You said above you’re using a 50$ pma tool. I have no reservation it is not as accurate or great as what the factory is doing.

How on earth can you be surprised about primer profusion when you’re crushing?? You would need to measure the cup and primer and the numbers would easily tell you where the primer would end up. Something doesn’t add up there…….

You're saying a precision cutting tool that indexs off a case head is less great than a punch process in the manufacturing process?

If I put a cutter into a pocket that only cuts the bottom of a virgin pocket and give it a quick turn you can see it's uneven. Either out in the corners, closer to the flash hole or some random spot.

I'm gonna say I don't even understand this question.

"How on earth can you be surprised about primer profusion when you’re crushing??"

So if you measure a virgin pocket or even a fired pocket with adequate tooling the pocket is rarely flat across the bottom.

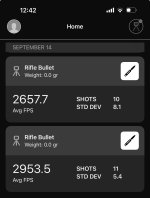

I'm working in the field and not sitting at my bench so I'm recalling numbers from memory.

Factory Lapua pocket .120" - .121" measuring off the corners of the pocket where the cup contacts.

CCI 400 depending on where you measure .122" - .123"

So what I'm doing is cutting the bottom of the pocket to .123" so with the CPS and F Class dial I can feel it touch bottom and apply .003" measured crush to the anvil and wind up .002-.003" below flush.

If these numbers don't "add up" again recalling from memory.

I assume what you're doing is setting the stop on the CPS so you are getting whatever flush to below flush setting you feel or have tested to be optimal?

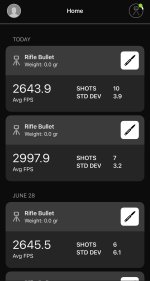

You and I are using the same tool differently to achieve two separate things. I'm not going to all the trouble of measuring primers when I can feel it touch bottom and apply the crush I feel is optimal for what I'm doing. I'll get 90% + at the same below flush doing it this way but I know they have exactly the same crush because I've measured and applied it.

Not just a below flush but a combined same crush with the same below flush.

IF and I say if because I don't know if you are just setting the stop to achieve a below flush on virgin pockets you are crushing anvil and cup probably not just a little. On fired cases definitely not just a little.

If it's working for you great, I've got no issue with what you do. While I don't have many posts here I'm not some noob reloader that's trying to reinvent the wheel.

I've done the measuring & sorting with better tools than a caliper and did some testing on paper at 600 yards that showed there was an improvement over doing nothing.

This thread is the exact reason for my extremely low post count, you confirm something someone else says in a thread because deniers won't believe it then somebody asks "why are you even putting a ruler to the bottom of a case" so you explain how that happened and next thing you know you're a knuckle dragging mouth breather.

I gotta get back to work, have a great day!