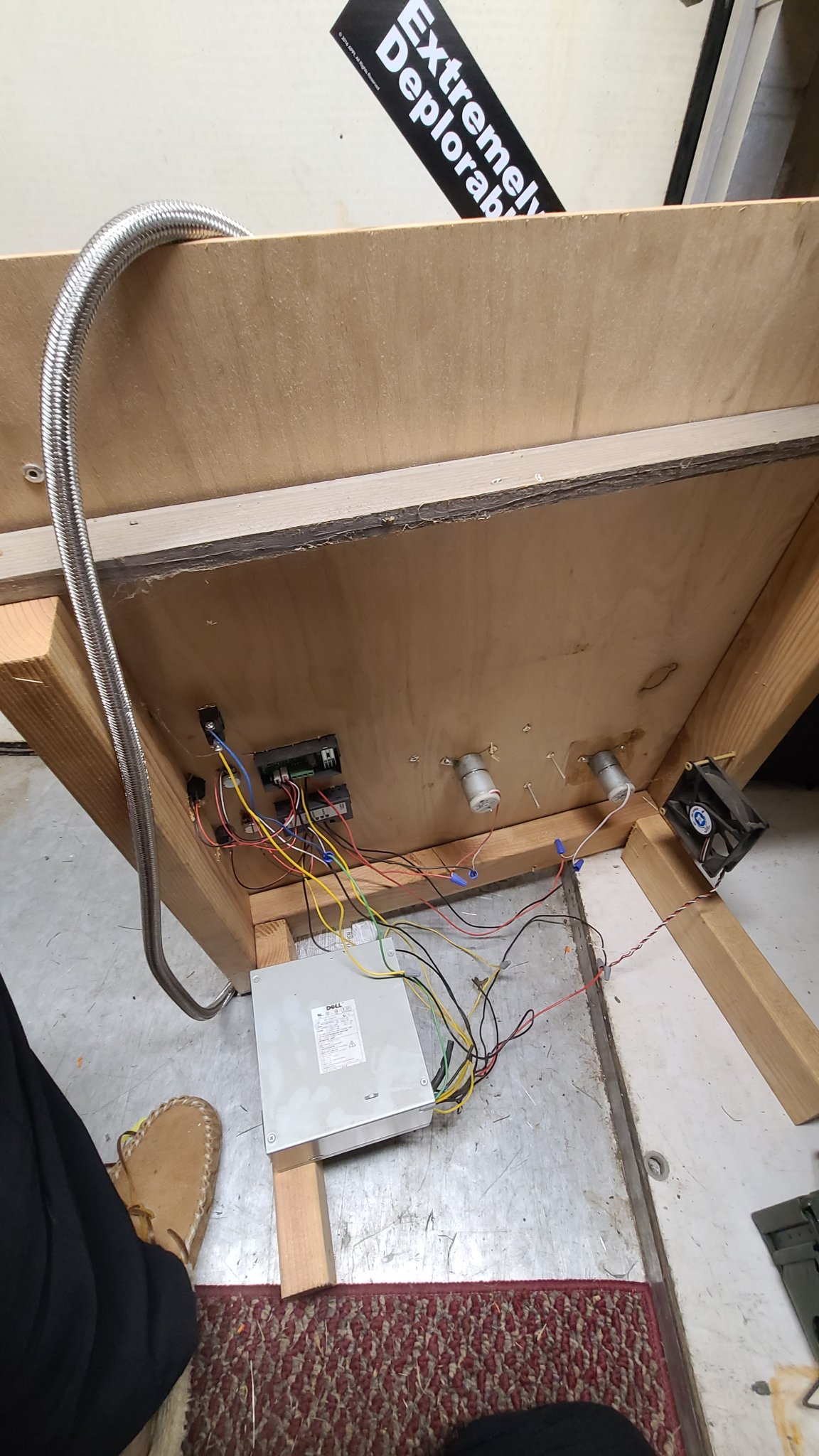

I don't know what happened to my old account here, so this will be an epic first post for my new account. Many years ago I built a home made case annealer using help found in the forums here. Well needless to say it never really worked great as the geared down motors I got from china just would not hold a constant RPM and they really suffered at low RPMs. So now that I have retired from the USCG I have time to get back into long range, and reloading. And since I'm cheap, I'm trying to extend the life of my brass. I'll skip they why to or why not to anneal and get into the brass tacks of my version 2 case annealer.

So a few months ago I bought a 3d printer. I noticed that they use stepper motors for motion control. that got me thinking, could I use a stepper motor to solve my version 1 annealer issues. Digging into the internet I found that yes I could use a stepper motor to precisely control speed to very low RPM, but how. This lead me to discovering Arduino and their micro processing boards. It seemed that I could make an Arduino precisely control a stepper motor speed, as well as display the speed on an LCD screen.

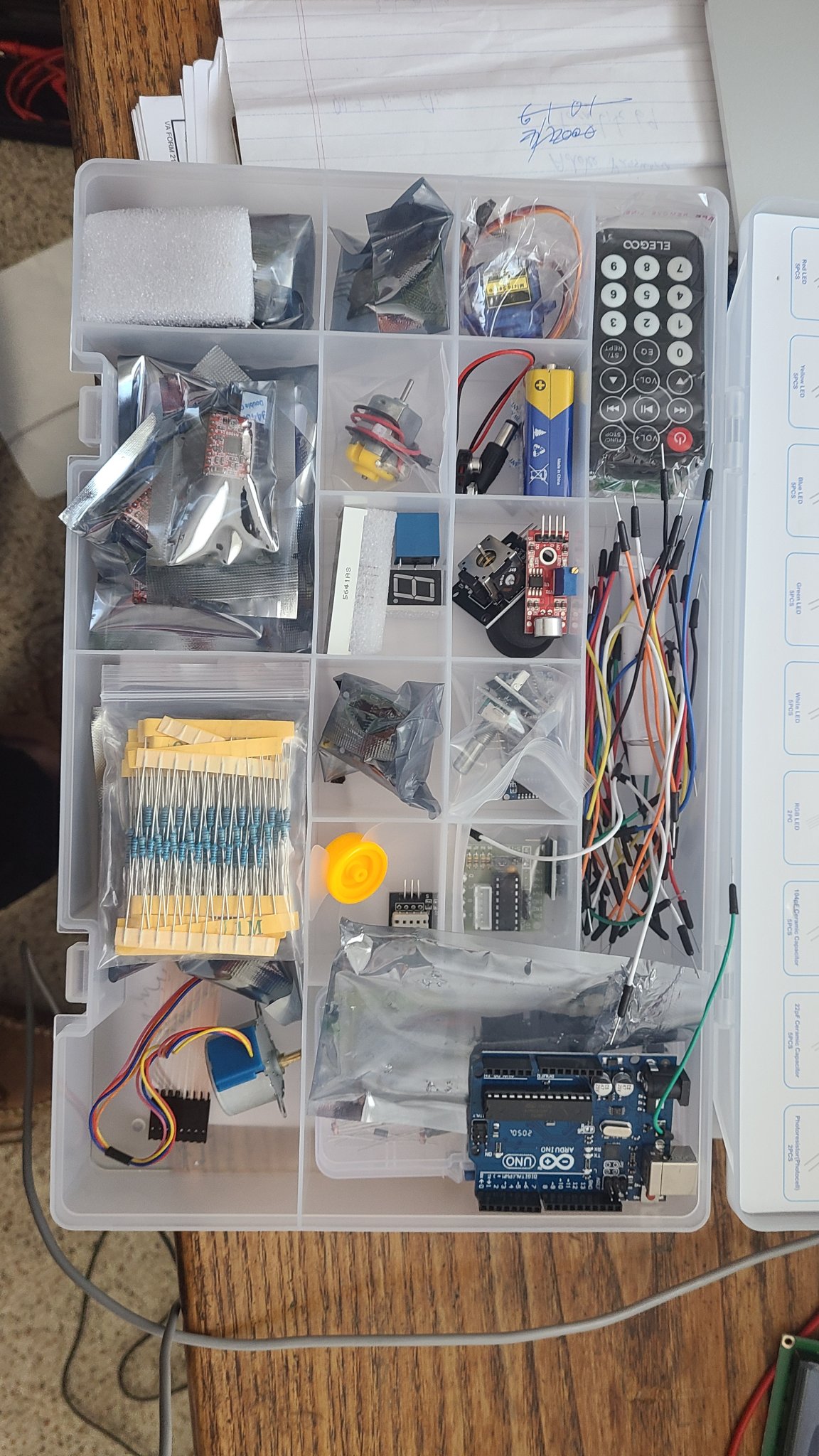

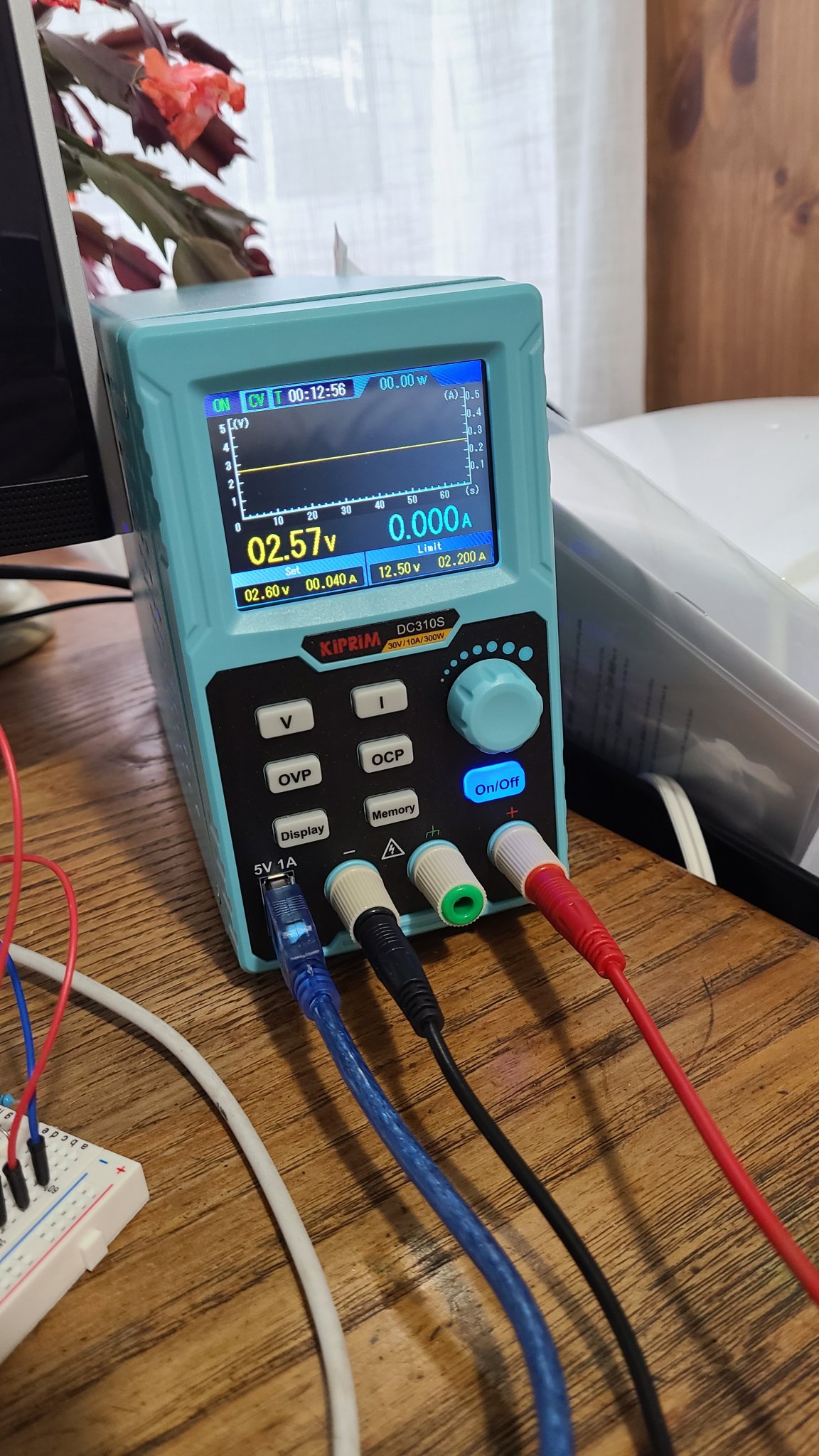

Knowing that I know nothing about Arduino and Arduino programming, I ordered a starter kit from amazon, and with the help of youtube learned the basics. I made LEDs flash, flicker, dim and of course burn up. (if you cant catch the blue smoke and put it back, it will never work again) . I also purchased a adjustable power supply, nema 17 stepper motor, A4988 stepper motor controller, and an 16x2 LCD screen. with these parts I could figure out all the electrical design and programing for the V2 annealer.

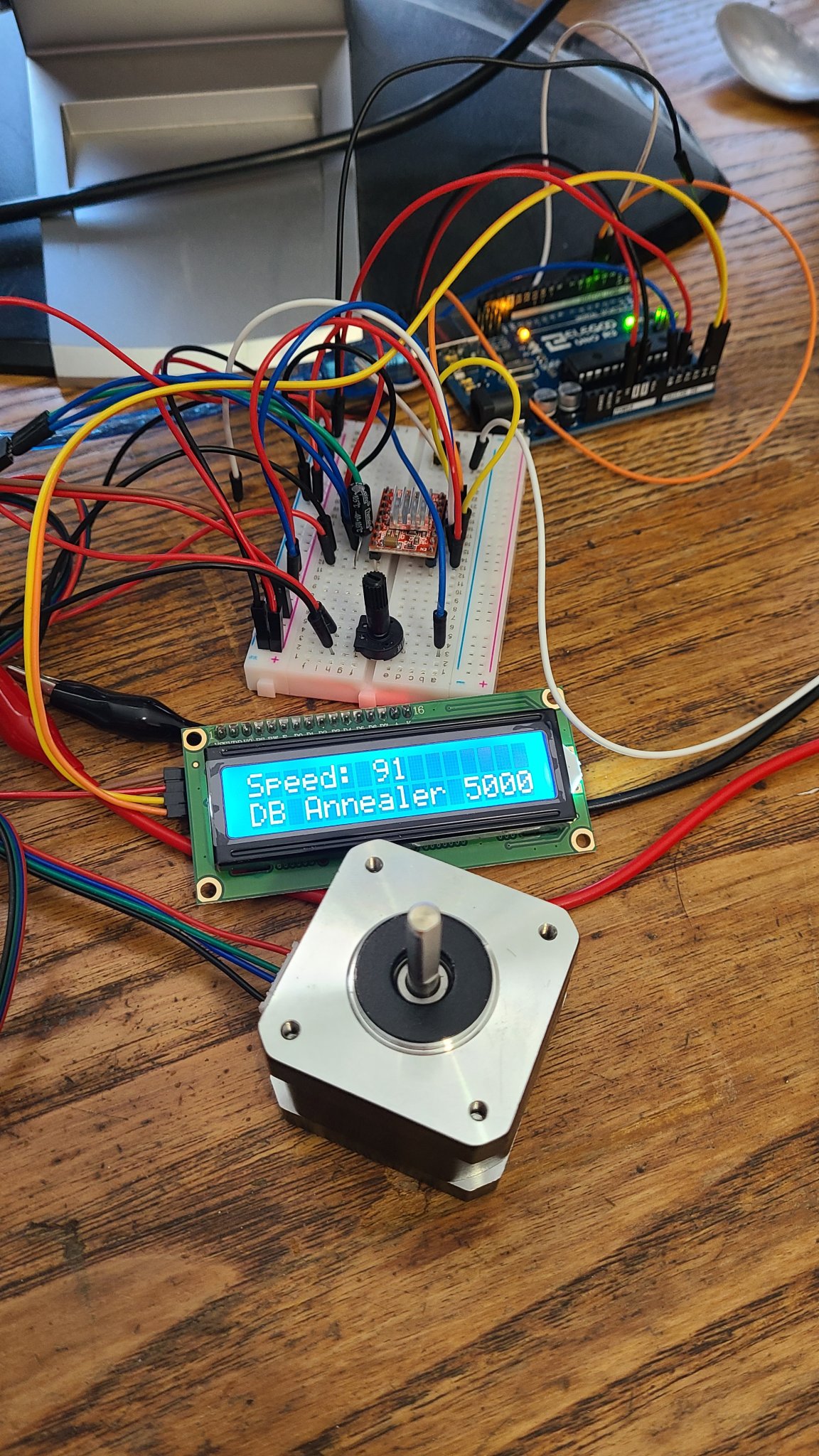

After many hours of head scratching I was able to write a program that gave the stepper motor variable speed controlled by a knob, and display the speed in percentage of low to high speed. 1 - 100% on an LCD screen. It took many many hours for me to get this to work as I wanted. There was a lot of, "well lets just start over" but at last I was able to get it to work by cobbling other peoples coding and my coding together. I can't explain it all, but it works.

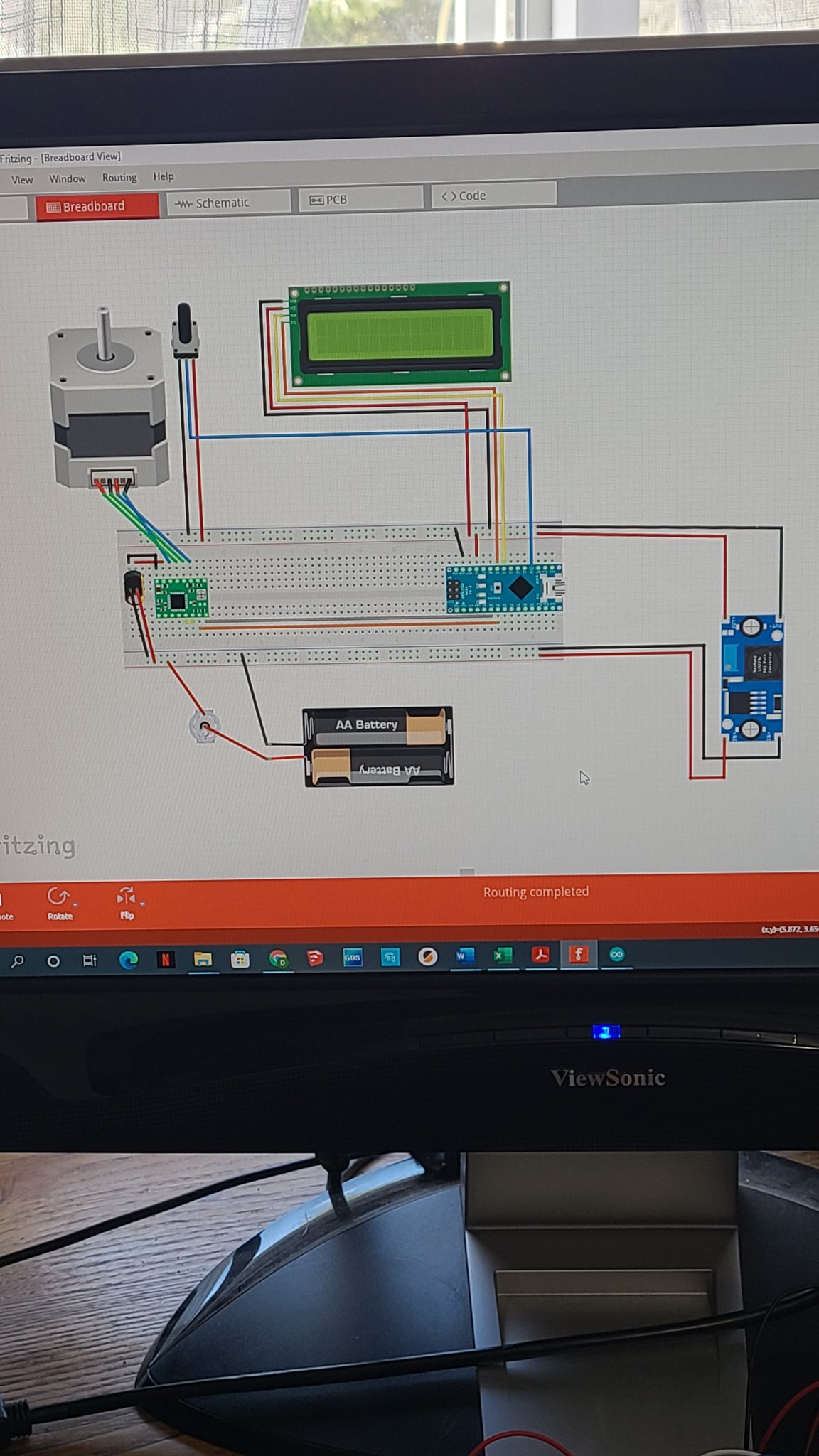

The Arduino board can be used for so much, and the board I have is an UNO revision 3, it is great for prototyping but I found I could get a Nano for about 7 bucks that does everything the UNO does and is much smaller. With this in mind I have used another program to layout my circuit design using this new board. Also incorporating a 12v power supply to feed the motor, and a voltage step down to feed the nano its 5v power. This will all get soldered onto a prototype PC board and placed into a 3d printed housing. the AA batteries in the photo are representing a 12v power supply.

Now I get to move onto the next step. designing a gear train to run the feeder and the drum off the one NEMA motor. I'll do the design work in fusion 360 cad (free for home use). My thought is to design a motor mount and directly attach a gear to the motor. and for the feeder and drum I'll design mounts that use skate board bearings (cheap) to reduce friction and gears to engage the motor gear. This will be too large to print all at once so I will incorporate line up tabs in the mounts so they lock into each other. And since I have some scrap aluminum around, I'll use that instead of wood this time. The form factor will be much much smaller than version 1 (what was I thinking). The LCD, Speed knob and power switch will all be in a printed housing on the front.

Now onto learning how to make gears in CAD, and also somehow getting all the parts design out of my head and into the computer. Fusion 360 is new to me and its a challenge at times. I'll be sure to update my progress as I continue on with this venture. First let me add a parts breakdown for cost reference.

1. Clone Arduino Nano......................................................................................$5.65

2. A4988 stepper motor driver ......................................................................$1.80

3. LM2596 adjustable step down buck power converter ....................$5.00

4. 5.5mm power plug, & switch ..................................................................$1.00

5. potentiometer & Capaciter.........................................................................$1.00

6. 12v power supply (wall wart) .....................................................................$10.00

7. 16x2 i2c lcd screen .........................................................................................$9.00

8. NEMA 17 stepper motor ..............................................................................$11.00

Total $44.45

Yes there is also cost in the aluminum, but its scrap from another project. I'm re using the cake pan from version 1 as well as the torch. also 3d print material will add a few dollars, but overall total cost should be around $100 bucks if you had to buy everything.

This has been a fun learning project and if I were to add up my time spent learning, it would be way cheaper to just buy a pre built. But the knowledge i have gained will greatly assist future projects.

END INITIAL POST: WILL UPDATE PROGRESS IN THE NEXT FEW WEEKS

So a few months ago I bought a 3d printer. I noticed that they use stepper motors for motion control. that got me thinking, could I use a stepper motor to solve my version 1 annealer issues. Digging into the internet I found that yes I could use a stepper motor to precisely control speed to very low RPM, but how. This lead me to discovering Arduino and their micro processing boards. It seemed that I could make an Arduino precisely control a stepper motor speed, as well as display the speed on an LCD screen.

Knowing that I know nothing about Arduino and Arduino programming, I ordered a starter kit from amazon, and with the help of youtube learned the basics. I made LEDs flash, flicker, dim and of course burn up. (if you cant catch the blue smoke and put it back, it will never work again) . I also purchased a adjustable power supply, nema 17 stepper motor, A4988 stepper motor controller, and an 16x2 LCD screen. with these parts I could figure out all the electrical design and programing for the V2 annealer.

After many hours of head scratching I was able to write a program that gave the stepper motor variable speed controlled by a knob, and display the speed in percentage of low to high speed. 1 - 100% on an LCD screen. It took many many hours for me to get this to work as I wanted. There was a lot of, "well lets just start over" but at last I was able to get it to work by cobbling other peoples coding and my coding together. I can't explain it all, but it works.

The Arduino board can be used for so much, and the board I have is an UNO revision 3, it is great for prototyping but I found I could get a Nano for about 7 bucks that does everything the UNO does and is much smaller. With this in mind I have used another program to layout my circuit design using this new board. Also incorporating a 12v power supply to feed the motor, and a voltage step down to feed the nano its 5v power. This will all get soldered onto a prototype PC board and placed into a 3d printed housing. the AA batteries in the photo are representing a 12v power supply.

Now I get to move onto the next step. designing a gear train to run the feeder and the drum off the one NEMA motor. I'll do the design work in fusion 360 cad (free for home use). My thought is to design a motor mount and directly attach a gear to the motor. and for the feeder and drum I'll design mounts that use skate board bearings (cheap) to reduce friction and gears to engage the motor gear. This will be too large to print all at once so I will incorporate line up tabs in the mounts so they lock into each other. And since I have some scrap aluminum around, I'll use that instead of wood this time. The form factor will be much much smaller than version 1 (what was I thinking). The LCD, Speed knob and power switch will all be in a printed housing on the front.

Now onto learning how to make gears in CAD, and also somehow getting all the parts design out of my head and into the computer. Fusion 360 is new to me and its a challenge at times. I'll be sure to update my progress as I continue on with this venture. First let me add a parts breakdown for cost reference.

1. Clone Arduino Nano......................................................................................$5.65

2. A4988 stepper motor driver ......................................................................$1.80

3. LM2596 adjustable step down buck power converter ....................$5.00

4. 5.5mm power plug, & switch ..................................................................$1.00

5. potentiometer & Capaciter.........................................................................$1.00

6. 12v power supply (wall wart) .....................................................................$10.00

7. 16x2 i2c lcd screen .........................................................................................$9.00

8. NEMA 17 stepper motor ..............................................................................$11.00

Total $44.45

Yes there is also cost in the aluminum, but its scrap from another project. I'm re using the cake pan from version 1 as well as the torch. also 3d print material will add a few dollars, but overall total cost should be around $100 bucks if you had to buy everything.

This has been a fun learning project and if I were to add up my time spent learning, it would be way cheaper to just buy a pre built. But the knowledge i have gained will greatly assist future projects.

END INITIAL POST: WILL UPDATE PROGRESS IN THE NEXT FEW WEEKS