I received a Tikka T3x lite .300 WSM earlier this year as a gift. I am looking to convert it to a 7SS or 7 SAUM. I am looking for a barrel vise and action wrench to help remove the barrel. I have read some horror stories on the difficult of this endeavor. I am thinking of the Wheeler Action Wrench and Brownell's Barrel Vise:

Action Wrench

Brownells Vise

Bushing

I was wondering what bushing size should I purchase for the light hunting profile of the barrel?

Also, I am going to put a heavy palma barrel for the 7mm, so I know I will need two different bushing.

Drag

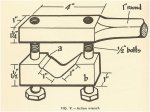

Action Wrench

Brownells Vise

Bushing

I was wondering what bushing size should I purchase for the light hunting profile of the barrel?

Also, I am going to put a heavy palma barrel for the 7mm, so I know I will need two different bushing.

Drag