Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6.5 Creedmoor

- Thread starter Sportin Wood

- Start date

139 scenar would fit the bill

Why are they not as popular?

Why are they not as popular?

Very consistent BC and a well made bullet with top notch QC. But the BC is significantly lower than the best Berger bullets.

Very consistent BC and a well made bullet with top notch QC. But the BC is significantly lower than the best Berger bullets.

How much does that BC really matter? Are there any discussions on it? Two similar fps bullets but one with better BCs.

How much does that BC really matter? Are there any discussions on it? Two similar fps bullets but one with better BCs.

IMHO it does not matter that much below 400 yards. You can run the calcs in a Ballistic calculator like Applied Ballistics or Strelok, and compare wind drift (it increases quadratically with distance, so x^2). At 1000 plus BC matters a great deal as wind is often the dominant reason for missing.

But: A very inconsistent high BC bullet could very easily lose out to a consistent moderate BC bullet. A bad vertical spread can make you lose a lot of points too, and a poorly developed load (high ES) or inconsistent BC can do that. That partially explains why the ELD-Ms are not really seen in F-class where group size (x count) matters greatly, while the lower BC Berger Hybrids are popular. For hitting large steel targets in PRS, the Hornady ELDMs have adequate performance, and they are cheaper.

Some people sort their bullets by weight and base to ogive measurement to improve consistency. That is a lot of extra work, and suddenly the extra 15-20 cents per bullet is more attractive... I do sort Hornady bullets, even the pricey A-tips, i do not sort Bergers.

What do you want to do with your ammo?

Last edited:

The Scenar is, in my estimation, like a better quality SMK. With better consistency and still easy to tune and a decent BC, but not like the more advanced projectiles. It's very predictable to at least 1k yds. I still shoot them with no complaints on accuracy or predictability to that distance. The BC difference does not seem to be a huge factor at that distance either.

That makes a ton of sense. I'm going to check that out. I want one for hunting and prs. Eventually I'll hopefully get a match gun in 6mm and it will be just hunting.IMHO it does not matter that much below 400 yards. You can run the calcs in a Ballistic calculator like Applied Ballistics or Strelok, and compare wind drift (it increases quadratically with distance, so x^2). At 1000 plus BC matters a great deal as wind is often the dominant reason for missing.

But: A very inconsistent high BC bullet could very easily lose out to a consistent moderate BC bullet. A bad vertical spread can make you lose a lot of points too. That explains why the ELD-Ms are not really seen in F class where group size (x count) matters greatly, while Berger Hybrids were popular. For hitting large steel targets in PRS, the Hornady ELDMs have adequate performance, and they are cheaper.

What do you want to do with the ammo?

Greetings,

Need to find a good load for my 6.5 CM. The data is;

26" Krieger Barrel

Hornady Brass

Berger 140 Hybrid

H4350 Powder

Any suggestions? I understand the COAL is 2.800, and I will probably start at 40 and work up at .3 increments.

Need to find a good load for my 6.5 CM. The data is;

26" Krieger Barrel

Hornady Brass

Berger 140 Hybrid

H4350 Powder

Any suggestions? I understand the COAL is 2.800, and I will probably start at 40 and work up at .3 increments.

There are 35 pages of data. I read through all of them and you will find several people with loads that are going to be close to each other. That kind of gave me a starting point and cut down on my development time by a lot.

The last box of factory Hornady I opened had 40.9 grains of H4350 with the 140 ELD-M but they were really slow. Maybe 2650 or so out mf my 26" Bartlein. So depending on your target velocity you may want to go up from there.

The last box of factory Hornady I opened had 40.9 grains of H4350 with the 140 ELD-M but they were really slow. Maybe 2650 or so out mf my 26" Bartlein. So depending on your target velocity you may want to go up from there.

Greetings,

Need to find a good load for my 6.5 CM. The data is;

26" Krieger Barrel

Hornady Brass

Berger 140 Hybrid

H4350 Powder

Any suggestions? I understand the COAL is 2.800, and I will probably start at 40 and work up at .3 increments.

Most people converge on 41.3 to 41.6 gn. Unless your chamber is exceptionally tight or sloppy.

Nothing wrong with volume/weight sorted Hornady brass in a factory rifle.

Not trying to offend anybody, but: That Krieger barrel is quite special, and not cheap either. IMHO your groups would benefit from premium brass: Lapua, Peterson, Alpha. In my experience you can expect a 30% reduction in group size, for a fairly limited additional expense. If you go for SRP brass, it will last 20-30 reloads if you stay with a reasonable load, Hornady gave me 4-6 reloads. That additional brass life pays for the good brass many times over.

Bullet choice: Well, I always got very good results with the Berger 140 Hybrid at 400-600 yards. Good consistent bullet, good BC, and i don’t have to weight sort them. And base to ogive is always good too. But i think the new factory pointed 144 gn Berger Hybrids are actually a little better. Same price, better BC, very similar speed.

Something to consider. Switching brass and bullet choice too often just wears out a good barrel with load development rounds. I know that for sure, because i use to try wayyyy too many options.

Last edited:

Most people converge on 41.3 to 41.6 gn. Unless your chamber is exceptionally tight or sloppy.

Nothing wrong with volume/weight sorted Hornady brass in a factory rifle.

Not trying to offend anybody, but: That Krieger barrel is quite special, and not cheap either. IMHO your groups would benefit from premium brass: Lapua, Peterson, Alpha. In my experience you can expect a 30% reduction in group size, for a fairly limited additional expense. If you go for SRP brass, it will last 20-30 reloads if you stay with a reasonable load, Hornady gave me 4-6 reloads. That additional brass life pays for the good brass many times over.

Bullet choice: Well, I always got very good results with the Berger 140 Hybrid at 400-600 yards. Good consistent bullet, good BC, and i don’t have to weight sort them. And base to ogive is always good too. But i think the new factory pointed 144 gn Berger Hybrids are actually a little better. Same price, better BC, very similar speed.

Something to consider. Switching brass and bullet choice too often just wears out a good barrel with load development rounds. I know that for sure, because i use to try wayyyy too many options.Better to start with premium components and stick with it.

Thank you for your response.

Does the small pocket brass (Peterson for example) take small rifle primers? Or can you use large rifle primers with it? I have over 15k of Federal 210M... I don't think I'll be switching for a very long time if that is the case.

Thank you for your response.

Does the small pocket brass (Peterson for example) take small rifle primers? Or can you use large rifle primers with it? I have over 15k of Federal 210M... I don't think I'll be switching for a very long time if that is the case.

SRP brass requires small rifle primers, by definition.

You have many quality options in Large Rifle Primer brass, like Nosler, Prime, and Lapua LRP brass derived from Berger hunting ammo like the 156 EOL round. Starline also gets good reviews, and they make both SRP and LRP variants, but i do not have enough experience with it yet. They had good weight and neck thickness measurements (checked a new batch of 100 when it arrived recently). Have only done fire forming so far.

When using premium LRP brass, you can expect the primer pockets to open up after 8-12 reloads, depending on how hot you load them. Premium LRP brass is noticeably better than Hornady Match brass, which is a bit soft and has fairly large variations in neck thickness (as measured at 6 positions around the circumference). [Btw, it has to be measured with a good ball micrometer, not calipers which are not accurate enough for this purpose.] And neck turning does not really “fix” them, as the thickness variation extends from the neck all the way down to the case head.

There is such a massive primer (and components) shortage right now that you can probably make a very nice profit on your LRP stash... but sadly SRP primers are just as hard to find now. Some folks might do a 1:1 swap if you advertise. Look for people in your city. Shipping primers is problematic (hazmat rules).

Perhaps best to stay with LRP brass for this barrel. Maybe switch to SRP when you rebarrel... and when we are not in an election year.

Last edited:

Has anyone tried Lapua 6.5 CM brass in the new large primer pocket? Does anyone know the flashole size of the large primer?

Pretty sure the new Berger/Lapua LRP brass is standard flash hole size. Will check.

I tested one box of the Berger 156 gn EOL hunting rounds, which is loaded in LRP brass, and that heavy bullet worked superbly well on large feral hogs.... And they are tough critters, and it also shot small groups on steel.

I tested one box of the Berger 156 gn EOL hunting rounds, which is loaded in LRP brass, and that heavy bullet worked superbly well on large feral hogs.... And they are tough critters, and it also shot small groups on steel.

Last edited:

Hybrid 100V is in stock and cheaper than everything else where I go. Anybody have recent numbers on that? 140ELD's. 8T. 27" bart. The primers I have are winchester large magnum. That gonna hurt anything?

I would say load the powders you can find during this component shortage, as long as their burn rate is suitable. Hybrid 100V is listed as suitable for the 6.5 Creed on the Hodgedon web site with a 41.4 gn max and descent speed (2760 fps):

You may or may not see pressure signs before 41.4 gn due to the magnum primer, but in my experience, the magnum primers work well, and does not really add any noticeable speed compared to LRP primers. That likely depends more on the particular batch of primers you got. Some batches are more ‘sparky’ than normal... and that goes for standard and magnum primers.

Just start 2 gn lower and work your way up in 0.3 or 0.5 gn increments, then back off 0.5 if you find pressure, and use that as a safe maximum.

Of course some powders are temperature sensitive, and then you may need to repeat the pressure test in summer and change you load recipe to achieve the same speed to hopefully get back to the same node as before. A little inconvenient perhaps, but not a huge burden either.

It is normally best to figure out what particular primer works best for your chosen set of components by trying a few, pick the one that gave the best ES, and then buy in bulk so you don’t need to switch primers later on, and possibly having to redo load development.

The hoarding will not help the rest of us, but oh welll...

Last edited:

Pretty sure the new Berger LRP brass is standard flash hole size. Will check.

I tested one box of the 156 gn EOL hunting round, which is loaded in LRP brass, and that heavy bullet worked superbly well on large feral hogs.... And they are tough critters, also shot small groups on steel.

Just double checked, and can confirm that the Berger/Lapua LRP brass has the larger (standard) flash hole.

I don’t have pin gauges in this size so could not measure it, but by eye it appears to be the same as Hornady, Prime, and Nosler brass.

Last edited:

I use Hybrid in my RPR's in 6.5 Creedmoor with 140g ELD's. It works good and maintains tight groups out to 1000 yards, usually less than .5 MOA unless it's very windy. I also load with Superformance in 140g and 147g because it gives faster FPS all across the board while still maintaining accuracy. My reasoning is less bullet drop, thus less dial ups at longer ranges. But use what's available to you. Hybrid is a good power for the Creedmoor.Hybrid 100V is in stock and cheaper than everything else where I go. Anybody have recent numbers on that? 140ELD's. 8T. 27" bart. The primers I have are winchester large magnum. That gonna hurt anything?

SRP brass requires small rifle primers, by definition.

You have many quality options in Large Rifle Primer brass, like Nosler, Prime, brass derived from Berger hunting ammo like the 156 EOL round. Starline also gets good reviews, and they make both SRP and LRP variants, but i do not have enough experience with it yet. They had good weight and neck thickness measurements (checked a new batch of 100 when it arrived recently). Have only done fire forming so far.

When using premium LRP brass, you can expect the primer pockets to open up after 8-12 reloads, depending on how hot you load them. Still: Premium LRP brass is noticeably better than Hornady Match brass, which is quite soft and has fairly large variations in neck thickness (as measured at 6 positions around the circumference, measured with a good ball micrometer, not calipers which are not accurate enough). And neck turning does not really “fix” them.

There is such a massive primer (and components) shortage right now that you can probably make a very nice profit on your LRP stash... but sadly SRP primers are just as hard to find now. Some folks might do a 1:1 swap if you advertise. Look for people in your city. Shipping primers is problematic (hazmat rules).

Perhaps best to stay with LRP brass for this barrel. Maybe switch to SRP when you rebarrel... and when we are not in an election year.

Thank you.

So, I found Lapula makes large primer 6.5 brass.

6.5mm Creedmoor Large Rifle Primer Unprimed Rifle Brass 100 Count

6.5mm Creedmoor Large Rifle Primer Unprimed Rifle Brass 100 Count By Lapua Product Overview Midsouth is proud to offer 6.5mm Creedmoor Large Rifle Primer Unprimed Rifle Brass 100 Count. These are brand new production cases from Lapua. The cases are scientifically designed and produced to...

I assume this would meet the need? Do people need to start their loads over with different brass brands?

Do people need to start their loads over with different brass brands?

Yes....

I haven't seen this powder talked about much on here but months ago I picked up some ramshot hunter.

Finally made up some loads with hornady brass, cci 250 and hornady 140bthp @ 2.810 coal.

I worked up to 45gr with an fps around 2860(24" howa), no 100yd groups but at 900yds it was very accurate.

Finally made up some loads with hornady brass, cci 250 and hornady 140bthp @ 2.810 coal.

I worked up to 45gr with an fps around 2860(24" howa), no 100yd groups but at 900yds it was very accurate.

41.5 h4350 140 grain hornady has been the best in the three 6.5 creeds Iv loaded for right around 2750 fps

I cant get that much in the case. Where does the base of the bullet sit in your case? How far can I stretch the bullet out of the neck?

Load the bullets longer (short jump), and you will likely gain quite a bit in case capacity and avoid the crunch of a compressed load, but it may or may not fit in your magazine anymore. How far you can go depends on the amount of freebore, and barrel erosion, and whether single feeding is practical for you or not.

I have two loads that shoot well, one has a jump of about 0.025” (25 thou), and has to be single fed by hand, which is not a major burden for a target round during practice, but perhaps not ideal as you sometimes break your position to see what you are doing, which can shift your POI and open up a group.

The second load has a jump of 0.150” (150 thou), and shoots almost as well, and feeds reliably from the mag. No need to chase the lands. Useful as competition ammo.

You can use a long drop tube or an old ultrasonic toothbrush to settle the powder before you seat a bullet. I also posted elsewhere how you can use an arbor press and an LE Wilson seating die upside down to get more powder into a case.

Last edited:

Started loading the berger 153s this summer. So far I found a node at 46.9 rl26 that looks very promising. Br primers, gas gun,22"barrel. Supposedly quick load says max pressure isn't until 47.4 ish..... if someone has program I'd like to hear 2nd opinion

Not a lot of information regarding Hodgdon Superperformance....im pretty new to all of this and the Superperformance is one of the powders i have been able to find. I have just recently stocked up on h4350 and am in the process of load development to see which one my rifle likes the most. Sorry in an advance for the novel.

I am running a Bergara HMR B14 Wilderness with a 24" stock barrel. Im able to achieve 1/2 moa and under 5 shot groups consistently now that I've refined my loads and my process. I've tested the superperformance out to 1k with good results.

Load using superperformance:

Hornady brass 2-4 firings, annealed each firing with 0.002" neck tension.

GM210M primers

45.0gr Superperformance

Bullet: 140gn Hornady Match BTHP. Ive also ran the Barnes Match Burners with similar results.

CBTO: 2.148" with 0.030" jump

COAL: 2.770"

Average speed checked with magnetospeed: 2730fps with temperatures ranging from 35F to 80F here in Wyoming.

Average ES and SD numbers across multiple loads.

Highest ES was 12 and lowest was 5.

Highest SD was 5 and lowest was 2.

ES:9

SD:3

I was chasing a higher charge node and after 3 firings on my brass the primers were starting to loosen up. I backed down 0.5grs and actually found a better load.

I've started load development using h4350 this week and after learning from my mistakes have managed to get a decent load made up in under 50 rounds total. I used the same cbto and coal measurements for my superperformance load.

Did my initial load test starting with 40.5gr and moved up to 43.3gr in 0.2gr increments. I found a flat spot between 41.3 and 41.7gr with speeds from 2720 to 2730. My next node was right where I started seeing pressure signs at 43.1(2823fps) and 43.3gr(2827fps).

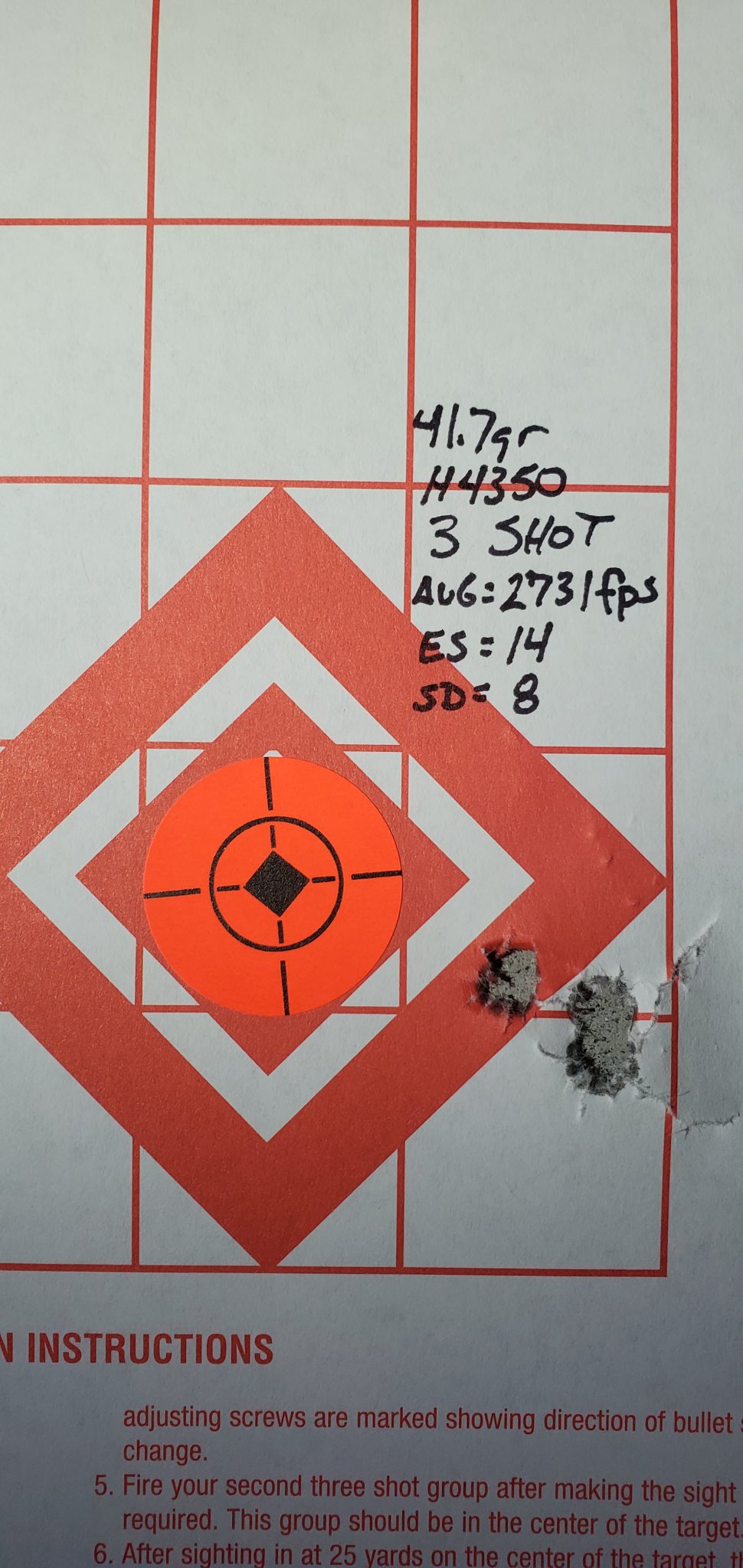

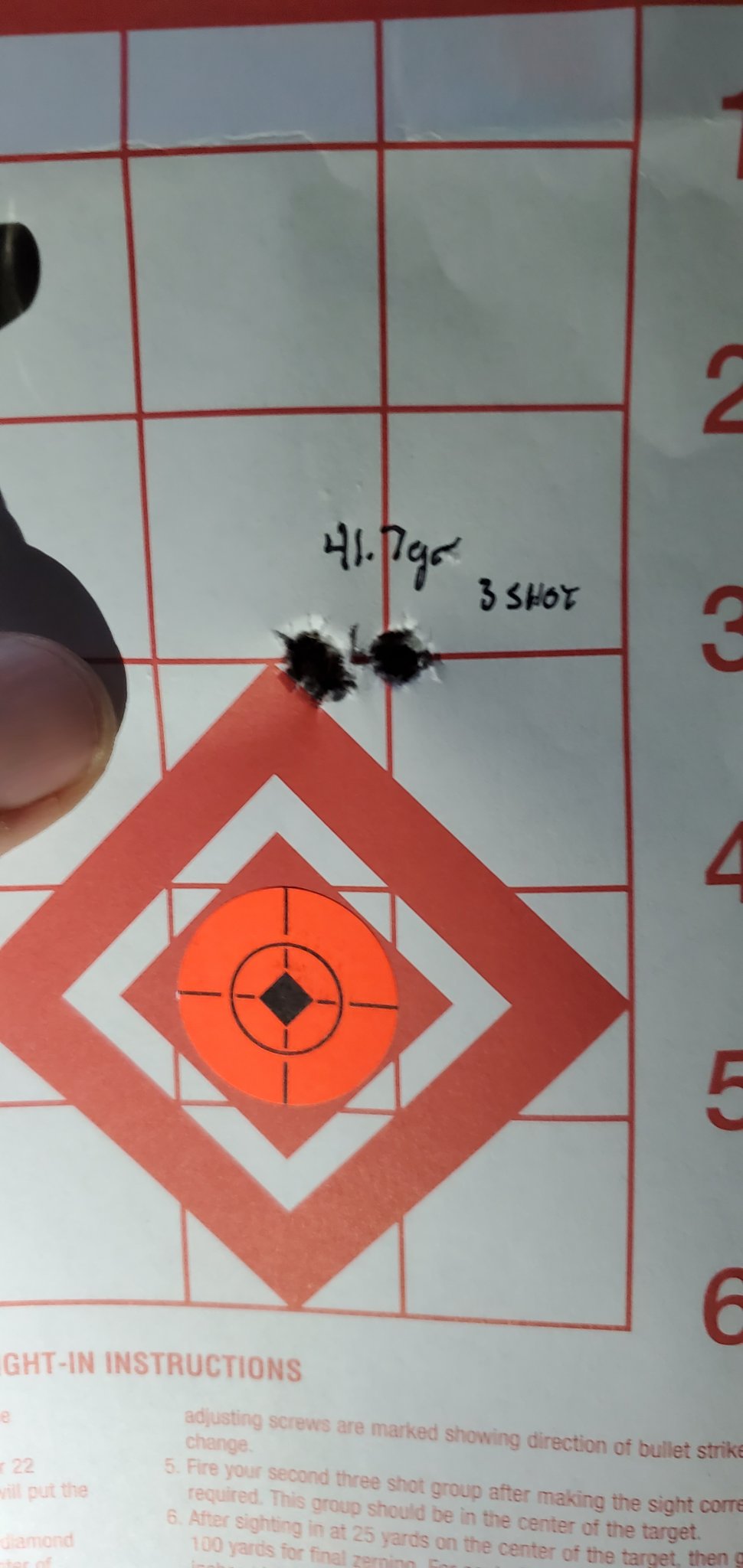

Loaded rounds from 41.3 to 41 7gr in 0.1gr increases and found a good load accuracy wise with good es and SD numbers at 41.7 that im going to pursue. See attached pictures with my results from last night.

I would like to note when using the magnetospeed my rifle shoots 3"-4" higher from my POI than it does without it. Shots posted with the magnetospeed I was holding 1mil down on my reticle. I did 3 shots with and 3 shots without the magnetospeed attached.

Above with magnetospeed and below without.

My group at 41.6gr without the magnetospeed attached was awesome but once I put it on things went to shit.

Above picture without the magnetospeed.

I am running a Bergara HMR B14 Wilderness with a 24" stock barrel. Im able to achieve 1/2 moa and under 5 shot groups consistently now that I've refined my loads and my process. I've tested the superperformance out to 1k with good results.

Load using superperformance:

Hornady brass 2-4 firings, annealed each firing with 0.002" neck tension.

GM210M primers

45.0gr Superperformance

Bullet: 140gn Hornady Match BTHP. Ive also ran the Barnes Match Burners with similar results.

CBTO: 2.148" with 0.030" jump

COAL: 2.770"

Average speed checked with magnetospeed: 2730fps with temperatures ranging from 35F to 80F here in Wyoming.

Average ES and SD numbers across multiple loads.

Highest ES was 12 and lowest was 5.

Highest SD was 5 and lowest was 2.

ES:9

SD:3

I was chasing a higher charge node and after 3 firings on my brass the primers were starting to loosen up. I backed down 0.5grs and actually found a better load.

I've started load development using h4350 this week and after learning from my mistakes have managed to get a decent load made up in under 50 rounds total. I used the same cbto and coal measurements for my superperformance load.

Did my initial load test starting with 40.5gr and moved up to 43.3gr in 0.2gr increments. I found a flat spot between 41.3 and 41.7gr with speeds from 2720 to 2730. My next node was right where I started seeing pressure signs at 43.1(2823fps) and 43.3gr(2827fps).

Loaded rounds from 41.3 to 41 7gr in 0.1gr increases and found a good load accuracy wise with good es and SD numbers at 41.7 that im going to pursue. See attached pictures with my results from last night.

I would like to note when using the magnetospeed my rifle shoots 3"-4" higher from my POI than it does without it. Shots posted with the magnetospeed I was holding 1mil down on my reticle. I did 3 shots with and 3 shots without the magnetospeed attached.

Above with magnetospeed and below without.

My group at 41.6gr without the magnetospeed attached was awesome but once I put it on things went to shit.

Above picture without the magnetospeed.

Anybody have experience with eld factory seconds? Got a bunch and the bullet geometry varies significantly. Having a helluva time getting them seated w my Forster seating die as I guess it seats at a different point than what my comparator measures to.

For those that use Lapua brass, what brushing size does it take?

I run a .289 bushing with Lapua and pass it through a mandrel. Gives me 2 thou neck tension loaded at .291

I like Superformance and use it solely in my Creedmoor with 147g ELD's. In my factory RPR my load consistently achieves low .5 MOA's at 1000 with wind, and low .3 a few times with no wind. Our range is at 1700 ft and nearly always has strong winds. My load is 44.8g in Hornady brass with .0015" neck tension and CCI BR-2 primers. My COAL is 2.810" and gives me .030" jump. I don't have a barrel chronograph to determine MV, but based on velocities at the target at 600, 800 and 1000 yards, my loads are consistently 150 fps faster at those ranges than factory 147g ammo that has a MV of 2690 fps. So im estimating mid-2800's at the muzzle. I am fixing to start developing loads for 140g ELD's and Bergers, 142g SMK and 144g Bergers for my wifes rifle that also has a RPR, and plan to use Superformance in those as well. I already have the load data, just need to get busy and start.

Last edited:

I run a .289 bushing with Lapua and pass it through a mandrel. Gives me 2 thou neck tension loaded at .291

Is a mandrel mandatory or just another method of reloading?

Is a mandrel mandatory or just another method of reloading?

Not necessary, but it has improved my concentricity/runout, as well as lowered my ES numbers. I can feel the difference when seating the bullet as well (Every one seats with the same amount of force)

Necessary? No. Worth the extra step? Absolutely!

Not necessary, but it has improved my concentricity/runout, as well as lowered my ES numbers. I can feel the difference when seating the bullet as well (Every one seats with the same amount of force)

Necessary? No. Worth the extra step? Absolutely!

Which one do you use?

Which one do you use?

I use this die

All SINCLAIR INTERNATIONAL Products for Sale Online - 236 Products

Brownells has 236 SINCLAIR INTERNATIONAL products for Sale Up To 91% Off including Reloading, Tools & Cleaning, and Gear.

with this mandrel ( or turning arbor as called). (NT26)

Arbors and Mandrels

21st Century Shooting, Reloading products, Reload, reloading ammo, 21st century, twenty first century shooting, shooting, gun arbors, mandrels, reloading, tools for reloading, front rest, f class, bench rest, short handle, arbor press, powder measure, bullet, bullet comparators, die base, shell...

You want the neck turning arbor, as this will give you 2 thou neck tension. Get the expander if you only want 1 thou tension.

As an added note to my previous post.

I was having issues with inconsistent neck tension using the Hornady custom grade die with expander ball. My process is/was as follows.

Decap using Lee decaping die.

Tumble with stainless pins media and dawn dish soap for 3-4 hours. Cases come out clean as they can possibly be.

Dry in dehydrator.

Hand anneal. Ive set my annealing time using tempilaq.

Full length size with 0.002" shoulder bump.

Trim if needed to1.915" then chamfer and debur.

Run through the vibratory to clean off any sizing lube. I use one shot.

Seat primers.

Dump charge and seat bullets. I am using the Hornady seating micrometer on my die.

While seating my bullets I was noticing that some seated harder than others. I started marking the cases on the ones that seated hard and when I shot them they were always the flyers. So I went back to my bench and started measuring my sized case neck openings with pin gauges and found that they varied between 0.260" and 0.262". I decided to try running them over the expander ball a few extra times to see if it helped and it did quite a bit. I also slowed down when sizing to give the brass more time to form. My necks now average 9.262" + or - 0.0005". I still plan on trying new dies using either a mandrel or bushing. Not decided yet.

The above steps dropped my ES and SD numbers across the board but I was still feeling inconsistent pressure while seating my bullets. A friend at a local shop mentioned lubricating the inside of my necks with something like one shot, so I gave it a shot.

I use a swab with one shot to lube the inside of my necks after dumping my powder and then seat my bullets. Much more consistent pressure (almost none) when seating and my ES and SD's have dropped almost 50%.

My questions are. Is this a method that is used by many and does anyone know of any issues from doing this? I'm getting single digit ES numbers across multiple calibers and loads that before were at best mid to high teens.

Thanks in advance for the advice.

I was having issues with inconsistent neck tension using the Hornady custom grade die with expander ball. My process is/was as follows.

Decap using Lee decaping die.

Tumble with stainless pins media and dawn dish soap for 3-4 hours. Cases come out clean as they can possibly be.

Dry in dehydrator.

Hand anneal. Ive set my annealing time using tempilaq.

Full length size with 0.002" shoulder bump.

Trim if needed to1.915" then chamfer and debur.

Run through the vibratory to clean off any sizing lube. I use one shot.

Seat primers.

Dump charge and seat bullets. I am using the Hornady seating micrometer on my die.

While seating my bullets I was noticing that some seated harder than others. I started marking the cases on the ones that seated hard and when I shot them they were always the flyers. So I went back to my bench and started measuring my sized case neck openings with pin gauges and found that they varied between 0.260" and 0.262". I decided to try running them over the expander ball a few extra times to see if it helped and it did quite a bit. I also slowed down when sizing to give the brass more time to form. My necks now average 9.262" + or - 0.0005". I still plan on trying new dies using either a mandrel or bushing. Not decided yet.

The above steps dropped my ES and SD numbers across the board but I was still feeling inconsistent pressure while seating my bullets. A friend at a local shop mentioned lubricating the inside of my necks with something like one shot, so I gave it a shot.

I use a swab with one shot to lube the inside of my necks after dumping my powder and then seat my bullets. Much more consistent pressure (almost none) when seating and my ES and SD's have dropped almost 50%.

My questions are. Is this a method that is used by many and does anyone know of any issues from doing this? I'm getting single digit ES numbers across multiple calibers and loads that before were at best mid to high teens.

Thanks in advance for the advice.

I am a newbie to reloading, but work with some hunters that got me on track from the get go. I had a similar issue myself at first, but discovered the timing of the ball sizer entering the case relative to the outside neck sizer doing its thing made a huge difference in consistent seating tension. I adjusted the ball height so it was about halfway into the case before the outside die contacted the case. I now get .0015" interference every time. May help if you check the timing of yours.

I would guess you full length size after removing the expander ball and rod? Then change dies to run the mandrel? Seems like a better option to using a bushing die due to not having to neck turn each case. Am I thinking about this one right?I use this die

All SINCLAIR INTERNATIONAL Products for Sale Online - 236 Products

Brownells has 236 SINCLAIR INTERNATIONAL products for Sale Up To 91% Off including Reloading, Tools & Cleaning, and Gear.www.sinclairintl.com

with this mandrel ( or turning arbor as called). (NT26)

Arbors and Mandrels

21st Century Shooting, Reloading products, Reload, reloading ammo, 21st century, twenty first century shooting, shooting, gun arbors, mandrels, reloading, tools for reloading, front rest, f class, bench rest, short handle, arbor press, powder measure, bullet, bullet comparators, die base, shell...www.xxicsi.com

You want the neck turning arbor, as this will give you 2 thou neck tension. Get the expander if you only want 1 thou tension.

I will definitely do that. I did adjust it after initially finding the issue. I believe its about centered in the die body now where it was down towards the bottom. It is now set about 0.250" lower from where the neck gets sized down at the top of my die.I am a newbie to reloading, but work with some hunters that got me on track from the get go. I had a similar issue myself at first, but discovered the timing of the ball sizer entering the case relative to the outside neck sizer doing its thing made a huge difference in consistent seating tension. I adjusted the ball height so it was about halfway into the case before the outside die contacted the case. I now get .0015" interference every time. May help if you check the timing of yours.

I would guess you full length size after removing the expander ball and rod? Then change dies to run the mandrel? Seems like a better option to using a bushing die due to not having to neck turn each case. Am I thinking about this one right?

I’m using Redding Type S dies on all calibers I load for. I full length resize, decapping rod and expander removed. I use a bushing to set the out, mandrel to iron out the inside.

Last edited:

Thank you.I’m using Redding Type S died on all calibers I load for. I full length resize, decapping rod and expander removed. I use a bushing to set the out, mandrel to iron out the inside.

Anybody have experience with eld factory seconds? Got a bunch and the bullet geometry varies significantly. Having a helluva time getting them seated w my Forster seating die as I guess it seats at a different point than what my comparator measures to.

I've been shooting a bunch of the factory seconds ELD-X 143 bullets. They do vary from the ogive to the tip but from the ogive to the base their consistent so at least I know their shooting at the same pressures and the chrono confirms this. What I do is back off the micrometer seating die .005 and seat the bullet and measure. Then dial back in and seat a second time. A little more time consuming but it's been working.

I should add that i measured all of the bullets with the comparator prior to loading them and I grouped them in to two groups.

Last edited:

I use this die

All SINCLAIR INTERNATIONAL Products for Sale Online - 236 Products

Brownells has 236 SINCLAIR INTERNATIONAL products for Sale Up To 91% Off including Reloading, Tools & Cleaning, and Gear.www.sinclairintl.com

with this mandrel ( or turning arbor as called). (NT26)

Arbors and Mandrels

21st Century Shooting, Reloading products, Reload, reloading ammo, 21st century, twenty first century shooting, shooting, gun arbors, mandrels, reloading, tools for reloading, front rest, f class, bench rest, short handle, arbor press, powder measure, bullet, bullet comparators, die base, shell...www.xxicsi.com

You want the neck turning arbor, as this will give you 2 thou neck tension. Get the expander if you only want 1 thou tension.

Thanks.

Guess I'll be ordering the .289 and a few other goodies.

Similar threads

- Replies

- 10

- Views

- 537

- Replies

- 17

- Views

- 2K