Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

do you shoot .308 FACTORY ammo out of your 7.62x51 chamber semi-auto?

- Thread starter elfster1234

- Start date

What are you even talking about?

Everything was going fine until you Trolled your way in. Once I see a Troll, I set up a trap, to see if the troll falls for the toll trap. Sometimes people confuse Trappers for Trolls. Once a Troll gets trapped, he comes back with personal attacks, "do not understand English", "go back to your mom's basement", etc, hahahahaha

I can understand someone not understanding what "Savage Fireform" is, all they have to do is ask. But you said you have "been in the business 20 years" and have never heard of it. Really? 20 years and you can't figure out what Savage Fireform Brass is?

You know what Brass is right? You know what Savage is right? You know what Fireform brass is right? You mean to tell me you can't put all 3 together even after "been in the business 20 years"? Haahahahah.

I do not think this is an English problem on my part (again English is my 3rd Language), I think this might be a math problem on your part! LOL

Please Discuss.....

I did not say I'd been in any business for any number of years.

Furthermore, its not called "Savage Fireform Brass".

I explained to you the proper terminology.

So far, we've established several things:

Your command of the English language isn't very good.

Your reading comprehension is bad.

You don't understand firearms terminology very well.

Finally, you're a troll.

Furthermore, its not called "Savage Fireform Brass".

I explained to you the proper terminology.

So far, we've established several things:

Your command of the English language isn't very good.

Your reading comprehension is bad.

You don't understand firearms terminology very well.

Finally, you're a troll.

There's a lot of strange things said on the errornet, sometimes it's just best to ask for clarification.

As far as the OP's question. Shooting full power 308 loads in a semi isn't going to blow it up but it may put a little premature wear and make that M1A bolt crack a little sooner.

I've had 4, 2 were high end custom rifles. I ran some pretty strong handloaded rounds trying to shoot 155s at 1000yds and did not break anything but I have seen several broken bolts from others rifles. Same deal with a AR10 type rifle, I push them until the primers begin to flatten. I have not ever had a 308 bolt break but when I started machining bolts I decided to use 9310 for the extra strength anyway. The extra 2000psi if a full power load isn't going to scatter a rifle, it will just wear more or break sooner.

Headspace? Some factory ammo is .020 below the chamber spec. Sometimes it does cause the primers to flatten a little.

1.630 is Min chamber size, 1.634 is a no-go

As far as the OP's question. Shooting full power 308 loads in a semi isn't going to blow it up but it may put a little premature wear and make that M1A bolt crack a little sooner.

I've had 4, 2 were high end custom rifles. I ran some pretty strong handloaded rounds trying to shoot 155s at 1000yds and did not break anything but I have seen several broken bolts from others rifles. Same deal with a AR10 type rifle, I push them until the primers begin to flatten. I have not ever had a 308 bolt break but when I started machining bolts I decided to use 9310 for the extra strength anyway. The extra 2000psi if a full power load isn't going to scatter a rifle, it will just wear more or break sooner.

Headspace? Some factory ammo is .020 below the chamber spec. Sometimes it does cause the primers to flatten a little.

1.630 is Min chamber size, 1.634 is a no-go

Last edited:

I did not say I'd been in any business for any number of years.

Furthermore, its not called "Savage Fireform Brass".

I explained to you the proper terminology.

So far, we've established several things:

Your command of the English language isn't very good.

Your reading comprehension is bad.

You don't understand firearms terminology very well.

Finally, you're a troll.

Trapper not Troll. The only one trolling was you. Go back and look at your original comments, you were not even attempting to have an open discussion, you just went on the attack right away. As a Trapper, when I see a Troll, I love to play along!

I think it's a shame when someone likes you knows only one language and can't seem to get that one right. Lastly, your math skills are highly lacking, you can't seem to put 2 and 2 together.

Now on to "Fireform Brass".. Firefrom means you are forming the brass by firing, and you are not doing a full resize. Do we agree here?

"Savage "on gun forums, we are usually talking about Savage Rifles. Do we agree here?

Before I continue, just want to get your agreement on these 2 points.

Please Discuss....

There's a lot of strange things said on the errornet, sometimes it's just best to ask for clarification.

As far as the OP's question. Shooting full power 308 loads in a semi isn't going to blow it up but it may put a little premature wear and make that M1A bolt crack a little sooner.

I've had 4, 2 were high end custom rifles. I ran some pretty strong handloaded rounds trying to shoot 155s at 1000yds and did not break anything but I have seen several broken bolts from others rifles. Same deal with a AR10 type rifle, I push them until the primers begin to flatten. I have not ever had a 308 bolt break but when I started machining bolts I decided to use 9310 for the extra strength anyway. The extra 2000psi if a full power load isn't going to scatter a rifle, it will just wear more or break sooner.

Headspace? Some factory ammo is .020 below the chamber spec. Sometimes it does cause the primers to flatten a little.

1.630 is Min chamber size, 1.634 is a no-go

.308 ammo and 7.62x51 Ammo is the same thing, the only thing really different between them is the thicker cases for NATO to prevent case separation in GPMGs such as the M240 or M60. GPMGs headspace can go out of whack sometimes and have overly excessive headspace. The thicker cases prevents case separation and still gives reliable cycling for these guns just in case their headspace goes out of whack.

SAAMI specs are on the tight side. 1.634" is No-Go for SAAMI, but for NATO 1.638 is No-Go. NATO Field is 1.6455".

I have a M14 Polytech on the loose side and and it shot all .308 ammo just fine. However, brass was really stretched and it beat it up brass pretty bad, so I decided to do a USGI Bolt Coversion with Warbird. Warbird told me my headspace was 1.643 (I would not know this because I only have a 1.638 and 1.6455 gauges, my gun would close on 1.638 but it did not close on 1.6455). Now my rifle is under 1.638 for HS after the work done by Warbird.

I think the only .308 Guns people have to worry about are foreign guns, and old ones at that. Guns such as a Ishapore or Polytech-M14 shows up in country with out of spec, even out of NATO spec for HS. They may work when shooting Military ammo, but commercial .308 ammo caused these guns to get case separation. I think the Ishapore is why we have all the 7.62NATO vs. .308 discussions (arguments).

Again, .308 and 7.62x51 ammo is the exact same. If you have case separation, the problem will not be from the ammo, it will be from the gun. If your gun is made in the last 10 years, it is most likely HS to spec and should be just fine to shoot any ammo. If you get case separation, then take it back, or get it re-headspaced (For AR's, this means you need to buy a new barrel).

Last edited:

Please, show me where I said something about 20 years experience? Until then, go chase a dog.

Oh my bad, that was bustin that said that. So it seems you both have Math problems putting 2 and 2 together LOL.....

But at least Bustin was nice enough to ask me to clarify before commencing the attack (he did not attack once I gave him clarification).

So can we continue?

Last edited:

No, I rarely shoot factory ammo.

Other than directly answering the OP's post, this thread lacked the discussion about ammo in semi-autos I had hoped for.

Other than directly answering the OP's post, this thread lacked the discussion about ammo in semi-autos I had hoped for.

No, I rarely shoot factory ammo.

Other than directly answering the OP's post, this thread lacked the discussion about ammo in semi-autos I had hoped for.

really? .....

.308 ammo and 7.62x51 Ammo is the same thing, the only thing really different between them is the thicker cases for NATO to prevent case separation in GPMGs such as the M240 or M60. GPMGs headspace can go out of whack sometimes and have overly excessive headspace. The thicker cases prevents case separation and still gives reliable cycling for these guns just in case their headspace goes out of whack.

SAAMI specs are on the tight side. 1.634" is No-Go for SAAMI, but for NATO 1.638 is No-Go. NATO Field is 1.6455".

I have a M14 Polytech on the loose side and and it shot all .308 ammo just fine. However, brass was really stretched and it beat it up brass pretty bad, so I decided to do a USGI Bolt Coversion with Warbird. Warbird told me my headspace was 1.643 (I would not know this because I only have a 1.638 and 1.6455 gauges, my gun would close on 1.638 but it did not close on 1.6455). Now my rifle is under 1.638 for HS after the work done by Warbird.

I think the only .308 Guns people have to worry about are foreign guns, and old ones at that. Guns such as a Ishapore or Polytech-M14 shows up in country with out of spec, even out of NATO spec for HS. They may work when shooting Military ammo, but commercial .308 ammo caused these guns to get case separation. I think the Ishapore is why we have all the 7.62NATO vs. .308 discussions (arguments).

Again, .308 and 7.62x51 ammo is the exact same. If you have case separation, the problem will not be from the ammo, it will be from the gun. If your gun is made in the last 10 years, it is most likely HS to spec and should be just fine to shoot any ammo. If you get case separation, then take it back, or get it re-headspaced (For AR's, this means you need to buy a new barrel).

Anyone can look up the 2 cartridges by google and find that the SAAMI specs for max pressure for the 2 rounds are different. Different because the mil did not want 62000psi cartridges used in semi-auto rifles. Chamber specs for the 2 rounds are slightly different, the brass should be the same.

Before anyone says it these are not SAAMI drawings. Both are more 7.62x51 chambers, look at the freebore dia, it's .3095-.310 and .140" long on 1 drawing.

Last edited:

Anyone can look up the 2 cartridges by google and find that the SAAMI specs for max pressure for the 2 rounds are different. Different because the mil did not want 62000psi cartridges used in semi-auto rifles. Chamber specs for the 2 rounds are slightly different, the brass should be the same.

Old info that is not only old, it is wrong. The 10k PSI difference in Max pressure between SAAMI and NATO is the result of using 2 different measuring techniques and 2 different gauges. The telling tale is muzzle velocity. If your "NATO Chamber" is getting roughly the same muzzle velocity with both NATO and Commercial (SAAMI) ammo, how does that result in 10k extra?

There was a well written piece by FALphil about 10 years ago, that went into details, I will post it later when I find it. Conclusion: .308 and 7.62 NATO cartridges are basically the same thing, that there will be as much variation in 308 ammo with other .308 ammo, as there will be with .308 and 7.62 NATO. NATO chamber is another story, NATO allows for looser tolerances. However, Remington .308 Chambers seems to be looser than NATO. Not only is the chamber wider in diameter, but the throat of Remington Chambers are really long, longer even than most NATO chambers.

I didn't have any questions. I enjoy reading threads where people discuss different topics. Sometimes threads go off topic, so I give the OP a straight answer and move on to other threads. Often threads here have very intelligent discussions, and it is easy to tell that the people posting have a wealth of knowledge to share. Other times, threads veer off topic, and can turn into petty arguments, or vicious personal attacks. Other times, threads go a direction no one would have expected, yet they still provide either valuable information, great entertainment, or both.

The neat thing bout this site is that in most cases, the threads are worth taking a look at. If threads go off topic, or don't interest

me, I can always look for a different one. There have been some off topic threads that were well worth reading through.

The neat thing bout this site is that in most cases, the threads are worth taking a look at. If threads go off topic, or don't interest

me, I can always look for a different one. There have been some off topic threads that were well worth reading through.

I didn't have any questions. I enjoy reading threads where people discuss different topics. Sometimes threads go off topic, so I give the OP a straight answer and move on to other threads. Often threads here have very intelligent discussions, and it is easy to tell that the people posting have a wealth of knowledge to share. Other times, threads veer off topic, and can turn into petty arguments, or vicious personal attacks. Other times, threads go a direction no one would have expected, yet they still provide either valuable information, great entertainment, or both.

The neat thing bout this site is that in most cases, the threads are worth taking a look at. If threads go off topic, or don't interest

me, I can always look for a different one. There have been some off topic threads that were well worth reading through.

what kind of info were you hoping for? what do you expect on an internet discussion forum? Do you expect Full Thesis Research Paper where all cases are covered with 100 samples each?

A:No. That would be an expectation, something that I try to avoid. In any case, I think a thesis would be far too long to keep many people's interest here. There are few thesis that wold hold my interest long enough to finish them in this forum format.what kind of info were you hoping for?

A: anything interesting, new, or that I don't already have.

what do you expect on an internet discussion forum?

A: Having expectations often, or usually results in disappointment, so I try to avoid expectations. Any time I can learn useful, new information is good.

Do you expect Full Thesis Research Paper where all cases are covered with 100 samples each?

do you shoot .308 FACTORY ammo out of your 7.62x51 chamber semi-auto?

yes. my LR308 chambered in 7.62x51 nato has no problem with it. I dont hesitate to stuff .308 or 7.62x51 into it and run.

Mine seems to like Hornady 168gr AMAX Match as its best factory load so far and will consistently shoot 3/4" 100 yd groups

Its pretty happy with winchester 180g power points as well. FGGM 168gr sierra BTHP shoots about 1" 100 yd groups.

boy oh boy does it fling the brass too - i get a nice pile somewhere between 2-4 oclock depending on the brand.

(edit)

in fact its had more .308 win put through it than 7.62x51 nato.

Last edited:

Some fairly current information on this.

Copyright © 2008, Cross Connect Corp. All rights reserved Page 1

The Truth About 7.62x51mm NATO and 308 Winchester

By FALPhil

Introduction

The internet firearms and shooting culture is a relatively close knit group and very computer savvy, as hobby groups go. Many of the community are members of the several dozen discussion groups that revolve around the special interests of gun owners. Because of the nature of the internet and the inherent tendency of human beings towards believing anything that sounds reasonable, without applying critical thinking skills (probably a result of trends in government school systems – but that is another treatise), there is much misinformation available to the casual gun enthusiast about a variety of subjects concerning firearms.

One of the most pernicious of these “urban legends” is that there is a significant difference in the pressures between the 7.62x51mm NATO cartridge and the 308 Winchester cartridge. The misinformation indicates that using the commercial offering in a military weapon will visit death and destruction of biblical proportions upon the miscreant who would attempt such a thing.

I first ran into this ugly rumor in 1996, while participating on the rec.guns usenet forum. It made for interesting reading. At one point, a well-known Highpower Match competitor, who will remain unnamed, asked the question, “Why would you expect significant differences in pressure when commercial and

military cartridges are loaded with the same technology (powders, primers, cases, and projectiles) and the velocities are very close to each other?” This issue reared its ugly head a couple of years ago when the many boatloads of Ishapore 2A1 rifles hit the US shores. Much disinformation about what was safe in these fine rifles was bandied about over the internet.

That got me to thinking. My brother had been a lab technician at Aberdeen Proving Grounds in the late ‘70s, so I called him to ask him about it. It turns out that he worked on artillery dispersal, but he still knew some technicians involved in small arms research. He said he would reach out to them and get back to

me with some information.

About a month later, my brother called and described to me the method (in general terms) by which small arms ammunition is tested by the US Army. After speaking to him, I came to my own conclusion that 308 Winchester and 7.62 NATO were completely interchangeable. However, I am an unknown to many firearms enthusiasts. So, in order to support my position, I have performed a little research and documented my findings.

The Cartridges

The .308 Winchester is a rifle round and is the commercial version of the military 7.62x51mm NATO centerfire cartridge. The .308 Winchester was introduced in 1952, two years prior to the NATO adoption of the 7.62x51mm NATO or T65 round as it was known during testing. Winchester (a subsidiary of Olin Corporation) branded the cartridge and introduced it to the commercial hunting market as the 308 Winchester. Winchester's Model 70 and Model 88 rifles were subsequently chambered for the new cartridge. Since then, the .308 Winchester has become one of the most popular short-action big-game hunting cartridges in the world. It is also commonly used for civilian target shooting, military sniping, and police sharpshooting.

The purpose of the T65 was to achieve the same or similar performance of the then-standard 30-06 cartridge in a package that was more conducive to reliability in fully automatic weapons and infantry weapons under extreme conditions. A weight savings was a by-product of the project, but it was not a

primary consideration.

While Winchester intended the T65 (later named 7.62x51mm NATO) and 308 Winchester ammunition to be identical and fully interchangeable, there are some differences. The two primary differences are the specification of chambers size between the two, and the construction or the cartridge case.

Chamber Size

Look at the table below. The right column represents a military headspace gauge specification; the left one, the SAAMI specification. With many military rifles, the chambers can be significantly longer than say, a Remington 700. Note that the military chamber would fail a NO GO check with a SAAMI gauge, but

pass a FIELD check using the proper military gauges.

There is a .013" difference in acceptability, between these two specifications. This is significant in that, for reloading purposes, brass will stretch more in a military chamber upon firing, thereby reducing the life of the brass and possibly promoting case head separation. But that additional length will allow a round to chamber in an incredibly dirty weapon, which is a requirement for military applications.

308 Winchester (SAAMI) Headspace

GO - 1.6300"

NOGO - 1.6340"

FIELD - 1.6380"

7.62 NATO (Military) Headspace

GO - 1.6350"

NOGO - 1.6405"

FIELD - 1.6455"

However, it must be noted that this is the chamber specification and not the ammunition specification. The external dimensions of the two types of ammunition are nearly identical Cartridge Case Construction.

In my personal experiments, I have found, on average, that commercial 308 Winchester cases are able to contain approximately 58 grains of water, on average. The average for Lake City 92 cases, according to my measurements approached very close to 56.2 grains of water, and for Portuguese NATO markedcases which are Berdan primed, the average was close to 55.9. All brass had been fired once was sized with the same die, a Hornady New Dimension 308 Winchester die.

These water measurements indicate that, for the military cases, the brass is thicker. This finding was not unanticipated, as the military brass weighs more, and the military specification calls for the “beefing up” of the area around the web for the purpose of providing an additional safety margin in case the cartridge is fired in an automatic weapon and the charge is ignited before the cartridge is completely in battery in said weapon.

This characteristic also has implications for hand loaders and other enthusiasts where pressure is concerned. More on that later

Regulating Bodies

The American Sporting Arms and Ammunition Manufacturers' Institute (commonly abbreviated as SAAMI and pronounced "Sammy") is an association of American firearms and ammunition manufacturers.

SAAMI publishes various industry standards related to the field, including fire code, ammunition and chamber specifications, and acceptable chamber pressure. SAAMI is an example of industry self regulations.

In the United States firearms and ammunition specifications are not overseen by the Consumer Product Safety Commission or any other branch of government. Firearms enthusiasts should be aware that only manufacturers that are members of SAAMI are bound by the Institute's guidelines. All other adherence to SAAMI specifications is strictly voluntary.

The European equivalent of SAAMI is the Commission Internationale Permanente pour l'Epreuve des Armes à Feu Portatives (Permanent International Commission for Testing Portable Firearms, commonly abbreviated as C.I.P. or CIP). CIP is funded and mandated by several governments that are part of the

European Union.

There are two other organizations that are germane to this discussion. They are the US Army and the North Atlantic Treaty Organization (NATO). Each has its own specifications and testing methodologies which are not influenced by commercial interests unless there is a very good reason.

Pressure

Despite working together, the two main industry standards organizations SAAMI and C.I.P. have assigned different standards for some cartridges. This leads to officially sanctioned conflicting differences between European and American ammunition and chamber dimensions and maximum allowed chamber

pressures.

Under SAAMI proof test procedures, for bottlenecked cases the center of the transducer is located .175" behind the shoulder of the case for large diameter (.250") transducers and .150" for small diameter (.194") transducers. For straight cases the center of the transducer is located one-half of the transducer

diameter plus .005" behind the base of the seated bullet. Small transducers are used when the case diameter at the point of measurement is less than .35".

Under C.I.P. proof test standards a drilled case is used and the piezo measuring device (transducer) will be positioned at a distance of 25 mm from the breech face when the length of the cartridge case permits that, including limits. When the length of the cartridge case is to short, pressure measurement will take place at a cartridge specific defined shorter distance from the breech face depending on the dimensions of the case. The difference in the location of the pressure measurement gives different results than the C.I.P. standard.

According to the official C.I.P guidelines the .308 Winchester (referred to as 7.62x51 by CIP) case can handle up to 415 MPa (60,190 psi) piezo pressure. In C.I.P. regulated countries every rifle cartridge combo has to be proofed at 125% of this maximum C.I.P. pressure to certify for sale to consumers.

The .308 Winchester and 7.62x51mm NATO cartridges are not identical and there are minor differences in their inner case dimensions, though SAAMI does not list either cartridge as unsafe in a firearm designed for use with the other. [http://www.saami.org/Unsafe_Combinations.cfm].

NATO EPVAT testing is one of the three recognized classes of procedures used in the world to control the safety and quality of firearms ammunition. EPVAT Testing is described in unclassified documents by NATO, more precisely by the AC/225 Army Armaments Group (NAAG). EPVAT is an abbreviation for "Electronic Pressure Velocity and Action Time". This is a comprehensive procedure for testing ammunition using state-of-the-art instruments and computers. The procedure itself is described in NATO document AC/225 (Com. III/SC.1)D/200.

Unlike the C.I.P. procedures aiming only at the user's safety, the NATO procedures for ammunition testing also includes comprehensive functional quality testing in relation with the intended use. That is, not only the soldier's safety is looked at, but also his capacity to incapacitate the enemy. As a result, for every ammunition order by NATO, a complete acceptance approval on both safety and functionality is performed by both NATO and the relevant ammunition manufacturers in a contradictory fashion. For this, a highly accurate and indisputable protocol has been defined by NATO experts using a system

of reference cartridges.

The civilian organizations C.I.P. and SAAMI use less comprehensive test procedures than NATO, but NATO test centers have the advantage that only a few chamberings are in military use. The C.I.P. and SAAMI proof houses must be capable of testing hundreds of different chamberings requiring lots of different test barrels, etc..[7.62 mm. STANAG 2310 and NATO Manual of Proof and Inspection AC/225 (LG/3-SG/1) D/9.]

The US Army continues to use (as of 1995) the M-11 Copper Crusher device for pressure measurements of small arms ammunition. The M-11 was enhanced, when in 1982, it was noted that the results generated at the high end of the test range did not meet NATO standards. [Defense Technical Information Center, ARMY BALLISTIC RESEARCH LAB/APD, Accession Number : ADP000024]

What is interesting to note is that around the time of the engineering change to the M-11 Copper Crusher device, the US Army changed the units of measurement for the device from PSI to Copper Units of Pressure, or CUP. Both SAAMI and CIP used the copper crusher method until the advent of inexpensive, reliable piezoelectric strain gauges, at which point, both organizations converted their methodologies to

take advantage of the newer technology.

The copper crusher method was the standard for small arms pressure measurements since the late 1800s. A copper pellet just like a small watch battery in placed in the test pressure chamber which is attached to the cartridge chamber, the test round is fired and the copper pellet is then measured with a micrometer. The micrometer measurement is then converted into a PSI reading by using a chart that converts the length of the pellet into a pressure reading. The charts are constructed using the theoretical modulus of compression for the particular copper alloy used in the pellet, and may or may not have any relation to the actual absolute pressure. BUT, the results of the copper crusher method are always relative to previous results, which allows for determining what is safe and what is not.

Both SAAMI and the CIP have detailed specifications for the arrangement and dimensions of the copper crusher. Because these two systems are not identical, the two crusher standards cannot always agree. Further, as explained above, CIP crusher ratings are generally a bit higher than SAAMI's due to differences in definitions. Also, SAAMI is generally more conservative with older military rounds, such as the 8mm Mauser.

With the SAAMI methodology, the piston is positioned over the brass case, and the case will rupture somewhere below 20,000 PSI. The resulting sudden jump in pressure under the piston magnifies problems with piston inertia, and this makes the reading more sensitive to parameters such as burning rate, case strength, and true peak pressure. The CIP methodology requires the piston case be drilled at the sensor location, and the benefit is that crusher and piezoelectric ratios are much more consistent from cartridge to cartridge, allowing them to reasonably use a conversion formula.

Pressure Confusion

However, neither method addresses the figure “50,000 PSI” that is so often misquoted, especially by “expert” sources such as 6mmbr.com and surplusrifle.com.

This figure comes from the US Army in various technical manuals, most notably, TM-D001-27

Copyright © 2008, Cross Connect Corp. All rights reserved Page 6. The real problem is the confusion between the old and the new methods of pressure testing. The old pressure testing method used for the 7.62 NATO cartridge started out life in the 1950s and is still published today in the US Army Technical Manuals. The figures are based on the copper crusher method in CUP, but are published as PSI.

The new method is the piezoelectric strain gauge transducer method; it is the same technology used today to show an automobile’s oil pressure. The piezoelectric strain gauge transducer pressure method is a direct pressure reading based on an absolute standard, where the older copper crusher method a conversion based on a relative measure and a conversion chart. And this is why you see the difference in the pressure readings, but the older 52,000 CUP is equal to 62,000 PSI (piezoelectric transducer method).

Today, these two methods are called CUP and PSI and the readings are different, but 52,000 CUP equals 62,000 PSI and both are the same pressure, similar to the way 60 MPH equals 100 KPH.

To add even more confusion about the Ishapore 2A1, which started me on this article, many shooters want to use the headspace specifications set by NATO, which is different from what the Indian Army set for the Ishapore rifles.

In the figure below, you can actually see a page from an older reloading manual in which equivalent loads are portrayed in both CUP (C) and piezoelectric transducer PSI (P). Copyright © 2008, Cross Connect Corp. All rights reserved Page 7

Karl Kleimenhagen points out:

In Denton Bramwell's article [http://www.shootingsoftware.com/ftp/psicuparticle2.pdf], a formula is derived using a basic statistical analysis of SAAMI's ratings, covering only pressures between 28,000 and 54,000 CUP : piezo = 1.52 * crusher - 18

He also demonstrates that within this pressure range, the CIP appears to have generally used a simple conversion between their crusher and piezo ratings, roughly equal to: piezo = 1.21 * crusher - 2.8

CIP pressures are multiples of 50 bar (about 700 psi), probably rounded after the conversion. (Please note that CIP crusher readings should not be equated with SAAMI CUP crusher readings.)

In the 09/1968 issue of Handloader, Lloyd Brownell presents test data (crusher, but not necessarily CUP) which suggests a linear conversion formula is not the best choice, and in my Powley Computer I use:

piezo = crusher * ( 1 + ( crusher^2.2 )/30000 ) From 0 to about 60 ksi crusher, it fits both SAAMI's ratings and Brownell's data well, but it is low at the high end of Brownell's data. Brownell's data shows little to no error below 20 ksi, and a curve fit to only his data between 20 and 67 ksi crusher is: piezo = crusher + ( (crusher - 20) ^ 2.3 ) / 210

Conclusions

The pressure difference between the two rounds is insignificant, the real problem is commercial ammunition has thinner cases that were not designed to shoot in military chambers BUT we do it all the time anyway and this why you see more case head separations on commercial cases fired in military chambers.

The M118 special long range round is loaded to 52,000 CUP (all other U.S. 7.62mm are 50,000 CUP) which would be equal to the pressure levels of commercial ammunition, this means actually there is no pressure difference between the .308 and 7.62 NATO for the M118 cartridge.

No accurate conversion between copper crusher and true pressure exists, but approximations can be made. In all the conversions outlined above, pressures are in thousands of PSI (KPSI). Expect errors of several KPSI, or about 15%, with such formulas. Many factors determine how much the indicated pressure reading from a crusher misses the true pressure, and the error varies among cartridges and even among different loads for one cartridge. The conversions might be accurate enough for many practical purposes.

So, to sum everything up, the pressure difference between the 308 Winchester and the 7.62x51mm NATO is less than 2,000 PSI which is statistically insignificant. The same pressure variation may be achieved by firing any rifle on a hot day and on a cold day or by changing brands of primers. It is safe to shoot 308 Winchester in your 7.62x51 rifles (even the Ishapores) and vice versa. Handloaders should be aware that they should reduce the amount of powder when using military 7.62 NATO cases by about 10- 12% and work up to safe pressures with corresponding velocities.

References:

[1] ANSI/SAAMI document Z299.4-1992 is the principle source for the SAAMI crusher and piezoelectric

ratings listed here. The ratings listed are the "maximum average pressure". The book they offer is dated

and doesn't include the ratings of newer commercial cartridges. The procedures and definitions should be

current.

[2] The CIP documents are available on their site, and these were the reference for CIP procedures,

definitions, and piezoelectric ratings. In these, past standards for crusher ratings are no longer listed.

Instead, they refer you to past editions when proofing for a cartridge for which no current standard exists.

[3] The Soapbox of Karl W. Kleimenhagen (Karl's Soapbox)

[4] Accurate Reloading Guide -

http://www.accuratepowder.com/data/...le/Standarddata(Rifle)/308Cal(7.82mm)/308%

20Winchester%20Pages%20260%20to%20262.pdf

Copyright © 2008, Cross Connect Corp. All rights reserved Page 1

The Truth About 7.62x51mm NATO and 308 Winchester

By FALPhil

Introduction

The internet firearms and shooting culture is a relatively close knit group and very computer savvy, as hobby groups go. Many of the community are members of the several dozen discussion groups that revolve around the special interests of gun owners. Because of the nature of the internet and the inherent tendency of human beings towards believing anything that sounds reasonable, without applying critical thinking skills (probably a result of trends in government school systems – but that is another treatise), there is much misinformation available to the casual gun enthusiast about a variety of subjects concerning firearms.

One of the most pernicious of these “urban legends” is that there is a significant difference in the pressures between the 7.62x51mm NATO cartridge and the 308 Winchester cartridge. The misinformation indicates that using the commercial offering in a military weapon will visit death and destruction of biblical proportions upon the miscreant who would attempt such a thing.

I first ran into this ugly rumor in 1996, while participating on the rec.guns usenet forum. It made for interesting reading. At one point, a well-known Highpower Match competitor, who will remain unnamed, asked the question, “Why would you expect significant differences in pressure when commercial and

military cartridges are loaded with the same technology (powders, primers, cases, and projectiles) and the velocities are very close to each other?” This issue reared its ugly head a couple of years ago when the many boatloads of Ishapore 2A1 rifles hit the US shores. Much disinformation about what was safe in these fine rifles was bandied about over the internet.

That got me to thinking. My brother had been a lab technician at Aberdeen Proving Grounds in the late ‘70s, so I called him to ask him about it. It turns out that he worked on artillery dispersal, but he still knew some technicians involved in small arms research. He said he would reach out to them and get back to

me with some information.

About a month later, my brother called and described to me the method (in general terms) by which small arms ammunition is tested by the US Army. After speaking to him, I came to my own conclusion that 308 Winchester and 7.62 NATO were completely interchangeable. However, I am an unknown to many firearms enthusiasts. So, in order to support my position, I have performed a little research and documented my findings.

The Cartridges

The .308 Winchester is a rifle round and is the commercial version of the military 7.62x51mm NATO centerfire cartridge. The .308 Winchester was introduced in 1952, two years prior to the NATO adoption of the 7.62x51mm NATO or T65 round as it was known during testing. Winchester (a subsidiary of Olin Corporation) branded the cartridge and introduced it to the commercial hunting market as the 308 Winchester. Winchester's Model 70 and Model 88 rifles were subsequently chambered for the new cartridge. Since then, the .308 Winchester has become one of the most popular short-action big-game hunting cartridges in the world. It is also commonly used for civilian target shooting, military sniping, and police sharpshooting.

The purpose of the T65 was to achieve the same or similar performance of the then-standard 30-06 cartridge in a package that was more conducive to reliability in fully automatic weapons and infantry weapons under extreme conditions. A weight savings was a by-product of the project, but it was not a

primary consideration.

While Winchester intended the T65 (later named 7.62x51mm NATO) and 308 Winchester ammunition to be identical and fully interchangeable, there are some differences. The two primary differences are the specification of chambers size between the two, and the construction or the cartridge case.

Chamber Size

Look at the table below. The right column represents a military headspace gauge specification; the left one, the SAAMI specification. With many military rifles, the chambers can be significantly longer than say, a Remington 700. Note that the military chamber would fail a NO GO check with a SAAMI gauge, but

pass a FIELD check using the proper military gauges.

There is a .013" difference in acceptability, between these two specifications. This is significant in that, for reloading purposes, brass will stretch more in a military chamber upon firing, thereby reducing the life of the brass and possibly promoting case head separation. But that additional length will allow a round to chamber in an incredibly dirty weapon, which is a requirement for military applications.

308 Winchester (SAAMI) Headspace

GO - 1.6300"

NOGO - 1.6340"

FIELD - 1.6380"

7.62 NATO (Military) Headspace

GO - 1.6350"

NOGO - 1.6405"

FIELD - 1.6455"

However, it must be noted that this is the chamber specification and not the ammunition specification. The external dimensions of the two types of ammunition are nearly identical Cartridge Case Construction.

In my personal experiments, I have found, on average, that commercial 308 Winchester cases are able to contain approximately 58 grains of water, on average. The average for Lake City 92 cases, according to my measurements approached very close to 56.2 grains of water, and for Portuguese NATO markedcases which are Berdan primed, the average was close to 55.9. All brass had been fired once was sized with the same die, a Hornady New Dimension 308 Winchester die.

These water measurements indicate that, for the military cases, the brass is thicker. This finding was not unanticipated, as the military brass weighs more, and the military specification calls for the “beefing up” of the area around the web for the purpose of providing an additional safety margin in case the cartridge is fired in an automatic weapon and the charge is ignited before the cartridge is completely in battery in said weapon.

This characteristic also has implications for hand loaders and other enthusiasts where pressure is concerned. More on that later

Regulating Bodies

The American Sporting Arms and Ammunition Manufacturers' Institute (commonly abbreviated as SAAMI and pronounced "Sammy") is an association of American firearms and ammunition manufacturers.

SAAMI publishes various industry standards related to the field, including fire code, ammunition and chamber specifications, and acceptable chamber pressure. SAAMI is an example of industry self regulations.

In the United States firearms and ammunition specifications are not overseen by the Consumer Product Safety Commission or any other branch of government. Firearms enthusiasts should be aware that only manufacturers that are members of SAAMI are bound by the Institute's guidelines. All other adherence to SAAMI specifications is strictly voluntary.

The European equivalent of SAAMI is the Commission Internationale Permanente pour l'Epreuve des Armes à Feu Portatives (Permanent International Commission for Testing Portable Firearms, commonly abbreviated as C.I.P. or CIP). CIP is funded and mandated by several governments that are part of the

European Union.

There are two other organizations that are germane to this discussion. They are the US Army and the North Atlantic Treaty Organization (NATO). Each has its own specifications and testing methodologies which are not influenced by commercial interests unless there is a very good reason.

Pressure

Despite working together, the two main industry standards organizations SAAMI and C.I.P. have assigned different standards for some cartridges. This leads to officially sanctioned conflicting differences between European and American ammunition and chamber dimensions and maximum allowed chamber

pressures.

Under SAAMI proof test procedures, for bottlenecked cases the center of the transducer is located .175" behind the shoulder of the case for large diameter (.250") transducers and .150" for small diameter (.194") transducers. For straight cases the center of the transducer is located one-half of the transducer

diameter plus .005" behind the base of the seated bullet. Small transducers are used when the case diameter at the point of measurement is less than .35".

Under C.I.P. proof test standards a drilled case is used and the piezo measuring device (transducer) will be positioned at a distance of 25 mm from the breech face when the length of the cartridge case permits that, including limits. When the length of the cartridge case is to short, pressure measurement will take place at a cartridge specific defined shorter distance from the breech face depending on the dimensions of the case. The difference in the location of the pressure measurement gives different results than the C.I.P. standard.

According to the official C.I.P guidelines the .308 Winchester (referred to as 7.62x51 by CIP) case can handle up to 415 MPa (60,190 psi) piezo pressure. In C.I.P. regulated countries every rifle cartridge combo has to be proofed at 125% of this maximum C.I.P. pressure to certify for sale to consumers.

The .308 Winchester and 7.62x51mm NATO cartridges are not identical and there are minor differences in their inner case dimensions, though SAAMI does not list either cartridge as unsafe in a firearm designed for use with the other. [http://www.saami.org/Unsafe_Combinations.cfm].

NATO EPVAT testing is one of the three recognized classes of procedures used in the world to control the safety and quality of firearms ammunition. EPVAT Testing is described in unclassified documents by NATO, more precisely by the AC/225 Army Armaments Group (NAAG). EPVAT is an abbreviation for "Electronic Pressure Velocity and Action Time". This is a comprehensive procedure for testing ammunition using state-of-the-art instruments and computers. The procedure itself is described in NATO document AC/225 (Com. III/SC.1)D/200.

Unlike the C.I.P. procedures aiming only at the user's safety, the NATO procedures for ammunition testing also includes comprehensive functional quality testing in relation with the intended use. That is, not only the soldier's safety is looked at, but also his capacity to incapacitate the enemy. As a result, for every ammunition order by NATO, a complete acceptance approval on both safety and functionality is performed by both NATO and the relevant ammunition manufacturers in a contradictory fashion. For this, a highly accurate and indisputable protocol has been defined by NATO experts using a system

of reference cartridges.

The civilian organizations C.I.P. and SAAMI use less comprehensive test procedures than NATO, but NATO test centers have the advantage that only a few chamberings are in military use. The C.I.P. and SAAMI proof houses must be capable of testing hundreds of different chamberings requiring lots of different test barrels, etc..[7.62 mm. STANAG 2310 and NATO Manual of Proof and Inspection AC/225 (LG/3-SG/1) D/9.]

The US Army continues to use (as of 1995) the M-11 Copper Crusher device for pressure measurements of small arms ammunition. The M-11 was enhanced, when in 1982, it was noted that the results generated at the high end of the test range did not meet NATO standards. [Defense Technical Information Center, ARMY BALLISTIC RESEARCH LAB/APD, Accession Number : ADP000024]

What is interesting to note is that around the time of the engineering change to the M-11 Copper Crusher device, the US Army changed the units of measurement for the device from PSI to Copper Units of Pressure, or CUP. Both SAAMI and CIP used the copper crusher method until the advent of inexpensive, reliable piezoelectric strain gauges, at which point, both organizations converted their methodologies to

take advantage of the newer technology.

The copper crusher method was the standard for small arms pressure measurements since the late 1800s. A copper pellet just like a small watch battery in placed in the test pressure chamber which is attached to the cartridge chamber, the test round is fired and the copper pellet is then measured with a micrometer. The micrometer measurement is then converted into a PSI reading by using a chart that converts the length of the pellet into a pressure reading. The charts are constructed using the theoretical modulus of compression for the particular copper alloy used in the pellet, and may or may not have any relation to the actual absolute pressure. BUT, the results of the copper crusher method are always relative to previous results, which allows for determining what is safe and what is not.

Both SAAMI and the CIP have detailed specifications for the arrangement and dimensions of the copper crusher. Because these two systems are not identical, the two crusher standards cannot always agree. Further, as explained above, CIP crusher ratings are generally a bit higher than SAAMI's due to differences in definitions. Also, SAAMI is generally more conservative with older military rounds, such as the 8mm Mauser.

With the SAAMI methodology, the piston is positioned over the brass case, and the case will rupture somewhere below 20,000 PSI. The resulting sudden jump in pressure under the piston magnifies problems with piston inertia, and this makes the reading more sensitive to parameters such as burning rate, case strength, and true peak pressure. The CIP methodology requires the piston case be drilled at the sensor location, and the benefit is that crusher and piezoelectric ratios are much more consistent from cartridge to cartridge, allowing them to reasonably use a conversion formula.

Pressure Confusion

However, neither method addresses the figure “50,000 PSI” that is so often misquoted, especially by “expert” sources such as 6mmbr.com and surplusrifle.com.

This figure comes from the US Army in various technical manuals, most notably, TM-D001-27

Copyright © 2008, Cross Connect Corp. All rights reserved Page 6. The real problem is the confusion between the old and the new methods of pressure testing. The old pressure testing method used for the 7.62 NATO cartridge started out life in the 1950s and is still published today in the US Army Technical Manuals. The figures are based on the copper crusher method in CUP, but are published as PSI.

The new method is the piezoelectric strain gauge transducer method; it is the same technology used today to show an automobile’s oil pressure. The piezoelectric strain gauge transducer pressure method is a direct pressure reading based on an absolute standard, where the older copper crusher method a conversion based on a relative measure and a conversion chart. And this is why you see the difference in the pressure readings, but the older 52,000 CUP is equal to 62,000 PSI (piezoelectric transducer method).

Today, these two methods are called CUP and PSI and the readings are different, but 52,000 CUP equals 62,000 PSI and both are the same pressure, similar to the way 60 MPH equals 100 KPH.

To add even more confusion about the Ishapore 2A1, which started me on this article, many shooters want to use the headspace specifications set by NATO, which is different from what the Indian Army set for the Ishapore rifles.

In the figure below, you can actually see a page from an older reloading manual in which equivalent loads are portrayed in both CUP (C) and piezoelectric transducer PSI (P). Copyright © 2008, Cross Connect Corp. All rights reserved Page 7

Karl Kleimenhagen points out:

In Denton Bramwell's article [http://www.shootingsoftware.com/ftp/psicuparticle2.pdf], a formula is derived using a basic statistical analysis of SAAMI's ratings, covering only pressures between 28,000 and 54,000 CUP : piezo = 1.52 * crusher - 18

He also demonstrates that within this pressure range, the CIP appears to have generally used a simple conversion between their crusher and piezo ratings, roughly equal to: piezo = 1.21 * crusher - 2.8

CIP pressures are multiples of 50 bar (about 700 psi), probably rounded after the conversion. (Please note that CIP crusher readings should not be equated with SAAMI CUP crusher readings.)

In the 09/1968 issue of Handloader, Lloyd Brownell presents test data (crusher, but not necessarily CUP) which suggests a linear conversion formula is not the best choice, and in my Powley Computer I use:

piezo = crusher * ( 1 + ( crusher^2.2 )/30000 ) From 0 to about 60 ksi crusher, it fits both SAAMI's ratings and Brownell's data well, but it is low at the high end of Brownell's data. Brownell's data shows little to no error below 20 ksi, and a curve fit to only his data between 20 and 67 ksi crusher is: piezo = crusher + ( (crusher - 20) ^ 2.3 ) / 210

Conclusions

The pressure difference between the two rounds is insignificant, the real problem is commercial ammunition has thinner cases that were not designed to shoot in military chambers BUT we do it all the time anyway and this why you see more case head separations on commercial cases fired in military chambers.

The M118 special long range round is loaded to 52,000 CUP (all other U.S. 7.62mm are 50,000 CUP) which would be equal to the pressure levels of commercial ammunition, this means actually there is no pressure difference between the .308 and 7.62 NATO for the M118 cartridge.

No accurate conversion between copper crusher and true pressure exists, but approximations can be made. In all the conversions outlined above, pressures are in thousands of PSI (KPSI). Expect errors of several KPSI, or about 15%, with such formulas. Many factors determine how much the indicated pressure reading from a crusher misses the true pressure, and the error varies among cartridges and even among different loads for one cartridge. The conversions might be accurate enough for many practical purposes.

So, to sum everything up, the pressure difference between the 308 Winchester and the 7.62x51mm NATO is less than 2,000 PSI which is statistically insignificant. The same pressure variation may be achieved by firing any rifle on a hot day and on a cold day or by changing brands of primers. It is safe to shoot 308 Winchester in your 7.62x51 rifles (even the Ishapores) and vice versa. Handloaders should be aware that they should reduce the amount of powder when using military 7.62 NATO cases by about 10- 12% and work up to safe pressures with corresponding velocities.

References:

[1] ANSI/SAAMI document Z299.4-1992 is the principle source for the SAAMI crusher and piezoelectric

ratings listed here. The ratings listed are the "maximum average pressure". The book they offer is dated

and doesn't include the ratings of newer commercial cartridges. The procedures and definitions should be

current.

[2] The CIP documents are available on their site, and these were the reference for CIP procedures,

definitions, and piezoelectric ratings. In these, past standards for crusher ratings are no longer listed.

Instead, they refer you to past editions when proofing for a cartridge for which no current standard exists.

[3] The Soapbox of Karl W. Kleimenhagen (Karl's Soapbox)

[4] Accurate Reloading Guide -

http://www.accuratepowder.com/data/...le/Standarddata(Rifle)/308Cal(7.82mm)/308%

20Winchester%20Pages%20260%20to%20262.pdf

I shot both both ways and never had a problem interchanging the two. SOme very tight chambers may have a slight issue though

Hmmm interesting thread. To the OP, I have used many different brands of 7.62 and 308 ammo in my Scar 17 and have never had an issue.

It depends on how over gassed you are. The more over gassed you are, the faster the groups will spread. It might take 10 rounds of rapid fire, it might take 20 rounds of rapid. I always said for gas guns, all groups will be 6" if you do 2 mag dumps (40 rounds) in less than a minute. Does not matter what ammo or how accurate your semi-auto rifle is, given enough rounds, the groups will spread.

Over gas can be a good thing in that it insures more reliability. I read stories where the Aussies ran their L1A1's (FALs) always ran their rifles on the highest setting. Bad about over gassing is the gun heats up faster.

So it's over-gassing that heats up the gun? Please explain then how this would affect a piston AR? (Here's a hint: it won't). The gas system bleeds off so little gas that it's miniscule for overall temperature, even in a DI gun.

Gradual group opening, It has nothing to do with over-gassing, it's the sheer heat generated from firing a projectile down the barrel. A bolt gun will do it just the same - in fact, it will do it moreso because all of the heat is trapped in the chamber and barrel, whereas an AR will bleed some of it off to areas that do not directly affect accuracy (i.e. the upper receiver, where it escapes out the magwell and ejection port).

I have fired many factory .308 rounds thru my 7.62 LMT with no issues and most likely never will have any issues with it OTHER than using high performance factory rounds with blown primers..... I guess the point I'm trying to make is...... I would never reload brass for my LMT with a datum shoulder bump of 1.624ish if the brass coming out of my rifle is around 1.632 +/- .001 ..... If brass coming out of my rifle is around 1.632, then my chamber is most likely a tad bit more than that = well over .010 difference with factory .308 ammo in my 7.62 chamber headspace and everyone that reloads would say this is not really that safe and should NOT be a practice followed when bumping back your shoulders when full length resizing for your AR..... With that said, it makes me more and more happy that I reload... Being able to purchase awesome lake city brass and being able to custom bump my shoulders back to about 1.628ish not only saves me money, but produces much much better accuracy results. It is just something for those that are completely new to reloading & the AR platform to think about. Thread has been interesting for damn sure. Thanks for everyone's input.

i guess the reason why i'm asking this open ended question, and yes i know this topic has been beaten like a dead horse on here before but i really would like to discuss this here and now, BUT....... i've been measuring some factory .308 ammo headspace and I've seen about an average of 1.625 headspace on brand spanking new factory ammo.... I even have a brand new box of hornady .308 factory ammo that was damn near all 1.624ish headspace.... Even my "nato" 7.62x51 american eagle designed for MIA all measures factory new at 1.626 headspace (which fires great out of my LMT by the way)...... now, if most of this factory .308 ammo is measuring around 1.625ish, some down to 1.624 as in the case of this brand new box of hornday ammo......... and my brass fired out of my LMT is around 1.631 to 1.632ish which is about normal IMO (which leads me to believe my 7.62x51 LMT's headspace is around 1.635ish after the brass springs back a little bit once ejected), then wouldn't that friggen make my headspace difference on this factory .308 ammo of 1.624 headspace damn near .011 difference!!!!? You would think I'd run into atleast some type of blown primers or case head seperation or something. That is the reason why I'm asking.

Hmmm interesting thread. To the OP, I have used many different brands of 7.62 and 308 ammo in my Scar 17 and have never had an issue.

Last edited:

So it's over-gassing that heats up the gun? Please explain then how this would affect a piston AR? (Here's a hint: it won't). The gas system bleeds off so little gas that it's miniscule for overall temperature, even in a DI gun.

Gradual group opening, It has nothing to do with over-gassing, it's the sheer heat generated from firing a projectile down the barrel. A bolt gun will do it just the same - in fact, it will do it moreso because all of the heat is trapped in the chamber and barrel, whereas an AR will bleed some of it off to areas that do not directly affect accuracy (i.e. the upper receiver, where it escapes out the magwell and ejection port).

Wrong. You need to shoot your guns and find out for yourself, quit listening to your gun smith.

An over gassed gun does heat up the gun faster, this will include the barrel. If you shoot bolt guns just as fast as AR's, the groups do not spread as much. For an LWRC or any other piston gun, they too heat the barrel faster because that gas block on piston gun gets dam hot, and that gas block is touches the barrel, the gas block on a piston gun is the hottest part of the gun.

Wrong. You need to shoot your guns and find out for yourself, quit listening to your gun smith.

An over gassed gun does heat up the gun faster, this will include the barrel. If you shoot bolt guns just as fast as AR's, the groups do not spread as much. For an LWRC or any other piston gun, they too heat the barrel faster because that gas block on piston gun gets dam hot, and that gas block is touches the barrel, the gas block on a piston gun is the hottest part of the gun.

What you've also failed to do is address barrel mass. Bolt actions tend to have heavier-profile, longer barrels. A longer, heavier-profile barrel has more mass and will therefore heat up slower than a shorter, thinner profile barrel. This is nothing inherent to bolt actions, it's simply that most AR's are set up as mobile combat platforms and therefore have barrels that accommodate such roles. Slap a 1" diameter, 24" long heavy barrel onto an AR and it'll take forever to expand it's grouping. This has nothing to do with the fact it's a gas gun.

Your argument that a piston AR expands groups because the gas block "gets damn hot" makes no sense logically because - guess what? If the gas block is "damn hot," so is the rest of the barrel. Having a gas block isn't going to trap extra heat. In fact, the extra mass will act as a heatsink and delay heating of the barrel, if anything.

Let's address functional use of the AR platform: since some of the gasses are still trapped in the barrel when the bolt unlocks, a decent amount of heat is released back into the receiver. This spreads the heat throughout the entire upper, not just the barrel as on a bolt action. This means that AR platforms have less heat transfer to the barrels than bolt action platforms. Doubt it? Watch a high speed IR video of both. The AR bleeds excess gas (and therefore heat) continually. A bolt action is forced to retain it due to the slower, manually-operated unlocking of the bold.

These tests have already been run on other forums (DI vs Piston chamber temperatures, bolt chambers vs AR chambers, etc.) using IR thermometers. Gas gun barrels run cooler. They introduce extra points of failure (such as a gas tube and other curiosities like gas port erosion), but they don't add extra heat to the barrel.

In fact, anyone with a piston AR and an adjustable gas block can prove this themselves. Fire a string of 30 shots and then measure the temperature of the upper receiver, barrel chamber, barrel midsection, and muzzle with a IR thermometer (they're $20 at Walmart). Let it cool for several hours, then fire another string of 30, this time with the gas block in the "OFF" position (you'll have to manually cycle each round). Measure the temperature in the same places and you'll find the barrel gets HOTTER in the "OFF" position. This is because all of the heat is forced to stay in the barrel until vented out the muzzle, instead of being able to escape out the chamber (and to a minor degree, out of the imperfect seal of the gas block).

Last edited:

However, most like who cares about super accurate AR's, when we are talking AR's, all rifles will be 3 MOA or more once you put a full 10 round mag through her no matter how quality your ammo is.

I disagree...

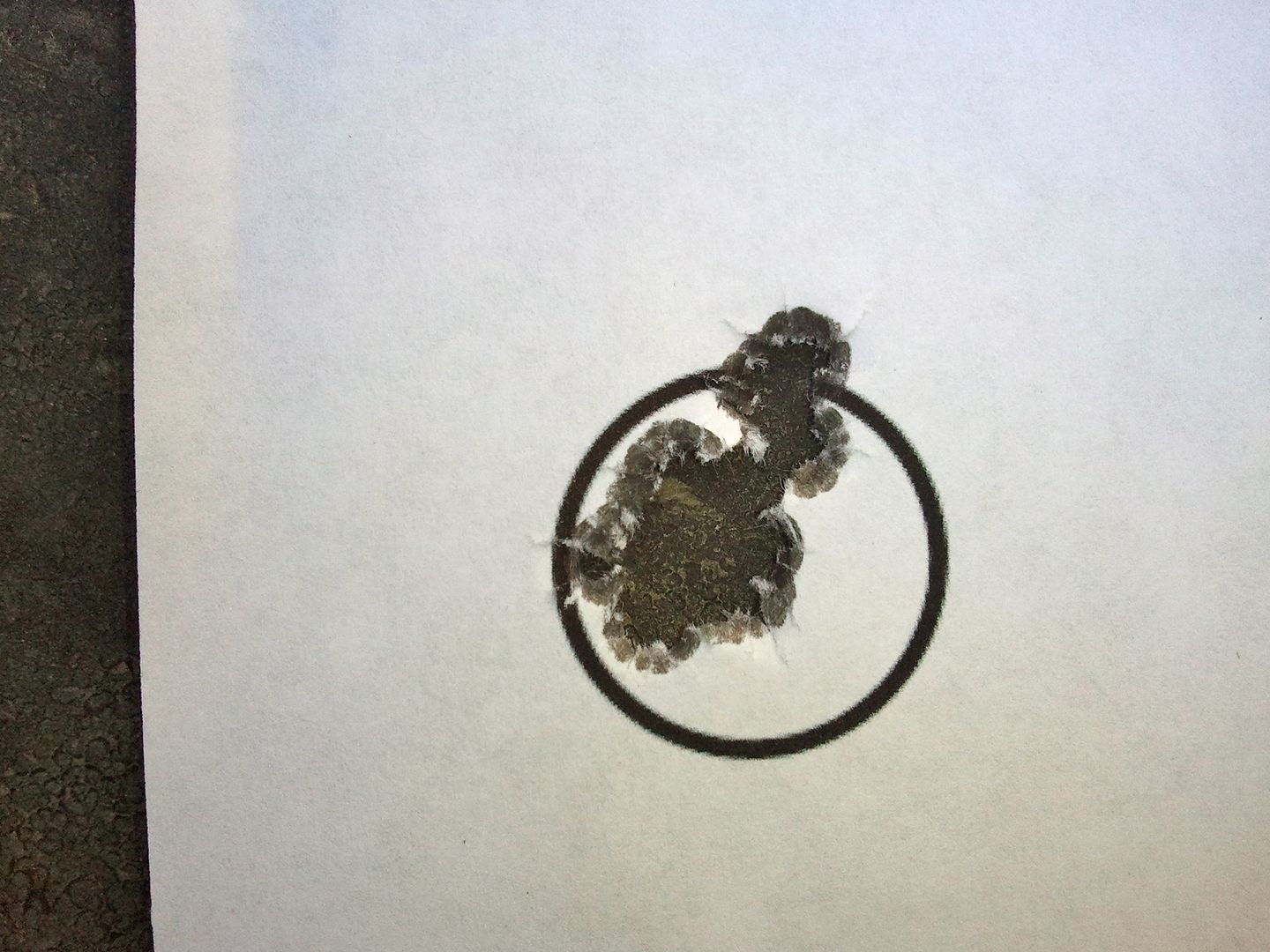

Here's a 10-round group at 100 yards from an AR:

Here's a 5-round group at 100 yards with different ammo shot after the 10-round group above using the same weapon:

It might take 10 rounds of rapid fire, it might take 20 rounds of rapid. I always said for gas guns, all groups will be 6" if you do 2 mag dumps (40 rounds) in less than a minute. Does not matter what ammo or how accurate your semi-auto rifle is, given enough rounds, the groups will spread.

I don't do "mag dumps" in my precision AR's, but often shoot dozens of rounds per session. I've never experienced groups opening to 3moa (from your first quote above), but I have seen groups open to 6" (from your second quote), although it happened on the 600-yard target.

I disagree...

Here's a 10-round group at 100 yards from an AR:

Here's a 5-round group at 100 yards with different ammo shot after the 10-round group above using the same weapon:

I don't do "mag dumps" in my precision AR's, but often shoot dozens of rounds per session. I've never experienced groups opening to 3moa (from your first quote above), but I have seen groups open to 6" (from your second quote), although it happened on the 600-yard target.

Nice Shootin!

My SASS gets similar groups with 5 and 10 rounds if I go about 20 seconds between shots. I have members here that witnessed it first hand. However, any faster and any more than 10, the groups will spread faster than Jenna Jameson on her third scene.

The reason we buy semi-auto is to unload rounds fast. If you are not rapid firing, why not just stick to a bolt gun?

What you've also failed to do is address barrel mass. Bolt actions tend to have heavier-profile, longer barrels. A longer, heavier-profile barrel has more mass and will therefore heat up slower than a shorter, thinner profile barrel. This is nothing inherent to bolt actions, it's simply that most AR's are set up as mobile combat platforms and therefore have barrels that accommodate such roles. Slap a 1" diameter, 24" long heavy barrel onto an AR and it'll take forever to expand it's grouping. This has nothing to do with the fact it's a gas gun.

Your argument that a piston AR expands groups because the gas block "gets damn hot" makes no sense logically because - guess what? If the gas block is "damn hot," so is the rest of the barrel. Having a gas block isn't going to trap extra heat. In fact, the extra mass will act as a heatsink and delay heating of the barrel, if anything.

Let's address functional use of the AR platform: since some of the gasses are still trapped in the barrel when the bolt unlocks, a decent amount of heat is released back into the receiver. This spreads the heat throughout the entire upper, not just the barrel as on a bolt action. This means that AR platforms have less heat transfer to the barrels than bolt action platforms. Doubt it? Watch a high speed IR video of both. The AR bleeds excess gas (and therefore heat) continually. A bolt action is forced to retain it due to the slower, manually-operated unlocking of the bold.

These tests have already been run on other forums (DI vs Piston chamber temperatures, bolt chambers vs AR chambers, etc.) using IR thermometers. Gas gun barrels run cooler. They introduce extra points of failure (such as a gas tube and other curiosities like gas port erosion), but they don't add extra heat to the barrel.

In fact, anyone with a piston AR and an adjustable gas block can prove this themselves. Fire a string of 30 shots and then measure the temperature of the upper receiver, barrel chamber, barrel midsection, and muzzle with a IR thermometer (they're $20 at Walmart). Let it cool for several hours, then fire another string of 30, this time with the gas block in the "OFF" position (you'll have to manually cycle each round). Measure the temperature in the same places and you'll find the barrel gets HOTTER in the "OFF" position. This is because all of the heat is forced to stay in the barrel until vented out the muzzle, instead of being able to escape out the chamber (and to a minor degree, out of the imperfect seal of the gas block).

I can see your point about the barrel. But both of my AR10s's now both have heavy profile barrels that is just as fat as my Bolt guns. Also just a little research and you will see I am not the only one that claims "spreading groups". Just a little search and you can find out M110s are known to have spreading groups.

My M1A has a lighter profile than my AR, and guess what? On a cold bore both gets about the same size groups, but after 10 rounds, the M1A will consistently hold the tighter groups (with the same load). Why is this? Maybe because the gun is not over gassed??? hmmmm

You seem to think the hot recycled gas has no part in the barrel heating up faster. Honestly, do you really think Hot recycled gas going back in the weapon has no effect whatsoever???

Please discuss...

Last edited:

I can see your point about the barrel. But both of my AR10s's now both have heavy profile barrels that is just as fat as my Bolt guns. Also just a little research and you will see I am not the only one that claims "spreading groups". Just a little search and you can find out M110s are known to have spreading groups.

My M1A has a lighter profile than my AR, and guess what? On a cold bore both gets about the same size groups, but after 10 rounds, the M1A will consistently hold the tighter groups (with the same load). Why is this? Maybe because the gun is not over gassed??? hmmmm

You seem to think the hot recycled gas has no part in the barrel heating up faster. Honestly, do you really think Hot recycled gas going back in the weapon has no effect whatsoever???

Please discuss...

You're comparing two different platforms entirely. Your M1A may very well be more accurate, it may simply have better accuracy than your AR-10, who knows? You can't compare the two and then jump to the conclusion that it's over-gassing that is causing the accuracy difference, especially when the only objective similarity between the two guns is that they are both gas guns shooting the same caliber. That's a logical fallacy.

Simply put, over-gassing simply means more gas is being vented out of the barrel before the bullet leaves the muzzle than is needed to reliably cycle the action of the rifle. Since it's the heating of the barrel that causes group size to expand, thermodynamics and logic tell us that it's not over-gassing because the gas contributes to heating the barrel, not the cooling of it.

Also, the "recycled" gas isn't really recycled in a DI rifle and it doesn't even come back near the chamber in a piston rifle. Most of the gas that actuates the piston in a piston rifle leaks out of the top of the gas block (which is why it typically needs to be cleaned after a range outing), so that is heat taken away from the system, not put back into it. In addition, the gas block itself serves as a heat sink (due to its mass) and will aid in slowing the heating of the barrel.

I'm not arguing that AR's don't open up, nor that they open up any more or less. My point is that it's not the over-gassing of the system. Again, you can try the test mentioned in my last post and run a string of rounds through the same piston AR, one in the "ON" position and another in the "OFF" and measure how much they open up. You can also measure the temperate of the barrel and chamber after each test and you'll find that the barrel is cooler in the "ON" position.

That said, my guess is that most AR's would tend to open (more than bolt actions, if that is indeed the case) due to the additional weight of the gas block and system and how it affects barrel harmonics, especially after the barrel starts heating.

Last edited:

You're comparing two different platforms entirely. Your M1A may very well be more accurate, it may simply have better accuracy than your AR-10, who knows? You can't compare the two and then jump to the conclusion that it's over-gassing that is causing the accuracy difference, especially when the only objective similarity between the two guns is that they are both gas guns shooting the same caliber. That's a logical fallacy.

It is not a logical fallacy that causes my M1A to hold tighter groups, it is the gas system. With my "Semi Auto Generic Full Sized 175smk loads" My AR10-SASS is slightly more accurate than my M1A under for the first 5 shots. After 5 shots, the groups for the M1A always stays tighter. I am convinced the M1A just stays cooler, hence the reason to tighter groups, the only logical conclusion is the gas system keeps it cooler.

It is not a logical fallacy that causes my M1A to hold tighter groups, it is the gas system. With my "Semi Auto Generic Full Sized 175smk loads" My AR10-SASS is slightly more accurate than my M1A under for the first 5 shots. After 5 shots, the groups for the M1A always stays tighter. I am convinced the M1A just stays cooler, hence the reason to tighter groups, the only logical conclusion is the gas system keeps it cooler.

Have you recorded the temperature of your M1A's chamber, barrel, and muzzle and then recorded the same temperatures on your AR10? Have you done it multiple times and gotten an average temperature reading? Have you recorded the percentage increase of shot grouping against a cold-bore shot grouping for your M1A, and then done the same for your AR-10? Have you ensured that both barrels have IDENTICAL twist rates (not advertised rates, but actually measured them down to 1/10")?

If you haven't done the above, or if any of the above items are not the same from rifle to rifle then you're simply making a wild assumption as you're not isolating the one factor you're claiming is contributing to the increase in group sizing: the gas system.

As I said, there's high-speed IR video validating my statements. There's also the simple test you can do - anyone can do - with a piston AR and an IR thermometer from Walmart. A gas gun with the gas-system in the "OFF" position runs hotter than one in the "ON" position. There's no debating it, unless you want to defy the laws of thermodynamics. Feel free to run the test for yourself.

Simply put, over-gassing simply means more gas is being vented out of the barrel before the bullet leaves the muzzle than is needed to reliably cycle the action of the rifle. Since it's the heating of the barrel that causes group size to expand, thermodynamics and logic tell us that it's not over-gassing because the gas contributes to heating the barrel, not the cooling of it.

What are you talking about when you mention Thermodynamics? I actually have a ME109, Thermodynamics, so I have something to reference.

This is wear I see you have no clue what is going on. "Over gassed" in gun terminology is not talking about the gas leaving the barrel, it is talking the gas being recycled in the system to get the gun to cycle. This excess gas causes the gun to get hotter... a hotter gun means a hotter barrel as well as inconsistencies in barrel harmonics.

Like I said, you seem to think an over gassed system has no effect on maintaining tight groups, I don't think there is nothing I can say to help you see the light. However, I am willing to still discuss this with you because I have nothing better to do, so... Please Discuss....

Have you recorded the temperature of your M1A's chamber, barrel, and muzzle and then recorded the same temperatures on your AR10? Have you done it multiple times and gotten an average temperature reading? Have you recorded the percentage increase of shot grouping against a cold-bore shot grouping for your M1A, and then done the same for your AR-10? Have you ensured that both barrels have IDENTICAL twist rates (not advertised rates, but actually measured them down to 1/10")?

If you haven't done the above, or if any of the above items are not the same from rifle to rifle then you're simply making a wild assumption as you're not isolating the one factor you're claiming is contributing to the increase in group sizing: the gas system.

As I said, there's high-speed IR video validating my statements. There's also the simple test you can do - anyone can do - with a piston AR and an IR thermometer from Walmart. A gas gun with the gas-system in the "OFF" position runs hotter than one in the "ON" position. There's no debating it, unless you want to defy the laws of thermodynamics. Feel free to run the test for yourself.

Why the hell would I do all that to come to the same conclusion?

Like I said, you seem to think an over gassed system has no effect on maintaining tight groups, I don't think there is nothing I can say to help you see the light. However, I am willing to still discuss this with you because I have nothing better to do, so... Please Discuss....

What are you talking about when you mention Thermodynamics? I actually have a ME109, Thermodynamics, so I have something to reference.

This is wear I see you have no clue what is going on. "Over gassed" in gun terminology is not talking about the gas leaving the barrel, it is talking the gas being recycled in the system to get the gun to cycle. This excess gas causes the gun to get hotter... a hotter gun means a hotter barrel as well as inconsistencies in barrel harmonics.

Like I said, you seem to think an over gassed system has no effect on maintaining tight groups, I don't think there is nothing I can say to help you see the light. However, I am willing to still discuss this with you because I have nothing better to do, so... Please Discuss....

I'm a flight instructor, among other things, so I very much understand (and am licensed to teach) thermodynamics (provided the ME109 you're referencing is a ME-109 warbird).

By thermodynamics, I'm referring the laws of thermodynamics, namely that matter (and therefore energy) can neither be created or destroyed. Comparing two gas systems, you can't bleed heated gas earlier out of a system A and have it heat that same system hotter than system B that keeps the same heated gas in it longer (in reference to the way the DI system works).

A piston rifle does not "recycle" gas into the system. Neither does a DI gun. The gas in a piston rifle stops at the gas block and either leaks out the top of the gas block or continues back down, out of the muzzle. There is no gas going anywhere back into the barrel after the action is cycled.

A DI rifle sends gas out of the gas tube, into the gas key on the BCG. Once the bolt is unlocked, that hot gas is vented out of the ejection port, down the magwell, and some of it is redirected towards the rear of the receiver (where it leaks out of the charging handle opening and the seams between the upper and lower receivers). The majority of the gas leaves the upper receiver before the bolt ever closes. The thing is, this is not "extra" gas - this is gas that was vented before the bullet left the muzzle end of the barrel. This results in a gas-operated rifle's barrel running cooler than a bolt actions, because the bolt action traps the gas in the barrel longer (a DI rifle allows it to leave the barrel earlier).