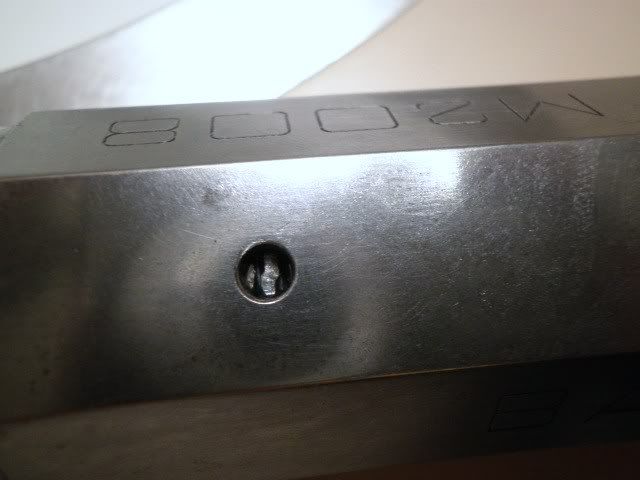

I found this while tearing down my rifle in prep. for coating.

The base screws were never torqued passed 20 inch-lbs.

Im in fear that when I take the barrel off, Im gaurentee'd to mangle the threads inside the action...not a good deal...

Is there anything I can do for this?

Aslo...Im confused as to why this even happened to begin with?

All my base screws are the same length...

The only thing i can think of is that a custom made 45MOA base is so much slimmer in the front that it allowed the base screw to do this.

The base screws were never torqued passed 20 inch-lbs.

Im in fear that when I take the barrel off, Im gaurentee'd to mangle the threads inside the action...not a good deal...

Is there anything I can do for this?

Aslo...Im confused as to why this even happened to begin with?

All my base screws are the same length...

The only thing i can think of is that a custom made 45MOA base is so much slimmer in the front that it allowed the base screw to do this.