Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Am I the only one here to pre-order the Tesla truck?

- Thread starter Jefe's Dope

- Start date

Love it or hate it, there's a couple notes of interest.

1. It's a frameless outer structure. It's not sheet metal but cold rolled steel. Hence being bullet proof. Not a design feature, just an added benefit of the structural steel. *There's no frame or body on frame construction.

2. Rides on airbags. Has three benefits. 1. Adjustable ride height. Lowers on hwy for increased effeciency. Raises for off road. Most clearance of any current similar truck i.e. F150. 2. Adjusts for load and active ride control. 3. On board compressor.

3. 120/220 volt outlets. No genny needed on the job site.

4. 0-60 in 2.9 seconds. Super Car territory and beat a 911 in the ¼ mile. 10 second ¼ mile.

5. 14,000 lb. towing capacity. This is legit.

6. Approach, departure, break over, and clearance are all very respectable for an off road type vehicle.

I'm happy to be first in line to resell to some one else or if it's as good as I think it might be, I'll keep it. I'll have plenty of time to consider it . And for $100 (refundable) you might consider it too. Probably be able to sell it for a profit due to demand. But only time will tell.

1. Unibody has been used in cars at least since late 40's , frames are used only on vehicles that require modularity of rear or stability for twisting off road or towing ,i dont quite get it what he is selling and why steel has to be so thick.Clading on moving elements like doors and bonets doesnt add much rigidity to the whole thing . Guy is a snake oil salesman only thing that is slightly diferent than typical unibody is the front fender being stresed part of it.

Large unibodies are already being used in SUVs , stressed skin which he is selling is definition of uni body construction.

2. Air suspension is borderline necesary for unibody to survive offroading and given the electro motor preformance to prevent you endin up on your roof all the time

3. Higher the voltage more efficient the motors and the charging station ,Ohm law , altough batteries are not quite that way

4. No question here electric motors have enormous torque is mosty question of how to cool battery off when drawing so much current

5. Again elecro motor torque ,limits to tow weight are often in unibody itself vs the ladder frame hardpoint for the hitch.

6. even better with electic motor diferential powering of wheels this thing could go places if has enough wheel travel and right tyres.

7. Could not think of a uglier car design even i tried. View trough front windsheld shoud be quite poor

Not sure if it's an actual unit body construction. The skin is the structure from what I understood.

Yet the Mustang flat outperformed the Camaro all through the 80's and early 90's and into the 2000's. There's a reason the '03-04 Mustang Cobra is nicknamed the Terminator. And the new Mustang outsold the Camaro because nobody wanted that ugly piece of shit...worldwide. Even the obese and ugly Challenger outsold the Camaro.True, but I think Savage has sold more Model 10's than AI has sold AT/AX's. Soaking up the market, forcing the other guy out, doesn't mean you necessarily have the best product; more likely, the cheapest. Look at VHS versus Betamax (yes, I'm dating myself)....

1. Unibody has been used in cars at least since late 40's , frames are used only on vehicles that require modularity of rear or stability for twisting off road ,i dont quite get it why this delorean style body would be of any benefit.Clading on movingn elements like doors and bonets doesnt add much rigidity to te whole thing .Love it or hate it, there's a couple notes of interest.

1. It's a frameless outer structure. It's not sheet metal but cold rolled steel. Hence being bullet proof. Not a design feature, just an added benefit of the structural steel. *There's no frame or body on frame construction.

2. Rides on airbags. Has three benefits. 1. Adjustable ride height. Lowers on hwy for increased effeciency. Raises for off road. Most clearance of any current similar truck i.e. F150. 2. Adjusts for load and active ride control. 3. On board compressor.

3. 120/220 volt outlets. No genny needed on the job site.

4. 0-60 in 2.9 seconds. Super Car territory and beat a 911 in the ¼ mile. 10 second ¼ mile.

5. 14,000 lb. towing capacity. This is legit.

6. Approach, departure, break over, and clearance are all very respectable for an off road type vehicle.

I'm happy to be first in line to resell to some one else or if it's as good as I think it might be, I'll keep it. I'll have plenty of time to consider it . And for $100 (refundable) you might consider it too. Probably be able to sell it for a profit due to demand. But only time will tell.

2. Air suspension is borderline necesary for unibody to survive offroading and given the electro motor preformance to prevent you ending up on your roof twice a day.

3. Higher the voltage more efficient the motors and the charging station ,Ohm law , altough batteries are not quite that way

4. No question here electric motors have enormous torque is mosty question of how to cool battery off when drawing so much current

5. Again elecro motor torque

6. even better with electic motor diferential powering of wheels this thing could go places if has enough wheel trawel and right tyres.

7. Could not think of a uglier car design if i tried. Look liek straigh out of some 80's flick.

This thing makes more sense when you figure that its really going to be the base of a lunar/mars rover and Musk wants to make a chassis for that so he can get the cost advantages of mass production.

1. Unibody has been used in cars at least since late 40's , frames are used only on vehicles that require modularity of rear or stability for twisting off road ,i dont quite get it why this delorean style body would be of any benefit.Clading on movingn elements like doors and bonets doesnt add much rigidity to te whole thing .

2. Air suspension is borderline necesary for unibody to survive offroading and given the electro motor preformance to prevent you ending up on your roof twice a day.

3. Higher the voltage more efficient the motors and the charging station ,Ohm law , altough batteries are not quite that way

4. No question here electric motors have enormous torque is mosty question of how to cool battery off when drawing so much current

5. Again elecro motor torque

6. even better with electic motor diferential powering of wheels this thing could go places if has enough wheel trawel and right tyres.

7. Could not think of a uglier car design if i tried. Look liek straigh out of some 80's flick.

The skin and shape create the structure and rigidity. Think bridge. It's also manufacturing consideration. Easier, cheaper. They are using the same steel as used in their SpaceX program.

7. Designed, manufactured and built in the USA. Where's your truck built? Tundra's are built in Texas and I think the rest are built in Mexico and maybe Canada.

The new camaros looked, and felt like cheap junk inside and out. About as gutless as a unmasked pantyfa in texas.Yet the Mustang flat outperformed the Camaro all through the 80's and early 90's and into the 2000's. There's a reason the '03-04 Mustang Cobra is nicknamed the Terminator. And the new Mustang outsold the Camaro because nobody wanted that ugly piece of shit...worldwide. Even the obese and ugly Challenger outsold the Camaro.

The "simple" trannys without computers seem to do just fine.I've had two Cummins. The motors are reliable. The trannys, not so much. ?

My buddy just posted this today from his restaurant.

It may take longer if all the chargers are full.

It may take longer if all the chargers are full.

The "simple" trannys without computers seem to do just fine.

Autos and manuals suffer behind Cummins. You're either a dolt or just playing one now.

My buddy just posted this today from his restaurant.

It may take longer if all the chargers are full.

View attachment 7188369

There's a Honda 2000i behind that fence. ?

The truck. Wheels wobble, windows shatter and a 4 year wait and 40k. Never going to happen.What is?

Most steel bridges are ladder frames.The skin and shape create the structure and rigidity. Think bridge. It's also manufacturing consideration. Easier, cheaper. They are using the same steel as used in their SpaceX program.

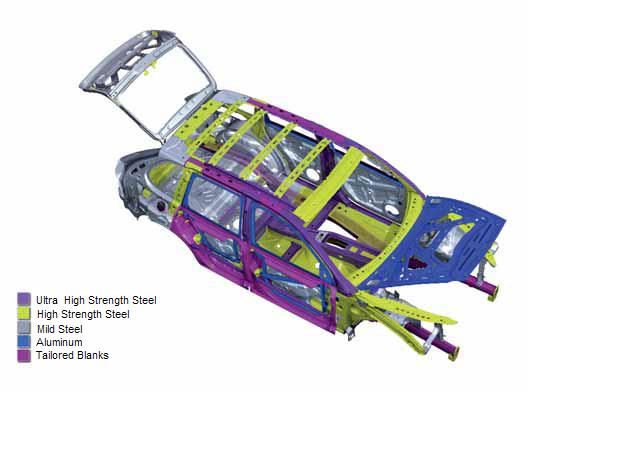

Stressed skin is a feature of all unibody cars!!! Larger and flater the panels thicker material you need to hold form ,hardly sophisticated feature. Modern cars fuction with ever thiner skins on these bodies as metalurgy and design evolve ,nowday unibody is welded up from many different grade steels that enable ever stiffer and lighter parts. On more expensive cars stressed carbon skins are already used for roofs of steel unibodies.

Steel used for spaceX is used for different purpose ,mainly to hold pressurised fuel .Materials for such tasks are primarily tough and elastic not necesarily the stiffest stuff , some of these properties are realy bad for bullet proofing (ever seen boiler plate take shrapnel or bullets , it goes trough it like butter) . That is snake oil salesman talking.

Laminated windows with a polycarbonate or similar outer layer ? only reason i can think why they would want them is to save weight.Glass is one of the heaviest elements on a car .

Here the Musks presure cooker goes off.

Large unibody SUV are built in US even tough they are German or Japanese , US has 60% tarifs in place on trucks for past 50 or so years that is why no one is realy importing any to US.

Last edited:

The truck. Wheels wobble, windows shatter and a 4 year wait and 40k. Never going to happen.

So you've laid hands on one and driven it?

How do your windows hold up to a 12 lb. ball bearing being thrown at it? I'd bet real money it would have not just shattered and bounced off but continued right on through into your lap. And it'll be fixed by production.*

You'll see the $40K version early 2021 if not sooner. One of the reasons, if not the only, it looks like it does is for simplicity of manufacturer. Also, no paint. And it will happen, just like their cars that continue to sell and sell. And their rockets that take off and land now. Their doing shit .govs can't get done.

*In all fairness, my nephew is a production manager. They have growing pains and they're trying to keep up. But the continued incoming sales isn't helping. They're not going away.

Most steel bridges are ladder frames.

Stressed skin is a feature of all unibody cars!!! Larger and flater the panels thicker material you need to hold form ,hardly sophisticated feature. Modern cars fuction with ever thiner skins on these bodies as metalurgy and design evolve ,nowday unibody is welded up from many different grade steels that enable ever stiffer and lighter parts. On more expensive cars stressed carbon skins are already used for roofs of steel unibodies.

Steel used for spaceX is used for different purpose ,mainly to hold pressurised fuel .Materials for such tasks are primarily tough and elastic not necesarily the stiffest stuff , some of these properties are realy bad for bullet proofing (ever seen boiler plate take shrapnel or bullets , it goes trough it like butter) . That is snake oil salesman talking.

Here the Musks presure cooker goes off.

Large unibody SUV are built in US even tough they are German or Japanese , US has 60% tarifs in place on trucks for past 50 or so years that is why no one is realy importing any to US.

There's no framing behind the steel. The steel skin IS the structure. The bends are structural.

Autos and manuals suffer behind Cummins. You're either a dolt or just playing one now.

cummins make too much torque for those factory autos

see we were made for each other

I don't care what you boys do in your tent on Brokeback Mountain but I'd prefer you leave it there.

Not that there's anything wrong with that. ?

It is at the network of stations like the one I posted.so is charging free?

Supercharger | Tesla

Supercharger keeps you charged when you’re away from home. With a reliable global network, you can go anywhere and conveniently fast charge. Simply plug in, charge and go.

cummins make too much torque for those factory autos

To the best of my knowledge the autos are stronger than the manuals now. Or at least hold up better. Probably because of those computers that keep shit from blowing up when Goober can't get his foot out of the accelerator.

I don't care what you boys do in your tent on Brokeback Mountain but I'd prefer you leave it there.

Not that there's anything wrong with that. ?

They’re having governments subsidize rockets via boutique car sales. But, technology will improve when you bother to try it on things.

We can subsidize American manufacturing and technology or would you rather continue sending "aid" and manufacturing to foreign countries?

yes there is,it gross.. who wants to stick mr pinky in a hairy poop chute

I don't but judging isn't my title.

The Cummins is about the only decent feature in a Dodge.cummins make too much torque for those factory autos

He has been known to pull some stunts. I still want Model S P100D. You can't build that and then be serious about putting this out.

Ok, carry on.So you've laid hands on one and driven it?

How do your windows hold up to a 12 lb. ball bearing being thrown at it? I'd bet real money it would have not just shattered and bounced off but continued right on through into your lap. And it'll be fixed by production.*

You'll see the $40K version early 2021 if not sooner. One of the reasons, if not the only, it looks like it does is for simplicity of manufacturer. Also, no paint. And it will happen, just like their cars that continue to sell and sell. And their rockets that take off and land now. Their doing shit .govs can't get done.

*In all fairness, my nephew is a production manager. They have growing pains and they're trying to keep up. But the continued incoming sales isn't helping. They're not going away.

Since those are my only choices, I’ll have to mull it over, but they never do listen to what I say.We can subsidize American manufacturing and technology or would you rather continue sending "aid" and manufacturing to foreign countries?

What about the yankee girl that’s piloting the thing?The Cummins is about the only decent feature in a Dodge.

Touche lolWhat about the yankee girl that’s piloting the thing?

Plenty of 300k+ mile manuals running around (including mine) that haven't had any problems.Autos and manuals suffer behind Cummins. You're either a dolt or just playing one now.

Plenty of 300k+ mile manuals running around (including mine) that haven't had any problems.

With a factory clutch?

A couple old farmers I know, yes, but not mine. I put that in the brake pad category of parts replacement. Its a wear item.With a factory clutch?

A couple old farmers I know, yes, but not mine. I put that in the brake pad category of parts replacement. Its a wear item.

So you get to pick and choose what's a "wear" item? Did you 'upgrade' or replace w/ an OEM?

How much HP/TQ you pushing?

Pick and choose? No, thats just what it is. I suppose next you'll tell me my regular oil changes are a symptom of unreliability.So you get to pick and choose what's a "wear" item? Did you 'upgrade' or replace w/ an OEM?

How much HP/TQ you pushing?

Replacement clutch is pretty OEM-ish.

No clue what it makes for power, its got some minor upgrades but its a driver, not a jacked up bro-dozer so its never seen a dyno or a track or been plastered all over Instagram.

Pick and choose? No, thats just what it is. I suppose next you'll tell me my regular oil changes are a symptom of unreliability.

Replacement clutch is pretty OEM-ish.

No clue what it makes for power, its got some minor upgrades but its a driver, not a jacked up bro-dozer so its never seen a dyno or a track or been plastered all over Instagram.

I'm just trying to understand your rules of our discussion.

What's the maintenance interval for a factory clutch replacement per the manual?

If the plates start slipping in an auto and you replace the auto, is that just like regular oil changes?

The company down the road from me, ATS diesel, was built on Cummins tranny issues. Sound like you have one of the older 12 valve motors?

What's the maintenance interval for a factory clutch replacement per the manual?

When it starts slipping is usually a good time.

I've had them replaced before, I had a car around 200k that needed the clutch replaced as it started slipping.

There aren't any rules, I'm making this game up as I go along. Now that we're moving towards a real discussion and away from the passive aggressive banter its not as fun. Mostly I just like hating on automatic transmissions.I'm just trying to understand your rules of our discussion.

What's the maintenance interval for a factory clutch replacement per the manual?

If the plates start slipping in an auto and you replace the auto, is that just like regular oil changes?

The company down the road from me, ATS diesel, was built on Cummins tranny issues. Sound like you have one of the older 12 valve motors?

Yes, its a 12v, so simple I can perform all necessary maintenance with a hammer and vice grips!

Similar threads

- Replies

- 9

- Views

- 732

- Replies

- 13

- Views

- 2K

- Replies

- 0

- Views

- 177