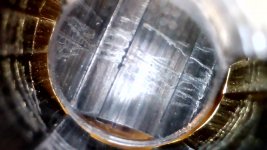

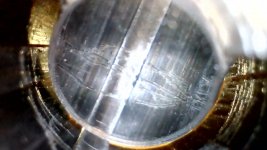

New 6mm, only 30 rounds down the tube. After cleaning, ran a bore scope and found this at the very end of the barrel. Not from cleaning as patches and nylon brush won't make those kind of marks. If I had to guess, they are remnants from the manufacturing process as a tool left the end of the barrel. I used a plastic pick to see if I could feel any grooves, but no "felt" scratch/groove, but you sure as heck can see it. Anyone see those marks before? Curious minds want to know. Thanks in advance for any input.

Joe

Joe