Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Introducing the AI Obsession Chassis

- Thread starter samb300

- Start date

Another reminder that this chassis rides bags like a boss and is at home on whatever prop your local MD throws at you.

The NV Bridge can be positioned anywhere along the forend in 1.575" increments. In addition, its orientation can be flipped, so there is even finer refinement for hand or optic placement.I really like the idea of the nvg rail that can be located anywhere along the rail.

I find myself using my support hand up there more and more.

I also bet it wouldn’t be hard to modify it to work with the gray ops thumb grip he makes for the MPA chassis.

I'm 6'0" with long-ish arms, and I have naturally gravitated towards a support hand forward position on props. Support hand on top of the scope just never clicked with me. The short Razor helps as well, since something like a NF7-35 or TT525 are almost 2" longer in front.

I find a strip of grip tape on top of the NV Bridge works well for my support hand. But I'm sure the GrayOps thumb rest or something similar could work. The production version will have 5 holes on top, so maybe the spacing will line up? If anyone has an MPA chassis with the bridge and can measure those holes I'll let you know.

Also, stupid and nitpicky question.

Any option with the front spigot piece as picatinny? Like the AT version?

I like having the option of pic rail up there. Makes me feel better having a more secure option for bipod at times.

Again, stupid picky. Just curious. It’s definitely not a deal breaker.

Any option with the front spigot piece as picatinny? Like the AT version?

I like having the option of pic rail up there. Makes me feel better having a more secure option for bipod at times.

Again, stupid picky. Just curious. It’s definitely not a deal breaker.

The production version will no longer have the spigot mount like the machined prototype did. It's for a couple of reasons:Also, stupid and nitpicky question.

Any option with the front spigot piece as picatinny? Like the AT version?

I like having the option of pic rail up there. Makes me feel better having a more secure option for bipod at times.

Again, stupid picky. Just curious. It’s definitely not a deal breaker.

- The prototype spigot had more flex than I liked

- The spigot would have to mount through the bottom, because a 16-18" barrel would make it impossible to remove or install the spigot from the top once the barrel was on

- It added an additional component and cost to the kit that I didn't think was necessary.

I really got stuck in no-man's land with that aspect of the design. It's kind of subtle, but it ended up being just a bunch of stuff competing for space at the end of the forend (internal weight, integrated QD sockets, RRS dovetail on bottom, 1.25" dia barrel). Since the production version is 1.25" longer than the prototype, that also made me lean into deleting the spigot. An MDT ACC has an 18" long forend, and the AO chassis has a 16" forend (magwell to end of forend).

What I do have is 2x M4 cap screws on the bottom of the RRS dovetail, so if you have the bipod all the way forward and it loosens up, the screws will prevent it from sliding off. The forend also has M-Lok slots along the bottom, so you could install a 3-slot picatinny rail that would act as both a sliding stop and a picatinny attachment point.

I'll be honest, I really wanted the spigot to work. You probably wouldn't believe how much time I spent going back and forth on it.

I will also add, if it hasn't been pointed out previously...

The forend rail is machined to RRS Dovetail spec, and the M-Lok slots are machined per Magpul drawings. I didn't source drawings from google images (they are WAY off haha), I got them from the actual manufacturers, so you can be confident that your RRS lever clamps and M-Lok spec accessories will work on the chassis.

The forend rail is machined to RRS Dovetail spec, and the M-Lok slots are machined per Magpul drawings. I didn't source drawings from google images (they are WAY off haha), I got them from the actual manufacturers, so you can be confident that your RRS lever clamps and M-Lok spec accessories will work on the chassis.

Gonna be getting in on pre-order this weekend.

I’m sure you’ve either thought of it, or it’s come up. An add on that would be cool too is a full length nvg rail that basically turns it into an enclosed forend.

Sold separately of course.

I’m sure you’ve either thought of it, or it’s come up. An add on that would be cool too is a full length nvg rail that basically turns it into an enclosed forend.

Sold separately of course.

Honestly hadn’t thought of that. I’m not sure what benefit it would provide over a smaller one that can be positioned front to back?Gonna be getting in on pre-order this weekend.

I’m sure you’ve either thought of it, or it’s come up. An add on that would be cool too is a full length nvg rail that basically turns it into an enclosed forend.

Sold separately of course.

Something like that could be done, the problem is quantity. This will already be a really small batch size, so getting 3 or 5 extended NV bridges programmed and machined would likely be too costly to make it worth it for anyone. Just one of the many problems of not having my own CNC ?

I'm actually considering picking up an AT just because of this chassis.

do it. you'll be thrilled with it once its all together.

Do it man. I was debating back and forth. Even was thinking of not doing a AI at all. Ended up buying a AT with intentions of getting this chassis. Now that I have it. I’m in love. And I don’t even have the chassis yet.I'm actually considering picking up an AT just because of this chassis.

Honestly hadn’t thought of that. I’m not sure what benefit it would provide over a smaller one that can be positioned front to back?

Something like that could be done, the problem is quantity. This will already be a really small batch size, so getting 3 or 5 extended NV bridges programmed and machined would likely be too costly to make it worth it for anyone. Just one of the many problems of not having my own CNC ?

Benefits:

1: it looks cool. This is the most important benefit. Fucking duh

2: allows placement of hand anywhere along the rail. I find myself using different placements depending on position (your nvg rail may be perfect with the length it is and being Able to place it anywhere. I’ve just had nvg rails in the past that work most of the time, but not all the time. A full rail alleviates that).

3: cuts down on barrel induced mirage

Again, number 1 is most important ?

The top of the NV Bridge is ~5" long, and the position of it on the forend can be adjusted in ~0.75" increments. That should cover most situations and optic placements, I hope.Benefits:

1: it looks cool. This is the most important benefit. Fucking duh

2: allows placement of hand anywhere along the rail. I find myself using different placements depending on position (your nvg rail may be perfect with the length it is and being Able to place it anywhere. I’ve just had nvg rails in the past that work most of the time, but not all the time. A full rail alleviates that).

3: cuts down on barrel induced mirage

Again, number 1 is most important ?

I was thinking about photoshopping a ridiculous array of NV Bridges, but I'm too lazy ?

if I go with this chassis for my aw I would be able to run the ax buttstock correct

Correct. The ax butt stock will be mounted directly to the AO chassis.

Yup, AT or AX buttstock will work ??if I go with this chassis for my aw I would be able to run the ax buttstock correct

I've found a pretty good deal on an AT with a fixed stock. If I get it and then get the AX stock conversion from mile high will it have the ability to fold or do I need to just get an AT with the folding stock?

A fixed AT is the most economical way to get what you want. The AX stock will come with a folder. All u would need to do is buy some skins for a folder (used preferably as they would be even cheaper) and the AO chassis, then Bob's your uncle.

Things are getting freaky again...double and triple checking final dimensions before I assemble and re-bond the prototype chassis to my AX action. Anyone interested in seeing some detailed videos on the de-bonding and re-bonding process? Instructional videos will be inbound this week, stay tuned!

The first video I made (which was not shared publicly) used the Devcon 2-part epoxy, which I have since switched to the Aluminum Putty that AI proper uses. I think the putty will not only be better, but make installation easier and faster.Its actually a very straight forward and easy process. Your first video detailed everything nicely. Technically, you dont HAVE to re-bond it. Just use the action screws, but the AI mojo may be due to bonding.

There are people that think the bonding agent is not needed, but I decided to design the action to chassis interface exactly as AI has done on this generation (AW/AT/AX) of actions. This means there is a small amount of putty between the recoil lug and the chassis. Should the end user decide to try the chassis without the putty, I cannot guarantee the fit and alignment of the chassis relative to the magwell. At the minimum if this is done, the action will need to be positioned rearward to contact the recoil lug with the chassis, much like a regular R700 pattern action in a stock or chassis.

A fixed AT is the most economical way to get what you want. The AX stock will come with a folder. All u would need to do is buy some skins for a folder (used preferably as they would be even cheaper) and the AO chassis, then Bob's your uncle.

I could be wrong, but I don’t think any folder skins are necessary. The AX stock doesn’t use skins. And the only skins that are different is the AT buttstock skins.

Pistol Grip and forearm skins are the same as far as I remember.

Correct. AT and AX share the same pistol grip skins and backstrap, regardless of fixed vs. folder.I could be wrong, but I don’t think any folder skins are necessary. The AX stock doesn’t use skins. And the only skins that are different is the AT buttstock skins.

Pistol Grip and forearm skins are the same as far as I remember.

On an AT, the forend skins are the same on fixed and folder. If you have buttstock skins on a fixed AT, you can convert to a folding AT buttstock and keep the same skins, you just need to trim/cut the excess material off.

I figured the grip and stock skins were all 1 piece on the non folders. I've never actually paid attention to them. Good catch, fellas.

Here are the detailed instructions, step-by-step for de-bonding an AI, prepping it, and bonding it back together with the Obsession chassis. Let me know if you have any questions or comments! I'm hoping this reassures anyone who has already pre-ordered the chassis that the installation isn't anything too scary. I'm also hoping that anyone on the fence about buying the chassis because of the de-bonding process will see these and have the confidence in my design and the instructions for doing it on your own.

1) De-bonding the buttstock

2) De-bonding the action

3) Bonding the action, chassis, and buttstock together

Thanks,

Sam

1) De-bonding the buttstock

2) De-bonding the action

3) Bonding the action, chassis, and buttstock together

Thanks,

Sam

Last edited:

Thank you, I appreciate it!I don't own an AI (I think I may have touched one, once) and I just read this whole thread. Mostly just because the entire design and prototyping process amazes me. Super cool stuff going on in here.

It's been quite the process over the past year...a "labor of love" if I could call it anything. Putting a bunch of work into something doesn't automatically mean it's any good; hopefully the people that end up taking the leap with me on this and buying a chassis will see the benefits as I have.

Sam

It definitely looks like a lot of thought has been put into it and while a spigot certainly looks cool, I've often wondered what advantages they have over just extending the forearm itself. I think that you came up with the best compromise between both options.Thank you, I appreciate it!

It's been quite the process over the past year...a "labor of love" if I could call it anything. Putting a bunch of work into something doesn't automatically mean it's any good; hopefully the people that end up taking the leap with me on this and buying a chassis will see the benefits as I have.

Sam

Thank you for the videos. I noticed in the videos there is a small piece that stays attached to the butt stock from your original AX chassis. If I do this it will be on my aw and I know that the AT/ax conversion doesn’t fit the aw. just wondering what your thoughts would be on how to make that work. Thanks

Thank you for the videos. I noticed in the videos there is a small piece that stays attached to the butt stock from your original AX chassis. If I do this it will be on my aw and I know that the AT/ax conversion doesn’t fit the aw. just wondering what your thoughts would be on how to make that work. Thanks

Have you thought about picking up either an AX stock or a takeoff AT stock?

That way you could just pop the action off the chassis and not have to worry about debonding the stock.

I haven’t really put much thought into that because of the price hell the conversion but stock $600But that might be a the best option

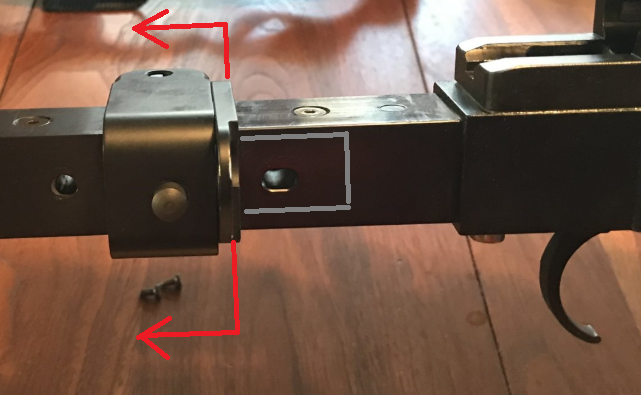

If possible, can you take off the skins on your AW and take a couple pictures of the chassis-to-buttstock connection, like this:Thank you for the videos. I noticed in the videos there is a small piece that stays attached to the butt stock from your original AX chassis. If I do this it will be on my aw and I know that the AT/ax conversion doesn’t fit the aw. just wondering what your thoughts would be on how to make that work. Thanks

If the AW has the pinned interface it might be a challenge to get that to work. Like @Luvman said, an AX or take-off AT buttstock might be an easier, but more expensive option. But let me see some pics and think about what we could do to possibly get the AW buttstock to work.

Posted this over in the Group Buy thread...

Alright guys, I have the formal Purchase Order in with the machine shop. Unfortunately the lead time is now longer than we had discussed a few weeks ago during the initial quotation. Current machining lead time is 14-16 weeks, and I will need 3-4 weeks after that for anodizing, nitriding, cerakoting, and packaging. That would put the delivery estimate at the end of June, 2020.

I was obviously hoping for a shorter time frame, but I'm at the mercy of the machine shop that did the protoypes and have the programming and tooling. They are a great shop, but busy. I will do my best to keep in touch with them - and you guys - to keep an accurate representation of the timeline. I absolutely don't want to provide any false promises, but also don't want to just let things slip by weeks/months as they often do.

The quantity of chassis kits is still open on the P.O., so the pre-order will continue until I have to firm that number so they can order raw material. I'm still hoping to get some more people on board, so if you or anyone you know is on the fence, shoot me a PM if you have any questions!

Thanks again,

Sam

Alright guys, I have the formal Purchase Order in with the machine shop. Unfortunately the lead time is now longer than we had discussed a few weeks ago during the initial quotation. Current machining lead time is 14-16 weeks, and I will need 3-4 weeks after that for anodizing, nitriding, cerakoting, and packaging. That would put the delivery estimate at the end of June, 2020.

I was obviously hoping for a shorter time frame, but I'm at the mercy of the machine shop that did the protoypes and have the programming and tooling. They are a great shop, but busy. I will do my best to keep in touch with them - and you guys - to keep an accurate representation of the timeline. I absolutely don't want to provide any false promises, but also don't want to just let things slip by weeks/months as they often do.

The quantity of chassis kits is still open on the P.O., so the pre-order will continue until I have to firm that number so they can order raw material. I'm still hoping to get some more people on board, so if you or anyone you know is on the fence, shoot me a PM if you have any questions!

Thanks again,

Sam

Sam,

What's the cost of the chassis? Maybe update/add that to the initial post(?)...

1200 for kit, 600 deposit.

I thought it best to keep ordering info in the Group Buy thread from here on out. Just trying to pass information on to people in this thread that aren't getting notifications in the other one.Sam,

What's the cost of the chassis? Maybe update/add that to the initial post(?)...

The chassis kit is $1200, and I'm asking for a $600 deposit to reserve a spot.

Thanks,

Sam

@killer-e what buttstock are you ultimately trying to use with the AO chassis? Because it looks like you've got a couple options.

1a) AX Buttstock: this is literally a direct fit onto the AO chassis, no drama. Basically you will just need to de-bond the AW action only from the factory chassis, no need to mess with the buttstock. When you're assembling the action to the AO chassis, the AX buttstock will install directly to the AO chassis.

1b) AT Buttstock: this will install the same as the AX buttstock will. You should be able to find one that someone is selling after they did the AX upgrade on their rifle, for about $250-$300, quite a bit less than an AX buttstock.

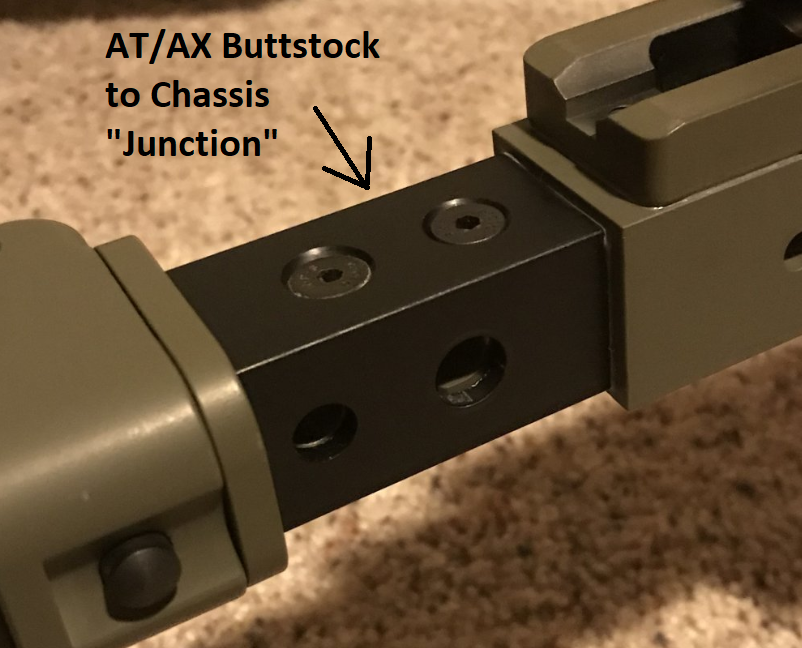

2) AW Buttstock: more work, but looking at the pics I think it's doable with a new buttstock junction.

---- First, de-bond the buttstock from the junction. Normally the junction is de-bonded from the chassis, and the junction is kept on the buttstock.

---- I believe the "male" tang on the AW buttstock is the same as on an AT or AX

---- To get it properly installed on the AO chassis, we will either need to source the junction from Mile High (not sure if it's a stocked part), or we can make one. It's a piece of square tube with a few holes drilled into it, so nothing complicated. I can draw this part up and find a way to get one made if needed.

1a) AX Buttstock: this is literally a direct fit onto the AO chassis, no drama. Basically you will just need to de-bond the AW action only from the factory chassis, no need to mess with the buttstock. When you're assembling the action to the AO chassis, the AX buttstock will install directly to the AO chassis.

1b) AT Buttstock: this will install the same as the AX buttstock will. You should be able to find one that someone is selling after they did the AX upgrade on their rifle, for about $250-$300, quite a bit less than an AX buttstock.

2) AW Buttstock: more work, but looking at the pics I think it's doable with a new buttstock junction.

---- First, de-bond the buttstock from the junction. Normally the junction is de-bonded from the chassis, and the junction is kept on the buttstock.

---- I believe the "male" tang on the AW buttstock is the same as on an AT or AX

---- To get it properly installed on the AO chassis, we will either need to source the junction from Mile High (not sure if it's a stocked part), or we can make one. It's a piece of square tube with a few holes drilled into it, so nothing complicated. I can draw this part up and find a way to get one made if needed.

I was really wanting to use the ax but stock . When the at/aX conversions came out I was told by mile high that it wouldn’t fit my older AW that’s where my concern comes from so if I have to use that junction off my aw I didn’t think it would work

This is how the AX buttstock is sold:

If you're talking about installing the AX buttstock on your AW (not buying the AO chassis), then I still think it's possible. You'd have to do just like I said above: de-bond the AW buttstock from the rear of the juction. Then you'd have to de-bond the AX buttstock from its junction. Then bond the AX buttstock to the AW, which has the original junction still in place.

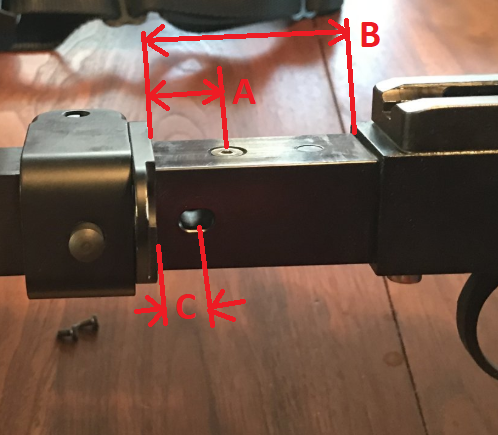

It you have your calipers handy, get me these numbers and I'll confirm the spacing is the same.

A = distance from face of hinge to center of screw (screw should have a 10 mm head diameter)

B = length of "junction"

C = distance from face of hinge to center of hole in side (also provide diameter of hole)

Again, if you're talking about the AX buttstock on the AO chassis there will be zero issues. If you're trying to figure out if you can get the AW buttstock on the AO chassis, take those measurements and let me know.

If you're talking about installing the AX buttstock on your AW (not buying the AO chassis), then I still think it's possible. You'd have to do just like I said above: de-bond the AW buttstock from the rear of the juction. Then you'd have to de-bond the AX buttstock from its junction. Then bond the AX buttstock to the AW, which has the original junction still in place.

It you have your calipers handy, get me these numbers and I'll confirm the spacing is the same.

A = distance from face of hinge to center of screw (screw should have a 10 mm head diameter)

B = length of "junction"

C = distance from face of hinge to center of hole in side (also provide diameter of hole)

Again, if you're talking about the AX buttstock on the AO chassis there will be zero issues. If you're trying to figure out if you can get the AW buttstock on the AO chassis, take those measurements and let me know.

I was really wanting to use the ax but stock . When the at/aX conversions came out I was told by mile high that it wouldn’t fit my older AW that’s where my concern comes from so if I have to use that junction off my aw I didn’t think it would work

Aye. I'll make u a deal. If u want to save some coin, I'll sell u my AT rear section with both the regular skins and thumb hole skins for $400 so u don't have to pay the $800 ish for the AX rear section.

Unfortunately with the action/chassis/trigger design from AI, it makes it really difficult to do this while retaining the bonded interface and the factory AI buttstock interface. I looked at this problem for a long time, and I won't say it's impossible, but I wasn't happy with what I could come up with.Anything in the works for making grips interchangeable similar to AR receivers?

My recommendation if you really want the AR grip tang interface, is to look at the MPA-AT chassis, or the new AI AXSR.

Makes sense, I've only handled an AI once and had no issue with it. I feel like I've seen a post somewhere that someone had done it and the axsr does it somehow. I was just curious. I'm hoping to buy or trade for an AT soon and put it in an obsession chassis.

Similar threads

- Replies

- 0

- Views

- 278

- Replies

- 6

- Views

- 1K