@r.tenorio671 thank you, I'll know pretty quick if that's been the problem all along, then I'll put your method to use.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AR new barrel cycling issues

- Thread starter Shoebox

- Start date

Here are those video links on AR15 troubleshooting from that other thread- I figure it can't hurt to have them here too.

www.arbuildjunkie.com

www.arbuildjunkie.com

www.wingtactical.com

www.wingtactical.com

www.wingtactical.com

www.wingtactical.com

AR-15 Gas System Issues – School of the American Rifle –

AR-15 gas system issues such as under-gassed or over-gassed are common. To learn more, we spoke with Chad Albrecht at School of the American Rifle.

How to Fix an Overgassed AR-15

If you have an overgassed AR-15, it’s nothing that can't be solved with the help of our gas block products from Wing Tactical. Shop what you need online today!

AR-15 Failure To Feed | Expert Information | Wing Tactical

At one time or another, you will likely encounter a situation where your AR-15 has a failure to feed. Learn how to fix this with the help of Wing Tactical.

Thanks dude your comment helped my dumb ass figure out why my new build wouldn’t cycle. Running an 18 in proof barrel in 6mm arc, it was advertised as rifle length gas system but turns out it’s rifle +1 so the rifle length gas tube I put in was too short. And yeah the barrel came with its own gas tube which was the right length, but I had to go and put in a different one I had on hand due to it being higher quality. Lol. It’s only my third build so didn’t notice anything was off with the length of the gas tube. Been reading through these forums for a week trying to figure out why this fucker won’t cycle, seen your comment, swapped out the gas tube and now it cycles flawlessly. Go figure.How far is your gas tube protruding into the upper? Does it end at the cam pin cutout like this one or is it shorter?

So I did essentially the opposite of your suggestion, started with adjustable block fully open and closed it 2 clicks each 2 rounds (40 clicks fully open to closed). 2 different factory loads (Norma and Winchester m193) would cycle the next round but not lock back, until about 10 clicks from closed. Then it wouldn't cycle the next round. Wouldn't run H335 24.5gr reloads at all.....just trying to contribute relevant info, it's up to you if you wish to use it. Keep in mind, an over-gassed system can also exhibit the same symptoms of an under-gassed system, i.e., the BCG out-racing the magazines feeding and activating the bolt catch speed. Good luck on your efforts.

Definitely not overgassed. Next step is sending to BA for evaluation.

Hello all, I've been reading here for a while, but this is my first post. I've read several other threads with similar issues, but every situation is different, so I figured I'd ask about my own situation.

Currently equipped:

PSA upper and lower receivers

BA 18" Stainless .223 Wylde rifle-length barrel

Toolcraft nickel-boron BCG

Aero Precision stainless rifle-length gas tube

No name basic .750 gas block

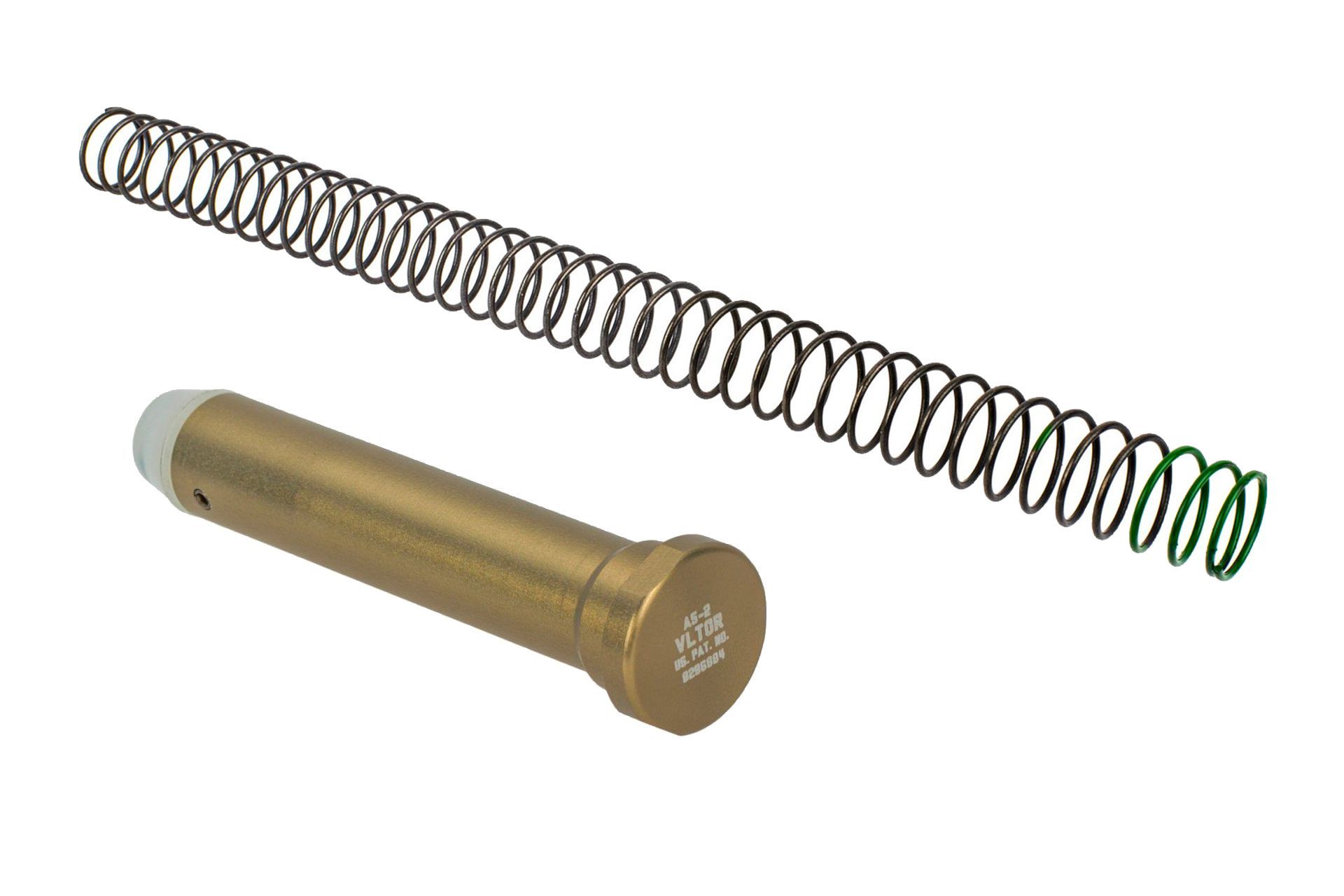

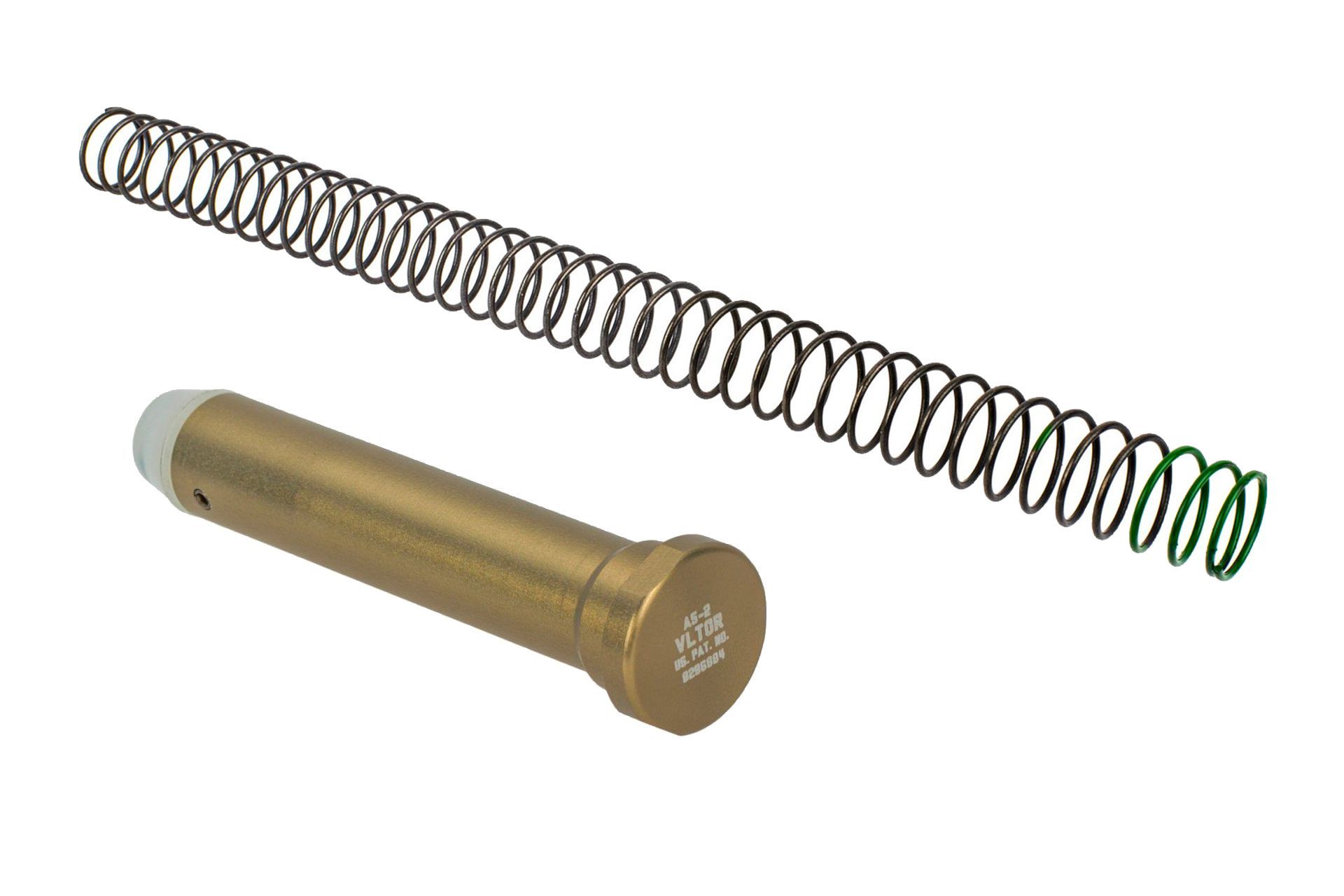

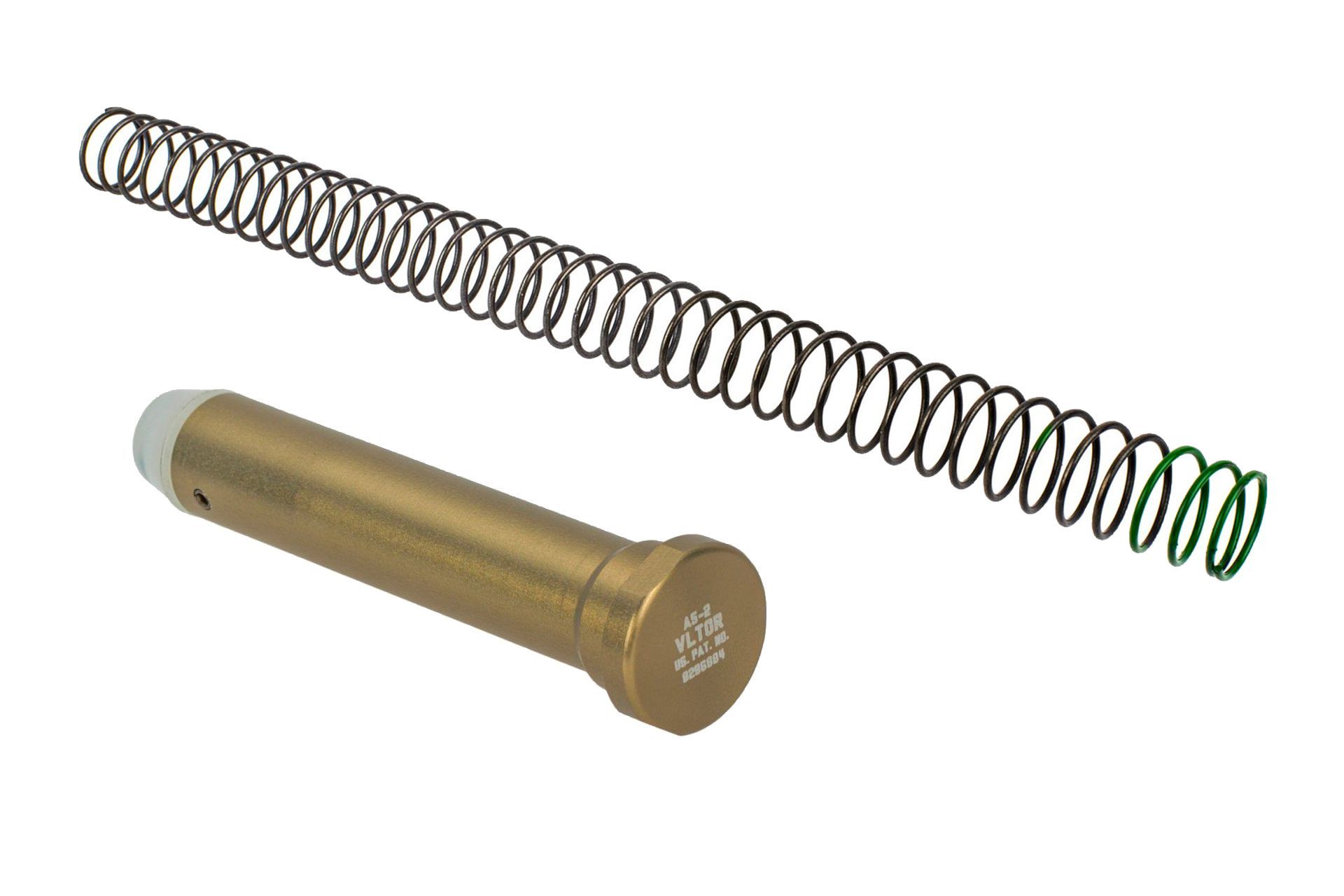

Tubb flat buffer spring with 2-3 coils removed

Odin adjustable buffer, currently about 2 oz

Rise RA-140 trigger

Strike ambi mag release

I have what started out as a basic PSA 16" carbine-length 5.56/.223 AR. First upgrade after about a year was a Rise RA-140SST drop in trigger. I was never happy with the accuracy of the barrel, so I was leaning toward a Faxon or BA 20" rifle-length .223 Wylde. JoeBob's had a great deal on an 18" BA rifle-length stainless barrel, so I jumped on that, with a Kaw Valley gas block and JoeBob's stainless gas tube. I dimpled the barrel for the gas block using a Kaw Valley dimpling jig. Also swapped to a Toolcraft nickel-boron BCG at the same time.

First time firing it, regardless of ammo type, it was short stroking and not locking back on an empty mag. Gas was blowing out everywhere around the gas block. I contacted Kaw Valley, and they sent out a replacement gas block. This one seemed to seal properly, and factory Norma 55gr .223, Winchester 55gr 5.56, and Winchester 62gr 5.56 all cycled properly and would lock back empty, as would a CFE223 55gr FMJ @ 26.3gr load. However, 55gr FMJ over 22.4 H335 and 24.0 AR Comp that ran reliably with the original 16" barrel would not lock back, and the AR comp was hit or miss whether it would cycle a subsequent round reliably.

I swapped out the buffer spring and buffer for a Tubb flat spring and Odin adjustable buffer. Tried various weights from 1.5oz to 4.5 oz, with no change. I tried 2 different BCGs, with no change. Tested the BCG with bolt removed to check gas tube fit, no issue. Tested to make sure the gas block was aligned (though the dimpling jig ensured it would be, and removing the block I could see the holes matched up perfectly) by blowing air through with the barrel plugged. Gas key is tight and properly staked. Thoroughly lubed the bcg.

Around this time, I also tried new, hotter H335 loads, from 24.3-25.2gr, with no change to cycling at all.

Called Tubb to see if they have a lighter weight flat spring, and was advised to try cutting off 3 coils. Swapped out to a basic, no-name gas block my buddy sent me to try, with a new Aero Precision gas tube installed. The new gas block actually had a much tighter fit around the barrel journal than the Kaw Valley did, so I was encouraged. Tested these changes today at the range, but no real change.

No real change, although today at the range for some reason the bolt wouldn't reliably lock back on any ammo but the CFE223 reloads, and wouldn't even reliably lock back when I cycled the bolt via the charging handle on an empty mag. I also was able to chrono the ammo I shot today - factory loads were 3000-3100fps, H335 22.3gr was around 2700fps, AR Comp 24.0 gr @ 3000fps, and CFE223 26.3 @ 2800fps.

I am pretty certain there is no real problem with the lower, as I have a PSA 16" 300blk upper that I also shot the same days on it, and it cycled reliably no matter what changes I made to the spring or buffer.

At this point I am at a loss. The only other thing I can think to try is to have the gas port enlarged from the 0.093" it is now to something larger, maybe 0.100"? I will try spinning the bolt in the chamber to ensure it turns freely, but that's about the only thing I've read on other threads that I haven't tried. My LGS and the gunsmith at the range were stumped as well.

Does anyone have any other ideas of anything I'm missing?

Hello all, I've been reading here for a while, but this is my first post. I've read several other threads with similar issues, but every situation is different, so I figured I'd ask about my own situation.

Currently equipped:

PSA upper and lower receivers

BA 18" Stainless .223 Wylde rifle-length barrel

Toolcraft nickel-boron BCG

Aero Precision stainless rifle-length gas tube

No name basic .750 gas block

Tubb flat buffer spring with 2-3 coils removed

Odin adjustable buffer, currently about 2 oz

Rise RA-140 trigger

Strike ambi mag release

I have what started out as a basic PSA 16" carbine-length 5.56/.223 AR. First upgrade after about a year was a Rise RA-140SST drop in trigger. I was never happy with the accuracy of the barrel, so I was leaning toward a Faxon or BA 20" rifle-length .223 Wylde. JoeBob's had a great deal on an 18" BA rifle-length stainless barrel, so I jumped on that, with a Kaw Valley gas block and JoeBob's stainless gas tube. I dimpled the barrel for the gas block using a Kaw Valley dimpling jig. Also swapped to a Toolcraft nickel-boron BCG at the same time.

First time firing it, regardless of ammo type, it was short stroking and not locking back on an empty mag. Gas was blowing out everywhere around the gas block. I contacted Kaw Valley, and they sent out a replacement gas block. This one seemed to seal properly, and factory Norma 55gr .223, Winchester 55gr 5.56, and Winchester 62gr 5.56 all cycled properly and would lock back empty, as would a CFE223 55gr FMJ @ 26.3gr load. However, 55gr FMJ over 22.4 H335 and 24.0 AR Comp that ran reliably with the original 16" barrel would not lock back, and the AR comp was hit or miss whether it would cycle a subsequent round reliably.

I swapped out the buffer spring and buffer for a Tubb flat spring and Odin adjustable buffer. Tried various weights from 1.5oz to 4.5 oz, with no change. I tried 2 different BCGs, with no change. Tested the BCG with bolt removed to check gas tube fit, no issue. Tested to make sure the gas block was aligned (though the dimpling jig ensured it would be, and removing the block I could see the holes matched up perfectly) by blowing air through with the barrel plugged. Gas key is tight and properly staked. Thoroughly lubed the bcg.

Around this time, I also tried new, hotter H335 loads, from 24.3-25.2gr, with no change to cycling at all.

Called Tubb to see if they have a lighter weight flat spring, and was advised to try cutting off 3 coils. Swapped out to a basic, no-name gas block my buddy sent me to try, with a new Aero Precision gas tube installed. The new gas block actually had a much tighter fit around the barrel journal than the Kaw Valley did, so I was encouraged. Tested these changes today at the range, but no real change.

No real change, although today at the range for some reason the bolt wouldn't reliably lock back on any ammo but the CFE223 reloads, and wouldn't even reliably lock back when I cycled the bolt via the charging handle on an empty mag. I also was able to chrono the ammo I shot today - factory loads were 3000-3100fps, H335 22.3gr was around 2700fps, AR Comp 24.0 gr @ 3000fps, and CFE223 26.3 @ 2800fps.

I am pretty certain there is no real problem with the lower, as I have a PSA 16" 300blk upper that I also shot the same days on it, and it cycled reliably no matter what changes I made to the spring or buffer.

At this point I am at a loss. The only other thing I can think to try is to have the gas port enlarged from the 0.093" it is now to something larger, maybe 0.100"? I will try spinning the bolt in the chamber to ensure it turns freely, but that's about the only thing I've read on other threads that I haven't tried. My LGS and the gunsmith at the range were stumped as well.

Does anyone have any other ideas of anything I'm missing?

I will test this week and see if this is the issue. I just assumed with it all the way open it was still under gassed. I'll try factory ammo and close the block a step every 2 rounds and see if anything changes.

Well I think I've solved my issue.

Initially the new gas block was leaking, but once I got a properly fitting block, factory ammo would run, but most of my reloads would not.

I was resigned to drilling out my gas port, but then decided to try one last thing - using a small base sizing die. That never occurred to me because these loads always ran reliably in the previous barrel. Apparently the BA 223 Wylde barrel has much tighter tolerance. The rounds would chamber, but apparently would expand enough to interfere with extraction, slowing the bolt in the process.

I ordered an RCBS small base die, and resized and loaded 50 rounds with H335, 10 each at 23.9, 24.2, 24.5, 24.8 and 25.2 (similar to a previous round of testing I had done that wouldn't lock the bolt back). All the 23.9-24.5 rounds functioned perfectly, but I had a few fail to lock back at 24.8 and 25.2. It may actually be a little overgassed at those loads, I had a light buffer in it at 2.5 oz.

I'm going to load up some more, and some different powders, add some weight back into the buffer, and see how it does, but I'm optimistic.

Initially the new gas block was leaking, but once I got a properly fitting block, factory ammo would run, but most of my reloads would not.

I was resigned to drilling out my gas port, but then decided to try one last thing - using a small base sizing die. That never occurred to me because these loads always ran reliably in the previous barrel. Apparently the BA 223 Wylde barrel has much tighter tolerance. The rounds would chamber, but apparently would expand enough to interfere with extraction, slowing the bolt in the process.

I ordered an RCBS small base die, and resized and loaded 50 rounds with H335, 10 each at 23.9, 24.2, 24.5, 24.8 and 25.2 (similar to a previous round of testing I had done that wouldn't lock the bolt back). All the 23.9-24.5 rounds functioned perfectly, but I had a few fail to lock back at 24.8 and 25.2. It may actually be a little overgassed at those loads, I had a light buffer in it at 2.5 oz.

I'm going to load up some more, and some different powders, add some weight back into the buffer, and see how it does, but I'm optimistic.

Or just a worn out reamer.Apparently the BA 223 Wylde barrel has much tighter tolerance.

I would also recommend checking the gas rings on your bolt to make sure they have a good seal.

You can do this by extending your bolt from the BCG and then standing it on the bolt face vertically on a flat surface. The tension of the gas rings should keep the bolt in the extended position. If the bolt collapses, your gas rings are weak.

You can do this by extending your bolt from the BCG and then standing it on the bolt face vertically on a flat surface. The tension of the gas rings should keep the bolt in the extended position. If the bolt collapses, your gas rings are weak.

I've tried 2 different bolts. Both are relatively new.I would also recommend checking the gas rings on your bolt to make sure they have a good seal.

You can do this by extending your bolt from the BCG and then standing it on the bolt face vertically on a flat surface. The tension of the gas rings should keep the bolt in the extended position. If the bolt collapses, your gas rings are weak.

I have sold tens of thousands of 18" RG barrels with .093" ports over the last 15 years and never get calls about short stroking unless they are using light 223 ammo and a H2 buffer.I have an 18” barrel with the same port size. Mine works fine with a standard spring and carbine buffer but chokes with an H.

I loaded up some 73gr tipped match seconds from Midway with several loads of AR Comp. Finally got out to the outdoor range for the first time in a while. All cycled normally, except the lightest didn't lock the bolt back empty. But that's a huge step in the right direction, considering no AR Comp under 55gr FMJ would lock back at all.Where does the round eject on first shot

They all eject about 4 o'clock and 8 ft or so.

Its not gassing issues then, forI loaded up some 73gr tipped match seconds from Midway with several loads of AR Comp. Finally got out to the outdoor range for the first time in a while. All cycled normally, except the lightest didn't lock the bolt back empty. But that's a huge step in the right direction, considering no AR Comp under 55gr FMJ would lock back at all.

They all eject about 4 o'clock and 8 ft or so.

Kicks if you have a spare bolt to try can bring light, carbine or rifle tube?

Here are a couple informative links

www.arbuildjunkie.com

www.arbuildjunkie.com

www.80percentarms.com

www.80percentarms.com

AR-15 Buffers and Buffer Springs Basics – AR-15 News, Reviews and...

One of the most frequently asked questions in AR-15 groups or boards is, "What AR-15 buffers should I consider for my build?" The answer is not always as simple as someone would like, as several factors will determine the proper buffer. Complicating the process is the fact that many who are new...

AR-15 Buffer Weights: Difference Is, and How to Choose

While AR-15 buffer weights are often overlooked in an 80% build, choosing the right one is important for your rifle's performance. Find out more at 80 Percent Arms!

Its not gassing issues then, for

Kicks if you have a spare bolt to try can bring light, carbine or rifle tube?

AR-15 Buffer Weights: Difference Is, and How to Choose

While AR-15 buffer weights are often overlooked in an 80% build, choosing the right one is important for your rifle's performance. Find out more at 80 Percent Arms!

AR-15 Buffers and Buffer Springs Basics – AR-15 News, Reviews and...

One of the most frequently asked questions in AR-15 groups or boards is, "What AR-15 buffers should I consider for my build?" The answer is not always as simple as someone would like, as several factors will determine the proper buffer. Complicating the process is the fact that many who are new...

I have tried 2 different BCGs, both of which work fine in my 300blk upper. Midway had an AR Stoner lightweight BCG on sale, so I picked one up, I'll try it next time.Its not gassing issues then, for

Kicks if you have a spare bolt to try can bring light, carbine or rifle tube?

I have tried milspec carbine spring and buffer, and Tubb flat spring stock and with 3 coils cut, with adjustable buffer from 1.5 oz to 5.6 oz. It's not a buffer or spring issue.

I have tried 2 different BCGs, both of which work fine in my 300blk upper. Midway had an AR Stoner lightweight BCG on sale, so I picked one up, I'll try it next time.

I have tried milspec carbine spring and buffer, and Tubb flat spring stock and with 3 coils cut, with adjustable buffer from 1.5 oz to 5.6 oz. It's not a buffer or spring issue.

Really odd only one that gave me issues were 308s amd cure was drowning in oil. Which you can also try, oil ot to death some. Even lay thin film of axle greese in the bcg rails. Some say the 15 csn be dry but i have a dozen now all from parts and all diff cals. Try and oil slick it. Worst that Can happen as you clean it I clean mine after every outing anyway including stripping the bowl all the way down, on a positive note there’s only a few things that create the problem so try not the stupid stuff first oil grease it’s even a good idea to get it set a readers and look at the bowl of clothes and see if it has any rough machining or birds or what not and see how well it slides for the upper when I have a deep PMS problem I took it to a gunsmith were sad for two weeks and did absolutely nothing said fuck it came home I don’t he’s silly ass possible solutions and low behold in an hour problem solved the reason I say it’s probably not a guessing problem is because that’s everyone’s first excuse and everyone loves to fuck with these gas blocks and everyone seem to think I need adjustables I don’t have one rifle in adjustable block and if you think about it it’s so simple it’s almost silly how they work try and receive the block look for Bluewell where is it might be leaking or actually what am I saying if you’re checking in 4 o’clock it’s not gassing, did you try the one around in the mag trick or utilize several magazines?

I appreciate you're trying to help but that reply hurt my brain.Really odd only one that gave me issues were 308s amd cure was drowning in oil. Which you can also try, oil ot to death some. Even lay thin film of axle greese in the bcg rails. Some say the 15 csn be dry but i have a dozen now all from parts and all diff cals. Try and oil slick it. Worst that Can happen as you clean it I clean mine after every outing anyway including stripping the bowl all the way down, on a positive note there’s only a few things that create the problem so try not the stupid stuff first oil grease it’s even a good idea to get it set a readers and look at the bowl of clothes and see if it has any rough machining or birds or what not and see how well it slides for the upper when I have a deep PMS problem I took it to a gunsmith were sad for two weeks and did absolutely nothing said fuck it came home I don’t he’s silly ass possible solutions and low behold in an hour problem solved the reason I say it’s probably not a guessing problem is because that’s everyone’s first excuse and everyone loves to fuck with these gas blocks and everyone seem to think I need adjustables I don’t have one rifle in adjustable block and if you think about it it’s so simple it’s almost silly how they work try and receive the block look for Bluewell where is it might be leaking or actually what am I saying if you’re checking in 4 o’clock it’s not gassing, did you try the one around in the mag trick or utilize several magazines?

I addressed all of that earlier in the thread.

Overlubed, lightly lubed, 8 or 10 different mags, etc etc.

I appreciate you're trying to help but that reply hurt my brain.

I addressed all of that earlier in the thread.

Overlubed, lightly lubed, 8 or 10 different mags, etc etc.

The reply system of this page is useless, that was for somewhere else, there are hundreds of similar ones lately, and got crossed in wrong box

LOL no worriesThe reply system of this page is useless, that was for somewhere else, there are hundreds of similar ones lately, and got crossed in wrong box

After trying several mags and adjusting my buffer weight i had a 10” barrel that wouldnt lock back with super sonic ammo or even super sonic suppressed. The barrel manufacturer said I should be running a stock buffer spring and carbine buffer for the barrel port size. I was running the JP SCS Heavy that i use in all my pistols and 6.8 AR both suppressed and not. After some research I found this manufacturer was using a smaller gas port and wouldn’t guarantee function with my JP SCS. I also tried a JPSCS standard and tried all the spring weights in both. No luck. Finally drilled out the gas port to 0.100” believe (its been a while). Worst case is i run an adjustable gas block if its over sized. Well it ran perfectly in my original configuration both suppressed and not. It would run subsonic supressed, but not lock back in subs not suppressed. Im happy with the outcome.

I rarely use an adjustbpable gas block or atleast not early on. I have more now, but I have SBR’s in 300BO that will run any configuration with no changes and without ADJ gas blocks. Buffer weight and spring combos in JO SCS silent bufffers. Food for thought. Maybe I got a little lucky.

I rarely use an adjustbpable gas block or atleast not early on. I have more now, but I have SBR’s in 300BO that will run any configuration with no changes and without ADJ gas blocks. Buffer weight and spring combos in JO SCS silent bufffers. Food for thought. Maybe I got a little lucky.

Thanks for all the troubleshooting help, I followed all the steps I found here and the problem was a “new style” captured buffer spring being too heavy. Installed mil spec buffer setup and it locks back non empty mag and got gas block adjusted along with a hudu brake and gas virtually no recoil now.

Similar threads

- Replies

- 15

- Views

- 780