Just like the title says. Brass has been fire-formed (two firings), rifle won't group better than 7/8" regardless the load, and I have a few of these calibers with established data.

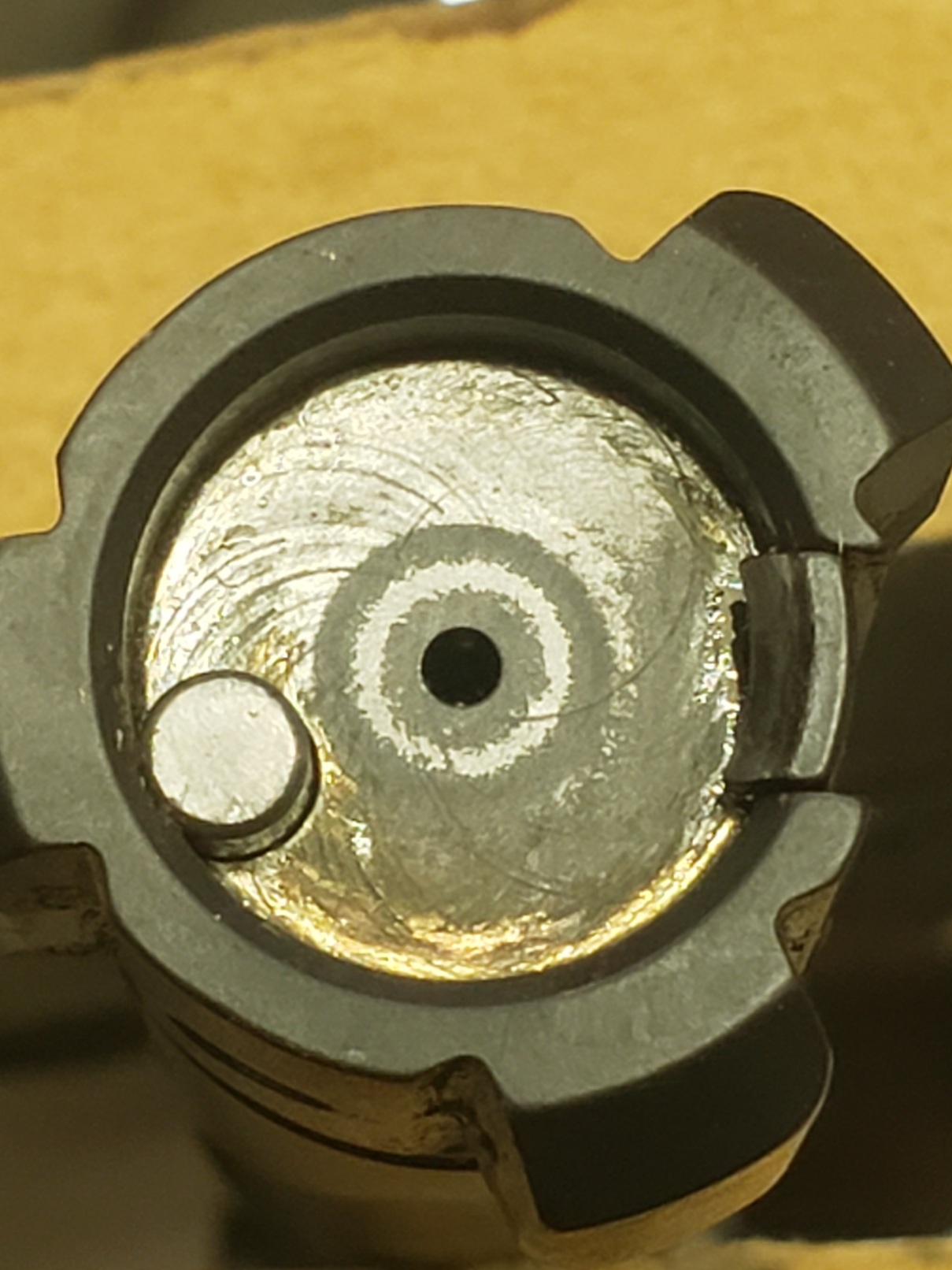

Shiny/clean on one half, dirty and carbon fouled on the other.. What would cause this? Since none of my other actions exhibit this pattern from chamberings from the guys listed below, my first thought was the barrel wasn't correctly indexed and trued prior to chambering. Would that deficiency show up like this on the bolt face?

Would appreciate some meaningful input from some of the masters on here, thanks for any help @LongRifles Inc. @Frank Green @spife7980 @pmclaine @Supersubes

Shiny/clean on one half, dirty and carbon fouled on the other.. What would cause this? Since none of my other actions exhibit this pattern from chamberings from the guys listed below, my first thought was the barrel wasn't correctly indexed and trued prior to chambering. Would that deficiency show up like this on the bolt face?

Would appreciate some meaningful input from some of the masters on here, thanks for any help @LongRifles Inc. @Frank Green @spife7980 @pmclaine @Supersubes

Last edited: