Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

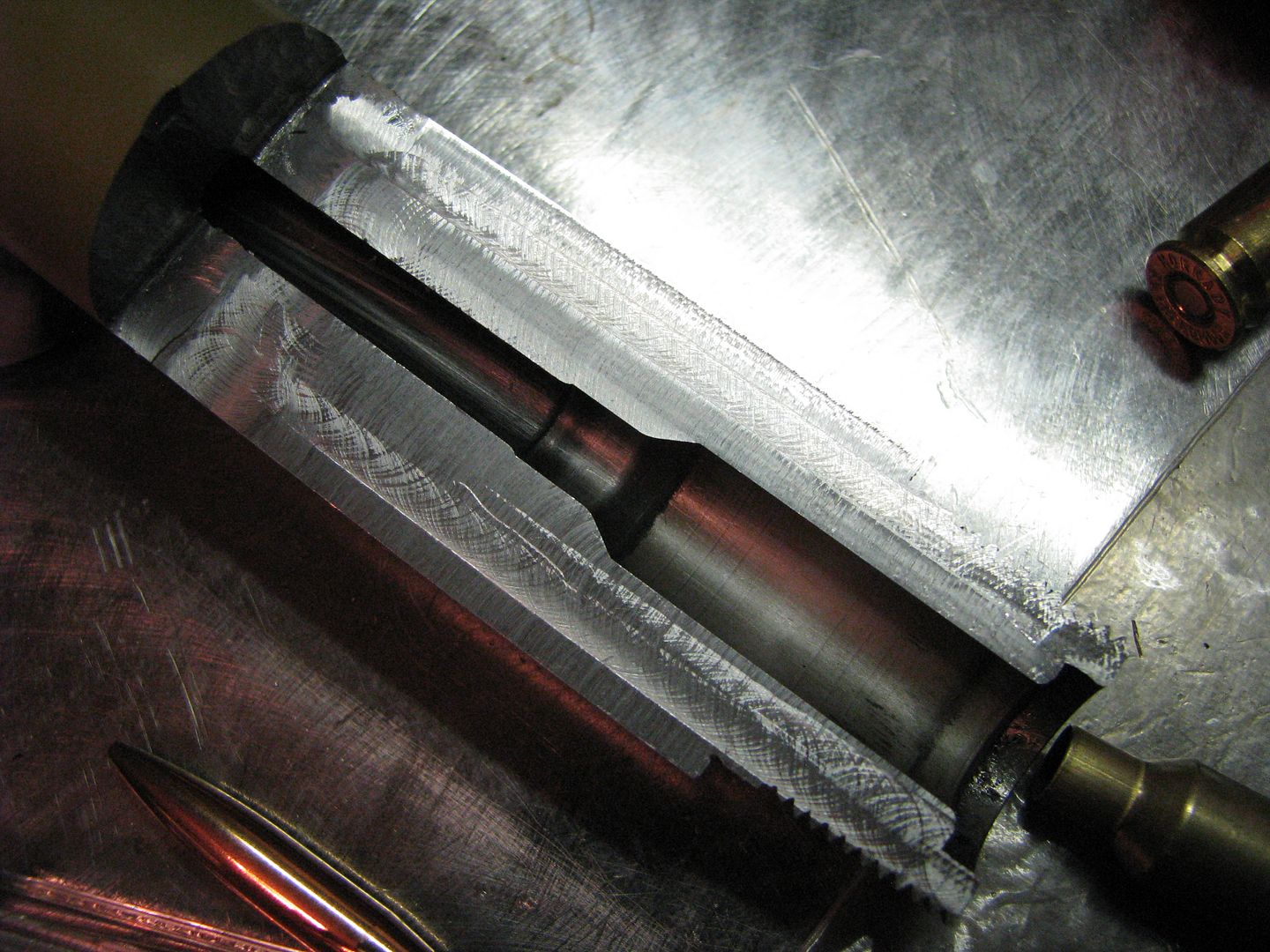

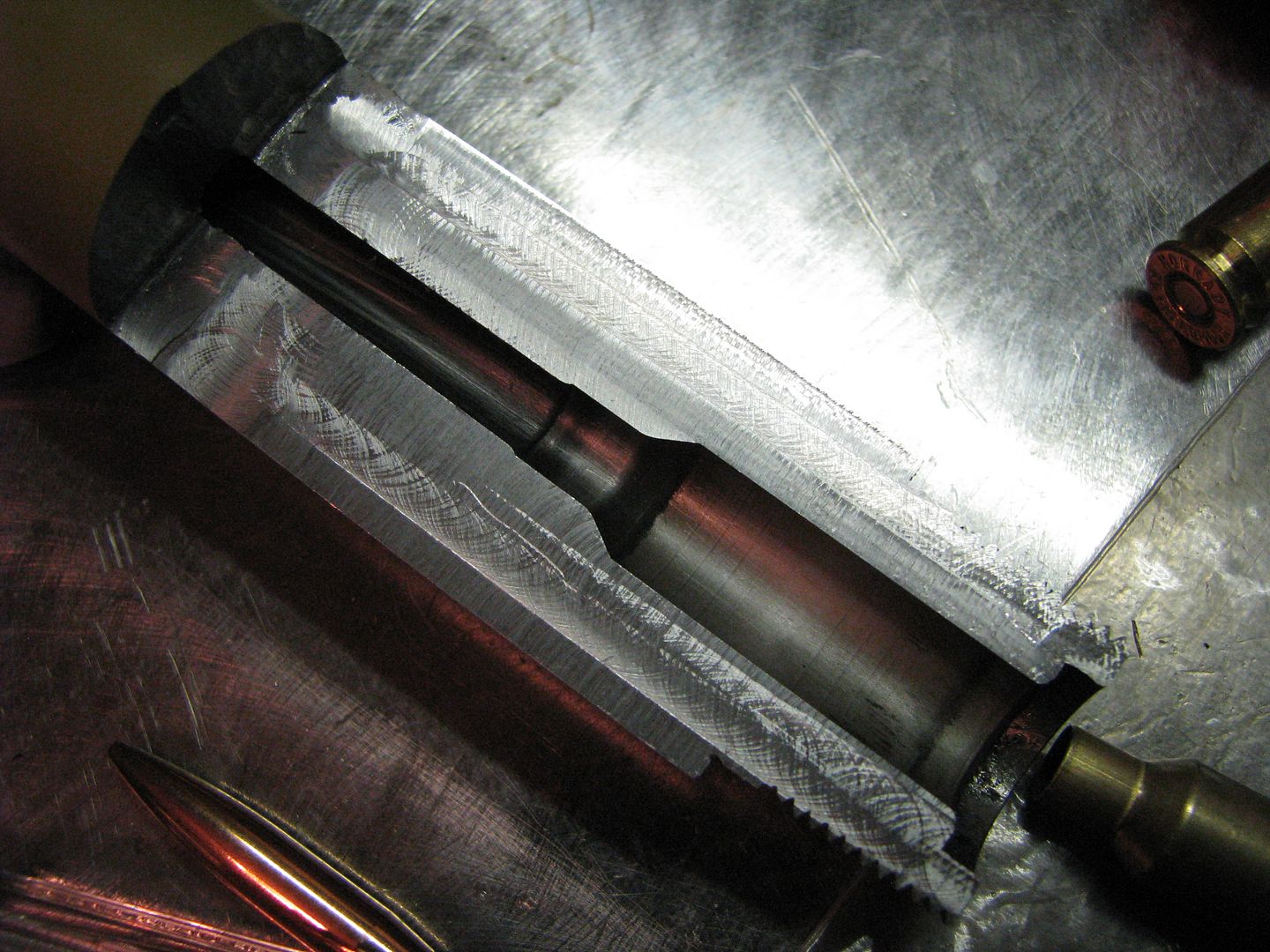

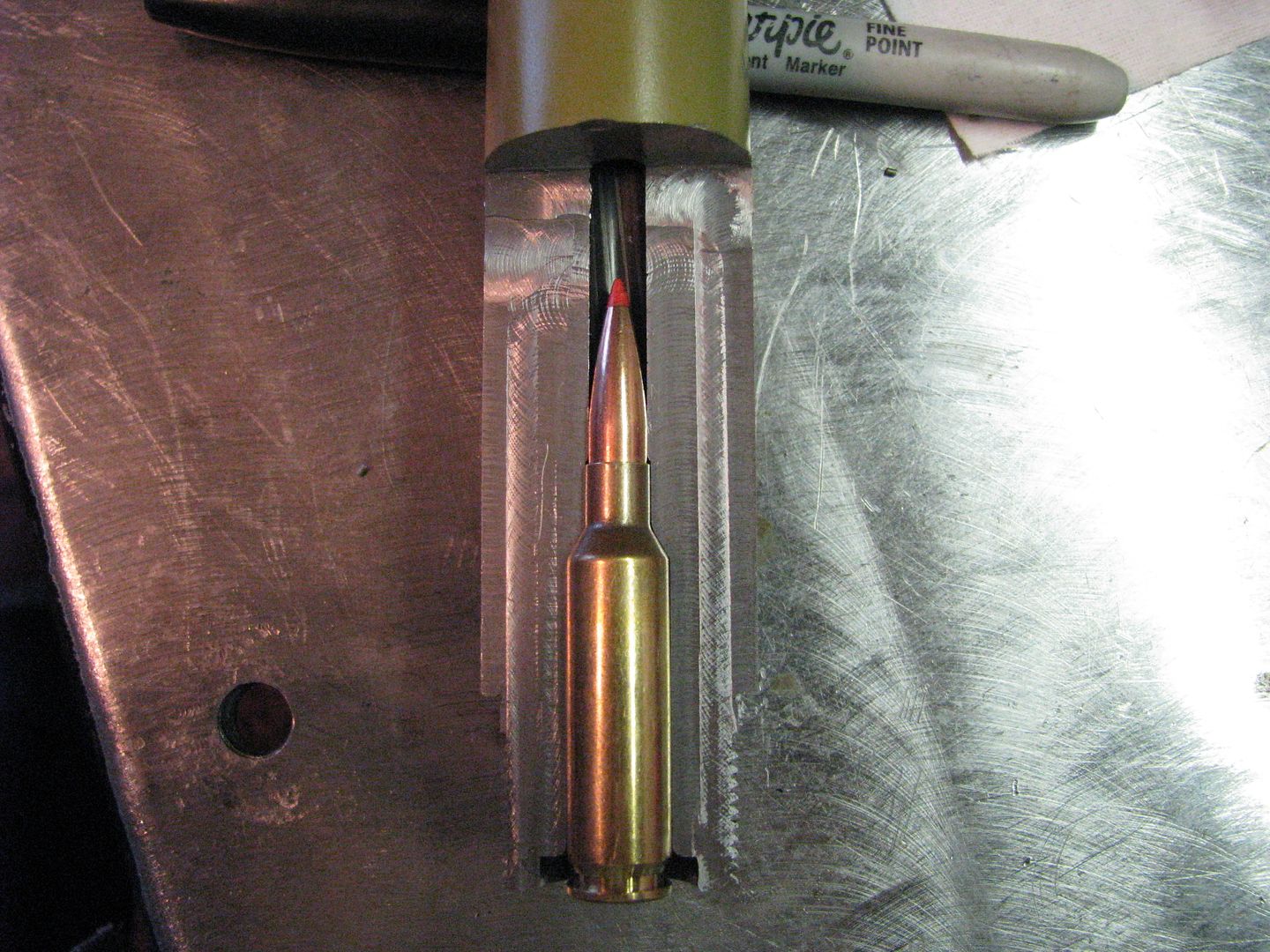

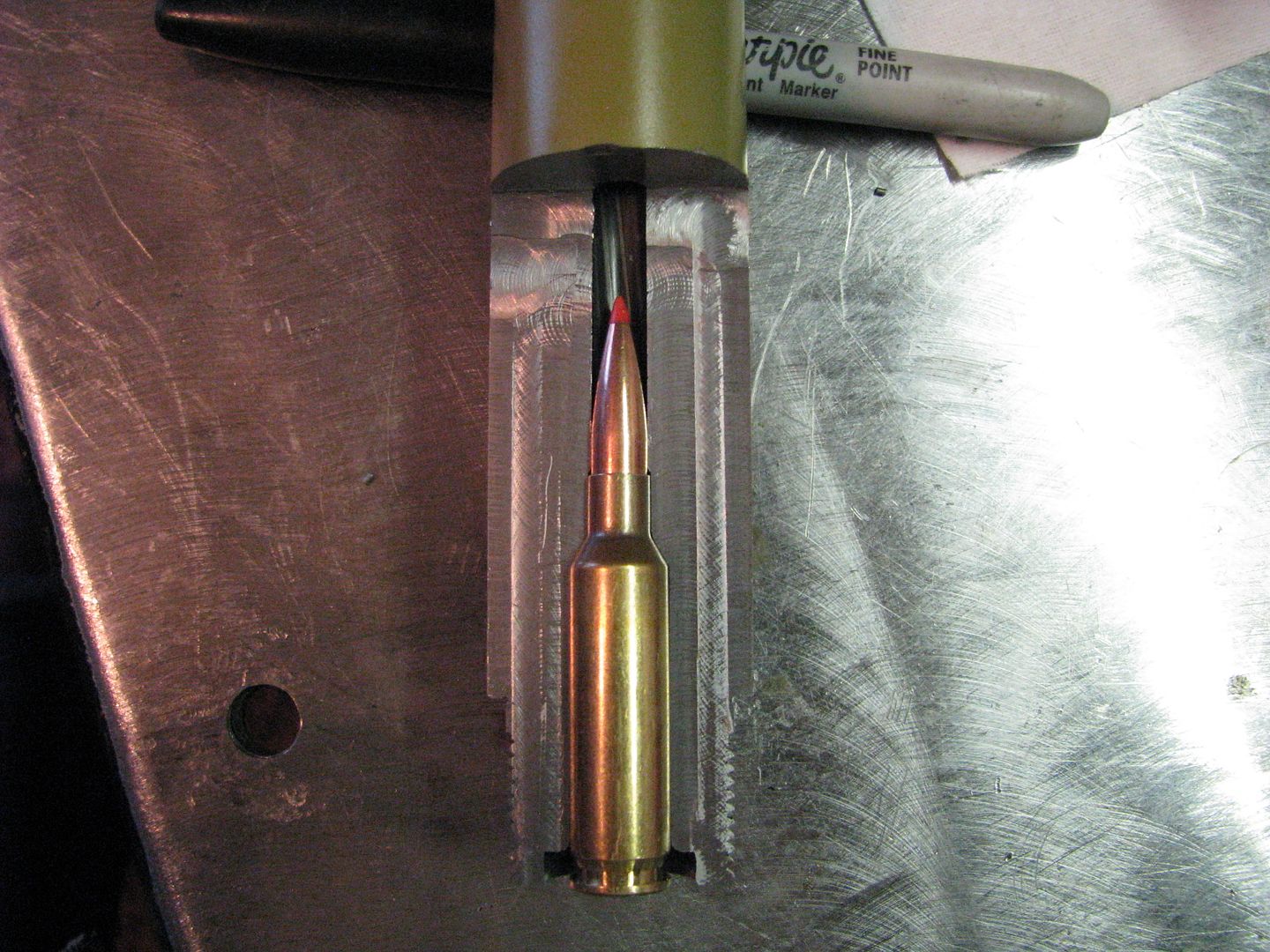

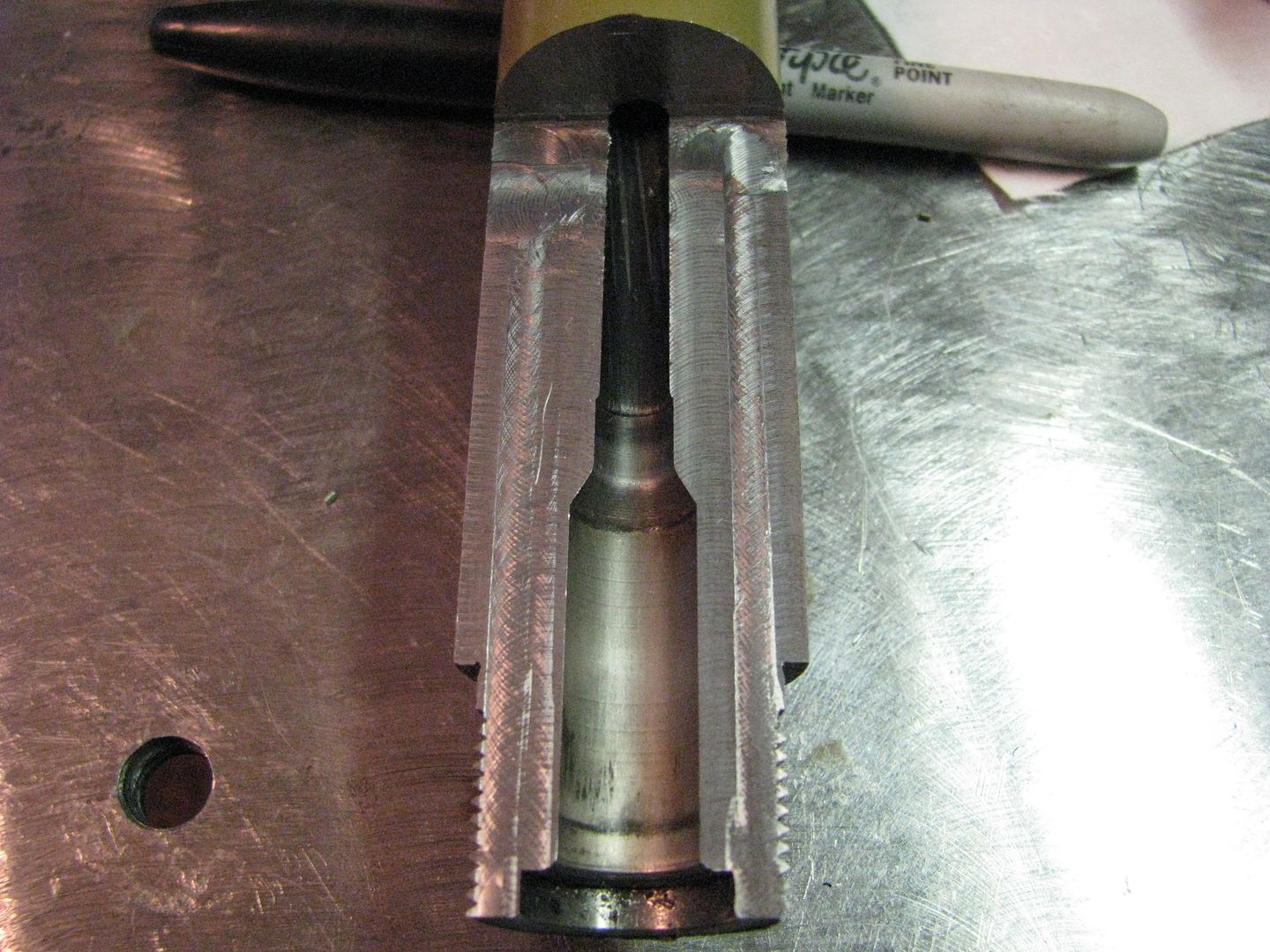

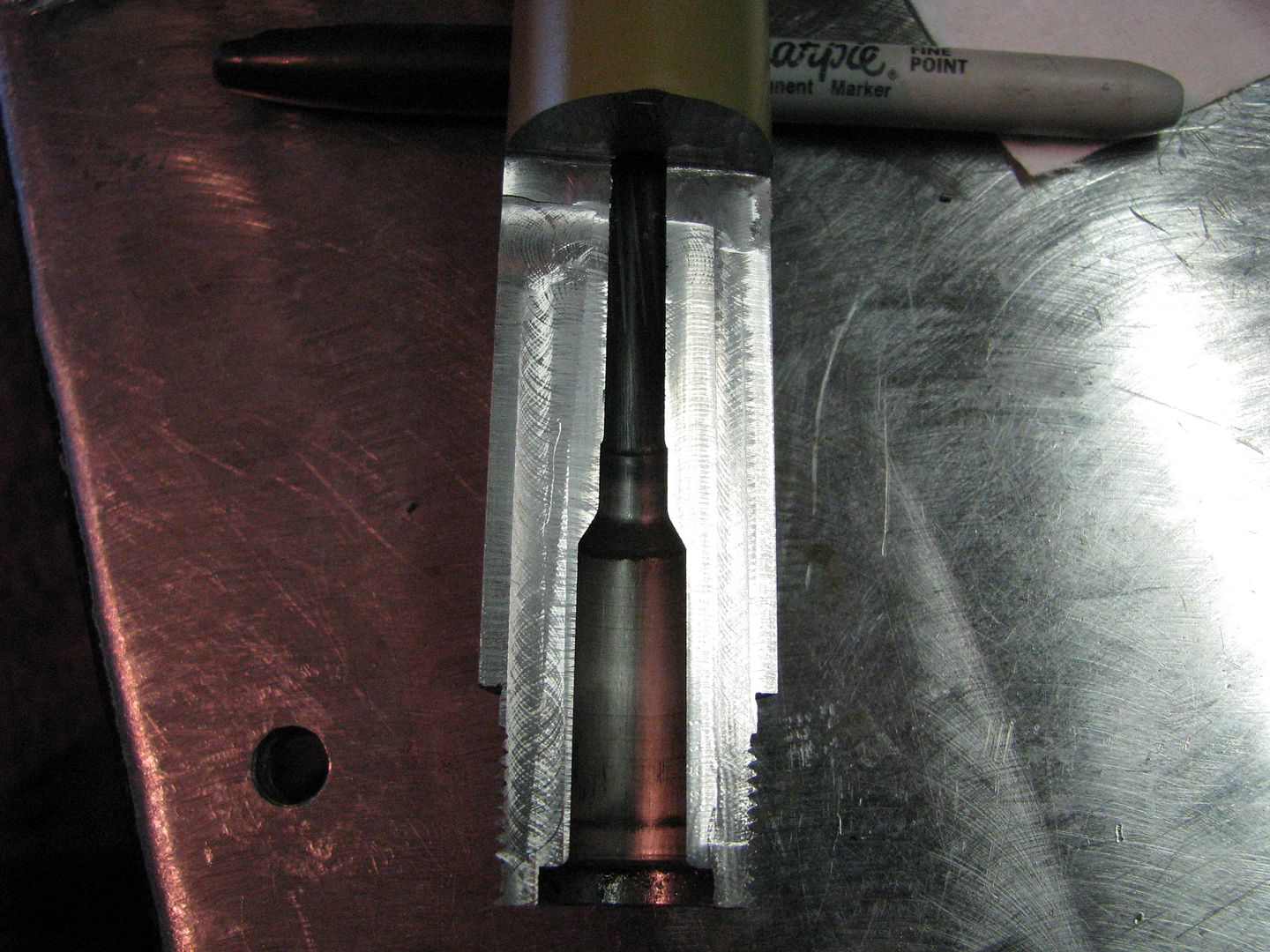

Cut away view of my chamber on 6.5 Creedmoor 3000 rounds down the tube

- Thread starter hognuts

- Start date

Nuts, you did the right thing, hope I didn't convey opposite message.

Not at all. I always appreciate your input.

I took the rifle out today with the new tube, it shoots lights out! Nice to have friends in low places.

Back in the saddle!!!

Looking forward to seeing these!

I got a few pics with my phone, a buddy JFComfort its going to take some good pics with his camera during the game today. My phone shit itself while I was at range today, when it comes back to life I will put up my Iphone pics, but I will have him chime in here with some better quality pics once he gets them. Probably will be able to see better, I can tell you this, once a loaded round was placed in there it doesn't look nearly as bad, there is a resemblence of rifling near the Ogive, but it definitely was worn down, you can see a faint line where the rifling was, but it definitely was leaking gasses by there and that is where my velocity loss was coming from.

Very nice rifle and good shooting. I was just curious why you have a left handed rifle but a right handed stock pack? I'm left handed, but my stock pack has the zippered pouch on the opposite side of my cheek.

Not at all. I always appreciate your input.

I took the rifle out today with the new tube, it shoots lights out! Nice to have friends in low places.I shot a match with the old barrel yesterday, we tore it apart after the match, milled out the chamber area, my buddy chambered the new barrel yesterday, went over this morning and cleaned up the mill mess while he threaded and crowned the muzzle end. Assembled the rifle and headed up to the range to check zero, grouping. Loaded up some virgin brass, so it may tighten up some after barrel is broke in and brass is once-fired in the chamber, but it already looks pretty titts!

Back in the saddle!!!

I took the rifle out today with the new tube, it shoots lights out! Nice to have friends in low places.  I shot a match with the old barrel yesterday, we tore it apart after the match, milled out the chamber area, my buddy chambered the new barrel yesterday, went over this morning and cleaned up the mill mess while he threaded and crowned the muzzle end. Assembled the rifle and headed up to the range to check zero, grouping. Loaded up some virgin brass, so it may tighten up some after barrel is broke in and brass is once-fired in the chamber, but it already looks pretty titts!

I shot a match with the old barrel yesterday, we tore it apart after the match, milled out the chamber area, my buddy chambered the new barrel yesterday, went over this morning and cleaned up the mill mess while he threaded and crowned the muzzle end. Assembled the rifle and headed up to the range to check zero, grouping. Loaded up some virgin brass, so it may tighten up some after barrel is broke in and brass is once-fired in the chamber, but it already looks pretty titts!

Back in the saddle!!![/QUOTE]

hognuts

Thanks for taking the time to share all of this; first time I got to see a cut-in-half barrel and chamber, sure it's a first for many other guys too. Bad ass rifle and it looks like your new barrel is going to be just fine

Back in the saddle!!![/QUOTE]

hognuts

Thanks for taking the time to share all of this; first time I got to see a cut-in-half barrel and chamber, sure it's a first for many other guys too. Bad ass rifle and it looks like your new barrel is going to be just fine

I have a related question..... for those of you who go through barrels at 2-3K rounds and then rebarrel - do you have to go through an entire load development process again? Or is the assumption that as long as you use the same chamber reamer - that your previous loads should (in theory) shoot the same with maybe minor tweaks?

I ask, because with these new hot 6-7mm calibers that are all the rage these days with barrel life often less than 3K and in many cases <2K, a proper load development might burn up quite of a bit of that total life expectancy. Its one of the things that has held me back from moving away from .308. I just didn't want to spend all my time doing load developments everytime I got a new barrel. Sorry for the dumb question, but I've always wondered how that works. Thanks.

I ask, because with these new hot 6-7mm calibers that are all the rage these days with barrel life often less than 3K and in many cases <2K, a proper load development might burn up quite of a bit of that total life expectancy. Its one of the things that has held me back from moving away from .308. I just didn't want to spend all my time doing load developments everytime I got a new barrel. Sorry for the dumb question, but I've always wondered how that works. Thanks.

I have a related question..... for those of you who go through barrels at 2-3K rounds and then rebarrel - do you have to go through an entire load development process again? Or is the assumption that as long as you use the same chamber reamer - that your previous loads should (in theory) shoot the same with maybe minor tweaks?

I ask, because with these new hot 6-7mm calibers that are all the rage these days with barrel life often less than 3K and in many cases <2K, a proper load development might burn up quite of a bit of that total life expectancy. Its one of the things that has held me back from moving away from .308. I just didn't want to spend all my time doing load developments everytime I got a new barrel. Sorry for the dumb question, but I've always wondered how that works. Thanks.

That is not a stupid question. If we can be of any help please do not hesitate to contact me. I will do my best to answer your question or find someone who knows the answer to your question.

We do not do load development every time we change barrels. We have two loads we run, the first is our "team 139 Scenar load" and the other is the "team 140 Barnes Match Burners load". Both shoot great, I think because we have a lathe and build our own rifles we are able to keep things very consistent. Consistency is accuracy so when we re-barrel a rifle we dial the bore axis down to 0.0001" and use the same rough reamer, the same finishing reamer and cut the chamber with the same +0.002" head space. That allows us to all use the same load depending on what projectile they are utilizing.

With factory rifles you can have different head spaces, different free bores and things like that. I hope that answers your question.

Thanks, JF, that looks alot better!

On the cheek rest thing, first of all good catch, if memory serves the McRee cheek rest it is reversible, I had stold the one off this rifle for another rifle and when I got the new one in it was set up righty and I just haven't reversed it yet, If I remember correctly it is just a matter of re adjusting a few velcroe straps, I just through that on the night before a match, but I will rectify that before the next outing.

On the cheek rest thing, first of all good catch, if memory serves the McRee cheek rest it is reversible, I had stold the one off this rifle for another rifle and when I got the new one in it was set up righty and I just haven't reversed it yet, If I remember correctly it is just a matter of re adjusting a few velcroe straps, I just through that on the night before a match, but I will rectify that before the next outing.

Yes Sir. When the chamber is cut it has a set free bore. As you shoot and the rounds wear out the lands the free bore gets extended.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

So when you have a barrel "set back" it's essentially shrinking the free bore area back to original length by re-cutting the chamber closer to the lands & grooves? Sorry for my ignorance. I find this all interesting.

Yes, you also have to move the recoil lug shoulder, bolt nose recess and tenon. If you move one thing you have to move everything else to keep the head space correct .

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Ah, if I may ask two more questions. Who or what determines the appropriate free bore length to begin with? Also, I read about some reloaders talk about their rounds liking a little "jump". Are they referring to seating their projectiles a little dealer to ride their free bore space a little longer before land and groove engagement?

Deep Throat lives.......until you sectioned the chamber.

How much did the distance increase ( bullet to lands) grow from new ?

Did you happen to re-measure the throat erosion along the way ?

I did not track it along the way. I just realized that when shooting at distance, my normal dope was no longer viable. I was having to add elevation to connect on targets that in the past I was able to drill with much less elevation. I would personally have to look at the Reamer specs to see what the free bore is, I know that with our "team load" OAL of 2.82" the Ogive is only about .001"-.004" off the lands (depending on the consistency of my reloading equipment). The free-bore now is not measured in thousandths, rather with a tape measure! There are still lines visible where the rifling was in the throat area, but they are very faint and not well defined like what you would see in a fresh tube. ( I am going to see if we can find one of the fresh take-offs to disect so we can take pics of a new-ish chamber).

Plenty of factory take off, and a pile of burn up barrels. lol

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Ah, if I may ask two more questions. Who or what determines the appropriate free bore length to begin with? Also, I read about some reloaders talk about their rounds liking a little "jump". Are they referring to seating their projectiles a little dealer to ride their free bore space a little longer before land and groove engagement?

That question is beyond my pay grade, but I will take a stab at it. ****This is my layman's take on this**** I think that most cartridges that are widely used, have one particular reamer that the free-bore is pre determined by the round. Now if you want to tweak the standard cartridge and "load them longer" for competitions you can get a custom chamber built "deeper" so you can load them longer or run a custom projectile....like some of the Barnes Bore-riders recommend that you have a custom throated chamber to run them. If you can draw it up, PTG can build you a reamer to whatever spec you want, the sky is the limit...depending on how much brass prep you are willing/able to dive into.

As far as "jump" you are correct, if you seat the bullet deeper it gives it more "jump" before the Ogive hits the lands and grooves of your barrel. I ran into a crash course with that with my 6.5 SAUM, I had always been taught that you find where the lands are and load the projectile so that the Ogive is a few thousandths off the lands and that is usually the "happy spot" That has been the case for most calibers I have reloaded for. Then once you are at that point my common practice was to play with OAL maybe .002-.003" at a time to try to find where the rifle shoots that projectile best. I started and pretty much "in the lands" and worked back to .017" off, thinking that was a HUGE jump, rifle still wouldn't shoot better than Minute/minute and a half groups. So then we started down a lonely road of re-torquing everything, field stripping rifle, measuring everything, sent a NF scope (that had nothing wrong with it) back for repair, recrowned muzzle, cut barrel down to make sure enough of the end had been cut off on initial build, bedded barreled action to chassis, (even though we have never had to bed any of our other chassis).....and it still wouldn't shoot. I tried different powders, scopes, you name it and it would not shoot. I finally stumbled on an article by Berger (Berger Bullets Seating Method for VLD Bullets - A "Sweet Spot" with a Long Bullet Jump will give the best accuracy.) I followed their procedure and found that the sweet spot for my SAUM was with the bullet seated for what amounts to a .063" jump. (if I would have tried to do that .002" at a time, I would have shot the barrel out before I found "the load") Now that rifle is an absolute hammer, but I almost broke it over a rock a few times on the journey of finding where it wanted to shoot. Killed a bull elk in Wyoming at 320 yards running away from me with it and a mule deer in Nevada, 560 yard head shot at a pretty steep angle, love the rifle now and am intimately framiliar with my chamber...way more than I ever cared to know about it in fact!

Last edited:

I did not track it along the way. I just realized that when shooting at distance, my normal dope was no longer viable. I was having to add elevation to connect on targets that in the past I was able to drill with much less elevation. I would personally have to look at the Reamer specs to see what the free bore is, I know that with our "team load" OAL of 2.82" the Ogive is only about .001"-.004" off the lands (depending on the consistency of my reloading equipment). The free-bore now is not measured in thousandths, rather with a tape measure! There are still lines visible where the rifling was in the throat area, but they are very faint and not well defined like what you would see in a fresh tube. ( I am going to see if we can find one of the fresh take-offs to disect so we can take pics of a new-ish chamber).

Any chronograph velocities logged when new vs the 3000 round mark ?

Wondering how much velocity dropped of along the way.

Nice pics BTW!

Any chronograph velocities logged when new vs the 3000 round mark ?

Wondering how much velocity dropped of along the way.

Nice pics BTW!

Based on what I was seeing in Dope differential I started out around 2820-2840 fps with new chamber, at the end it was slightly below 2700 fps. That was obtained from "reverse engineering" the velocity through "truing" functions of our ballistic programs. (unfortunately, although we as a group have access to a great array of gear and some very fine weapons, none of us has a chrono, that you can trust any further than you can kick the SOB!)

That is not a stupid question. If we can be of any help please do not hesitate to contact me. I will do my best to answer your question or find someone who knows the answer to your question.

We do not do load development every time we change barrels. We have two loads we run, the first is our "team 139 Scenar load" and the other is the "team 140 Barnes Match Burners load". Both shoot great, I think because we have a lathe and build our own rifles we are able to keep things very consistent. Consistency is accuracy so when we re-barrel a rifle we dial the bore axis down to 0.0001" and use the same rough reamer, the same finishing reamer and cut the chamber with the same +0.002" head space. That allows us to all use the same load depending on what projectile they are utilizing.

With factory rifles you can have different head spaces, different free bores and things like that. I hope that answers your question.

Great, that's what I was thinking that as long as the new barrel and chamber has been cut exactly like the previous one, the same loads should perform the same in the new barrel. Conversely, I would think if you go with a different smith who has a different reamer on your next barrel - then you would have to start almost from scratch on load development.

Thanks for the pics. Great stuff!

That question is beyond my pay grade, but I will take a stab at it. ****This is my layman's take on this**** I think that most cartridges that are widely used, have one particular reamer that the free-bore is pre determined by the round. Now if you want to tweak the standard cartridge and "load them longer" for competitions you can get a custom chamber built "deeper" so you can load them longer or run a custom projectile....like some of the Barnes Bore-riders recommend that you have a custom throated chamber to run them. If you can draw it up, PTG can build you a reamer to whatever spec you want, the sky is the limit...depending on how much brass prep you are willing/able to dive into.

As far as "jump" you are correct, if you seat the bullet deeper it gives it more "jump" before the Ogive hits the lands and grooves of your barrel. I ran into a crash course with that with my 6.5 SAUM, I had always been taught that you find where the lands are and load the projectile so that the Ogive is a few thousandths off the lands and that is usually the "happy spot" That has been the case for most calibers I have reloaded for. Then once you are at that point my common practice was to play with OAL maybe .002-.003" at a time to try to find where the rifle shoots that projectile best. I started and pretty much "in the lands" and worked back to .017" off, thinking that was a HUGE jump, rifle still wouldn't shoot better than Minute/minute and a half groups. So then we started down a lonely road of re-torquing everything, field stripping rifle, measuring everything, sent a NF scope (that had nothing wrong with it) back for repair, recrowned muzzle, cut barrel down to make sure enough of the end had been cut off on initial build, bedded barreled action to chassis, (even though we have never had to bed any of our other chassis).....and it still wouldn't shoot. I tried different powders, scopes, you name it and it would not shoot. I finally stumbled on an article by Berger (Berger Bullets Seating Method for VLD Bullets - A "Sweet Spot" with a Long Bullet Jump will give the best accuracy.) I followed their procedure and found that the sweet spot for my SAUM was with the bullet seated for what amounts to a .063" jump. (if I would have tried to do that .002" at a time, I would have shot the barrel out before I found "the load") Now that rifle is an absolute hammer, but I almost broke it over a rock a few times on the journey of finding where it wanted to shoot. Killed a bull elk in Wyoming at 320 yards running away from me with it and a mule deer in Nevada, 560 yard head shot at a pretty steep angle, love the rifle now and am intimately framiliar with my chamber...way more than I ever cared to know about it in fact!Good luck and shoot straight!

Thank you for taking the time to help me understand. Great info here. I apologize for hijacking your thread with my curiosity. I had one too many glasses of scotch last night and it managed to turn the curious part of my brain on. Not to worry, I've turned it back off again.... Lol

Thanks very much for taking the time to do this and share it. Per above, a picture is always worth a thousand words!

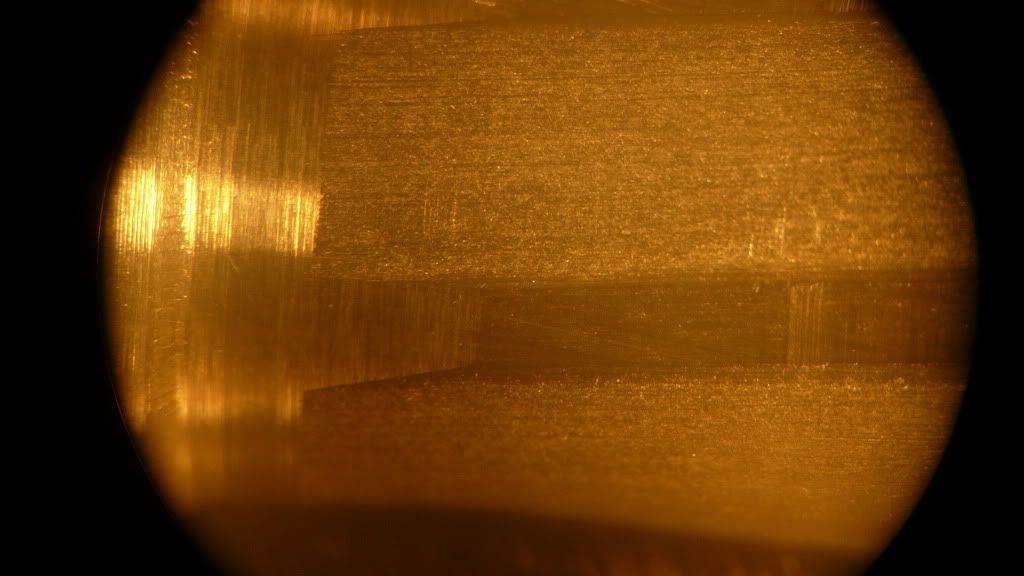

Guys before Shot I said I would post some pics and have a discussion about barrel maintenance. If hognuts agrees to me joining in this thread I'll add some pics and start the discussion.. Below is one of a fresh cut 338 Lapua. It's not perfect as it was about 2" piece of barrel thrown in a chuck and hogged out but you get the idea of what a fresh cut throat looks like.

Good thread. This thread illustrates what I have suspected for awhile, that most bullets are more tolerant to jump than we think. Looking forward to more on this, thanks for all the pics.

M

milo 2.0

Guest

I'd like to see your pics Mr Tooley, even with all the ooh's and aah's, to me Hognut's barrel is in remarkably good shape. Though the close ups aren't the clearest, the throat looks totally void of firecracking, a tribute to load or powder choice. The bullets aren't coated, and maintenance can't stop cracks.

I'd like to see your pics Mr Tooley, even with all the ooh's and aah's, to me Hognut's barrel is in remarkably good shape. Though the close ups aren't the clearest, the throat looks totally void of firecracking, a tribute to load or powder choice. The bullets aren't coated, and maintenance can't stop cracks.

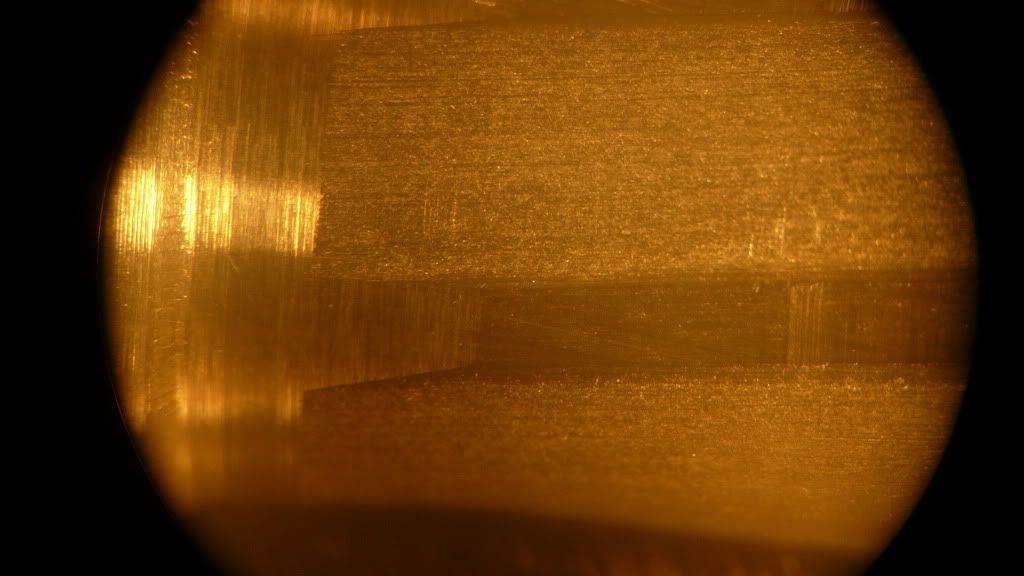

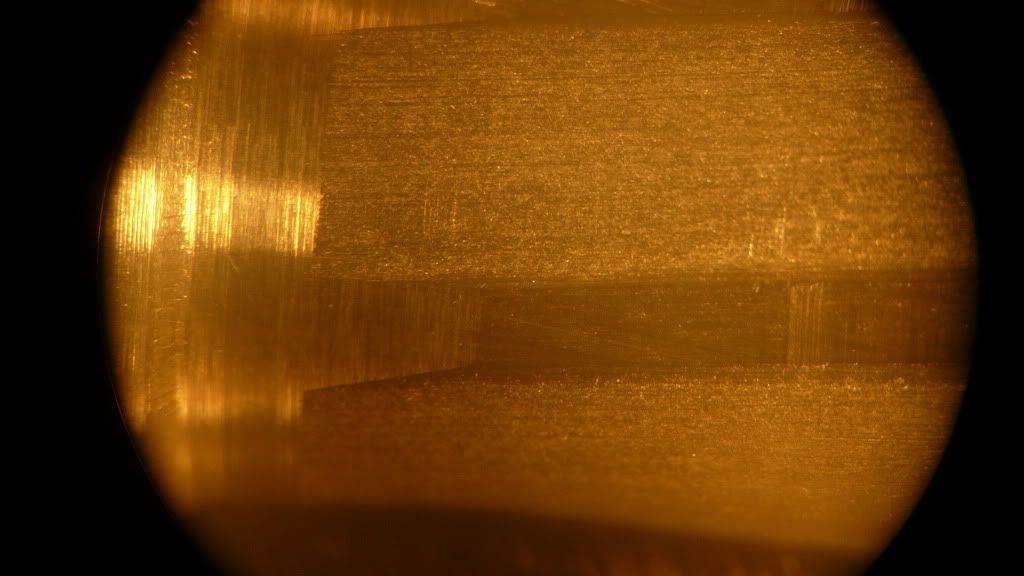

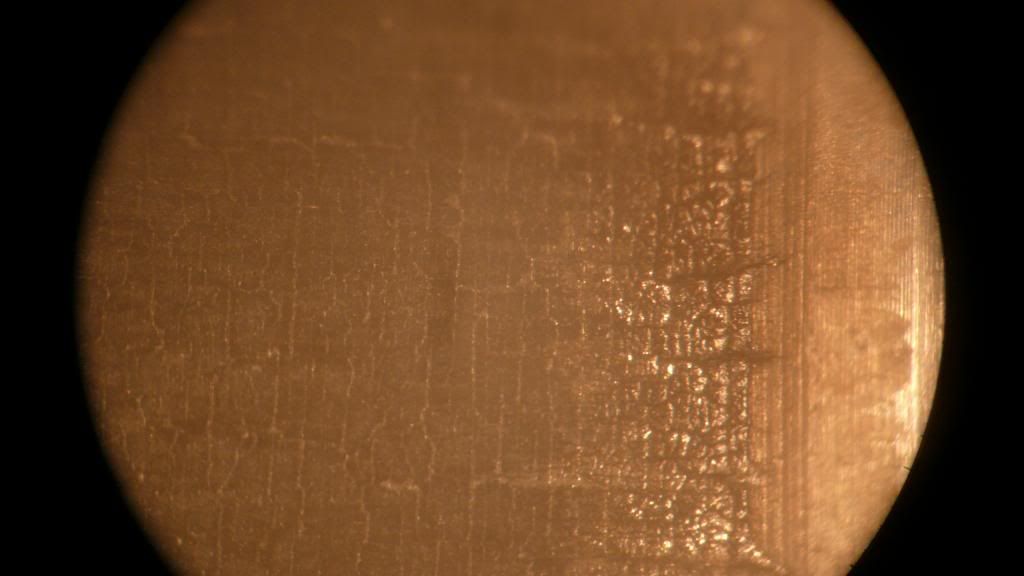

I'll wait on a reply from him. I can guarantee you he has heat checking. Also heat checking filled with copper. In one of his photos there is a considerable amount of copper just ahead of the throat area. All the bad stuff is there. I use a stereo microscope and can get considerably more detail. The photo below is just the top of one land in a 338.

I sent HOG a text. Hopefully that wakes him up if he wasn't already!

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Did you see anything you didnt already know? I would like to examine my old barrel but its long gone.

I'll wait on a reply from him. I can guarantee you he has heat checking. Also heat checking filled with copper. In one of his photos there is a considerable amount of copper just ahead of the throat area. All the bad stuff is there. I use a stereo microscope and can get considerably more detail. The photo below is just the top of one land in a 338.

Please do join the topic. Looking forward to seeing some of your thoughts and pics. Always good to see as much info as possible.

Guys before Shot I said I would post some pics and have a discussion about barrel maintenance. If hognuts agrees to me joining in this thread I'll add some pics and start the discussion.. Below is one of a fresh cut 338 Lapua. It's not perfect as it was about 2" piece of barrel thrown in a chuck and hogged out but you get the idea of what a fresh cut throat looks like.

You did indeed say that on my barrel break in thread which started classic arguments so I am looking forward to more as well.

I have a potentially stupid question. You guys (Sin City Guys) obviously shoot a lot, I noticed your gun is painted and I obviously cant see if its bedded but if it were bedded would you paint that area of the action? Im not trying to highjack the thread but my rifel is bedded and I want to paint it but Im not sure about that area.

.300Winny, I think HOG is the only one if us to bed a rifle. One of the reasons we like chassis systems is because we can just bolt them together and go.

I would coat/paint the receiver and once it cured then do your bedding work. Once you bed your rifle I wouldn't paint that area of the stock/chassis. That is the point of view from a garage hack machinist/gun plummet. Hopefully those more experienced than I can do a better job answering your question.

Sent from my iPhone using Tapatalk

I would coat/paint the receiver and once it cured then do your bedding work. Once you bed your rifle I wouldn't paint that area of the stock/chassis. That is the point of view from a garage hack machinist/gun plummet. Hopefully those more experienced than I can do a better job answering your question.

Sent from my iPhone using Tapatalk

I agree with JF on the painting then bedding. I know a lot of smiths will bed then do all their painting but they have the paint thing down and know how much (how thick of a layer of paint) they are putting down. I think they don't want to take the chance of messing the paint up with the bedding process. If the bedding is done correct with quality materials then you should have VERY little shrinkage and there for a layer of paint will basically make the action OD larger and the stock inlet smaller and they will not fit together properly.

On the free bore thing I thought that was mainly determined by what bullet you are planning on using with that specific barrel.

But these are just my .02 and may be way off. Someone please correct me if I have my head in my ass...

On the free bore thing I thought that was mainly determined by what bullet you are planning on using with that specific barrel.

But these are just my .02 and may be way off. Someone please correct me if I have my head in my ass...

By the way great thread with some great pics!! Thank you to Hognuts, JFComfort, and Dave Tooley. I look forward to more.

Here goes. Not all will agree, surprise, but this has been my experience over many years and many different calibers. Probably one of the most extreme I own is a 17-224 Weatherby. 9 shots and you have to clean the barrel or you get exploding bullets.

Some basics that affect accuracy; throat wear, heat checking, carbon fouling and copper fouling.

1. Case capacity. The larger the case the faster bad things happen to barrel. It's the "you can't fool Mother Nature" thing.

2. rate of fire will add to or delay the issues with heat checking and fouling.

3. carbon fouling will affect pressure and accuracy.

Accuracy is affected by any build up in the barrel. As a smith I go to great lengths to build accurate rifles/barrels. Quality barrels, spec'd out reamers, concentric throats, smooth easy transitioning lead angles for the bullets. The reason is to do the least amount of damage to the bullet while it's in the barrel.

Some observations I've made over the years.

High performance cartridges come with a price to be paid. Heat checking is visible in 100 rounds in magnum size cases. Throat wear is in the neighborhood of .001" to .0015" per 100 rounds. Nothing is free if you want go fast or long.

308's can stand a lot of abuse and still shoot well but eventually they need maintenance also.

I'm a barrel cleaner. To manage heat checking, to manage powder fouling, to manage cooper fouling you have to clean the barrel. Now what kind of schedule and regime do you follow.

This is just a broad general recommendation as there are too many variables to give specific, as in exact round count recommendations.

308's I would

1. always push a dry patch down the barrel to get out the powder fouling before storing for any length of time. The reason is fouling attracts moisture and traps it against the barrel. I'll put a pic or two up that very plainly shows what happens if you don't get it out. This happens to S/S also just more slowly. 2. For the first 1500 rounds a rigorous cleaning every 100 if possible. After 1000-2000 rounds I would occasionally use a mild abrasive to manage the heat checking. This helps with carbon fouling also. After say 2000 I would be more aggressive and diligent with cleaning.

Here's two pic of LE rifles. One shows where powder fouling was laying in the groove and caused pitting the other has a lot of bad stuff going on. Pits that collected bullet jacket material.

Here's a pic of LE rifle, round count 5207. This is the throat area. You can see the neck on the right. On the left you can see the heat checking that has copper in the cracks. The heat checking extends down the barrel a ways.

HP rounds. Smaller bores with capacity of say 40 Grs. and up and then the magnums.

1.never put it away dirty. 2. For the first 300-400 rounds clean every 50-100 rounds. The more extreme a round the more frequently it requires attention. After 400 I would consider using abrasives. The more powder that's burned the more important it is. After 500-600 abrasives would part of my routine. Throats wear that's a fact of life. Barrels still shoot well but if carbon fouling, heat checking which leads to increased copper fouling get ahead of you accuracy will fall off quickly. Flyers will be more the norm than the exception.

One thing that shows up particularly with 338's is powder fouling between the case neck and the end of the neck area in the chamber. It can become a problem. On HP cartridges I insert my bore brush into the neck and give a couple of twists to clean this area.

This barrel is a 338 LAPUA Imp with 1173 rounds on it. It is a 1K yd. benchrest barrel that was well maintained until it's final days.

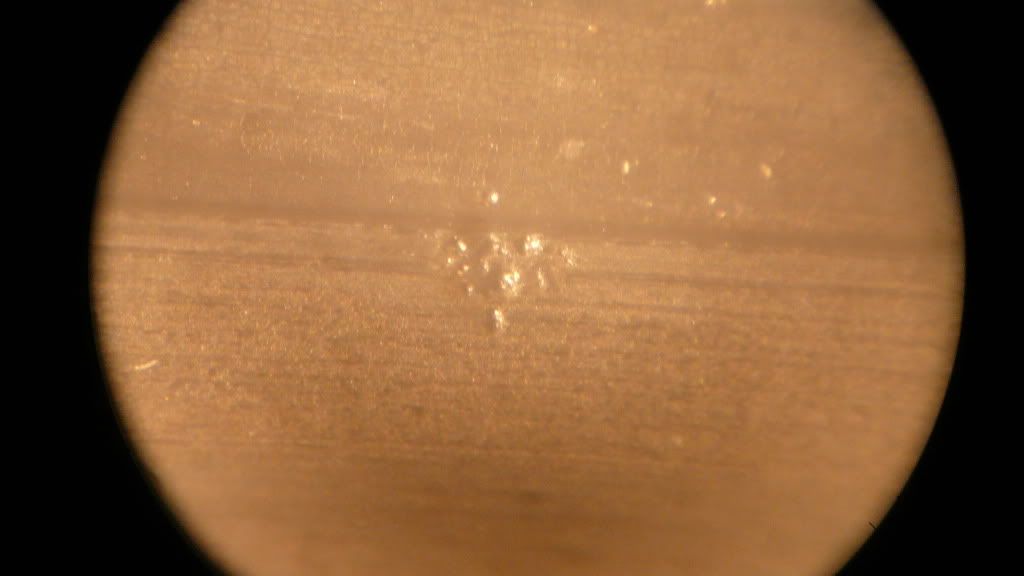

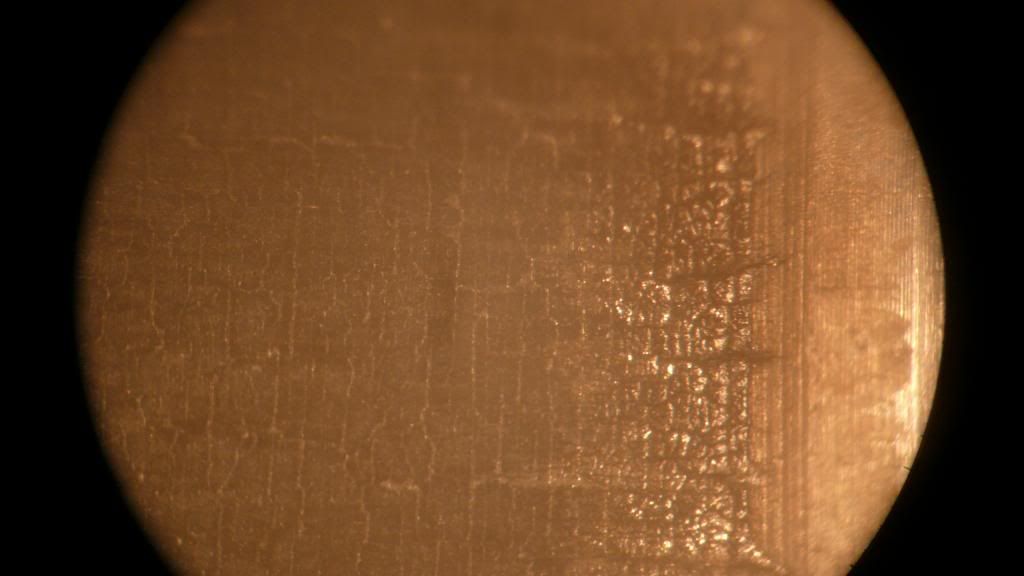

The first pic is 6" down the barrel.

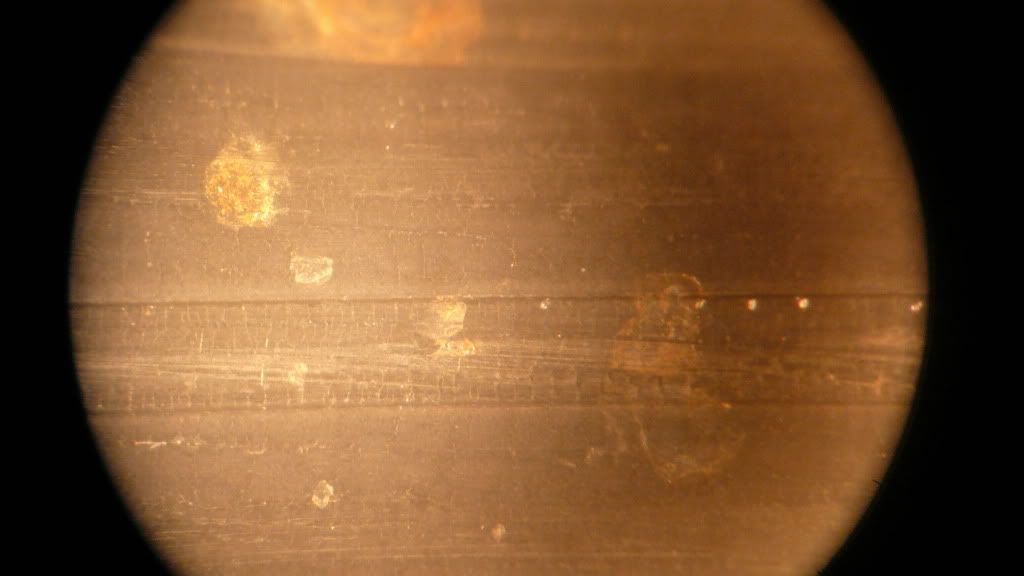

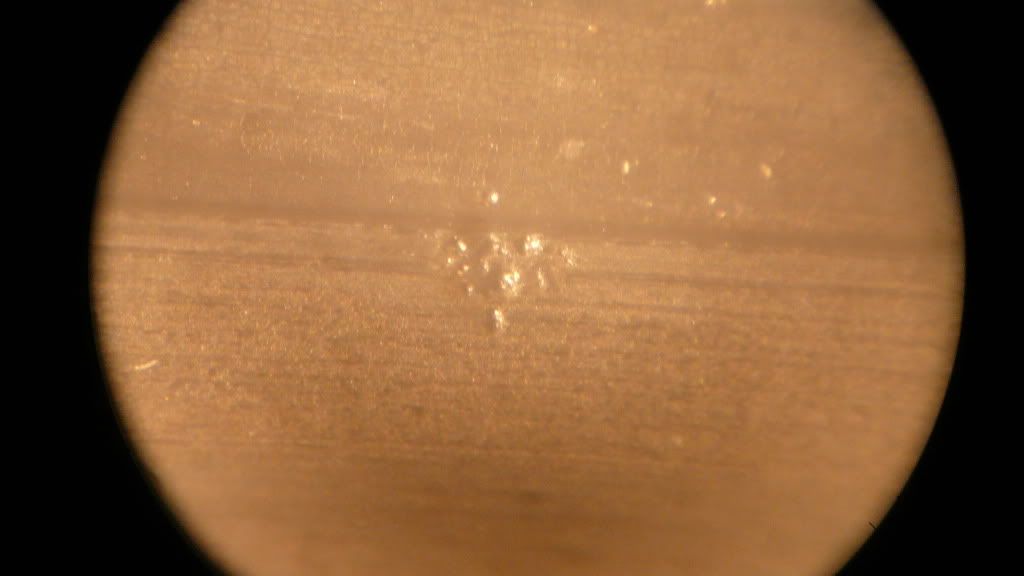

This is 2" down the barrel. Notice the copper in the cracks and copper laying on top of the lands. Not good for accuracy.

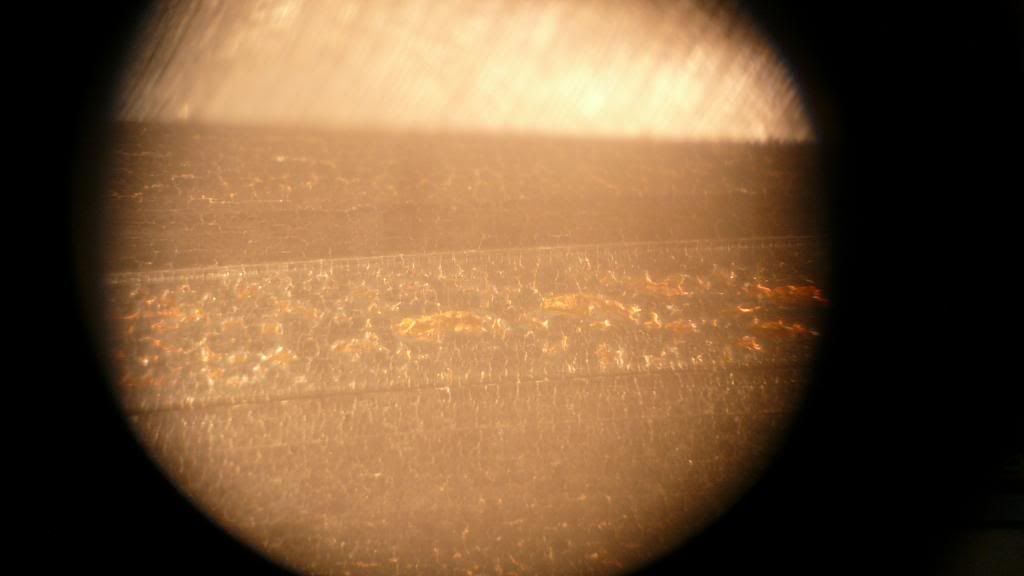

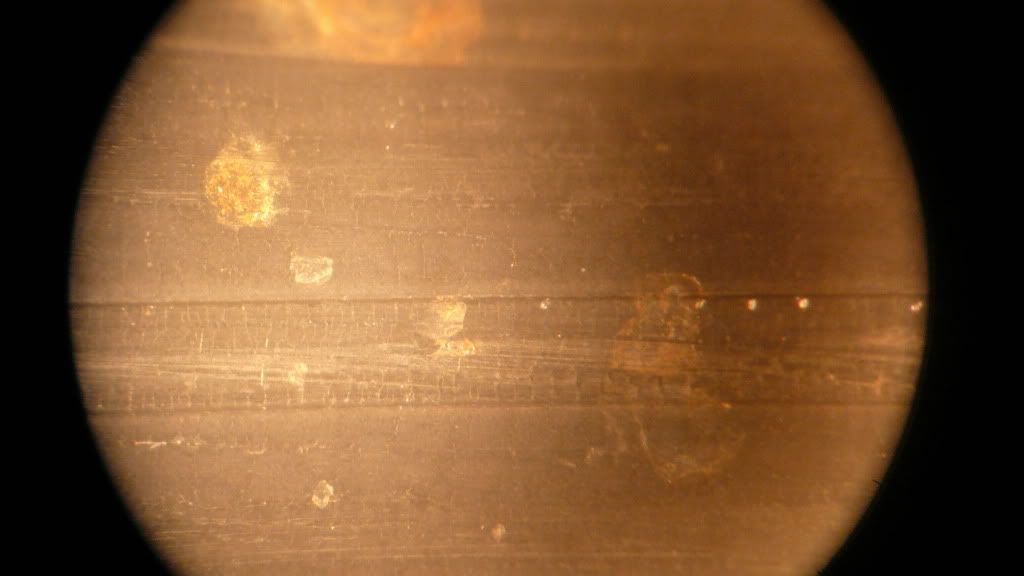

This is a close up of the top of the land 1.5" down the barrel. Once copper gets into the cracks you can't get it out. Then consistent repeatable accuracy will fall off.

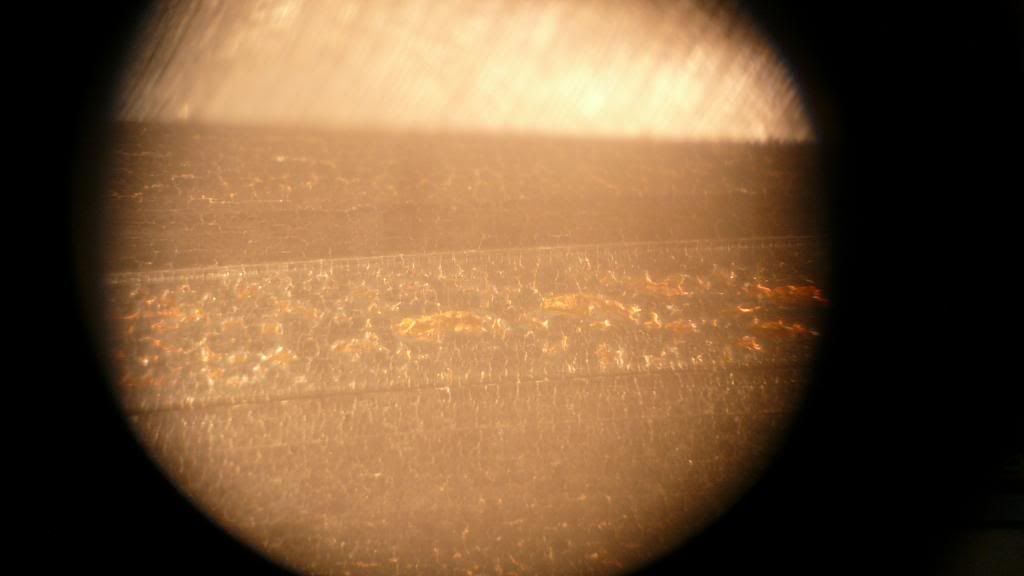

This is just in front of the freebore area.

This is the throat area.

As they say a picture is worth a thousand words.

YMMV

Some basics that affect accuracy; throat wear, heat checking, carbon fouling and copper fouling.

1. Case capacity. The larger the case the faster bad things happen to barrel. It's the "you can't fool Mother Nature" thing.

2. rate of fire will add to or delay the issues with heat checking and fouling.

3. carbon fouling will affect pressure and accuracy.

Accuracy is affected by any build up in the barrel. As a smith I go to great lengths to build accurate rifles/barrels. Quality barrels, spec'd out reamers, concentric throats, smooth easy transitioning lead angles for the bullets. The reason is to do the least amount of damage to the bullet while it's in the barrel.

Some observations I've made over the years.

High performance cartridges come with a price to be paid. Heat checking is visible in 100 rounds in magnum size cases. Throat wear is in the neighborhood of .001" to .0015" per 100 rounds. Nothing is free if you want go fast or long.

308's can stand a lot of abuse and still shoot well but eventually they need maintenance also.

I'm a barrel cleaner. To manage heat checking, to manage powder fouling, to manage cooper fouling you have to clean the barrel. Now what kind of schedule and regime do you follow.

This is just a broad general recommendation as there are too many variables to give specific, as in exact round count recommendations.

308's I would

1. always push a dry patch down the barrel to get out the powder fouling before storing for any length of time. The reason is fouling attracts moisture and traps it against the barrel. I'll put a pic or two up that very plainly shows what happens if you don't get it out. This happens to S/S also just more slowly. 2. For the first 1500 rounds a rigorous cleaning every 100 if possible. After 1000-2000 rounds I would occasionally use a mild abrasive to manage the heat checking. This helps with carbon fouling also. After say 2000 I would be more aggressive and diligent with cleaning.

Here's two pic of LE rifles. One shows where powder fouling was laying in the groove and caused pitting the other has a lot of bad stuff going on. Pits that collected bullet jacket material.

Here's a pic of LE rifle, round count 5207. This is the throat area. You can see the neck on the right. On the left you can see the heat checking that has copper in the cracks. The heat checking extends down the barrel a ways.

HP rounds. Smaller bores with capacity of say 40 Grs. and up and then the magnums.

1.never put it away dirty. 2. For the first 300-400 rounds clean every 50-100 rounds. The more extreme a round the more frequently it requires attention. After 400 I would consider using abrasives. The more powder that's burned the more important it is. After 500-600 abrasives would part of my routine. Throats wear that's a fact of life. Barrels still shoot well but if carbon fouling, heat checking which leads to increased copper fouling get ahead of you accuracy will fall off quickly. Flyers will be more the norm than the exception.

One thing that shows up particularly with 338's is powder fouling between the case neck and the end of the neck area in the chamber. It can become a problem. On HP cartridges I insert my bore brush into the neck and give a couple of twists to clean this area.

This barrel is a 338 LAPUA Imp with 1173 rounds on it. It is a 1K yd. benchrest barrel that was well maintained until it's final days.

The first pic is 6" down the barrel.

This is 2" down the barrel. Notice the copper in the cracks and copper laying on top of the lands. Not good for accuracy.

This is a close up of the top of the land 1.5" down the barrel. Once copper gets into the cracks you can't get it out. Then consistent repeatable accuracy will fall off.

This is just in front of the freebore area.

This is the throat area.

As they say a picture is worth a thousand words.

YMMV

Wow, Mr. Tooley thank you for the pictures and the education. If you don't mind me asking what type of bore scope are you using?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Similar threads

- Replies

- 0

- Views

- 634

- Replies

- 142

- Views

- 17K