Ok, so I had an interesting load development session earlier this week and I don’t know what to make of it. I was specifically load testing my Lapua brass to find a good node for 175 SMKs and Varget. Some background: I have a Rem 700 SPS-T in a Manners T4A w/mini-chassis and S&B PMII optics. I had the “SPS accuracy package” done this past summer by SAC and it is absolutely a tack driver. But ever since the gun came back from SAC, my previous accurate loads using 175 SMK, 44.6 and 45.0 grs Varget in Lapua brass just never seem to shoot well. I was even getting some case head separation issues in my 9-10 x fired Lapua brass – but I traced that to incorrect FL die setup where I was over-bumping the shoulder. So I ordered another 200 pieces of virgin Lapua and decided to re-load develop from scratch since it was essentially a completely different chamber from the factory one. I’m up to 4 range trips on that brass now and I’m getting nowhere.

I do have a smoking good load for 168 AMAXs and 175 SMKs but in WIN brass. They shoot ½ MOA or under almost every time. This past week when I was load developing again for the lapua, brass – I had some of the good known WIN brass loads left over from a recent TAC match along on this range trip to use as a reference load, which I had never had on previous trips shooting the Lapua loads.

So for this trip, I loaded up 10 rounds each of:

175 SMK

Lapua brass (4x fired, freshly annealed)

Fed 210M

2.820 COAL

.337 Bushing, FL sized in Redding S-type Comp dies

Varget loads of:

44.6

44.7

44.8

44.9

45.0

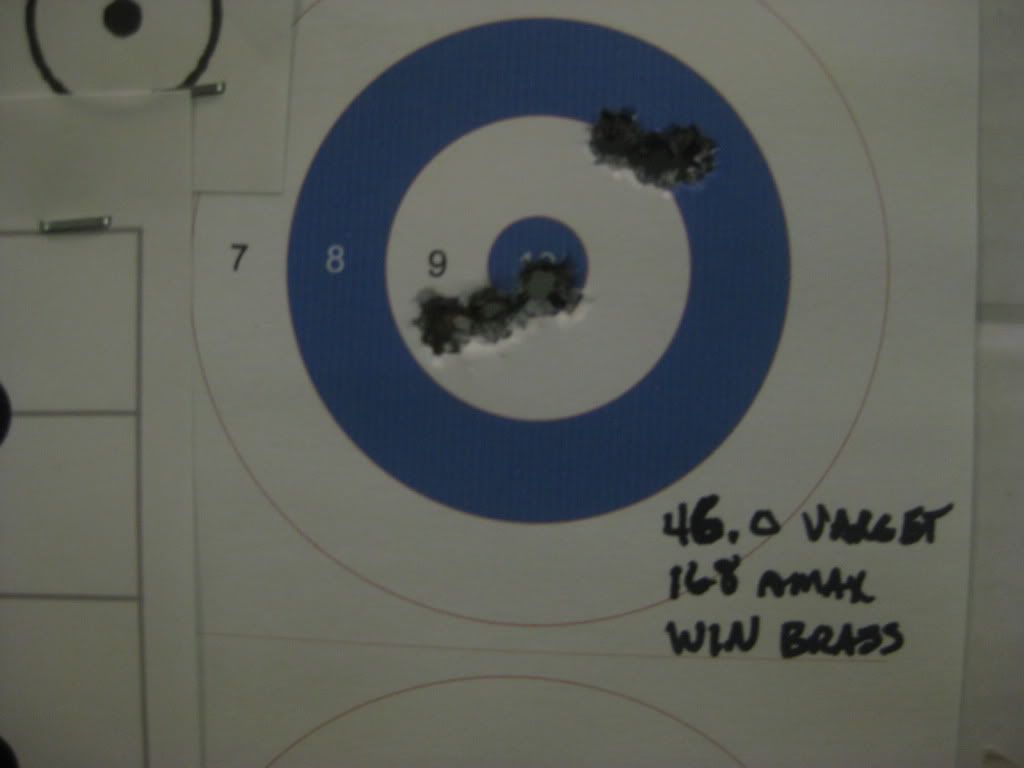

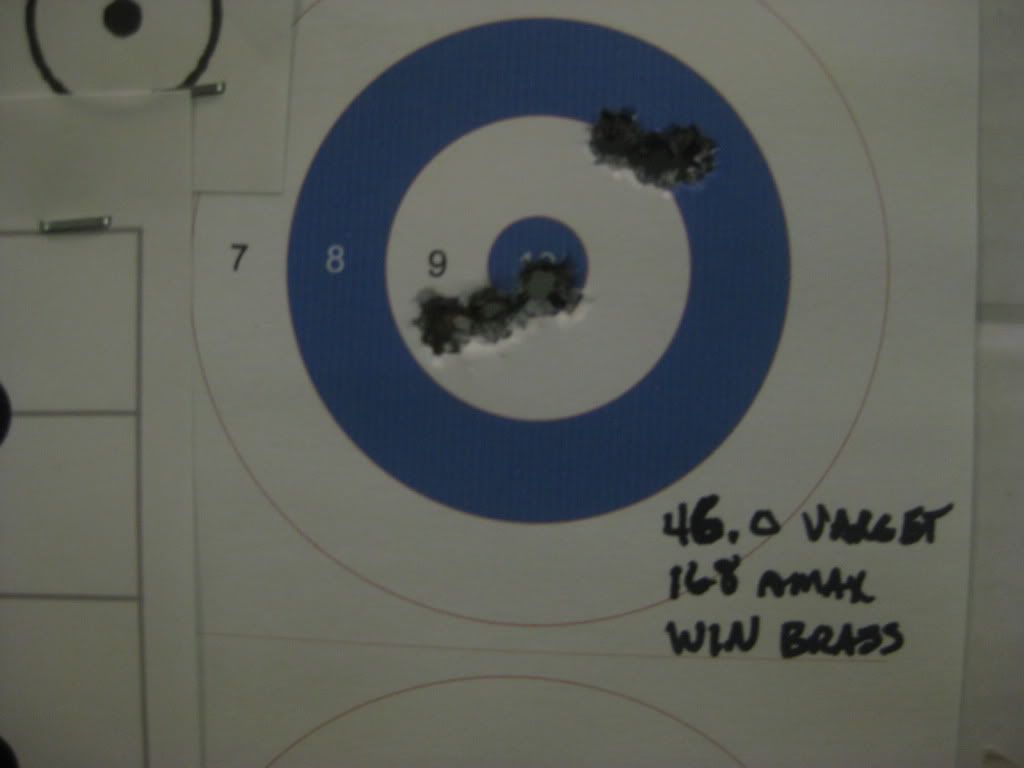

I was sure my node was going to be in there somewhere. So I started at 100 yds with my reference load of 168 AMAXs (46.0 Varget) in WIN brass to check zero. 1st three were a little high and right for about a .35" 3-shot group:

Moved the scope to adjust and shot another 5 with the same 168 AMAX/Win at the same target above, still under 1/2 MOA.. It was feeling like it was going to be a good day.

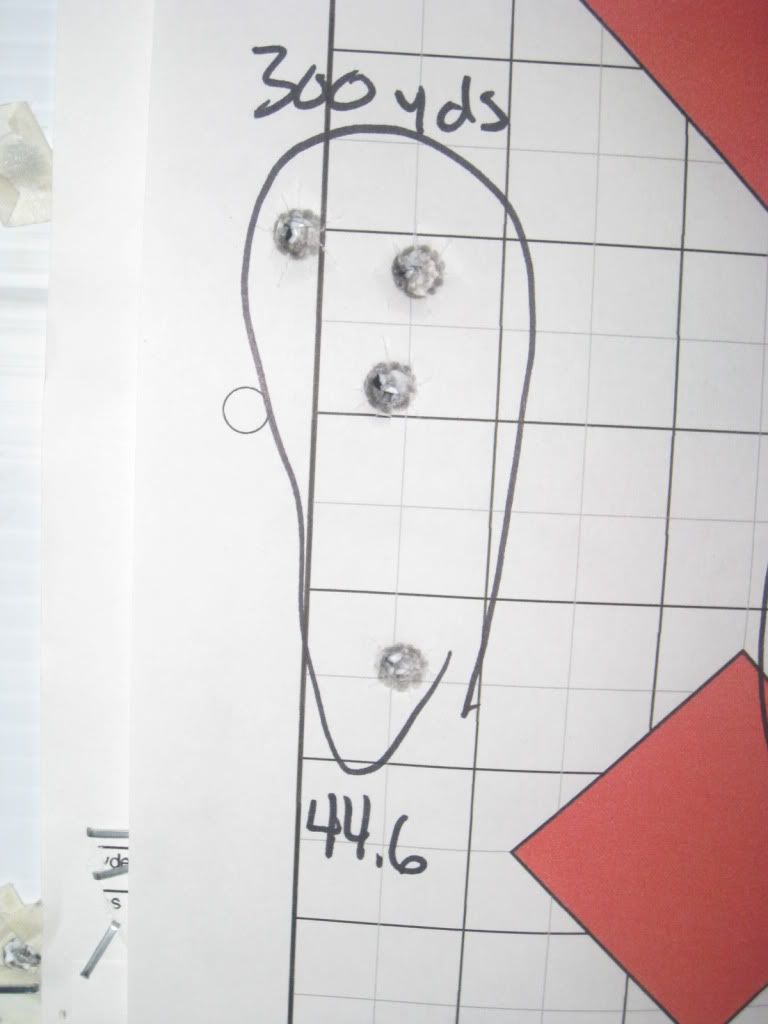

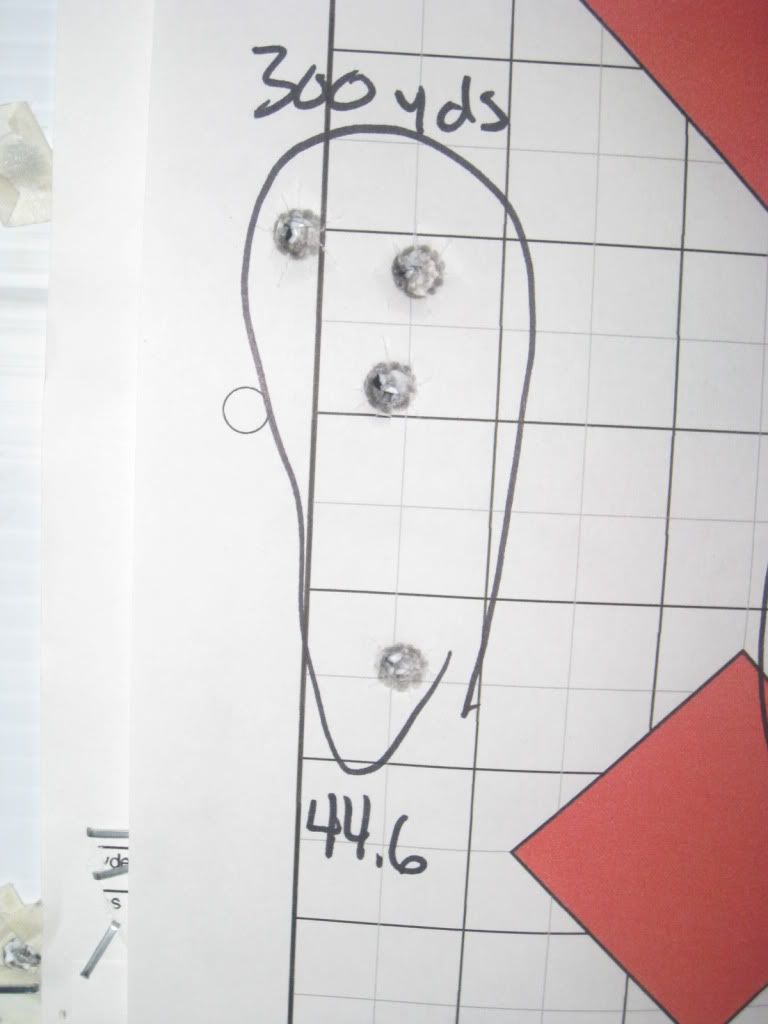

So then I moved out to 300 yds to start my load devel with the Lapua brass and say these results:

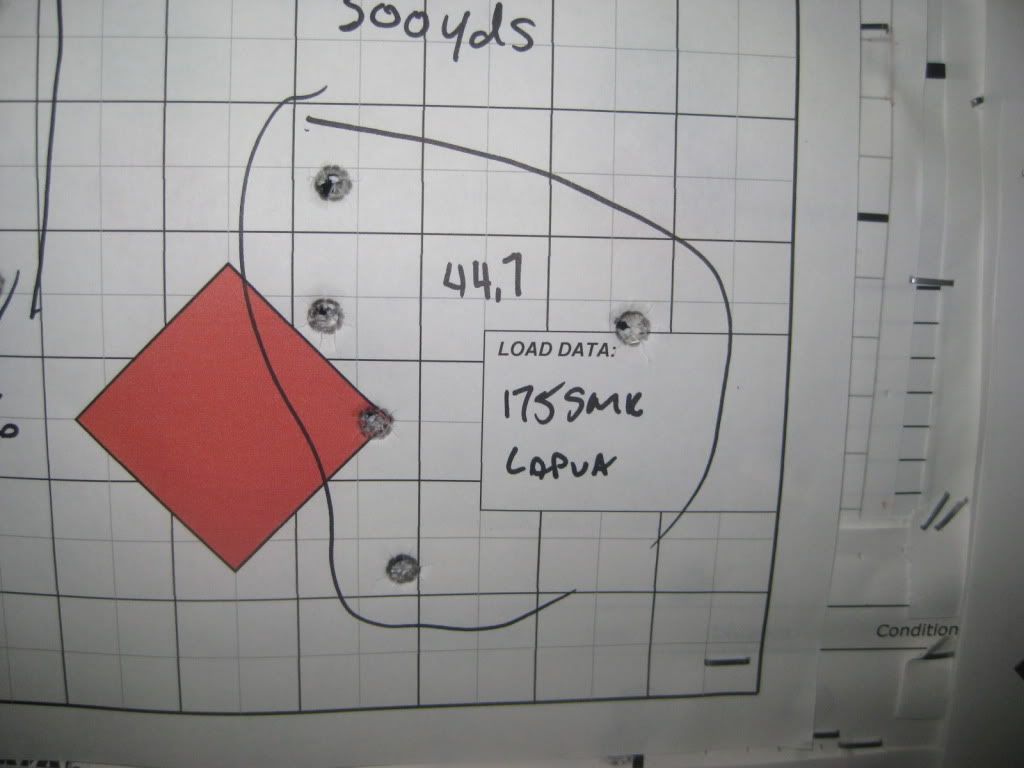

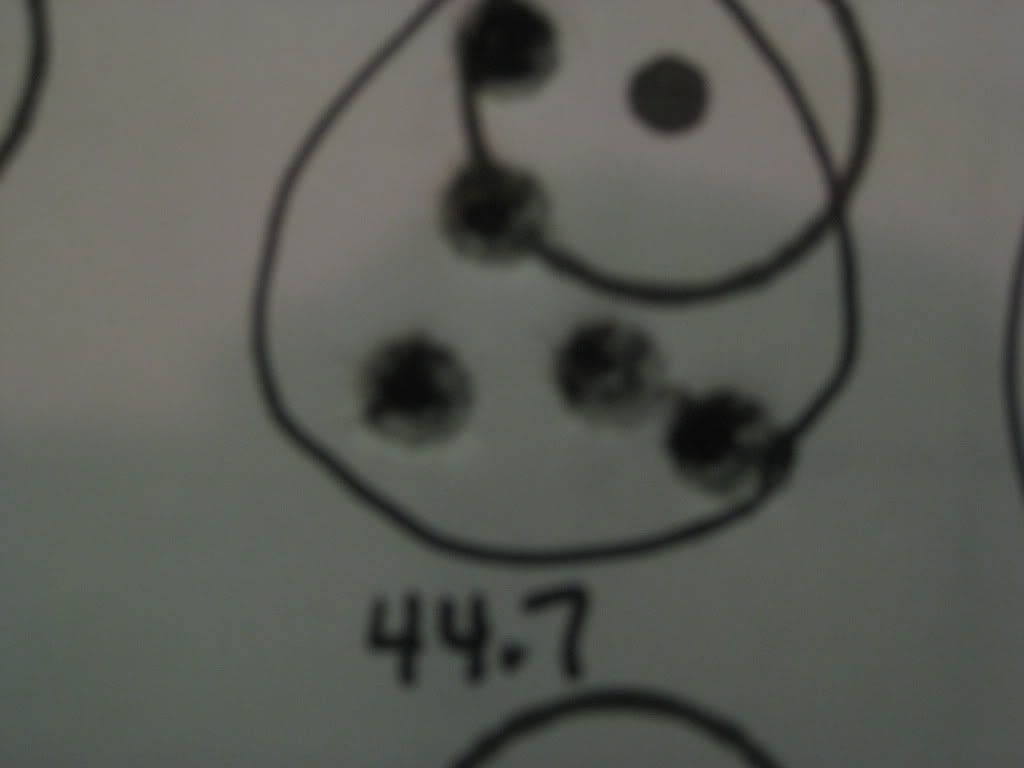

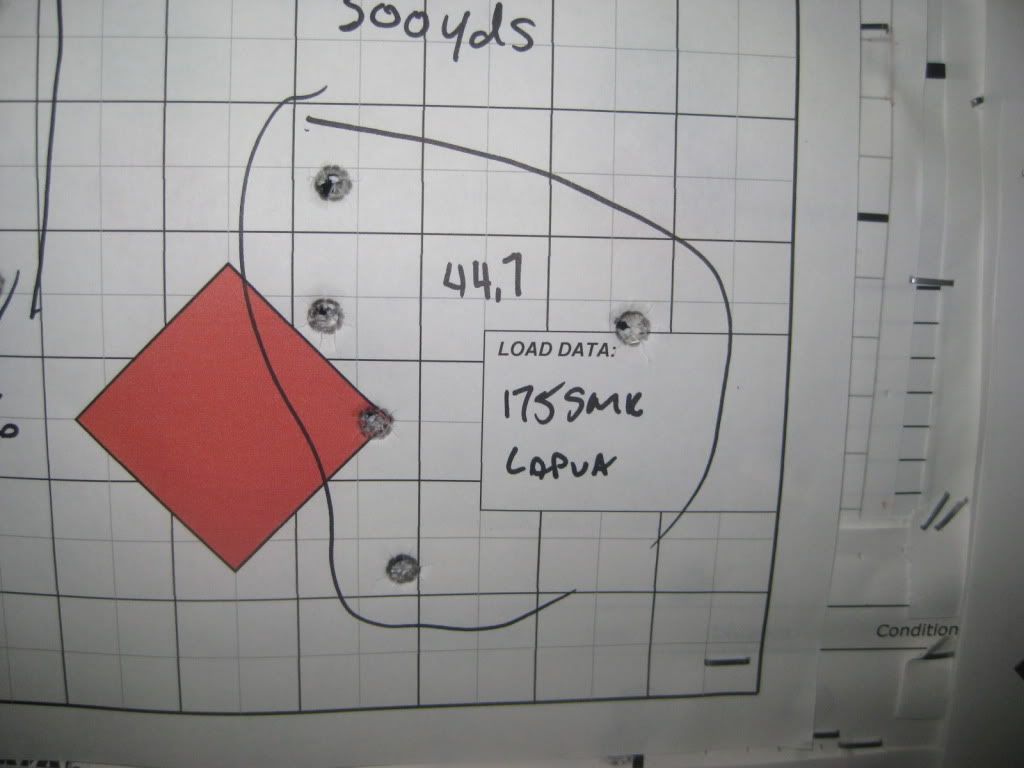

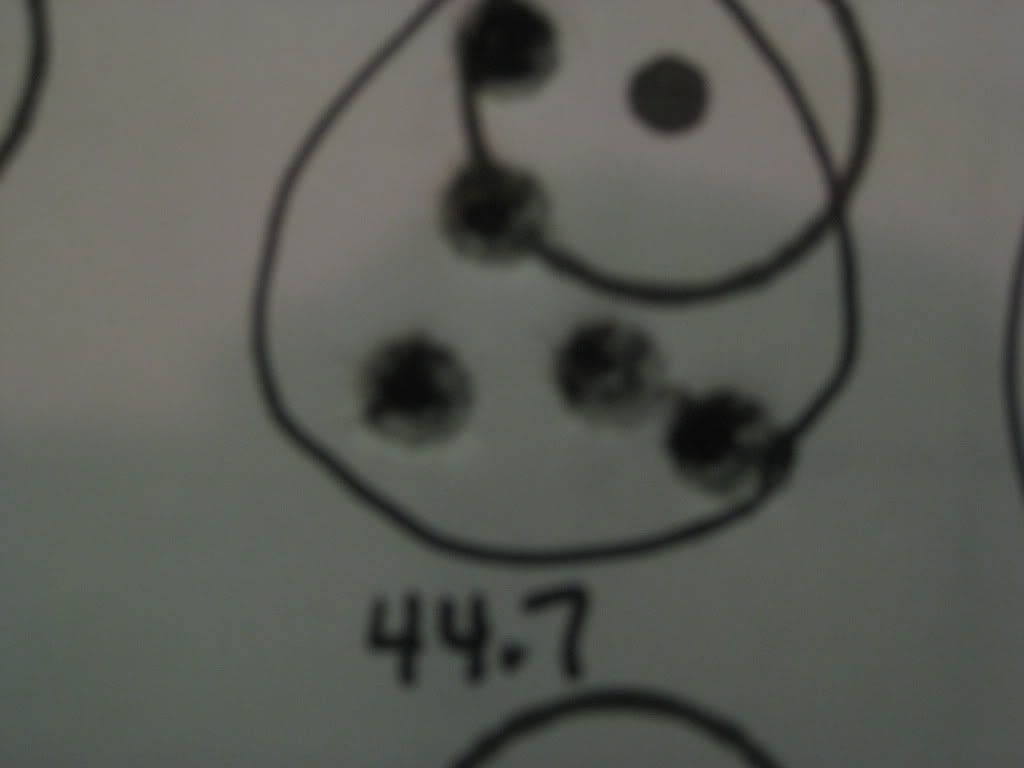

I didn’t bother shooting the 45.0 load at 300 because it was sucking so bad. The above are all greater than 1 MOA and close to 1.2. I didn’t think I was shooting that poorly, so I moved back to 100yds and had my mentor who is a MUCH better shooter than me shoot the rest of the loads over again at 100. Results are as follows:

The last pic was the 45.0 load, 3-shots each. That’s a 1 inch outer circle and I measured them all at right about 1.2" 5-shot groups.

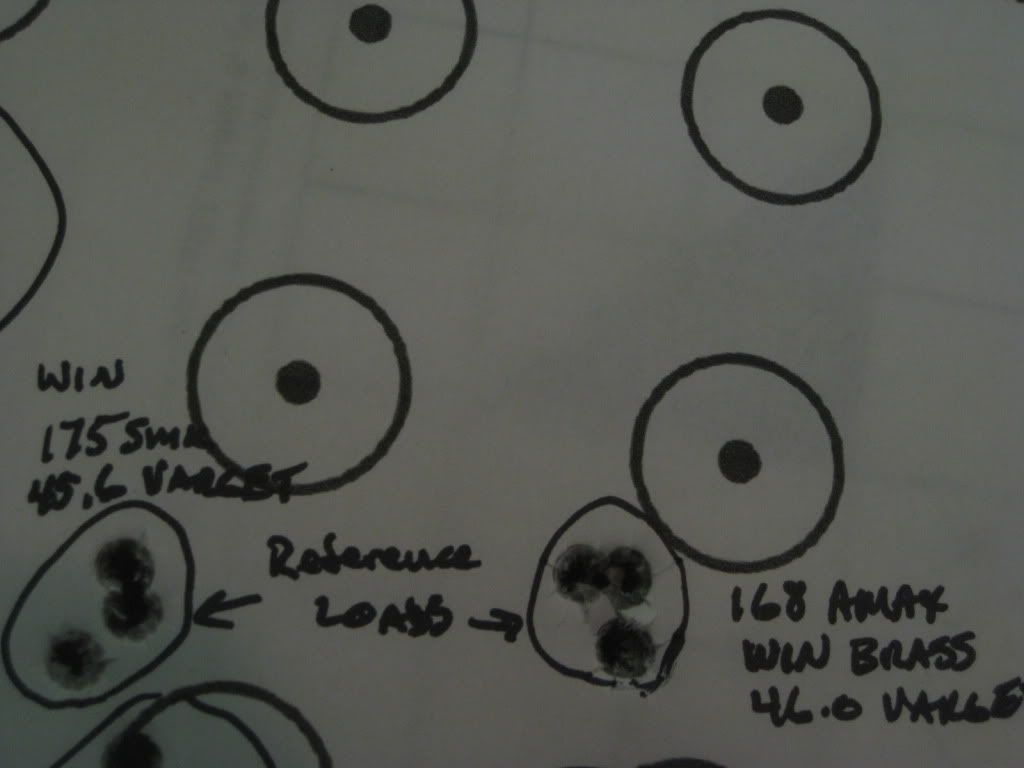

So I’m thinking holy frack, what has happened to my gun. So to test a theory – I shot the few remaining “reference Loads” in WIN brass I had left to see if they were also shooting poorly now. I had 3 left of my 168 AMAX load (46.0 Varget) and 175 SMK (45.6 Varget – both in WIN brass.

Both of those shot as expected – the 168 AMAX is .38” and the 175 SMK is .48”.

So….. I’m really at a loss as to why there is no node in there. I was NOT able to chrono these as my friends Ohler took a shit that day. But I had previously chrono’d the same strings and they were right in the 2600-2630 fps range (20” barrel), which is right where the 175 SMK load in Win brass is (2630fps). By the last couple of loads (44.8-45.0) I was just getting some pressure signs (ejector swipe). But no sticky bolt and no flattened primers at all. So maybe I can go up a little, or go down below 44.6 and try some more loads.

It’s not the end of the world, because I have two really great loads in WIN brass that shoot lights out. I just hate that I can’t get the Lapua brass to shoot worth a shit.

My next step is to weigh the Lapua brass and do the water measurement and run that data through QL and see where those loads fall on the OBT scale. Any other suggestions??? I’m frustrated

I do have a smoking good load for 168 AMAXs and 175 SMKs but in WIN brass. They shoot ½ MOA or under almost every time. This past week when I was load developing again for the lapua, brass – I had some of the good known WIN brass loads left over from a recent TAC match along on this range trip to use as a reference load, which I had never had on previous trips shooting the Lapua loads.

So for this trip, I loaded up 10 rounds each of:

175 SMK

Lapua brass (4x fired, freshly annealed)

Fed 210M

2.820 COAL

.337 Bushing, FL sized in Redding S-type Comp dies

Varget loads of:

44.6

44.7

44.8

44.9

45.0

I was sure my node was going to be in there somewhere. So I started at 100 yds with my reference load of 168 AMAXs (46.0 Varget) in WIN brass to check zero. 1st three were a little high and right for about a .35" 3-shot group:

Moved the scope to adjust and shot another 5 with the same 168 AMAX/Win at the same target above, still under 1/2 MOA.. It was feeling like it was going to be a good day.

So then I moved out to 300 yds to start my load devel with the Lapua brass and say these results:

I didn’t bother shooting the 45.0 load at 300 because it was sucking so bad. The above are all greater than 1 MOA and close to 1.2. I didn’t think I was shooting that poorly, so I moved back to 100yds and had my mentor who is a MUCH better shooter than me shoot the rest of the loads over again at 100. Results are as follows:

The last pic was the 45.0 load, 3-shots each. That’s a 1 inch outer circle and I measured them all at right about 1.2" 5-shot groups.

So I’m thinking holy frack, what has happened to my gun. So to test a theory – I shot the few remaining “reference Loads” in WIN brass I had left to see if they were also shooting poorly now. I had 3 left of my 168 AMAX load (46.0 Varget) and 175 SMK (45.6 Varget – both in WIN brass.

Both of those shot as expected – the 168 AMAX is .38” and the 175 SMK is .48”.

So….. I’m really at a loss as to why there is no node in there. I was NOT able to chrono these as my friends Ohler took a shit that day. But I had previously chrono’d the same strings and they were right in the 2600-2630 fps range (20” barrel), which is right where the 175 SMK load in Win brass is (2630fps). By the last couple of loads (44.8-45.0) I was just getting some pressure signs (ejector swipe). But no sticky bolt and no flattened primers at all. So maybe I can go up a little, or go down below 44.6 and try some more loads.

It’s not the end of the world, because I have two really great loads in WIN brass that shoot lights out. I just hate that I can’t get the Lapua brass to shoot worth a shit.

My next step is to weigh the Lapua brass and do the water measurement and run that data through QL and see where those loads fall on the OBT scale. Any other suggestions??? I’m frustrated