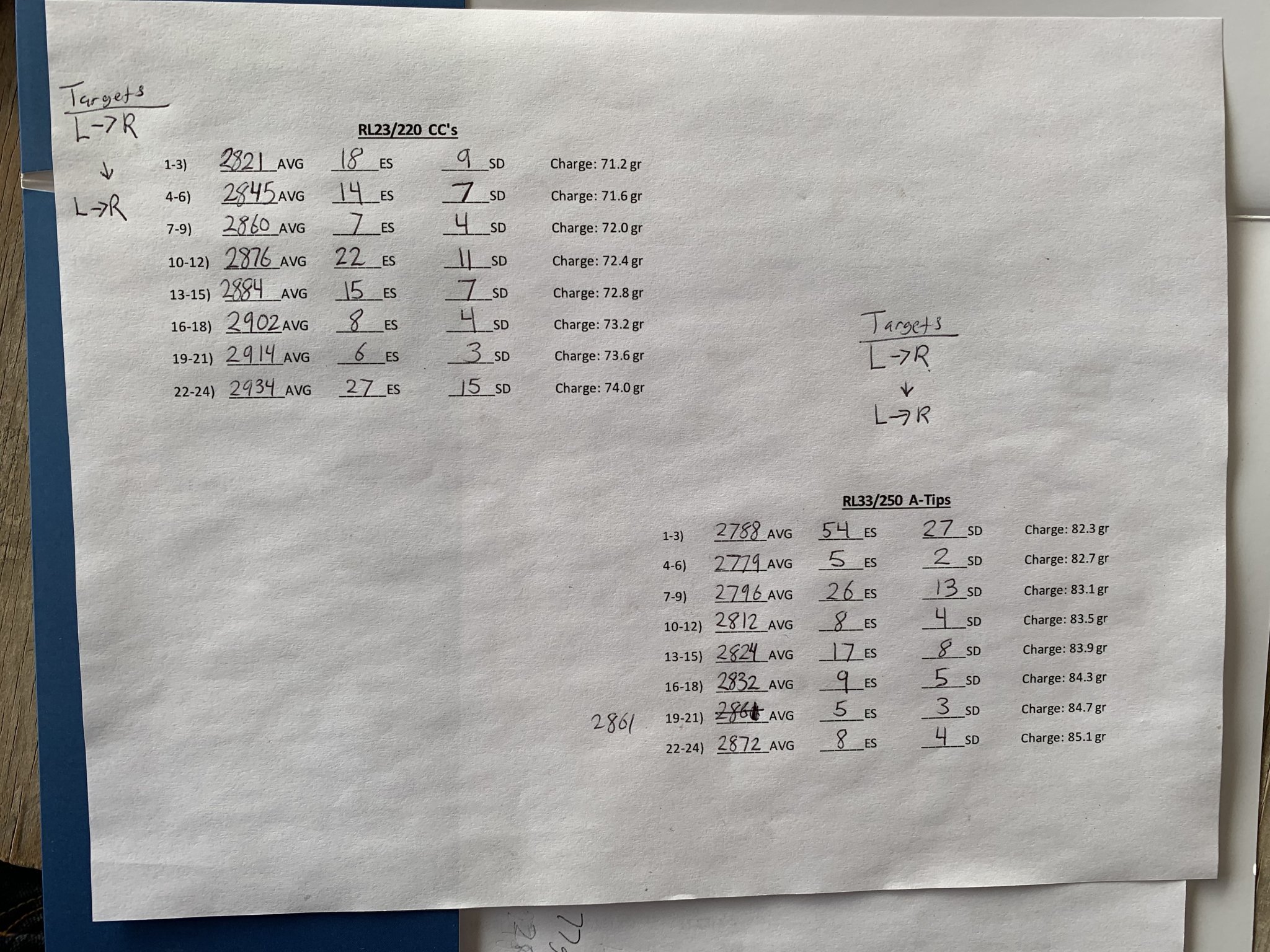

First powder weight testing on my PRC with fireformed Hornady (reformed 375 Ruger) brass. Magneto speed with Tubb mount.

220 gr Nosler Custom Competitions & RL 23

250 gr A-Tips & RL 33

Last 2 photos are where I’m thinking to pick a node.

73.2 gr for 220/RL 23

84.7 gr for 250/RL 33

Only pressure signs was heavier bolt lift, no cratering/ejector marks.

Would you do any further charge weights testing or just pick a node in between to account for +/- 0.2 gr accuracy? Using an RCBS ChargeMaster Lite.

27” 1:8 twist barrel

Thanks in advance!

220 gr Nosler Custom Competitions & RL 23

250 gr A-Tips & RL 33

Last 2 photos are where I’m thinking to pick a node.

73.2 gr for 220/RL 23

84.7 gr for 250/RL 33

Only pressure signs was heavier bolt lift, no cratering/ejector marks.

Would you do any further charge weights testing or just pick a node in between to account for +/- 0.2 gr accuracy? Using an RCBS ChargeMaster Lite.

27” 1:8 twist barrel

Thanks in advance!

Attachments

Last edited:

I put a 30 Sherman Magnum barrel on and pulled my 300PRC barrel. The 300PRC barrel has quite a bit more life left in it but figured what the hell.

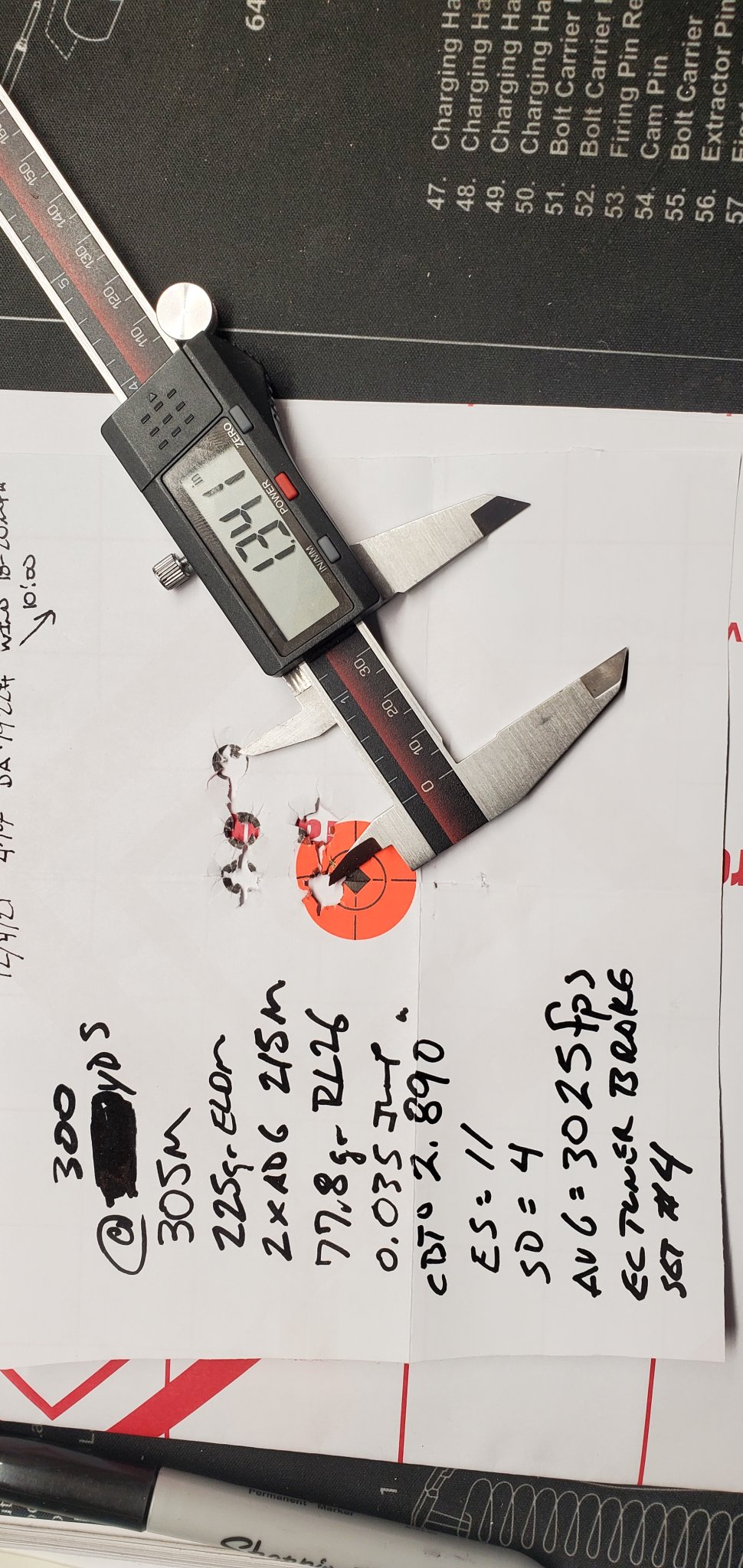

The 30SM is doing well. Not sure if the difference between it and the PRC justifies the added cost overall. I'm going to track them and decide which one I will keep using. My PRC load uses 3gr less powder than my SM load. Both running RL26 and 225gr ELDM's.

300PRC:

Hornady brass

225grELDM

215m primers

75.5gr RL26

2925fps avg from a 28" 9 twist SS proof barrel

30SM:

ADG brass

225gr ELDM's

215m primers

78.8gr RL26

3028fps avg 28" 8 twist bartlein barrel

I have not been running either one even close to pressure and have settled on middle of the road velocity nodes.

I'm able to get better accuracy out of my 30SM but I believe that it is related to who did the barrel work. No names to be given. My 300PRC has not been the best. I've had some issues with it but have been able to dial it in to just over 1/2 moa. My 30SM easily is a 3/8 moa or better.

In the end I will see which one edges out the other.

Another thing that actually got me writing this post. I just picked up a 8lb jug of RL33 to try in the 30SM. I have heard good things and I was actually able to find it. I'm running out of RL26 and will probably save it for my 300PRC barrel.

Here is a picture of how well my 30SM is doing. String was at 300 yards in some nasty winds.

The 30SM is doing well. Not sure if the difference between it and the PRC justifies the added cost overall. I'm going to track them and decide which one I will keep using. My PRC load uses 3gr less powder than my SM load. Both running RL26 and 225gr ELDM's.

300PRC:

Hornady brass

225grELDM

215m primers

75.5gr RL26

2925fps avg from a 28" 9 twist SS proof barrel

30SM:

ADG brass

225gr ELDM's

215m primers

78.8gr RL26

3028fps avg 28" 8 twist bartlein barrel

I have not been running either one even close to pressure and have settled on middle of the road velocity nodes.

I'm able to get better accuracy out of my 30SM but I believe that it is related to who did the barrel work. No names to be given. My 300PRC has not been the best. I've had some issues with it but have been able to dial it in to just over 1/2 moa. My 30SM easily is a 3/8 moa or better.

In the end I will see which one edges out the other.

Another thing that actually got me writing this post. I just picked up a 8lb jug of RL33 to try in the 30SM. I have heard good things and I was actually able to find it. I'm running out of RL26 and will probably save it for my 300PRC barrel.

Here is a picture of how well my 30SM is doing. String was at 300 yards in some nasty winds.

I prefer Lapua. Whether or not it is a co-inky-dink or not...new Lapua 300PRC is EXACTLY a 2 thou shoulder bump from my chamber and measures exactly to my fired then bumped back brass....so it is just mandrel and load on virgin brass.

Lapua:

Positives:

lot to lot consistency on dimensions, weight, volume

Primer Pocket lifespan

Price: I've bought all my Lapua cheaper than I bought my ADG

Negatives:

Really...Really tight necks when you get them. I re-anneal, chamfer and mandrel before loading and have found this combo to give me the best neck tensions

ADG:

Positives:

Better than Hornady...by a long shot.

Decent primer pocket life.

Decent neck tensions from the box.

Negatives:

I haven't seen the best lot to lot consistency...but much better than Hornady.

Price. For me it has been slightly more expensive than Lapua.

Primer pockets haven't been that great on stout loads.

Higher pressures due to volume vs Hornady and Lapua.

Here lately, Lapua was easier to get in quantity over ADG as well.

These are my opinions...yours may differ.

Lapua:

Positives:

lot to lot consistency on dimensions, weight, volume

Primer Pocket lifespan

Price: I've bought all my Lapua cheaper than I bought my ADG

Negatives:

Really...Really tight necks when you get them. I re-anneal, chamfer and mandrel before loading and have found this combo to give me the best neck tensions

ADG:

Positives:

Better than Hornady...by a long shot.

Decent primer pocket life.

Decent neck tensions from the box.

Negatives:

I haven't seen the best lot to lot consistency...but much better than Hornady.

Price. For me it has been slightly more expensive than Lapua.

Primer pockets haven't been that great on stout loads.

Higher pressures due to volume vs Hornady and Lapua.

Here lately, Lapua was easier to get in quantity over ADG as well.

These are my opinions...yours may differ.

Here lately, Lapua was easier to get in quantity over ADG as well.

Where are you finding it? I've got plenty of ADG, but want some Lapua to compare.

Where are you finding it? I've got plenty of ADG, but want some Lapua to compare.

I guess 'here lately' depends on your concept of time. I bought 600 pieces about 3 months back. I believe it was from Grafs. Rumor is...you should see some more soon.

Ive seen it on the shelf up here.Where are you finding it? I've got plenty of ADG, but want some Lapua to compare.

Ive seen it on the shelf up here.

Where did you see it? We're in the same area

Boise, Idaho. I relocated.Where did you see it? We're in the same area

Boise, Idaho. I relocated.

Dang dude - I'm jealous.

Yeah been here since June. It's really nice. Reminds me of Sacramento and surrounding areas without all the bad stuff. Bonus that im only 20min from shootable BLM land, its everywhere.Dang dude - I'm jealous.

If you really want some Lapua brass I could pick some up and send it your way.

@JBartonI put a 30 Sherman Magnum barrel on and pulled my 300PRC barrel. The 300PRC barrel has quite a bit more life left in it but figured what the hell.

The 30SM is doing well. Not sure if the difference between it and the PRC justifies the added cost overall. I'm going to track them and decide which one I will keep using. My PRC load uses 3gr less powder than my SM load. Both running RL26 and 225gr ELDM's.

300PRC:

Hornady brass

225grELDM

215m primers

75.5gr RL26

2925fps avg from a 28" 9 twist SS proof barrel

30SM:

ADG brass

225gr ELDM's

215m primers

78.8gr RL26

3028fps avg 28" 8 twist bartlein barrel

I have not been running either one even close to pressure and have settled on middle of the road velocity nodes.

I'm able to get better accuracy out of my 30SM but I believe that it is related to who did the barrel work. No names to be given. My 300PRC has not been the best. I've had some issues with it but have been able to dial it in to just over 1/2 moa. My 30SM easily is a 3/8 moa or better.

In the end I will see which one edges out the other.

Another thing that actually got me writing this post. I just picked up a 8lb jug of RL33 to try in the 30SM. I have heard good things and I was actually able to find it. I'm running out of RL26 and will probably save it for my 300PRC barrel.

Here is a picture of how well my 30SM is doing. String was at 300 yards in some nasty winds.

View attachment 7757094

RL33 may not be the very best/optimal powder. But for me so far with the little bit of testing I’ve done (OCW) results look promising. I could try to push it a little further, 85.5-86 potentially. But I think for now I’m just going to pick a load from what I’ve got and make sure it’s consistent and then go into dialing in my tuner.

I think it’d do well in your 300 NM with some 250s.

Snagged an 8-lb jug of RL33. I have not seen RL26, RL33, H1000 or Retumbo on the shelf in over a year. I've never seen n564, n568 or n570. Partially due to the store size and volume I'm sure. Brass? What's that?

Thank God for the hide and other forums. If not I wouldn't have fuck all.

I'm going to do a ladder using ADG brass, 215m primers, 225gr ELDM's and RL33. I will post the results. If it pans out u will spin my 300PRC barrel back on and do a quick test with it as well. If I do I will post the results.

Thank God for the hide and other forums. If not I wouldn't have fuck all.

I'm going to do a ladder using ADG brass, 215m primers, 225gr ELDM's and RL33. I will post the results. If it pans out u will spin my 300PRC barrel back on and do a quick test with it as well. If I do I will post the results.

I'm running an EC Tuner brake, which one are you running? I had it on my 6.5cm and found it works well. The brake works good on my 30SM with it being comparable to the Sidewinder on my 300PRC barrel. I did a group size test with my RL26 load from setting 0 to 6. I settled on 4.@JBarton

RL33 may not be the very best/optimal powder. But for me so far with the little bit of testing I’ve done (OCW) results look promising. I could try to push it a little further, 85.5-86 potentially. But I think for now I’m just going to pick a load from what I’ve got and make sure it’s consistent and then go into dialing in my tuner.

I think it’d do well in your 300 NM with some 250s.

That is very interesting, thx for sharing. cool to see the tightest group was in between two other shots that are fairly open groups. Looks like your foulers did really well. I think I would pick Stt#1 because the ones adjacent are also very great.

I never did mess with the tuner on mine but the brake part definitely worked well. I have a set of 230s to try next and will tune if after finding a good velocity node.

I never did mess with the tuner on mine but the brake part definitely worked well. I have a set of 230s to try next and will tune if after finding a good velocity node.

The tuner is a nice tool. I set my tuner on 4 for my RL26/ 225gr ELDM load. Something that I have recently realized is how much the rear bag fill matters. I've been using a traust bag with light fill and recently switched to a wiebad mini fortune cookie with heavy fill while shooting this rifle. The wiebad has helped my recoil management and in return my group size consistency. It is never just one thing.That is very interesting, thx for sharing. cool to see the tightest group was in between two other shots that are fairly open groups. Looks like your foulers did really well. I think I would pick Stt#1 because the ones adjacent are also very great.

I never did mess with the tuner on mine but the brake part definitely worked well. I have a set of 230s to try next and will tune if after finding a good velocity node.

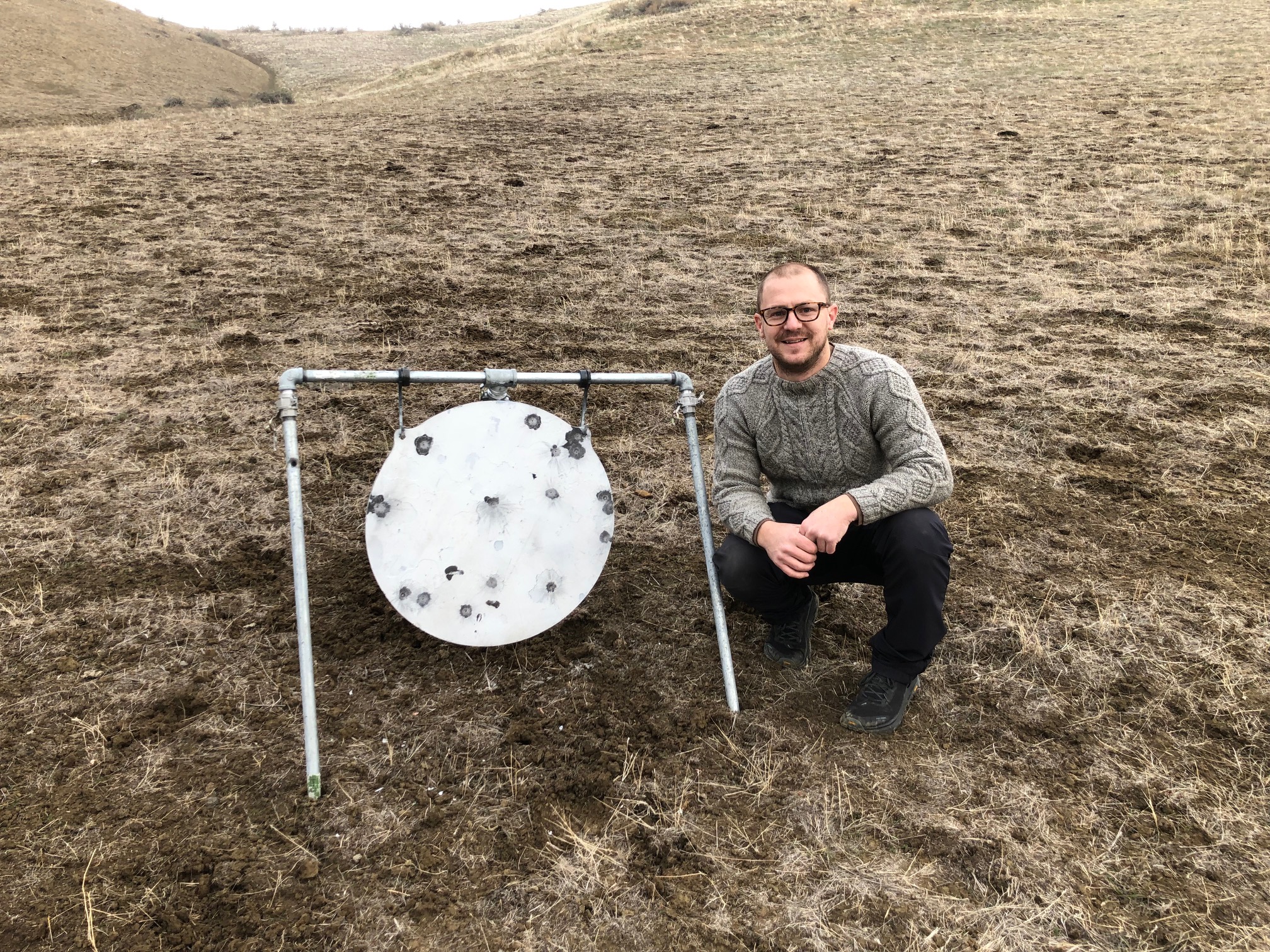

Trip today out to BLM land and a new shooting spot that @BFuller thought would be good. He was right. The day was supposed to be mid-50s and sunny. When we arrived, the fog was so thick we couldn't see more than 50 yards. When we got down into the valley, we could see a little farther. We scouted all corners of the valley and finally came up with a spot that we thought could get us to a good range, but the LRF wouldn't range correctly in the fog.

The first spot we went, it was a little too iffy to get to where we wanted to set the targets - and we couldn't see them clearly due to the fog. We ended up going to the ridgeline shown by the arrow.

By the time we had set the target, it cleared a bit. Here is BFuller behind his 300 PRC and you can see where we set the target by the arrow. This target was 1800 yards. We believe we can get to 3k+ in this valley.

It was overcast and 40 degrees all day because the fog never truly cleared... until we were leaving:

Dual 300 PRCs didn't do too badly

Then the fog came back on the way out.

The first spot we went, it was a little too iffy to get to where we wanted to set the targets - and we couldn't see them clearly due to the fog. We ended up going to the ridgeline shown by the arrow.

By the time we had set the target, it cleared a bit. Here is BFuller behind his 300 PRC and you can see where we set the target by the arrow. This target was 1800 yards. We believe we can get to 3k+ in this valley.

It was overcast and 40 degrees all day because the fog never truly cleared... until we were leaving:

Dual 300 PRCs didn't do too badly

Then the fog came back on the way out.

Attachments

looks like a great day! persistence pays off. Great parting shot too!

Yeah, we had to climb out of the valley and that took us up into the fog/clouds. We crested a hill, saw the setting sun peeking through and were like whoa.

Was also a fun opportunity to rangefind using our scopes. After the fog cleared a bit, we were able to get range to our first target (a 12x20 ipsec), but couldn't get range to our other one. We measured the width and calc'd it at 1700 and change. It took a few low shots to get set on the target. Later in the day when most of the fog had gone, we were able to use the LRF and range it at just over 1800.

Also, you'll hear a lot of people talk about spotting hits and misses with ELR. On a day like this, especially when you can't get an accurate reading from your LRF, it is critical. The ground was damp and dark and at first it was very difficult to spot. Self-spotting was tougher still. Eventually we learned what to look for in these particular conditions and probably spotted around 75% of both hits and misses by later in the day. A surprisingly large number of hits were only identified by the gong.

Great insight.. sounds like a great lesson on shortcomings of both distance measurement processes.Yeah, we had to climb out of the valley and that took us up into the fog/clouds. We crested a hill, saw the setting sun peeking through and were like whoa.

Was also a fun opportunity to rangefind using our scopes. After the fog cleared a bit, we were able to get range to our first target (a 12x20 ipsec), but couldn't get range to our other one. We measured the width and calc'd it at 1700 and change. It took a few low shots to get set on the target. Later in the day when most of the fog had gone, we were able to use the LRF and range it at just over 1800.

Also, you'll hear a lot of people talk about spotting hits and misses with ELR. On a day like this, especially when you can't get an accurate reading from your LRF, it is critical. The ground was damp and dark and at first it was very difficult to spot. Self-spotting was tougher still. Eventually we learned what to look for in these particular conditions and probably spotted around 75% of both hits and misses by later in the day. A surprisingly large number of hits were only identified by the gong.

Sounds like the electronics are more accurate, when the conditions allow the to work, manual calc seemed to be close, not perfect but less dependent on conditions? looking back what was off on the manual yardage calculations?

So toward the end of the day, when you were used to spotting shots, if you didn't spot a miss, would you assume a hit on the gong? It's weird but seems correct and inverse compared to general public target shooting (looking for hits as opposed to looking for misses).

just trying to gleam a bit until I can get out in the spring...

Great insight.. sounds like a great lesson on shortcomings of both distance measurement processes.

Sounds like the electronics are more accurate, when the conditions allow the to work, manual calc seemed to be close, not perfect but less dependent on conditions? looking back what was off on the manual yardage calculations?

The error will almost always be in measuring the target. For the most part, scope reticle markings go down to (best case) either .2 mil or 1/2 MOA (keep me honest, haven't had an MOA scope in a while). Look at the reticle I was using (MSR2) below - the target size is shown as the orange dot.

How easily can you tell the difference between, for example, .37 mil and .39 mil? The reticle's fidelity doesn't allow that, so you have to estimate. For this range, we had a 2' target and it just barely fit inside .4 mil, so we based it on .39. It turns out it was actually about .37. That's the difference between 1700ish and 1800ish. It is not accurate, but good enough to get misses inside your sight picture so you can sight and adjust.

To clarify, we only counted unsighted shots as hits when we would hear the "goooonnnnnnggggg" - it was dead quiet, so it was easy to hear. When the wind's up, it gets a little tougher. It's a good reason to have electronic ear protection.So toward the end of the day, when you were used to spotting shots, if you didn't spot a miss, would you assume a hit on the gong? It's weird but seems correct and inverse compared to general public target shooting (looking for hits as opposed to looking for misses).

EDIT: There were quite a few shots where I was spotting and I'd call "No joy" then a couple seconds later we'd hear the gong. I think bfuller is a better spotter than I am, because I don't remember the same from him

Last edited:

I used to range almost everything with the reticle.The error will almost always be in measuring the target. For the most part, scope reticle markings go down to (best case) either .2 mil or 1/2 MOA (keep me honest, haven't had an MOA scope in a while). Look at the reticle I was using (MSR2) below - the target size is shown as the orange dot.

View attachment 7765361

How easily can you tell the difference between, for example, .37 mil and .39 mil? The reticle's fidelity doesn't allow that, so you have to estimate. For this range, we had a 2' target and it just barely fit inside .4 mil, so we based it on .39. It turns out it was actually about .37. That's the difference between 1700ish and 1800ish. It is not accurate, but good enough to get misses inside your sight picture so you can sight and adjust.

To clarify, we only counted unsighted shots as hits when we would hear the "goooonnnnnnggggg" - it was dead quiet, so it was easy to hear. When the wind's up, it gets a little tougher. It's a good reason to have electronic ear protection.

EDIT: There were quite a few shots where I was spotting and I'd call "No joy" then a couple seconds later we'd hear the gong. I think bfuller is a better spotter than I am, because I don't remember the same from him

When I started shooting past 1200Ish yard I found I started to get inaccurate yardages and by a mile it was really bad.

Just not enough resolution with the scope and reticle to see a difference between 1700 and 1800

Similar threads

- Replies

- 0

- Views

- 187

- Replies

- 0

- Views

- 179

- Replies

- 25

- Views

- 1K