I got a new batch of 168’s the other day. And in two of my rifles that I’ve never had issues with started having issues chambering this new lot. Like it will eventually go in but you have to hammer and force the bolt closed. Seems to shoot ok but damn it running the bolt is problematic assuming you ever needed to do it in a timed event or something. Not to mention when ejecting it cocks and cants the rifle to one side. Talked to some buddies and they are having the same problems with their .308’s. I’m just wondering if anyone else is having this issue. I haven’t had a chance to mic any yet to see what might be the deal.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone had trouble chambering the new FGMM 168 or 175’s?

- Thread starter SilentStalkr

- Start date

Send me the ammo you have left and Ill try it out.

I got a new lot of 175 and noticed the brass looks like dogshit, haven’t checked to see if it chambers easily

Check it and let me know please sir.

This, employed according to the accompanying instructions.

We can conjecture, but I'm lousy at solving problems unseen over the internet. Others may share that deficit.

With this gauge, you can confirm a go or no-go as a genuine fact. If the cartridges fail, they are outside SAAMI Spec, so contact the manufacturer. They need to know these things, and they may make it good for you.

With these gauges, a 'pass' could still miss a problem in seating depth, so chamber a few rounds and extract them unfired. If the bullet curvature indicates some mechanical marking there's near certainty the chamber and bullet ogive are in an interference relationship. Considering that this is a new problem, not experienced with previous commercial ammunition, the problem is probably an ammunition issue, and the above contacts with the manufacturer could also apply here.

Check the ogive/curve for markings before you order the gauge.

Greg

We can conjecture, but I'm lousy at solving problems unseen over the internet. Others may share that deficit.

With this gauge, you can confirm a go or no-go as a genuine fact. If the cartridges fail, they are outside SAAMI Spec, so contact the manufacturer. They need to know these things, and they may make it good for you.

With these gauges, a 'pass' could still miss a problem in seating depth, so chamber a few rounds and extract them unfired. If the bullet curvature indicates some mechanical marking there's near certainty the chamber and bullet ogive are in an interference relationship. Considering that this is a new problem, not experienced with previous commercial ammunition, the problem is probably an ammunition issue, and the above contacts with the manufacturer could also apply here.

Check the ogive/curve for markings before you order the gauge.

Greg

Last edited:

I got a new batch of 168’s the other day. And in two of my rifles that I’ve never had issues with started having issues chambering this new lot. Like it will eventually go in but you have to hammer and force the bolt closed. Seems to shoot ok but damn it running the bolt is problematic assuming you ever needed to do it in a timed event or something. Not to mention when ejecting it cocks and cants the rifle to one side. Talked to some buddies and they are having the same problems with their .308’s. I’m just wondering if anyone else is having this issue. I haven’t had a chance to mic any yet to see what might be the deal.

Several Lots of GM have had issues being long on the shoulder datum.

Your issue has zero to do with bullet pushing into the lands.

Basically the "headspace" of the ammo is slightly too long so when you are trying to force the bolt into battery, you are trying to crush the shoulder of the cartridge back a thousandth or two.

Checking the ammo with any "drop in" type gauge will likely be iffy because the issue with the shoulder datum of the ammo is only a couple of thousandths out of spec which is difficult for most to eyeball when using those type gauges.

I have one such lot of GM308M from a about 3 years ago.

./

Several Lots of GM have had issues being long on the shoulder datum.

Your issue has zero to do with bullet pushing into the lands.

Basically the "headspace" of the ammo is slightly too long so when you are trying to force the bolt into battery, you are trying to crush the shoulder of the cartridge back a thousandth or two.

Checking the ammo with any "drop in" type gauge will likely be iffy because the issue with the shoulder datum of the ammo is only a couple of thousandths out of spec which is difficult for most to eyeball when using those type gauges.

I have one such lot of GM308M from a about 3 years ago.

./

I always compare my new stuff to older stuff that I know ran and honestly, I thought the shoulder looked a little off but just said to myself I was seeing things and didn’t measure it in any way to know for sure and went on about my business. Anyways, I believe you are right. Even after a thorough cleaning old stuff chambers fantastic, new stuff will go but not near as smooth. It’s also this way in all my .308’s so I know it’s not a particular rifle issue. Thanks for the feedback guys! Now the question is, do I write federal or just roll with it until this lot is used up? Good news for me is that it’s not all the same lot! Normally that would be less than ideal but in this case that works in my favor.

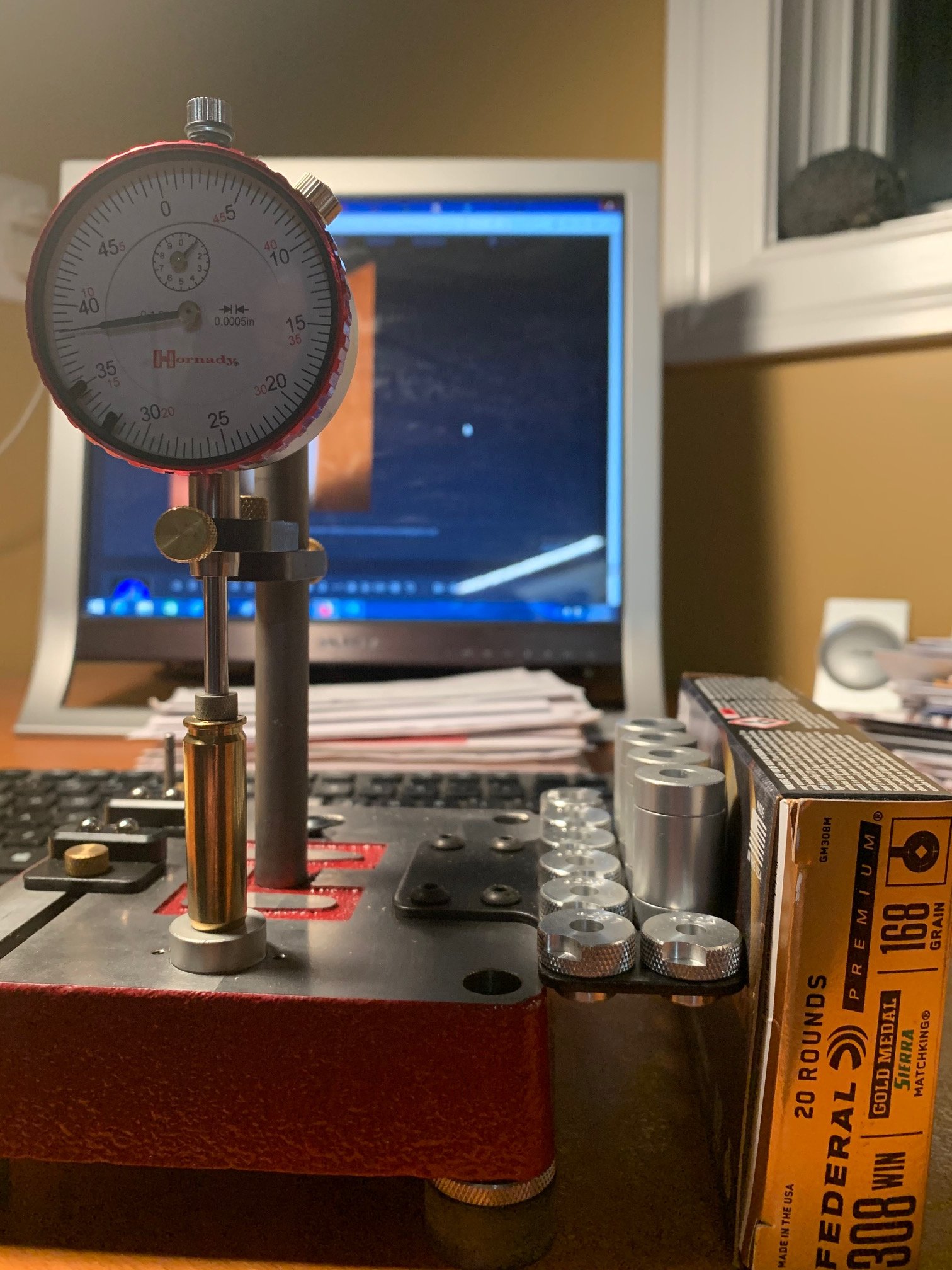

The best way by far to check ammo for this issue is the same way one would properly setup a body die for their reloading press.

Using a shoulder datum gauge you can set your zero using a headspace gauge for whatever caliber you are going to measure ammo or brass for.

After zeroing the instrument, you can check the shoulder datum.

Here is a factory Hornady TAP round that was very tight chambering in a factory Rem M700.

The gauge indicates that the shoulder is at least 0.0015" longer than the HS gauge. *This round was likely even longer before the bolt was forced down on it by a student in our class.

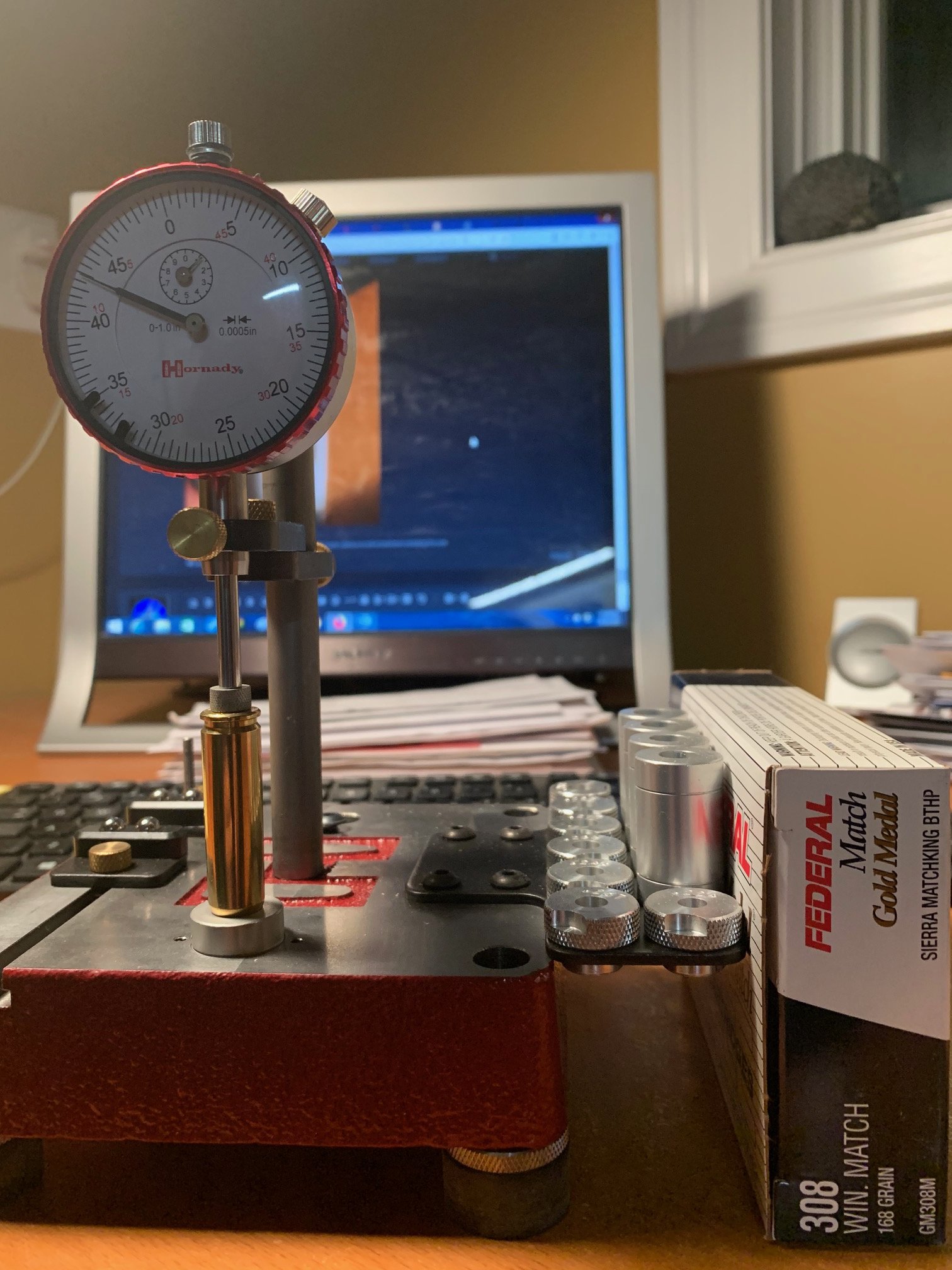

Here is a factory Federal T308T round that is 0.0025" under the HS gauge and is right about where most should fall to insure good function in rifles that are in H.S. spec.

I'm betting $100.00 that your ammo is falling into the middle category of being too long on the shoulder datum.

Hope this better explains what I am trying to get across.

./

Using a shoulder datum gauge you can set your zero using a headspace gauge for whatever caliber you are going to measure ammo or brass for.

After zeroing the instrument, you can check the shoulder datum.

Here is a factory Hornady TAP round that was very tight chambering in a factory Rem M700.

The gauge indicates that the shoulder is at least 0.0015" longer than the HS gauge. *This round was likely even longer before the bolt was forced down on it by a student in our class.

Here is a factory Federal T308T round that is 0.0025" under the HS gauge and is right about where most should fall to insure good function in rifles that are in H.S. spec.

I'm betting $100.00 that your ammo is falling into the middle category of being too long on the shoulder datum.

Hope this better explains what I am trying to get across.

./

Last edited:

It would be worth contacting Federal. Be sure to have a pic of the box with the product production lot number. They would want that.Now the question is, do I write federal or just roll with it until this lot is used up? Good news for me is that it’s not all the same lot! Normally that would be less than ideal but in this case that works in my favor.

I would encourage you to swap it out.

While it will fire and extract once you get the bolt down, we would usually see such a round being a squirrel compared to other shots fired into a group or at a target. Not much but enough to notice under good conditions.

When running basic and advanced classes, we see more of this now than ever before. We assume it is because all of the ammo companies are running 24/7 while not PMing their machines and not staying tight enough on their QC.

We insist that if an officer finds a tight round like that they should side line it. But then again I insist on every PMO get in the habit of visually inspecting each round that they will deploy with and then literally cycling each round through the rifle before stowing their gear.

./

Last edited:

The best way by far to check ammo for this issue is the same way one would properly setup a body die for their reloading press.

Using a should datum gauge you can set your zero using a headspace gauge for whatever caliber you are going to measure ammo or brass for.

View attachment 7370238

After zeroing the instrument, you can check the shoulder datum.

Here is a factory Hornady TAP round that was very tight chambering in a factory Rem M700.

The gauge indicates that the shoulder is at least 0.0015" longer than the HS gauge. *This round was likely even longer before the bolt was forced down on it by a student in our class.

View attachment 7370239

Here is a factory Federal T308T round that is 0.0025" under the HS gauge and is right about where most should fall to insure good function in rifles that are in H.S. spec.

View attachment 7370240

I'm betting $100.00 that your ammo is falling into the middle category of being too long on the shoulder datum.

Hope this better explains what I am trying to get across.

./

I need to get a headspace gauge for this.

Thing is they are sort of a mystery to me....go, no-go, field?

I usually use an RCBS precision mic and try to get "0" sizing which should be SAAMI spec for ammo to be used in a variety of rifles.

Measuring FGMM in my RCBS I find that it is usually 1-2 thou under the "0".

Thing is I dont have a good HS gauge to determine if the RCBS gauge is accurate.

Like wise if using a Hornady HS gauge Im not starting from a known measurement.

Its the reloading "Theory of Relativity" everything is relative to what you start with - a fired case, an RCBS tool that may or may not be accurate, or using a loaded factory round that may or may not be in spec.

@Terry Cross is there a specific brand of HS tool you recommend?

Not chambering rifles but thinking to use more for sizing ammo what tool would be the correct one to eliminate some of the relativity? It would become my standard.

Measure a fired case from your rifle and compare it to the ammunition that’s tight.

Measure a fired case from your rifle and compare it to the ammunition that’s tight.

@Steel head

Im assuming your post is directed toward the OP?

Would be a good way for OP to determine if factory is "oversize" assuming his chamber is being used as a sizing die when he closes the bolt.

Likely he would get some spring back on the brass though when he extracts it from the chamber.

Maybe a thousandth worth.@Steel head

Im assuming your post is directed toward the OP?

Would be a good way for OP to determine if factory is "oversize" assuming his chamber is being used as a sizing die when he closes the bolt.

Likely he would get some spring back on the brass though when he extracts it from the chamber.

Still would give some useful information.

I have New brass, fired brass, headspace gauge and stand off Measurements for all my barrels in a log book.

Maybe a thousandth worth.

Still would give some useful information.

I have New brass, fired brass, headspace gauge and stand off Measurements for all my barrels in a log book.

Agreed would be good for him to see whats going on.

I shoot so many guns with the same caliber that Ive gotten away from individual gun reloading.

Measuring a fired piece of brass than setting back, 1-2 thou for bolt or 3-4 thou for semi was a pain in the balls.

FGMM shooting great in everything I own I go for their standard size just about -1 thou on the RCBS precision mic.

Loading on a Dillon though, that can be a crap shoot.

I went through this when I returned my 260 barrel to the original Ghost Dancer Rifle, which had just competed a disappointing project involving a rejected M-14 barrel gifted by a stranger friend of a friend named "Doug", chambered for 30BR by using a 7mm chamber reamer, followed up by a 30-06 reamer to produce the neck and leade, then threaded for the Savage action. FWIW, a long time after it was removed, a bore scope session revealed tool marks that appeared about as deep as the Marianas Trench. That barrel was never going to shoot, it was cursed. I got what I paid for it, which was Zilch.

Anyhoo, I had made up some 260 cartridges using my standard load which was borderline max. The carrtridges were hard to close the bolt on, and even required fist pounding the bolt handle to achieve that. First shot, considerable primer flattening but not totally excessive. Second shot, blown primer, stopped right there and then.

Noting that I had never gotten around to obtaining either case gauge nor headspace gauges, I immediately ordered some. The bolt wouldn't close on the GO gauge, headspace was short. Up until then I had removed and replaced the barrel several times, using a fired case for a headspace gauge. Dumb; but not all that unusual, either. Never doing that again. Short case/chamber equals smaller chamber volume trying to burn the original charge. Something has to give, and I got a serious pressure spike. Careful disassembly and measuring against an identical bolt says no distortion was present.

Barrel remounted and headspaced OK according to genuine (308) GO and NOGO, I used the case gauge (308, same shoulder dimensions as the 260) to set up the resizing die again, and produce cases which were just shy of max length. I also pulled own every 260 round I had in shop and reconstructed them with projectiles, propellants, and charges intended to find the next lower node. These cartridges chamber with the hoped-for mild bolt closure drag.

Summarizing, I had made assumptions (wrong assumptions) about how to properly headspace a Savage barrel, and compounded the error by running a marginally max load in a remounted and unfired barrel.

My problem then was not this above problem now, but can illustrate what occurs when ammunition/chamber dimensions are off. All bets are off then.

Greg

Anyhoo, I had made up some 260 cartridges using my standard load which was borderline max. The carrtridges were hard to close the bolt on, and even required fist pounding the bolt handle to achieve that. First shot, considerable primer flattening but not totally excessive. Second shot, blown primer, stopped right there and then.

Noting that I had never gotten around to obtaining either case gauge nor headspace gauges, I immediately ordered some. The bolt wouldn't close on the GO gauge, headspace was short. Up until then I had removed and replaced the barrel several times, using a fired case for a headspace gauge. Dumb; but not all that unusual, either. Never doing that again. Short case/chamber equals smaller chamber volume trying to burn the original charge. Something has to give, and I got a serious pressure spike. Careful disassembly and measuring against an identical bolt says no distortion was present.

Barrel remounted and headspaced OK according to genuine (308) GO and NOGO, I used the case gauge (308, same shoulder dimensions as the 260) to set up the resizing die again, and produce cases which were just shy of max length. I also pulled own every 260 round I had in shop and reconstructed them with projectiles, propellants, and charges intended to find the next lower node. These cartridges chamber with the hoped-for mild bolt closure drag.

Summarizing, I had made assumptions (wrong assumptions) about how to properly headspace a Savage barrel, and compounded the error by running a marginally max load in a remounted and unfired barrel.

My problem then was not this above problem now, but can illustrate what occurs when ammunition/chamber dimensions are off. All bets are off then.

Greg

if this is a "bad lot", it would be great to get the lot# so i can check my stocks.

Still doing some more investigating. I sharpied the bullet and casings to see if that would tell me much. Unfortunately, me trying some rounds last night sort of re-sized them. However, there were a couple that clearly had small dimples in the shoulder even tho it’s hard to see even through the sharpie on camera but it’s there. Some are worse than others. I need to measure and mic some. Will try to do that tonight. I’ll definitely post up the lot number.

if this is a "bad lot", it would be great to get the lot# so i can check my stocks.

The 168 grain FGMM in question is 421A269 for anyone that wants to look.

Attachments

Won’t chamber in my AR10. Gonna have to grab the gap308 later to check

View attachment 7370541

View attachment 7370542

View attachment 7370550

Yours is doing exactly what mine is doing but mine isn’t quite as bad and I can force it in. You can see the marks clearly on yours!

Won’t chamber in my AR10. Gonna have to grab the gap308 later to check

View attachment 7370541

View attachment 7370542

View attachment 7370550

Do those have the blue sealant on the primer?

That projo looks kind of ugly compared to how my FGMM looks.

They must be that busy making ammo they sweep the SMKs off the floor.

Do those have the blue sealant on the primer?

That projo looks kind of ugly compared to how my FGMM looks.

They must be that busy making ammo they sweep the SMKs off the floor.

Mine do. Stamped FC .308Win as well. It’s not off brand. I think it’s like you said, they so busy their QC has gone to shit!

Last edited:

@Terry Cross and @MikeRTacOps

Any recommendations for a Headspace gauge that would serve to be a good "standard datum" for checking RCBS precision mic tools, setting up sizing dies, checking sized brass vs fired?

Most interested in an accurate gauge specifically for reloading not so much for chamber issues....although Id consider buying a full set, wouldnt be bad to monitor chambers.

Any recommendations for a Headspace gauge that would serve to be a good "standard datum" for checking RCBS precision mic tools, setting up sizing dies, checking sized brass vs fired?

Most interested in an accurate gauge specifically for reloading not so much for chamber issues....although Id consider buying a full set, wouldnt be bad to monitor chambers.

Talked to Mike, found some shit out. Will post back details later. Seems trivial but Mike has it figured out. Amazing what some small detail makes!

Last edited:

What type of rifle are you using ? I’m having the same issue using my Remington 700 with the 168’s , it doesn’t seem to happen on every round but a select fewI got a new batch of 168’s the other day. And in two of my rifles that I’ve never had issues with started having issues chambering this new lot. Like it will eventually go in but you have to hammer and force the bolt closed. Seems to shoot ok but damn it running the bolt is problematic assuming you ever needed to do it in a timed event or something. Not to mention when ejecting it cocks and cants the rifle to one side. Talked to some buddies and they are having the same problems with their .308’s. I’m just wondering if anyone else is having this issue. I haven’t had a chance to mic any yet to see what might be the deal.

Shoot me a pm with your number and let me know how late I can call you ? I'm on comms from 10:00 a.m. till 3:00 a.m. seven days a week PST...

Check...

Mike R.

Check...

Mike R.

I need to get a headspace gauge for this.

Thing is they are sort of a mystery to me....go, no-go, field?

I usually use an RCBS precision mic and try to get "0" sizing which should be SAAMI spec for ammo to be used in a variety of rifles.

Measuring FGMM in my RCBS I find that it is usually 1-2 thou under the "0".

Thing is I dont have a good HS gauge to determine if the RCBS gauge is accurate.

Like wise if using a Hornady HS gauge Im not starting from a known measurement.

Its the reloading "Theory of Relativity" everything is relative to what you start with - a fired case, an RCBS tool that may or may not be accurate, or using a loaded factory round that may or may not be in spec.

@Terry Cross is there a specific brand of HS tool you recommend?

Not chambering rifles but thinking to use more for sizing ammo what tool would be the correct one to eliminate some of the relativity? It would become my standard.

P, what he shows in picture is what you want. It delivers a true measurement of case head to shoulder datum or a relative measurment to a known sample. Works with any set of calipers. I've been using that tool for 20 years and it's invaluable.

Used to be made by Stoney Point, Hornady bought them out: https://www.sinclairintl.com/reload...ck-n-load-headspace-gauge-tool-prod35168.aspx

What type of rifle are you using ? I’m having the same issue using my Remington 700 with the 168’s , it doesn’t seem to happen on every round but a select few

It’s a custom built rifle by Short Action Customs on a Surgeon action and Bartlein barrel. It’s definitely not the rifle. It did it in at least six other rifles, some factory. I did manage to not have any issues in a Tikka and a Barrett REC10. I did a thorough cleaning and havent taken the rifle back out since. I tend to agree with Mike at TacOps but I just don’t see how a burr could be the issue. However, he is right, every round that I have this issue with has a burr. But we are talking hardened steel here vs brass. A burr shouldnt really cause that much of an issue. Interestingly, he said the new, more expensive blue tip crap doesn’t have this issue despite both being manufactured by federal. I still haven’t contacted them about it as I need more proof and haven’t had the time to screw with it. It just sucks I got his for one particular rifle and it’s the one with the problems lol.

Swell...........I just got a 500 round case of that lot number as @SilentStalkr for my AR10.

Haven't tried it yet.

Haven't tried it yet.

Swell...........I just got a 500 round case of that lot number as @SilentStalkr for my AR10.

Haven't tried it yet.

View attachment 7431969

Give it a go and let us know. I’ll be curious.

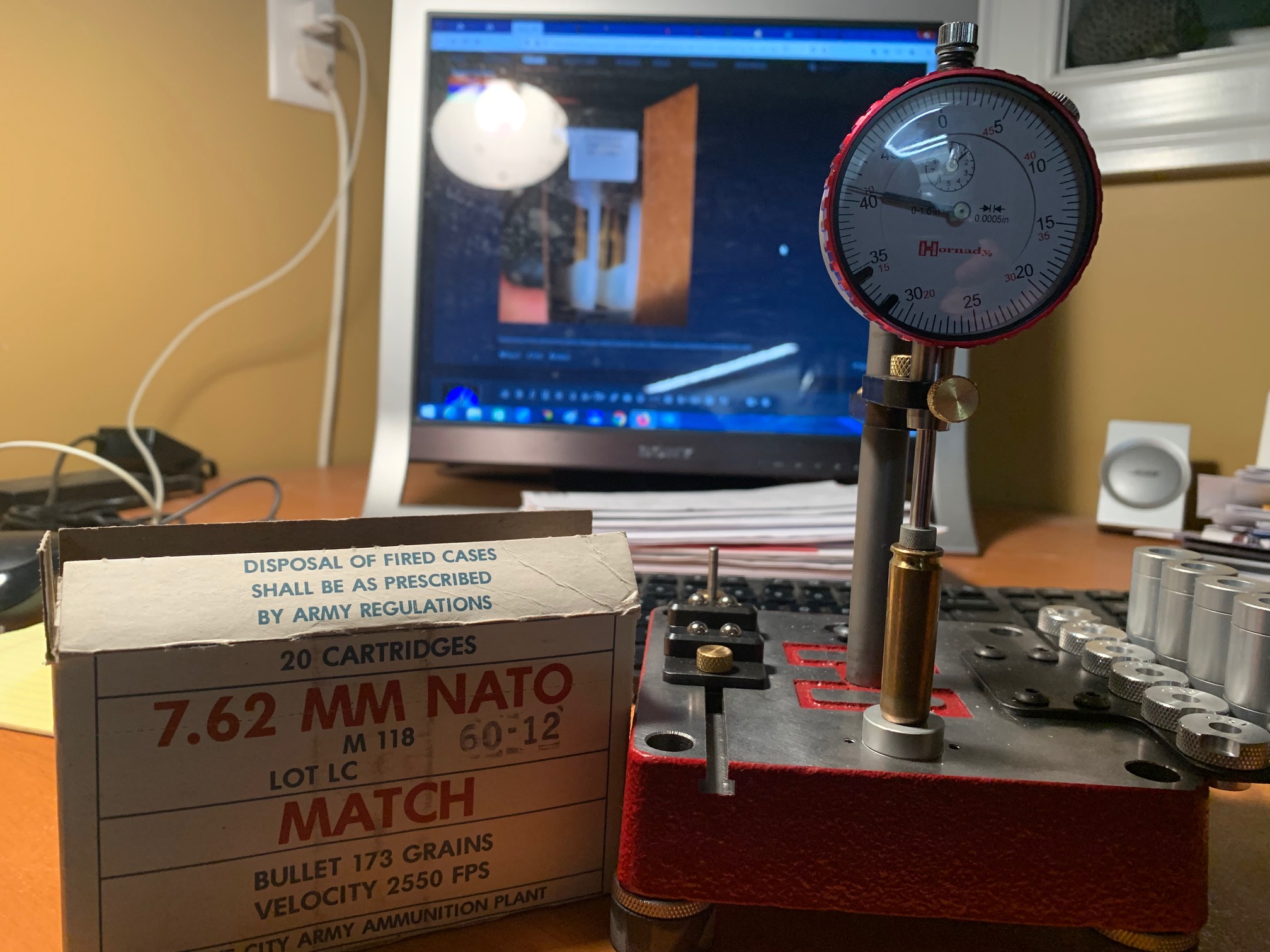

Just measured some. Not what I expected. The questionable batch has more headspace. Checked 6 random rounds of the new 168.

Mine does look better then @hic28 pictures.

I'll try a box of the new stuff this weekend. Group of 5 new 168 vs old @ 100. Curious to see if the added headspace affects accuracy.

My AR 10 was a royal PITA to get dialed, but it's like Mikey now, & eats everything. Shouldn't be a problem and the Proof 11 twist loves FGMM 175 & 168.

Zeroed guage on NoGo so deduct .004

New FGMM 175 = .003 - .0035 HS checked 6

New FGMM 168 batch in question = .005 - .0075 HS checked 6

Older batch FGMM 168 = .003 - .0035 HS checked 6

For ref. some old M118 173 = .005 HS only checked 1

Shot all my Hornady 178's no new on hand.

Mine does look better then @hic28 pictures.

I'll try a box of the new stuff this weekend. Group of 5 new 168 vs old @ 100. Curious to see if the added headspace affects accuracy.

My AR 10 was a royal PITA to get dialed, but it's like Mikey now, & eats everything. Shouldn't be a problem and the Proof 11 twist loves FGMM 175 & 168.

Zeroed guage on NoGo so deduct .004

New FGMM 175 = .003 - .0035 HS checked 6

New FGMM 168 batch in question = .005 - .0075 HS checked 6

Older batch FGMM 168 = .003 - .0035 HS checked 6

For ref. some old M118 173 = .005 HS only checked 1

Shot all my Hornady 178's no new on hand.

Glad I ran across this... Picked up four boxes of the stuff recently ... I'll have to check it tomorrow

P, what he shows in picture is what you want. It delivers a true measurement of case head to shoulder datum or a relative measurment to a known sample. Works with any set of calipers. I've been using that tool for 20 years and it's invaluable.

Used to be made by Stoney Point, Hornady bought them out: https://www.sinclairintl.com/reload...ck-n-load-headspace-gauge-tool-prod35168.aspx

Have one of those and its great for me to get info on factory in the box, fired ammo and pre/post sized ammo.

A great tool for sure but its all relative to - my calipers, my chambers, that box of ammo, my die, and my chamber wear.

I want whichever go, no go, or field gauge that represents a SAAMI ideal. Something I can check tools on and will say if used with an RCBS precision mic show "0" or if run on a stony point should always register "X" measurement or if I get a new box of ammo I could zero my stony point on the gauge than check the ammo to see if that production was plu, minus, dead nuts.

Im not chambering barrels nor likely to continue using a barrel to the point it has not only become inaccurate but the chamber is wallowed out creating excessive HS.

The need is for knowing which manufacturer makes the best gauges and which of field, go, no go is the best representation of SAAMI ideal?

Interesting I came across this. I've noticed that my "last year purchase" boxes of FGMM are slightly more accurate than purchased in recent months. None have been difficult to chamber in my Savage 12FV, for which they are (but I swear that gun would chamber a 30-06 with all the leverage and its lug design).

I say "slightly less accurate" but there are a lot of variables, no doubt. I just found it dead nuts easy to ragged hole FGMM 168 and 175s at 100 yards. At 400 yards those same rounds were always damn near dead nuts center on steel. Interestingly, even at 100 yards and no wind, the 168s POI slightly left of center compared to the 175s (the gun is zeroed for the 175s to theoretically better accomplish up to 1,000 yards in PRS Tactical class).

Now, with recently purchased boxes (in the last couple months) and only 300 rounds in with the same barrel (which is a factory HB), I'm having a hard time getting the same ragged holes at 100 and at 400 yards, I hit steal every time, but rounds from boxes I bought last year hit almost dead center on the steal and the newest rounds seem to migrate around center notably more. I thought it was the gun, but I had it eyeballed by a smith and he said it's tight.

Interestingly, the gun will shoot recently purchased Norma Match 308 168 gr into ragged holes. That uses the same SMK bullet, too. (Norma 6.5 CM rounds shoot out of my Bergara HMR Pro like a laser, too... it's too bad you can never find much of either in stock.)

Anyway, I only noticed this difference because I saw the lot numbers were different so I figured why not compare. That's what I found... could be a fluke.

I say "slightly less accurate" but there are a lot of variables, no doubt. I just found it dead nuts easy to ragged hole FGMM 168 and 175s at 100 yards. At 400 yards those same rounds were always damn near dead nuts center on steel. Interestingly, even at 100 yards and no wind, the 168s POI slightly left of center compared to the 175s (the gun is zeroed for the 175s to theoretically better accomplish up to 1,000 yards in PRS Tactical class).

Now, with recently purchased boxes (in the last couple months) and only 300 rounds in with the same barrel (which is a factory HB), I'm having a hard time getting the same ragged holes at 100 and at 400 yards, I hit steal every time, but rounds from boxes I bought last year hit almost dead center on the steal and the newest rounds seem to migrate around center notably more. I thought it was the gun, but I had it eyeballed by a smith and he said it's tight.

Interestingly, the gun will shoot recently purchased Norma Match 308 168 gr into ragged holes. That uses the same SMK bullet, too. (Norma 6.5 CM rounds shoot out of my Bergara HMR Pro like a laser, too... it's too bad you can never find much of either in stock.)

Anyway, I only noticed this difference because I saw the lot numbers were different so I figured why not compare. That's what I found... could be a fluke.

Had a chance to try out the batch in question today. It ran fine in my Frankenstein 18" DPMF10.

I show the boxes used for this in previous post checking head space difference.

I stagger loaded the mag, new 168, new 175, old 168 (White & Blue box). Shot left, middle, then right targets. Rinse & repeat till I had 5 shot groups.

Shot @ 100yards prone with Atlas PSR & rear bag, but set up lower then ideal to keep scope under a barricade type deal the range has.

I don't see a whole lot of difference. This barrel seems to favor 175's when I don't get to twitchy.

I show the boxes used for this in previous post checking head space difference.

I stagger loaded the mag, new 168, new 175, old 168 (White & Blue box). Shot left, middle, then right targets. Rinse & repeat till I had 5 shot groups.

Shot @ 100yards prone with Atlas PSR & rear bag, but set up lower then ideal to keep scope under a barricade type deal the range has.

I don't see a whole lot of difference. This barrel seems to favor 175's when I don't get to twitchy.

Had a chance to try out the batch in question today. It ran fine in my Frankenstein 18" DPMF10.

View attachment 7434186

I show the boxes used for this in previous post checking head space difference.

I stagger loaded the mag, new 168, new 175, old 168 (White & Blue box). Shot left, middle, then right targets. Rinse & repeat till I had 5 shot groups.

Shot @ 100yards prone with Atlas PSR & rear bag, but set up lower then ideal to keep scope under a barricade type deal the range has.

I don't see a whole lot of difference. This barrel seems to favor 175's when I don't get to twitchy.

View attachment 7434175

I didn’t see any difference in accuracy, that I recall. But if it doesn’t chamber easily, if at all, that’s a problem for me. Nothing more annoying then getting on target and then having to run the bolt so damn hard that it throws you way off your target and then you have to set back up again. You really shouldn’t have to be forcing it and that’s what I was having to do.

Was yours burred up like the one in Hick's picture? Mine wasn't & actually had more headspace then the older stuff. Then again if their QC Department has Covid - All bets are off even within the same lot.I didn’t see any difference in accuracy, that I recall. But if it doesn’t chamber easily, if at all, that’s a problem for me. Nothing more annoying then getting on target and then having to run the bolt so damn hard that it throws you way off your target and then you have to set back up again. You really shouldn’t have to be forcing it and that’s what I was having to do.

Was yours burred up like the one in Hick's picture? Mine wasn't & actually had more headspace then the older stuff. Then again if their QC Department has Covid - All bets are off even within the same lot.

Nothing like Hicks!

This has been happening from Federal for a while now the QC sucks with the Fed Match. Try the new Federal Premium Law Enforcement 168 Tactical Tip Match king the ammo shoots in the zero's in our rifles and the ballistics are lights fucking out  It seems that the QC on this cartridge is the Gold Standard for Federal now . This ammo doesn't over penetrate like the Fed Match and makes very nice holes in Tango's or animals...

It seems that the QC on this cartridge is the Gold Standard for Federal now . This ammo doesn't over penetrate like the Fed Match and makes very nice holes in Tango's or animals...

Mike R.

Mike R.

The 168 grain FGMM in question is 421A269 for anyone that wants to look.

Thank you for bringing attention to this batch. I have 200rds of the same. I fired 20rds last week w my Seekins SP10 (wo suppressor) and had issues with 4 of them, from harsh right pulls upon exit to a misfire (had to play the mortar game). I ran rounds of 175g fgmm and 168g Hornady match prior and after with zero issues.

Thank you for bringing attention to this batch. I have 200rds of the same. I fired 20rds last week w my Seekins SP10 (wo suppressor) and had issues with 4 of them, from harsh right pulls upon exit to a misfire (had to play the mortar game). I ran rounds of 175g fgmm and 168g Hornady match prior and after with zero issues.

Maybe it’s time to contact Federal. I think enough of us have had issues at this point.

I'm a 100rnds into the 500rnd case (of this lot #). Zero issues for me so far. All shot in DPMS.

The problem must not be the entire lot #.

The problem must not be the entire lot #.

That’s my understanding. The lot number posted by Silent Stalker is 168’sSo it’s just the 168 ? I jus bought a case of 175s

I have same lot without issues & also lot# ending 60 of 175’s again no issues for me.

YMMV.

The 168 in Hicks picture looked like a dog had chewed on it.

I’d look them over for burrs & check head space on a few to be sure yours are GTG.

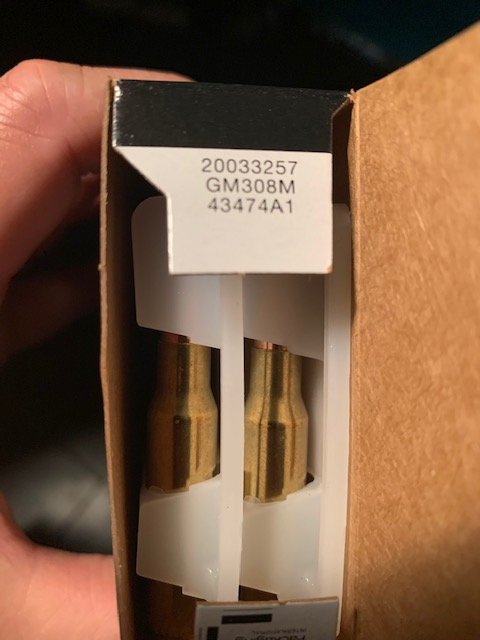

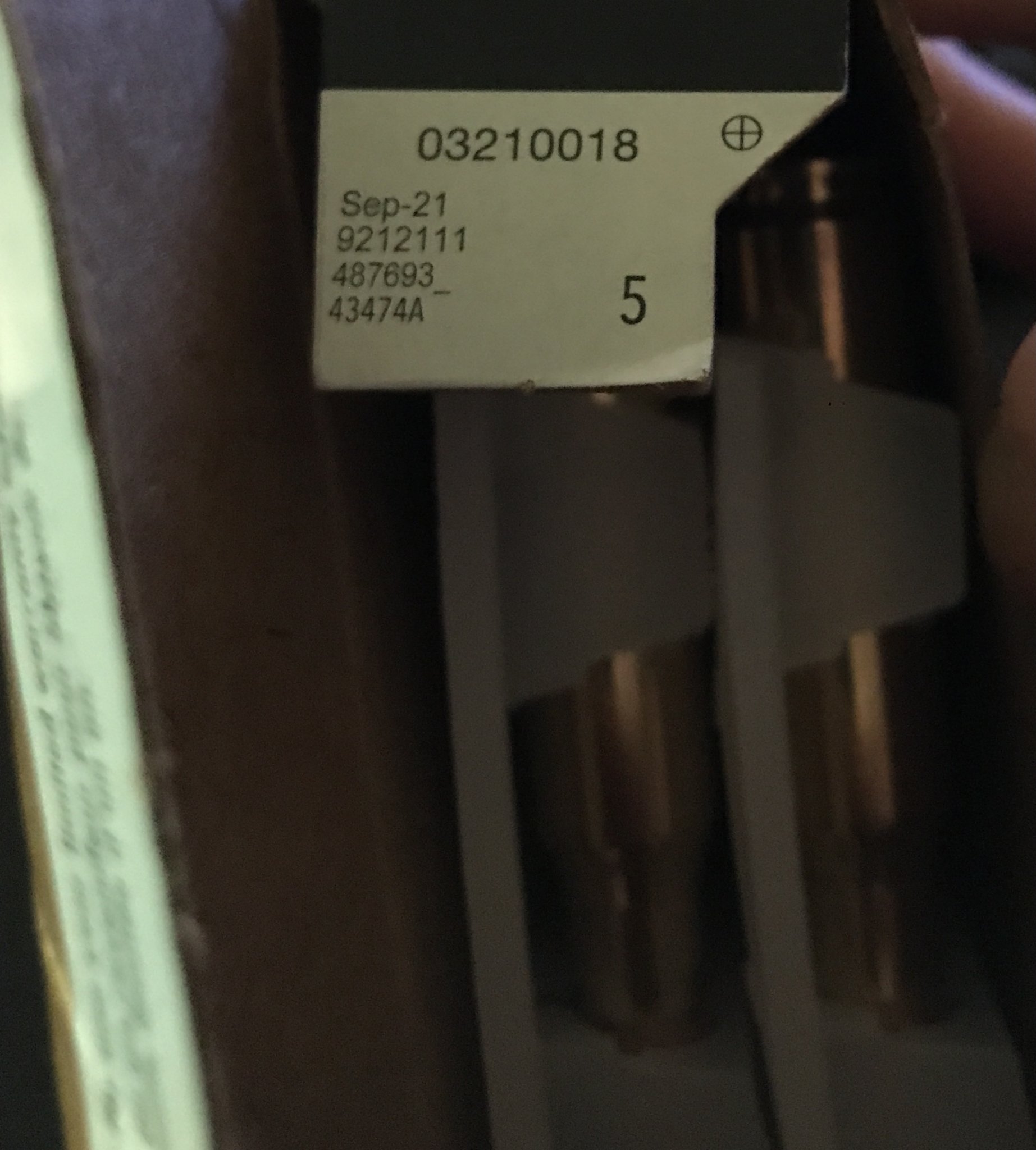

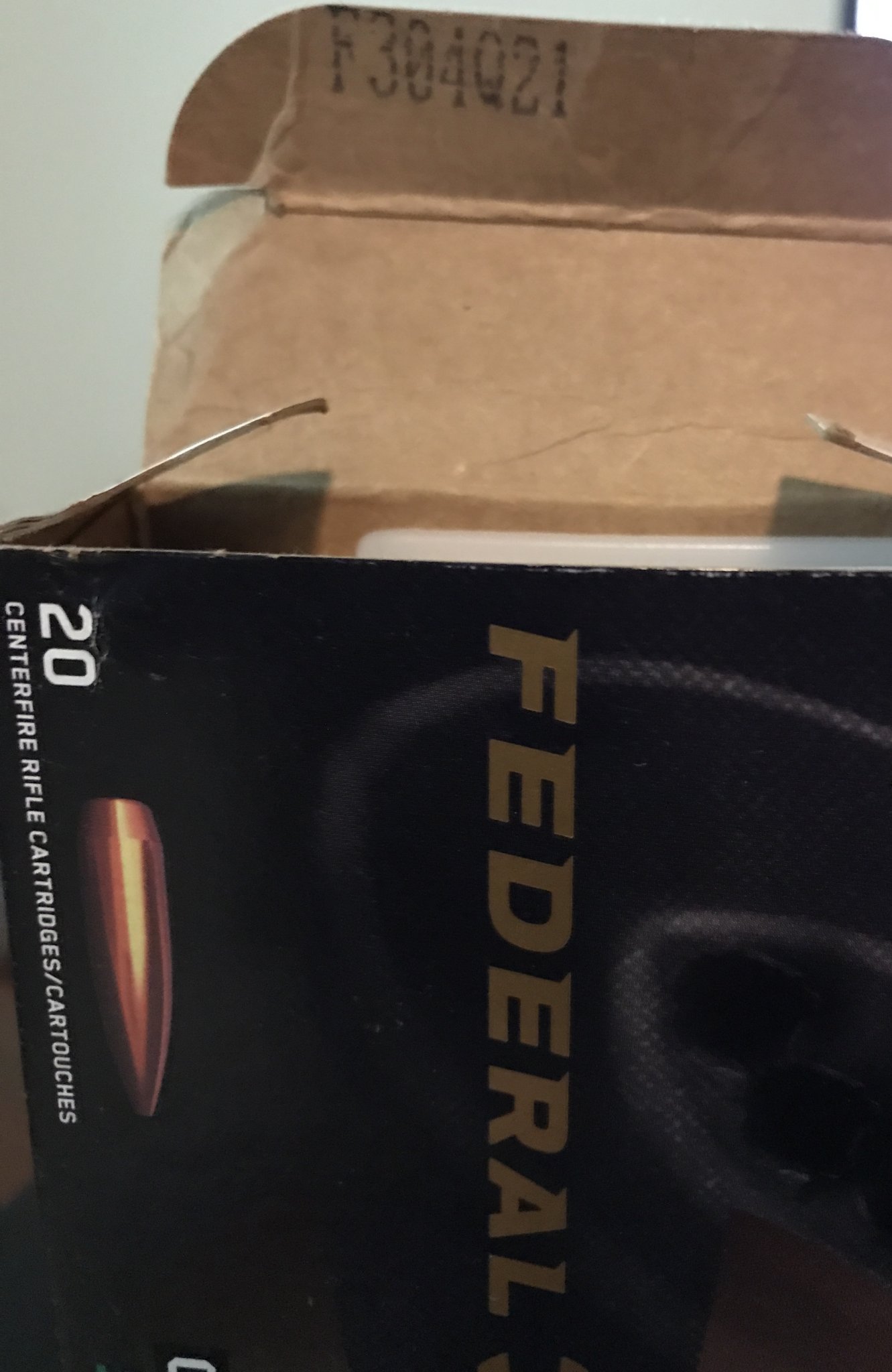

Sorry to resurrect this dead thread but I also had issues with ammo from two boxes of Federal 168 Grain Gold Medal Match (which I found about a week ago at a Walmart in Columbus Ohio). I have a Bergara B14 HMR in 308 and this ammo was extremely difficult to chamber, to the point I'm not comfortable shooting it or putting that much stress on my bolt handle/lugs. This is from two different boxes of ammo with all the same markings on them (see below).

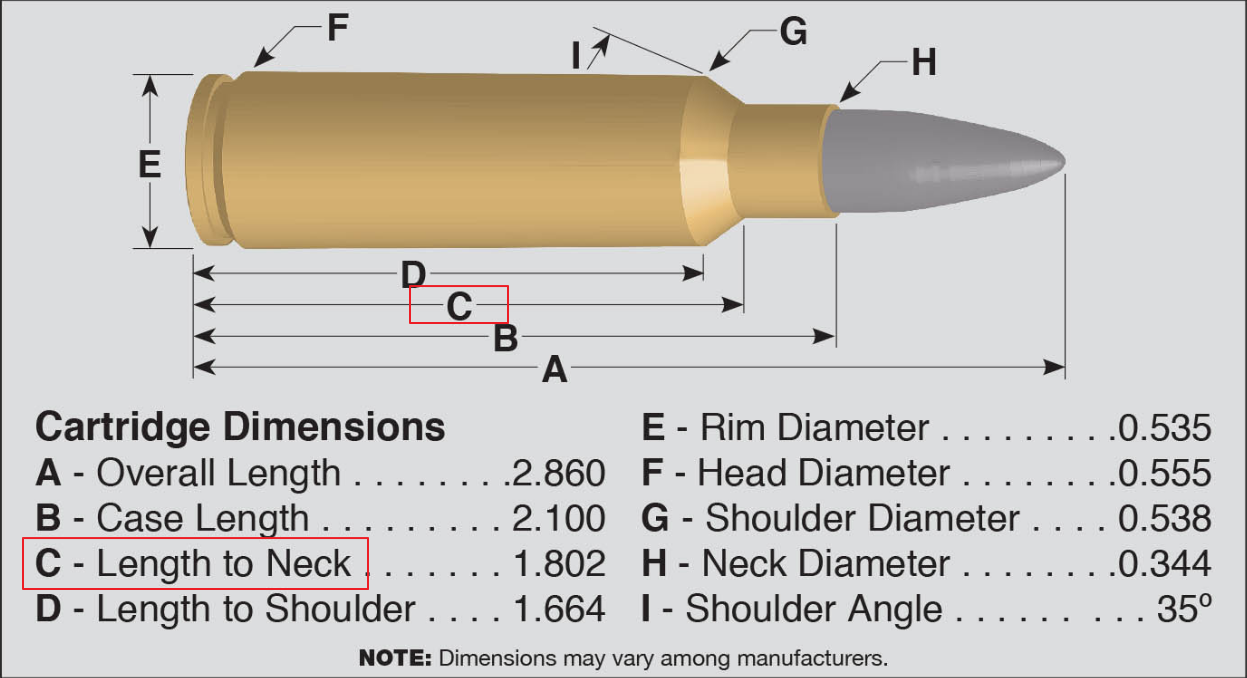

From the rub marks on one of the rounds I got to chamber it looks like the "length-to-neck" wasn't set back far enough. I haven't had this issue come up with any other factory ammo. Anyway, I am going to call Federal on Tuesday (I assume they are closed tomorrow) and let them know about this. I was just searching for this issue with this ammo and thought I'd add to this thread. Looks like the ammo was manufactured in Sept 2021.

Box Flap

Internal Flap

(Left To Right) Hornady Superformance, Offending GMM Ammo, My Reloads

Length-To-Neck

From the rub marks on one of the rounds I got to chamber it looks like the "length-to-neck" wasn't set back far enough. I haven't had this issue come up with any other factory ammo. Anyway, I am going to call Federal on Tuesday (I assume they are closed tomorrow) and let them know about this. I was just searching for this issue with this ammo and thought I'd add to this thread. Looks like the ammo was manufactured in Sept 2021.

Box Flap

Internal Flap

(Left To Right) Hornady Superformance, Offending GMM Ammo, My Reloads

Length-To-Neck

I'm glad you resurrected it because while my 270 loves the Federal Premium 140gr Berger Hybrid Hunter bullets?...despite the premium price the nickel plated casings look like crap with all sorts of mini dings (and some not so mini).

I also did some ammo testing lately on my DPMS and FN PBR both in .308 which did include some chambering issues with the FGMM 175gr loadings which caused some of the first FTF hiccups ever from my DPMS and abnormally hard closing on my bolt on the FN but the good news is both grouped way better with Winchester's Black Box Match 168gr MK's and when I went to separate the brass when I got home?....that's when I noticed a huge overall difference in the eye appeal between winchester and federal brass...the win brass still looked brand new while the fed brass looked like it was at the end of its reloading life.

Like I said...I'm glad you resurrected this thread because I would've felt guilty about ordering the Winchester 168gr Match without at least giving the FGMM 168gr loading a try but all things considered?...I went with Winchester and I'm not looking back.

Federal needs to get their pooh together and start making ammo that looks like they give a crap.

I also did some ammo testing lately on my DPMS and FN PBR both in .308 which did include some chambering issues with the FGMM 175gr loadings which caused some of the first FTF hiccups ever from my DPMS and abnormally hard closing on my bolt on the FN but the good news is both grouped way better with Winchester's Black Box Match 168gr MK's and when I went to separate the brass when I got home?....that's when I noticed a huge overall difference in the eye appeal between winchester and federal brass...the win brass still looked brand new while the fed brass looked like it was at the end of its reloading life.

Like I said...I'm glad you resurrected this thread because I would've felt guilty about ordering the Winchester 168gr Match without at least giving the FGMM 168gr loading a try but all things considered?...I went with Winchester and I'm not looking back.

Federal needs to get their pooh together and start making ammo that looks like they give a crap.

Similar threads

- Replies

- 47

- Views

- 2K

- Replies

- 11

- Views

- 883