Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

History of the SR25

- Thread starter Forgetful Coyote

- Start date

Looks like you still need one of the Otis(?) cleaning kits in the round pouch for that round area on the lid.Finally rounded out the Mk11 kit. Happy is an understatement.

View attachment 8123342View attachment 8123344View attachment 8123345

Do you know how many of the 'SEAL package' budrichard mentioned were produced?

Were they all white laser engraved with matching upper serial # marks and the Mk11 Mod 0 on the lower but the rest of the markings milled or stamped deeply like yours appear?

Were any completely laser engraved in a gold-ish or perhaps bronze(?) shade? Similar to the suppressor marks but maybe not quite that bright. The only pictures I could find years ago of in-use Mk11s appeared white or silver laser marked except for the one being shot by Major General Dell I believe which was a gold-ish or bronze shade it appears in the photo. The others clearly had to have been taped over before painting or had the paint removed so that the necessary numbers could be seen for checking in and out of the armory I guess. The vast majority of pics are of clone builds or airsoft.

Try the ‘Bigger Hammer’ archives for numbers?

The guys on that Forum were very knowledgable at the time.

-Richard

The guys on that Forum were very knowledgable at the time.

-Richard

Couple of questions here- I'll try and answer them.Looks like you still need one of the Otis(?) cleaning kits in the round pouch for that round area on the lid.

Do you know how many of the 'SEAL package' budrichard mentioned were produced?

Were they all white laser engraved with matching upper serial # marks and the Mk11 Mod 0 on the lower but the rest of the markings milled or stamped deeply like yours appear?

Were any completely laser engraved in a gold-ish or perhaps bronze(?) shade? Similar to the suppressor marks but maybe not quite that bright. The only pictures I could find years ago of in-use Mk11s appeared white or silver laser marked except for the one being shot by Major General Dell I believe which was a gold-ish or bronze shade it appears in the photo. The others clearly had to have been taped over before painting or had the paint removed so that the necessary numbers could be seen for checking in and out of the armory I guess. The vast majority of pics are of clone builds or airsoft.

-I have Otis kits covered.

-No clue on the kits. Knights has been historically pretty tight lipped about certain things. The early Mk11 years don't have a lot of info out there Re how/what got out.

-There is 3-4 different versions of Mk11s I've seen so far. Converted LWMs, All white engraved Vero, Mix-Match Vero engraving like mine (starting around mid 2002 from what I've found) and the later Titusville.

Some of my Otis kits lol

lol, wow I'll say that's covered.Couple of questions here- I'll try and answer them.

-I have Otis kits covered.

-No clue on the kits. Knights has been historically pretty tight lipped about certain things. The early Mk11 years don't have a lot of info out there Re how/what got out.

-There is 3-4 different versions of Mk11s I've seen so far. Converted LWMs, All white engraved Vero, Mix-Match Vero engraving like mine (starting around mid 2002 from what I've found) and the later Titusville.

Some of my Otis kits lol

View attachment 8232720View attachment 8232721

I just looked again and the test target is from November '01, listed as a LWM, tested by J. NEFF.

Its Vero and Mk11 mod0 marked, single letter prefix serial number, matching upper/lower, hidden matching serial # stamping. Bought from John Carney in 2002 if I remember right. I was pulling a lot of hours back then post 9/11 and saw an ad for multiple Mk11 and SR25k. I bought and stored it away. Never looked at it for a decade. That was like 2012. All the talk online was about returns being sold at the time. I forget if it was mk11 or m110 and someone stressing about how the lowers should be deep engraved which mine wasn't. I didn't really want to think about it so I ignored it for another decade and then started to search and learn what's what.

In the photo I took, the markings have a bronze/gold-ish hue probably from the incandescent lightbulbs. Holding the rifle under an incandescent lamp a few minutes ago makes it look that way as well while white led lighting gives it more a silver/white look to the markings. Maybe my eyes are worse than I thought. I'd only seen that marking shade appearance in the picture of the general on the range from back then. My apologies to the general, his name is O'Dell not Dell.

It's interesting that there were that many markings variations all changed relatively quickly it appears.

May I ask how much you paid sir?Very interesting thread. This is my bring back I bought that is confirmed from Knights. My guess is this was made around 1995 as a SR25 and later updated to Mk11 with a new barrel and hand guard. Any thoughts?

View attachment 7790465

View attachment 7790466

View attachment 7790467

View attachment 7790468

View attachment 7790469

@USMCSGT0331 do you have a pic by chance of a SR25 with the rail pulled off by chance??

Last edited:

Having been there in the 90’s, I can tell you the first 50 SR25’s sent to Crane were not even functional. At the range, they were quick fired into a dirt back stop at close range and each one short stroked after one or two mags and never ran again. After examination, gas leakage could be seen from the gas blocks onto the bbls. Also the bolt lugs were square not beveled on one side for proper locking and unlocking. Mags did not drop freely but had to be yanked out. Obviously, the gas blocks fit loosely and a new taper pin placement might be needed. The gas leak was fixed by applying RockSett. A poor fix. Opening the gas port on one bbl was suggested to see if that would help with the short strokes. That was flatly turned downed. The 50 non functioning 25’s were sent to Crane otherwise KAC would be charged a late fee.

Of course, no warning was given to Crane. Crane had them for about 60 days, sent them back with a list of changes they wanted made. Crane wanted the gas ports opened from .088 to .091 as we suggested. Those first rifles were junk. You would never waste money on one if you saw what I did. There was no proper “breaking in a bbl”. Unless burning out a Kreiger bbl with 250rds of ball ammo is “breaking in”. The 25’s sent back by Crane had bbls completely worn out, full of rust and copper. The bbls were re-coated black and re-used on civilian rifles. Some were sent back by the lucky few civilians that had bore scopes.

Etc…

Of course, no warning was given to Crane. Crane had them for about 60 days, sent them back with a list of changes they wanted made. Crane wanted the gas ports opened from .088 to .091 as we suggested. Those first rifles were junk. You would never waste money on one if you saw what I did. There was no proper “breaking in a bbl”. Unless burning out a Kreiger bbl with 250rds of ball ammo is “breaking in”. The 25’s sent back by Crane had bbls completely worn out, full of rust and copper. The bbls were re-coated black and re-used on civilian rifles. Some were sent back by the lucky few civilians that had bore scopes.

Etc…

I did not know all this history about the SR-25. I came to the game kind of late on that.

I have read of the exploits from his memoirs, Sgt. Nicholas "Reaper" Irving of the 3rd Ranger Battalion 75th Ranger Regiment. Actually, when he started, he was the shooter, of course. And, as a sgt, outranked his sniper team leader. The sniper team leader was carrying a .300 WM, which seemed to jam, odd for a bolt gun, but there you are.

Irving carried an SR-25 that would become the Army's Mk 11 Mod 0. He earned his nickname with the most confirmed kills in a deployment, using the SR-25, usually from a kneeling position with his off hand (left) elbow resting on his left knee. As well as countless others in his duties in overwatch or just plain being caught in an ambush. So, they must have worked some problems out.

Someone corrected me not to long ago. 20 years ago, I had read an article that the reason the military used the .308 W (7.62 NATO) was because it could knock down a 200 lb target at 600 yards. Such was not the case.

It was about awarding contracts and who pleases whom to get the money. But it stuck.

So, maybe that is the case with the SR-25. People kept pushing it in spite of early problems.

I have read of the exploits from his memoirs, Sgt. Nicholas "Reaper" Irving of the 3rd Ranger Battalion 75th Ranger Regiment. Actually, when he started, he was the shooter, of course. And, as a sgt, outranked his sniper team leader. The sniper team leader was carrying a .300 WM, which seemed to jam, odd for a bolt gun, but there you are.

Irving carried an SR-25 that would become the Army's Mk 11 Mod 0. He earned his nickname with the most confirmed kills in a deployment, using the SR-25, usually from a kneeling position with his off hand (left) elbow resting on his left knee. As well as countless others in his duties in overwatch or just plain being caught in an ambush. So, they must have worked some problems out.

Someone corrected me not to long ago. 20 years ago, I had read an article that the reason the military used the .308 W (7.62 NATO) was because it could knock down a 200 lb target at 600 yards. Such was not the case.

It was about awarding contracts and who pleases whom to get the money. But it stuck.

So, maybe that is the case with the SR-25. People kept pushing it in spite of early problems.

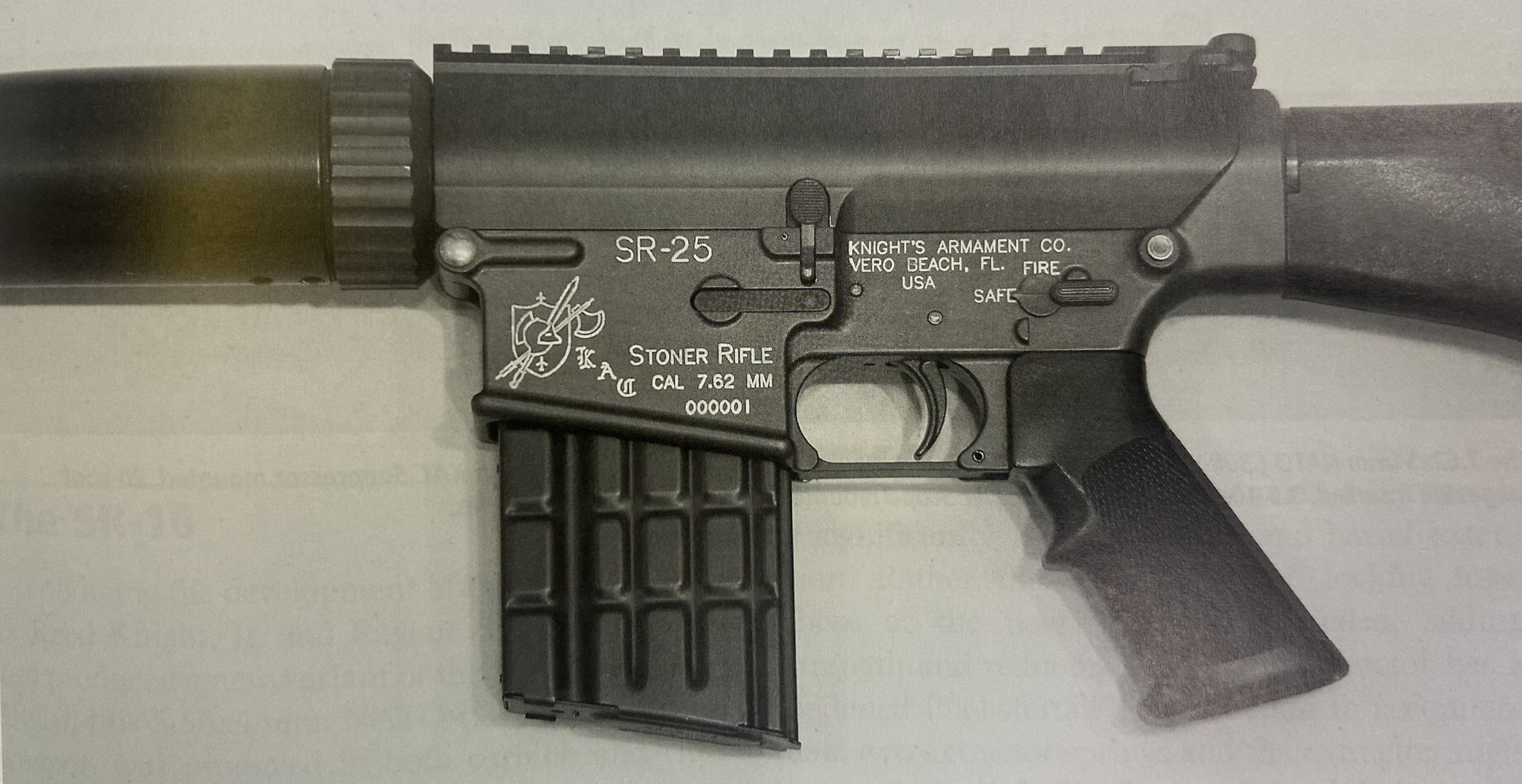

A bit more history. Gene Stoner reportedly designed the SR-25 during the summer of 1991 (while staying at his house up in Michigan, although his new employer, KAC was down in Florida). He took his original AR-10 design plus his original AR-15 design from the mid-1950s, combined various design elements together, added the 10 to the 15 to make 25, and SR-25 was born that summer. I think the first civilian SR-25s were sold in late 1991 or 1992.

Like almost all semi-automatic firearm designs that are tested harshly by the military, problems large and small are identified that need to be corrected.(This pattern of large and small functional issues with prototype examples of the M1 Garand, the M14, and M16 - appears universal. The SR-25 followed the same pattern as all other semi-automatic predecessors).

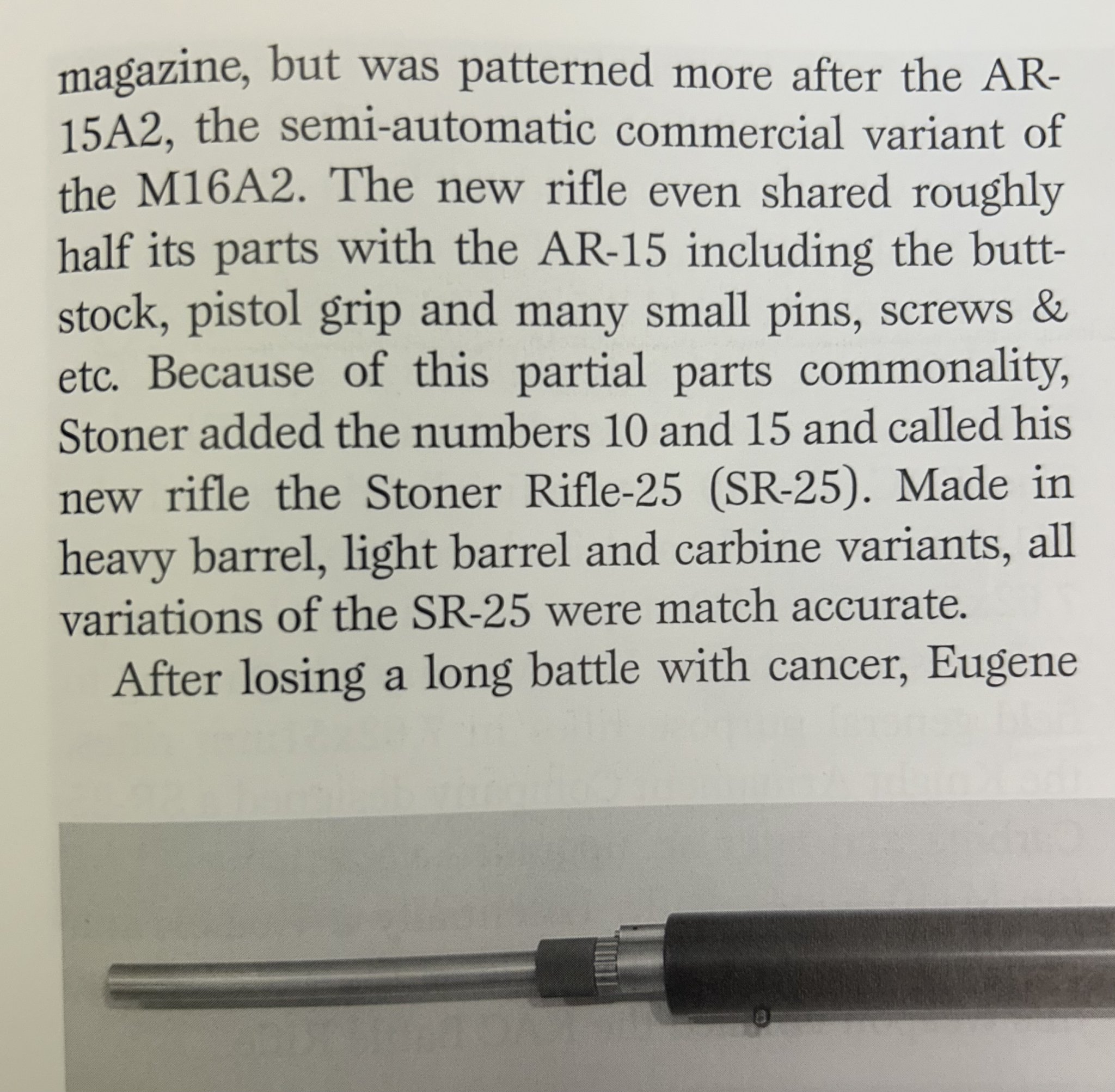

The Crane small arms engineer who tested SR-25 s/n 00001 with Reed Knight, shown below, told me about some of the issues (but not all of them apparently). 1. The 1960s era AR-10 “waffle” mags were not very unreliable, and KAC subsequently redesigned them. 2. Gas port issues, 3. some bolt extractor/lubrication issues, and 4. the 24” barrel was too heavy and too long. 5. It took a while to get the KAC suppressor to perform as required. Most of that development occurred between 1992 and likely 1995 or 96, but the suppressor design was still being worked out in the late 1990s. Gene Stoner died of cancer in 1997.

As I understand it, by late 1990s the SR-25 had finally been refined into a complete “mil-spec” system, complete with all the kit needed for a SEAL sniper. The first 300 of the new Mk 11 Mod 0s were ordered by Crane in May 2000. It was a rather expensive system, but orders started flowing in from other military branches and federal agencies throughout that turbulent decade.

FWIW, I suspect commonality of many of the small parts with the AR-15 was a valid selling feature to the military, as it simplifies repairs/logistics somewhat.

Lastly, in the 1990s Crane/SOCOM reportedly wanted to replace their old non-suppressed M14 SSR semi-automatic 7.62 NATO sniper rifles with a suppressed semi-automatic 7.62 NATO rifle that was still procurable and supported. The last USGI M14 receivers were made in 1964 (problem 1), and gas port rifles simply don’t play/function very well with suppressors (problem 2) - so those were two issues that the SR-25 resolved. That’s my take on why Crane spent the 1992-1999 era working closely with KAC to refine the SR-25 into a mil-spec, semi-auto, suppressed, 1-MOA capable sniper system by the year 2000.

Like almost all semi-automatic firearm designs that are tested harshly by the military, problems large and small are identified that need to be corrected.(This pattern of large and small functional issues with prototype examples of the M1 Garand, the M14, and M16 - appears universal. The SR-25 followed the same pattern as all other semi-automatic predecessors).

The Crane small arms engineer who tested SR-25 s/n 00001 with Reed Knight, shown below, told me about some of the issues (but not all of them apparently). 1. The 1960s era AR-10 “waffle” mags were not very unreliable, and KAC subsequently redesigned them. 2. Gas port issues, 3. some bolt extractor/lubrication issues, and 4. the 24” barrel was too heavy and too long. 5. It took a while to get the KAC suppressor to perform as required. Most of that development occurred between 1992 and likely 1995 or 96, but the suppressor design was still being worked out in the late 1990s. Gene Stoner died of cancer in 1997.

As I understand it, by late 1990s the SR-25 had finally been refined into a complete “mil-spec” system, complete with all the kit needed for a SEAL sniper. The first 300 of the new Mk 11 Mod 0s were ordered by Crane in May 2000. It was a rather expensive system, but orders started flowing in from other military branches and federal agencies throughout that turbulent decade.

FWIW, I suspect commonality of many of the small parts with the AR-15 was a valid selling feature to the military, as it simplifies repairs/logistics somewhat.

Lastly, in the 1990s Crane/SOCOM reportedly wanted to replace their old non-suppressed M14 SSR semi-automatic 7.62 NATO sniper rifles with a suppressed semi-automatic 7.62 NATO rifle that was still procurable and supported. The last USGI M14 receivers were made in 1964 (problem 1), and gas port rifles simply don’t play/function very well with suppressors (problem 2) - so those were two issues that the SR-25 resolved. That’s my take on why Crane spent the 1992-1999 era working closely with KAC to refine the SR-25 into a mil-spec, semi-auto, suppressed, 1-MOA capable sniper system by the year 2000.

Last edited:

The time-line posts above explain a lot. I signed the first Army Quality Deficiency Reports on the SR-25 and sent my rifles back to Crane for repair in late 1995-early 1996. They were gone two years.

Kevin Boland was very passionate about the guns when he was working for KAC, explaining my rifles were ancient and (fairly) did not reflect the quality standard during his tenure there.

What surprised me was the decline in Lake City M118 Long Range quality after adoption around 1999. SOCOM specified Mark 11 rifles had to group sub-MOA on acceptance -- yet even out of bolt guns the government-supplied ammo could not. Kevin was very objective about it -- nobody can make a gun shoot mediocre ammo better.

There were a number of 2002 lots that should have gone straight to the dumpster. Probably due to the post 9-11 production surge. Some we got (surplus) at Camp Perry was only worth the brass.

Kevin Boland was very passionate about the guns when he was working for KAC, explaining my rifles were ancient and (fairly) did not reflect the quality standard during his tenure there.

What surprised me was the decline in Lake City M118 Long Range quality after adoption around 1999. SOCOM specified Mark 11 rifles had to group sub-MOA on acceptance -- yet even out of bolt guns the government-supplied ammo could not. Kevin was very objective about it -- nobody can make a gun shoot mediocre ammo better.

There were a number of 2002 lots that should have gone straight to the dumpster. Probably due to the post 9-11 production surge. Some we got (surplus) at Camp Perry was only worth the brass.

Last edited:

And Russ's unit locked theirs in a conex in the US and carried their bolt guns to Afg bc half would not function,

Somebody here helped that unit with the Army Times deal that eventually got theirs repaired.

And Chuck O withheld final payment until the last units were delivered and function tested.

RK hated Chuck.

RK had a booth at snipercraft, I made the "mistake" of asking him if he had talked to Chuck lately... hooo boy howdy...

Those guns malfunctions were not the 118lr back then, were bolt stops breaking, locking up the gun, suppressors loose enough to cause cap strikes, moa gun no can, 5 moa gun add can... and a couple of other small parts failures that were like mosquitoes around the camp fire, that were truly "just a bad run of small parts" inside a lot of good small parts....

The problems later, were the same problems Crane identified with the first batch and unfortunately they persisted the life of the system, in some part because of the inability to know which group of parts were bad and mixed in w good parts.

Guns had to go back just bc of a broken small part rather than a unit armorer replacing it.

and that took forever.

The first civilian unit we had, the upper failed, handguard threads cut too deep. Barrel and handguard came off in our hand...

Somebody here helped that unit with the Army Times deal that eventually got theirs repaired.

And Chuck O withheld final payment until the last units were delivered and function tested.

RK hated Chuck.

RK had a booth at snipercraft, I made the "mistake" of asking him if he had talked to Chuck lately... hooo boy howdy...

Those guns malfunctions were not the 118lr back then, were bolt stops breaking, locking up the gun, suppressors loose enough to cause cap strikes, moa gun no can, 5 moa gun add can... and a couple of other small parts failures that were like mosquitoes around the camp fire, that were truly "just a bad run of small parts" inside a lot of good small parts....

The problems later, were the same problems Crane identified with the first batch and unfortunately they persisted the life of the system, in some part because of the inability to know which group of parts were bad and mixed in w good parts.

Guns had to go back just bc of a broken small part rather than a unit armorer replacing it.

and that took forever.

The first civilian unit we had, the upper failed, handguard threads cut too deep. Barrel and handguard came off in our hand...

Last edited:

What surprised me was the decline in Lake City M118 Long Range quality after adoption around 1999. SOCOM specified Mark 11 rifles had to group sub-MOA on acceptance -- yet even out of bolt guns the government-supplied ammo could not. Kevin was very objective about it -- nobody can make a gun shoot mediocre ammo better.

There were a number of 2002 lots that should have gone straight to the dumpster. Probably due to the post 9-11 production surge. Some we got (surplus) at Camp Perry was only worth the brass.

Digressing, and the link is long-gone, but back in 2011 or 2012 I copied a rather interesting technical history of the 7.62 NATO match cartridge. Long story short, there were issues in the early 200Xs that required changes to the powder charge and all this lead to the development of the Mk 316 Mod 0.

7.62 NATO Long Range Match Cartridges

By Frederick Salberta

"...The result was the 1995 adoption of the M118LR cartridge. Due to the arsenal’s preference for ball powders for uniformity of loading on high-speed machinery, the new cartridge utilized WC750 ball powder. The first published powder charge for this load was nominally 42.8 gr. of WC750. The load used a Lake City case and the Sierra 175 gr. Matchking projectile. The nominal velocity was 2,600 fps at 78 feet, from a 22″ barrel, which correlates to a velocity of 2,660 fps at the muzzle of the M24 bolt action rifle with a 24″ barrel. By Frederick Salberta

The powder charge was increased to a nominal 43.3 gr. of WC750 in 1996. This load gave a higher muzzle velocity, on the order of 2,700 fps at 78 feet from the 24 inch barrel of the M24/M40 sniper rifles. This correlates to an approximate muzzle velocity of 2,750 fps from a 24 inch barrel. The higher velocity gave better performance and less wind deflection. By the middle to late 1990s, the Army, Marines and Coast Guard were using bolt action sniper rifles based on the Remington 700 design, which eliminated some of the restrictions on the cartridge that the M14 design had imposed. As the M14 was seen as largely obsolete, the new updated cartridge did not have to meet the gas port pressure requirements of the M14. The last lot of M118LR known to be loaded with theWC750 powder was LC-99C173-013 in 1999.

In 1999 the powder type was changed to Alliant Reloder 15. The new nominal charge was 44.3 gr. of RE-15 powder, which produced a muzzle velocity of approximately 2,750 fps from the 24 inch barrel of the M24/M40 with a velocity at 78 feet of approximately 2,700 fps. The reason for the change has not been definitely published, but seems to have to do with some improvement in either temperature stability or accuracy. In any case neither of these cartridges variants was intended for use in the M14, though the early lots of M118LR (those loaded with 42.8 gr. instead of 43.3 gr. of WC750) were suitable for the M14, although hard on the rifles due to the high gas port pressure. Indeed the Marine Corp prohibited the use of the M118LR cartridge in the M14 DMR rifle until 2002.

Between 2001 and 2003 several events occurred which lead to a reassessment of the M118LR cartridge. First with the start of the war on terror in 2001 the Marine Corp and Army began to issue the M14 in a Designated Marksman Rifle (DMR) role. The lack of sufficient M852 ammunition in the supply system (last lots were loaded in 1994 or 1995) and the lack of long range accuracy of the M118 special ball cartridge meant that these troops were looking for a substitute cartridge. The Navy had already tried using the M118LR cartridge in their match M14 rifles in the all-Navy matches in the spring of 2001 due to the lack of remaining M852 stocks (last issue of Navy M852 occurred in 2000). Though the lots of M118LR they issued were from 1995 and presumably some of the earlier lower pressure lots, the Navy found the M14 rifles not to be damaged and the accuracy was very good. As a result, it appears that in 2002 both the Army and Marines began using M1118LR in their M14 rifles for the DMR/SDM role.

With the start of the Gulf War II in 2003 the high temperatures encountered in Iraq (in excess of 115 degrees F) began to produce some M14 op-rod failures due to excessive pressure at the gas port. Both the Army and Marines found the range marking on their scopes to be off of calibration with the higher velocity M118LR loads in such desert conditions. The result was a decision to reduce the load to a more moderate level.

This was done in late 2003 or early 2004, when the M118LR nominal change was lowered to 43.1 gr. of RE-15 from 44.3 gr. of that powder. This is the nominal load, assuming use of canister grade powder; however, most lots disassembled show an actual powder charge of about 42.8 grains of RE-15. The result was a 40 fps reduction in the velocity at 78 feet to around 2659 fps, which correlates to a 2,709 fps velocity from the 24″ barrel of the M24 or M40 rifle. Out of an M14, the muzzle velocity will be around 2685 fps. This load, though slower than the earlier lots of M118LR, can be used in the M14 with minimal risk to the rifle or gas system and it is this cartridge that is intended to be used with both the Army and Marines new M14 based EBR/EMR and M110 rifles.

Although this cartridge remains the current M118LR standard, it apparently still suffers from excessive velocity variation as the temperature changes and less accuracy than might be desired for truly precise shots at mid-range to long-range distances. The specification for M118LR requires 14 shots in less than 8 inches at 600 yards. To correct that difficulty, in 2008 the SOCOM/Navy sponsored a new developmental project to enhance the accuracy of the M118LR cartridge while maintaining its suitability for use in the M14, SR25 and M700 Remington rifle designs. As such port pressure consistency was a primary concern. The contract was given the Federal Cartridge Company, which for a long time has made a series of match cartridges under the “Gold Medal” brand. These were developed from the custom loads designed for the Marine Corp MTU in the 1970s (the IMR 3031 39 gr. match load). By this time IMR 4064 was the powder of preference for the Gold Medal match cartridge line. One of the areas considered by Federal Cartridge Co. was the case itself, with a more uniform neck concentricity tolerance than Lake City brass and beefed up web to cartridge case head interface being part of the finished cartridge design.

The result, when it was standardized as the MK316 Mod 0 cartridge, was a Federal modified case (Drawing number 8347636), Federal match primer, Sierra 175 grain Matchking and 41.75 grains of IMR 4064 powder. According to the published sources this load will produce a muzzle velocity of 2640 fps out of a 24 inch barrel. The load as produced by Federal is claimed to produce under 1 MOA out to 1000 yards from an appropriate rifle. With the IMR (4064) powder the shift in velocity is only 20 fps from 0 to 100 Deg C, with the Standard deviation in velocity over 40 rounds being 15 fps or less. In contrast the M118LR loaded with RE-15 powder will see a 50 fps rise in velocity for a 50 deg rise in temperature.

The MK316 ammunition is essentially the finest possible mass produced match ammunition, comparable to the hand loads utilized by the various service MTUs. The cost is higher than M118LR, with a government cost of 78 cents per round for the MK 316 Mod 0 rather than 55 cents for the M118LR (2009 prices).

With the IMR (4064) powder the shift in velocity is only 20 fps from 0 to 100 Deg C, with the Standard deviation in velocity over 40 rounds being 15 fps or less. In contrast the M118LR loaded with RE-15 powder will see a 50 fps rise in velocity for a 50 deg rise in temperature.

This surprises me. I never tested temp swings as I cut my teeth reloading on almost this exact load in Black Hills brass before moving to Varget. The trends in NRA Highpower being what they were in 2001. I may restock some 4064.

Always wanted a Mk11 mod0, but being a semi-poor it’s likely never going to be in my safe. In the end, I think the platforms that have grown out of the resurgence of the AR-10/SE-25 these days is maybe this platforms greatest contribution to our community. Anyone think LMT would have unitized large frames if the mk11 was never fielded? We have dozens of choices in an equal number of chamberings that IMO all stated growing out of the deployment of the mk11.

Winchester-Olin helped develop M118LR using WC-750 powder (produced by Saint Marks which Olin owned at the time).In 1999 the powder type was changed to Alliant Reloder 15. The new nominal charge was 44.3 gr. of RE-15 powder, which produced a muzzle velocity of approximately 2,750 fps from the 24 inch barrel of the M24/M40 with a velocity at 78 feet of approximately 2,700 fps. The reason for the change has not been definitely published ...

Lake City Army Ammunition Plant is a government-owned / contractor-operated enterprise. The Army awards the contract to cover five-year terms. Olin-Winchester operated Lake City until the end of 1999.

Alliant-ATK (Federal) won the contract for Fiscal Years 2000-2005 starting 1 October 1999. ATK owns the Alliant powder factory at Radford Army Ammunition Plant in Virginia. Rather than buy powder from Winchester-Olin, ATK proposed Army change to use Reloader-15 (an ATK product) which would have lowered their internal cost. I'm surprised the Army allowed it -- I don't know if there was a formal engineering re-do (between Picatinny and Tank and Automotive Command) for approval and safety release.

ATK got the contract to operate Lake City in 1999 (taking over from OLIN-Winchester)....What surprised me was the decline in Lake City M118 Long Range quality after adoption around 1999. SOCOM specified Mark 11 rifles had to group sub-MOA on acceptance -- yet even out of bolt guns the government-supplied ammo could not. Kevin was very objective about it -- nobody can make a gun shoot mediocre ammo better.

There were a number of 2002 lots that should have gone straight to the dumpster. Probably due to the post 9-11 production surge. Some we got (surplus) at Camp Perry was only worth the brass.

They went very hard to cutting costs in very typically uninformed executive ways, deferring maintenance, and slashing whole departments like... QA. Yes, really: QA. The GWOT production surges didn't help but the issues were already there.

It has been back up to snuff for a decade or so, and well on the way to better than ever in most respects, but there was a good period there when it was really not great and it showed.

Irving carried an SR-25 that would become the Army's Mk 11 Mod 0.

Irving joined in 2004, the Mk11 Mod 0 well predates that.

The MK11 was a great gun within it's limitations.

In his memoirs, he calls it an SR-25, rather than the other name.Irving joined in 2004, the Mk11 Mod 0 well predates that.

The MK11 was a great gun within it's limitations.

Having been there in the 90’s, I can tell you the first 50 SR25’s sent to Crane were not even functional. At the range, they were quick fired into a dirt back stop at close range and each one short stroked after one or two mags and never ran again. After examination, gas leakage could be seen from the gas blocks onto the bbls. Also the bolt lugs were square not beveled on one side for proper locking and unlocking. Mags did not drop freely but had to be yanked out. Obviously, the gas blocks fit loosely and a new taper pin placement might be needed. The gas leak was fixed by applying RockSett. A poor fix. Opening the gas port on one bbl was suggested to see if that would help with the short strokes. That was flatly turned downed. The 50 non functioning 25’s were sent to Crane otherwise KAC would be charged a late fee.

Of course, no warning was given to Crane. Crane had them for about 60 days, sent them back with a list of changes they wanted made. Crane wanted the gas ports opened from .088 to .091 as we suggested. Those first rifles were junk. You would never waste money on one if you saw what I did. There was no proper “breaking in a bbl”. Unless burning out a Kreiger bbl with 250rds of ball ammo is “breaking in”. The 25’s sent back by Crane had bbls completely worn out, full of rust and copper. The bbls were re-coated black and re-used on civilian rifles. Some were sent back by the lucky few civilians that had bore scopes.

Etc…

The time-line posts above explain a lot. I signed the first Army Quality Deficiency Reports on the SR-25 and sent my rifles back to Crane for repair in late 1995-early 1996. They were gone two years.

Kevin Boland was very passionate about the guns when he was working for KAC, explaining my rifles were ancient and (fairly) did not reflect the quality standard during his tenure there.

What surprised me was the decline in Lake City M118 Long Range quality after adoption around 1999. SOCOM specified Mark 11 rifles had to group sub-MOA on acceptance -- yet even out of bolt guns the government-supplied ammo could not. Kevin was very objective about it -- nobody can make a gun shoot mediocre ammo better.

There were a number of 2002 lots that should have gone straight to the dumpster. Probably due to the post 9-11 production surge. Some we got (surplus) at Camp Perry was only worth the brass.

And Russ's unit locked theirs in a conex in the US and carried their bolt guns to Afg bc half would not function,

Somebody here helped that unit with the Army Times deal that eventually got theirs repaired.

And Chuck O withheld final payment until the last units were delivered and function tested.

RK hated Chuck.

RK had a booth at snipercraft, I made the "mistake" of asking him if he had talked to Chuck lately... hooo boy howdy...

Those guns malfunctions were not the 118lr back then, were bolt stops breaking, locking up the gun, suppressors loose enough to cause cap strikes, moa gun no can, 5 moa gun add can... and a couple of other small parts failures that were like mosquitoes around the camp fire, that were truly "just a bad run of small parts" inside a lot of good small parts....

The problems later, were the same problems Crane identified with the first batch and unfortunately they persisted the life of the system, in some part because of the inability to know which group of parts were bad and mixed in w good parts.

Guns had to go back just bc of a broken small part rather than a unit armorer replacing it.

and that took forever.

The first civilian unit we had, the upper failed, handguard threads cut too deep. Barrel and handguard came off in our hand...

Interesting reports. It's surprising to me since I've handled and shot several of the early SR-25 Match Rifles from the 1993-1994 time period (see my posts earlier in this thread) and have never had any issues. Barrels and accuracy were always excellent, and their reliability was perfect. Of course, as primarily match rifles, they were not put through the rigors of testing at Crane, but you would think those issues would have still turned up over time.

You would think that experience would have carried over into the later rifles you're describing.

A little more history:

I believe the shooter in the middle photo testing the early SR-25 is retired Master Sergeant Steve Holland. He started the 5th SF GRP Sniper Training Detachment in 1991 and was the lead on getting KAC to develop the SR-25. He is also the inventor of 6.8 SPC and the “Mod H” version of the Mk-12 stands for Holland.

My Steve Holland war story ("No shit, there I was ..."):A little more history:

I believe the shooter in the middle photo testing the early SR-25 is retired Master Sergeant Steve Holland. He started the 5th SF GRP Sniper Training Detachment in 1991 and was the lead on getting KAC to develop the SR-25. He is also the inventor of 6.8 SPC and the “Mod H” version of the Mk-12 stands for Holland.

Steve came through the Military Free Fall School at Bragg when I worked there back in the 20th century (he was a staff sergeant then). If we had C-141 jet support for the last day's jumps we would coordinate in advance with the crew for a mass emergency exit (usually around 30-odd students and maybe eight to twelve instructors). Of course the students wouldn't know or have a clue.

When the C-141 loadmasters raise the internal cabin pressure door and open the clam-shells it's horrifically loud (it's already loud -- it's a four-engine jet). Instead of "Stand up" at two minutes out, "Move to the rear" at one minute, and "Stand by!" at 15 seconds the pilot would give violent rudder turns about 90 seconds out. The loadmasters would run back-and-forth with their flashlights almost in a panic. then consult with the jumpmaster, with the students getting that uncomfortable look. The pilot would give three long rings on the emergency bell (just like you maybe had in public school).

The jumpmaster would then give the hand-and-arm signals for "EVERYONE -- STAND UP! MOVE TO THE REAR!"

Instructors have to be double on-the-ball to make sure all equipment and ripcord pins are checked and safe. SFC Paul F. said when he got to Steve, all he heard was "HOLY MARY JESUS -- HOLY MARY JESUS" as he secured his goggles and assembled on the ramp.

The pilot would then stand on the emergency bell and the jumpmaster would signal "BAIL OUT! GO!" at the real release point.

Lots of fun and memorable to be in the air with forty of your new best friends bailing out of a jet to finish the course.

My Steve Holland war story ("No shit, there I was ..."):

Steve came through the Military Free Fall School at Bragg when I worked there back in the 20th century (he was a staff sergeant then). If we had C-141 jet support for the last day's jumps we would coordinate in advance with the crew for a mass emergency exit (usually around 30-odd students and maybe eight to twelve instructors). Of course the students wouldn't know or have a clue.

When the C-141 loadmasters raise the internal cabin pressure door and open the clam-shells it's horrifically loud (it's already loud -- it's a four-engine jet). Instead of "Stand up" at two minutes out, "Move to the rear" at one minute, and "Stand by!" at 15 seconds the pilot would give violent rudder turns about 90 seconds out. The loadmasters would run back-and-forth with their flashlights almost in a panic. then consult with the jumpmaster, with the students getting that uncomfortable look. The pilot would give three long rings on the emergency bell (just like you maybe had in public school).

The jumpmaster would then give the hand-and-arm signals for "EVERYONE -- STAND UP! MOVE TO THE REAR!"

Instructors have to be double on-the-ball to make sure all equipment and ripcord pins are checked and safe. SFC Paul F. said when he got to Steve, all he heard was "HOLY MARY JESUS -- HOLY MARY JESUS" as he secured his goggles and assembled on the ramp.

The pilot would then stand on the emergency bell and the jumpmaster would signal "BAIL OUT! GO!" at the real release point.

Lots of fun and memorable to be in the air with forty of your new best friends bailing out of a jet to finish the course.

Side story. Talking about jumping out of perfectly good airplanes, one of the entertainers at the facility where my wife stays was SF in Vietnam, jumping out of good airplanes. He passed away playing a gig at our location. I watched him fall forward. He never woke up.

Jessie Leroy Frank Obituary (2023) - Allen, TX - Turrentine-Jackson-Morrow Funeral Home - Allen

View Jessie Leroy Frank's obituary, send flowers and sign the guestbook.

www.legacy.com

Don't mean to be a downer. Just paying respects to the brave men and women going into harm's way.

Last edited:

I would also be interested in any info on the BR or "SR-25k"Anybody seen any pics of the original battle rifle/ chopped gun prototypes?

Anybody seen any pics of the original battle rifle/ chopped gun prototypes?

I would also be interested in any info on the BR or "SR-25k"

I think you are asking for pics of the early SR-25s with the shorter 20" barrel and smooth handguard, but before the RAS rail was developed?

That was called the SR-25 Special Military Lightweight (SpLW) Match rifle. Those date mid-to-late 1990s. SOCOM purchased 45 of them in 1999, along with 45 KAC suppressors, but pictures of them being used n service seem non-existent, or at least I have never seen such pictures.

That said, I found this picture somewhere on the Internet of the KAC 'museum' or display room, and one can be seen on that wall:

I don't know anything about this rifle, but it looks like the late 1990s era SR-25 SpLW with the suppressor - note the round handguard.

My poor man's Mk 11 Mod 0 replica uses the upper from one of those late 1990s era SR-25 SpLW rifles, but I am using an LMT lower.

Here you can see the original round hardguard and original gas block. Upper was later fitted with the proper Mk 11 rail and gas block.

I've been slowly piecing it together since I got this salty old case in 2019, followed by an LMT lower. Hope to finish it this year.

One interesting thing about that original Mk 11 case is that the "Q" prefix scope serial number is for a Nightforce NXS 3.5-15x50mm scope.

When I called NF about it, they said that serial number was from either 2005 or 2006. So this Mk 11 was apparently updated with a Nighforce scope shortly after they won their first contract with SOCOM, which was July 2005. Fwiw, my replica has one of those NF scopes too.

It's been a long and expensive journey to get this far, but I still need a few things to finish it up. I have misplaced the KAC buffer and the front sight, but hopefully they will turn up with a little more searching...that what happened to this project that was purchased more or less piece by piece over a 5 year period...

Hard to see, but this is a "P" prefix Mil-Spec NF scope, so it's serial number is likely from the 2005-06 era, similar to the old case.

One can also see the early shell deflector that was bolted to the rail. Got lucky with some basically free KAC rings last month.

Here's my poor-man's LMT lower that started this project. Not correct, but I recently added that UID tag to slightly improve the aesthetics.

Unfortunately the original Mk 11 KAC suppressors are discontinued and today's prices mean I'll never be able to purchase one to fully complete this Mk 11 Mod 0 project. (Still kicking myself for not biting the bullet back in 2019-20, and buying one for $1800, but I didn't have an upper at that time, and didn't realize what would happen to the prices over the past year or two). Anyhow, that's about all I know.

Last edited:

I was actually referring to the SR-25 thats 3 rifles up from the one you pointed out. I’ve seen a photo from a book that said they were originally rifles that Delta armorers chopped down while in country.I think you are asking for pics of the early SR-25s with the shorter 20" barrel and smooth handguard, but before the RAS rail was developed?

That was called the SR-25 Special Military Lightweight (SpLW) Match rifle. Those date mid-to-late 1990s. SOCOM purchased 45 of them in 1999, along with 45 KAC suppressors, but pictures of them being used n service seem non-existent, or at least I have never seen such pictures.

That said, I found this picture somewhere on the Internet of the KAC 'museum' or display room, and one can be seen on that wall:

View attachment 8457436

View attachment 8457466

I don't know anything about this rifle, but it looks like the late 1990s era SR-25 SpLW with the suppressor - note the round handguard.

View attachment 8457448

My poor man's Mk 11 Mod 0 replica uses the upper from one of those late 1990s era SR-25 SpLW rifles, but I am using an LMT lower.

Here you can see the original round hardguard and original gas block. Upper was later fitted with the proper Mk 11 rail and gas block.

View attachment 8457450

I've been slowly piecing it together since I got this salty old case in 2019, followed by an LMT lower. Hope to finish it this year.

View attachment 8457455

One interesting thing about that original Mk 11 case is that the "Q" prefix scope serial number is for a Nightforce NXS 3.5-15x50mm scope.

When I called NF about it, they said that serial number was from either 2005 or 2006. So this Mk 11 was apparently updated with a Nighforce scope shortly after they won their first contract with SOCOM, which was July 2005. Fwiw, my replica has one of those NF scopes too.

View attachment 8457456

It's been a long and expensive journey to get this far, but I still need a few things to finish it up. I have misplaced the KAC buffer and the front sight, but hopefully they will turn up with a little more searching...that what happened to this project that was purchased more or less piece by piece over a 5 year period...

View attachment 8457460

Hard to see, but this is a "P" prefix Mil-Spec NF scope, so it's serial number is likely from the 2005-06 era, similar to the old case.

One can also see the early shell deflector that was bolted to the rail. Got lucky with some basically free KAC rings last month.

View attachment 8457461

Here's my poor-man's LMT lower that started this project. Not correct, but I recently added that UID tag to slightly improve the aesthetics.

View attachment 8457462

Unfortunately the original Mk 11 KAC suppressors are discontinued and today's prices mean I'll never be able to purchase one to fully complete this Mk 11 Mod 0 project. (Still kicking myself for not biting the bullet back in 2019-20, and buying one for $1800, but I didn't have an upper at that time, and didn't realize what would happen to the prices over the past year or two). Anyhow, that's about all I know.

IIRC- @USMCSGT0331 had a SR25 BR + very hard to find 7.62 corn cob can. Let me find his post in the AR-15 picture thread in pretty sure he mentions it there...I was actually referring to the SR-25 thats 3 rifles up from the one you pointed out. I’ve seen a photo from a book that said they were originally rifles that Delta armorers chopped down while in country.

View attachment 8457538View attachment 8457539View attachment 8457540View attachment 8457542

@Random Guy how are you liking your Mk 11 clone?

Thoughts on it vs your various M14 DMR clones?

@abc0600

Scroll down on this page you can see USMCSGT0331's SR25 BR w/ 7.62 corn cob.

www.snipershide.com

Also on page 49 of that thread he posted some of his Secret Service SR16's. Idk who his connections are but they're hella good LOL...

www.snipershide.com

Also on page 49 of that thread he posted some of his Secret Service SR16's. Idk who his connections are but they're hella good LOL...

Scroll down on this page you can see USMCSGT0331's SR25 BR w/ 7.62 corn cob.

The AR15 Picture Thread

Sometimes I'll get it in my head to want to change something on my SPR because reasons but then I'll take it to the range and I'll be like "nah, I'll leave it as it, why fuck up a good thing". I did swap out the Magpul K2 XL for the old Sierra Precision grip. At the range today, it was just...

Last edited:

@Random Guy how are you liking your Mk 11 clone?

Thoughts on it vs your various M14 DMR clones?

To answer your question, I like my Mk 11 Mod 0 replica very much, aside from the issue of the bolt stop not working for reasons unknown. (I think the stop needs to stick out about 1mm more to lock it back, but haven't figured out to achieve that. I has new LMT lower and related parts). I used at a QSC match last month at Quantico, only the 2nd time I have shot it, and cleaned the 300 yard target with 15 second exposure, scoring 150-7x out of 15 shots, so that is a little better than I typically get with my M1As.

I think in 2025 I'll try it in a CMP AR Tactical Match, which is 60 shots for score at 600 yards.

Last edited:

Not many. Probably less than a hundred.I don’t know how many 16” SR25’s were deployed?

Are you using an LMT big frame bolt stop? They're usually really reliable as far as function.To answer your question, I like my Mk 11 Mod 0 replica very much, aside from the issue of the bolt stop not working for reasons unknown. (I think the stop needs to stick out about 1mm more to lock it back, but haven't figured out to achieve that. I has new LMT lower and related parts).

This is an Armalite catch. If that little nose dingus isn't long enough it won't catch the follower tail. It's also got to be relieved enough it doesn't catch the inside of the upper when the follower pushes the catch up.

Last edited:

Similar threads

- Replies

- 153

- Views

- 9K

- Replies

- 14

- Views

- 5K

- Replies

- 1

- Views

- 316

- Replies

- 7

- Views

- 725

Rifle Competition Events

NRL Hunter Dust Devil Dual AAR

- Replies

- 8

- Views

- 489