So long story short, I went shooting last weekend and well, didn't get to shoot. The bolt would not lock with a round in it, it will cycle fine without one etc, just not with one. A while back I sent the bolt out to get fluted, that's the only thing that changed... I shot this gun a lot years back and haven't since I sent the bolt out. So this is what Im thinking...

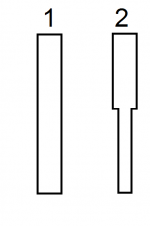

I took the ejector apart, removed the spring and inserted the ejector- it doesn't sit flush with the bolt face. This would cause the round to not chamber correctly/bolt lock... right? ( Image attached shows the ejector bottomed out int he bolt, with NO spring )

Does that mean the ejector is the wrong one and maybe for something else? Should I file some off of the thin stem end, or just buy a new one? I don't know even this is even my bolt... lol Sure it looks like the same handle I had and it is a Rem700 bolt - but I don't know. Im just confused as to why it was sent out before hand working and not its not.

1. Say they gave me the wrong bolt back ( why, how or else, I don't know ) will that cause headspace issues?

2. Say they just installed the wrong ejector - would installing a new one fix the problem?

3. Does someone have a Rem700 and can you compare my measurement with yours?

4. Any other thoughts on this? Yes, I don't know much at all but I think THIS is the issue...

I took the ejector apart, removed the spring and inserted the ejector- it doesn't sit flush with the bolt face. This would cause the round to not chamber correctly/bolt lock... right? ( Image attached shows the ejector bottomed out int he bolt, with NO spring )

Does that mean the ejector is the wrong one and maybe for something else? Should I file some off of the thin stem end, or just buy a new one? I don't know even this is even my bolt... lol Sure it looks like the same handle I had and it is a Rem700 bolt - but I don't know. Im just confused as to why it was sent out before hand working and not its not.

1. Say they gave me the wrong bolt back ( why, how or else, I don't know ) will that cause headspace issues?

2. Say they just installed the wrong ejector - would installing a new one fix the problem?

3. Does someone have a Rem700 and can you compare my measurement with yours?

4. Any other thoughts on this? Yes, I don't know much at all but I think THIS is the issue...