Have one in the way for my Remington 700 .308, the stock comes with aluminum pillars already installed. Are there any A5 shooters i. here shooting Mcmillian stocks without glass bedding? Also, is there really any benefit going the chassis route down the road? Love the look of the A5, but Mcmillian doesn't offer any type of chassis. Thanks

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is bedding a Mcmillian a5 necessary

- Thread starter G101489

- Start date

Have one in the way for my Remington 700 .308, the stock comes with aluminum pillars already installed. Are there any A5 shooters i. here shooting Mcmillian stocks without glass bedding? Also, is there really any benefit going the chassis route down the road? Love the look of the A5, but Mcmillian doesn't offer any type of chassis. Thanks

Some smiths still say that a proper bedding job will beat out a chassis. I personally can't shoot good enough to tell the difference on either one. I am not a gunsmith but from what I understand, I would recommend glass bedding yours as the pillars are only a piece of the puzzle.

I also just read on Mcmillians website that you DO NOT need to bed the stock. This whole thing has me slightly confused, as there are so many different opinions when it comes to these stocks. Makes me wish I would have just gotten a chassis LOL

I had an A5 that was never bedded. It shot so well, I never felt the need. Half moa was normal and 1/3 moa wasn't unusual. It didn't have pillars by the way. And this was a stock 5R in .308

I also have a Manners T2 that is only pillar bedded, it has shot 1/4 moa many times and is every bit as accurate as any bedded stocks I have. This is a fully built 700 with Bartlein, Jewell, etc.

My advice would mirror that of my gunsmith, shoot it and then determine if it needs to be bedded.

I also have a Manners T2 that is only pillar bedded, it has shot 1/4 moa many times and is every bit as accurate as any bedded stocks I have. This is a fully built 700 with Bartlein, Jewell, etc.

My advice would mirror that of my gunsmith, shoot it and then determine if it needs to be bedded.

Last edited:

Get an inch pound torque wrench and torque the action consistently every time and you may be pleasantly surprised.

with a high quality stock or chassis, you aren't bedding for the sake of the stock, you are bedding because the action. If you are going to be removing the action from the stock on a regular basis, then pillar bedding will help to protect the stock.

I have an XLR chassis, it is a very well made chassis, but I had to bed it because the remington action was out of square. When I torqued it into the stock, it would put pressure on the action and cause problems with the trigger.

I have an XLR chassis, it is a very well made chassis, but I had to bed it because the remington action was out of square. When I torqued it into the stock, it would put pressure on the action and cause problems with the trigger.

with a high quality stock or chassis, you aren't bedding for the sake of the stock, you are bedding because the action. If you are going to be removing the action from the stock on a regular basis, then pillar bedding will help to protect the stock.

I have an XLR chassis, it is a very well made chassis, but I had to bed it because the remington action was out of square. When I torqued it into the stock, it would put pressure on the action and cause problems with the trigger.

Never thought of it that way. Always wondered why folks would bed $1000 stocks. Now I know it's the action, not the stock.

I have 2 A5's. One bedded by GAP and one by AO. Both shoot great and now if I build or buy a custom gun it must be bedded. It's more a mental thing for me now. IMHO it's a case by case bases. Remington builds thousands of guns with the same parts. Some are shooters and some aren't. Luck of the draw there. If I were you I would put the gun in the stock and shoot it. If it meets or beats your expectations then your GTG and you saved $300 bucks. If not send it off to a gunsmith and have them bed it.

You don't have to bed it. All you are really after is a tension free register for the action to reside in. It's better if there's a little "squish" when the action goes in. Meaning the sides should not be wider than the receiver's diameter.

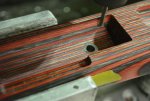

Taking this to the extreme: 3 dimensional cnc machined using what's called "surfacing". Instead of a big ol paddle type cutter this is done with something much smaller. 3/16" tool diameter in this case. It race tracks around and with the use of software I'm mirroring the action's profile. Pillars are stainless. Gets it all in one carefully controlled tool path.

Same with recoil lug, barrel channel, etc. We've proven this shoots as well as a bedding job. The only "rub" is the fit/finish isn't as good as what we can do with a full effort setup. You just leave a little on a table going this route. Speed/affordability was the end goal here.

Bolt the thing together once its done and go shoot it. The target always tells the truth...

Taking this to the extreme: 3 dimensional cnc machined using what's called "surfacing". Instead of a big ol paddle type cutter this is done with something much smaller. 3/16" tool diameter in this case. It race tracks around and with the use of software I'm mirroring the action's profile. Pillars are stainless. Gets it all in one carefully controlled tool path.

Same with recoil lug, barrel channel, etc. We've proven this shoots as well as a bedding job. The only "rub" is the fit/finish isn't as good as what we can do with a full effort setup. You just leave a little on a table going this route. Speed/affordability was the end goal here.

Bolt the thing together once its done and go shoot it. The target always tells the truth...

You don't have to bed it. All you are really after is a tension free register for the action to reside in. It's better if there's a little "squish" when the action goes in. Meaning the sides should not be wider than the receiver's diameter.

Taking this to the extreme: 3 dimensional cnc machined using what's called "surfacing". Instead of a big ol paddle type cutter this is done with something much smaller. 3/16" tool diameter in this case. It race tracks around and with the use of software I'm mirroring the action's profile. Pillars are stainless. Gets it all in one carefully controlled tool path.

Same with recoil lug, barrel channel, etc. We've proven this shoots as well as a bedding job. The only "rub" is the fit/finish isn't as good as what we can do with a full effort setup. You just leave a little on a table going this route. Speed/affordability was the end goal here.

Bolt the thing together once its done and go shoot it. The target always tells the truth...

Wow, thanks for the indepth analysis for my question. Is the CNC process you mentioned above, y'alls way of inletting or is that standard way it's done? Thanks again!

Last edited:

It's standard, but there's two different standards.

For the 1:1 inlet I run "to the number". Just meaning there's no additional clearance allowed. For a bedded stock, it's different. I punch out the inlet for the action .05" radially. The idea being a concentric .05" thick film of bedding between stock/action. I never cared for skinned bed jobs when I first started farting around with this stuff. Seemed they always chipped easier, etc. The other reason is if were going to talk about compression tolerance etc, just how realistic is it for a material less than a sheet of paper in thickness in some instances, to deliver all of the prescribed standards?

We wouldn't dare pour a sidewalk like this.

It goes all the way to the pillar design as well. I make those in house also. What I've done is try to make a system of the whole thing. Food/Beverage grade stainless. Never aluminum. I won't use AL on a composite (or wood). AL/glass/carbon are polar opposites on the galvanic table. Introduce an electrolyte such as seawater and it's a breeding ground for corrosion. There's also some adhesion issues. Its not uncommon at all for inletted stocks with AL pillars to pop loose. I've repaired a lot of em.

Whether or not this matters in performance is certainly open for debate. I can say I've never had a bedding job that caused random acts of torture to a target. I know for a fact there's many others who enjoy that same standard, yet they go "thin" on the bedding job.

My opinion has a lot to do with final fit and finish. I genuinely like the way our stuff presents. I like seeing a concentric film of known distance between action and stock. It's become a bit of a hallmark for my shop. For those that really go this "deep" into a gun, it's a big deal. That is the client I'm trying to appeal to with all the extra work.

It's gotten to the point of being a bit absurd at times. Surface modeling the recoil lug for instance. Every radius, everything. Everyone that we do gets that treatment. Same with the inlets afterwards. I now have very accurate CAD solid models on every action we fit for. Not an easy thing to do (reverse engineering other people's stuff just sucks as its very time consuming)

Thanks for asking.

C.

For the 1:1 inlet I run "to the number". Just meaning there's no additional clearance allowed. For a bedded stock, it's different. I punch out the inlet for the action .05" radially. The idea being a concentric .05" thick film of bedding between stock/action. I never cared for skinned bed jobs when I first started farting around with this stuff. Seemed they always chipped easier, etc. The other reason is if were going to talk about compression tolerance etc, just how realistic is it for a material less than a sheet of paper in thickness in some instances, to deliver all of the prescribed standards?

We wouldn't dare pour a sidewalk like this.

It goes all the way to the pillar design as well. I make those in house also. What I've done is try to make a system of the whole thing. Food/Beverage grade stainless. Never aluminum. I won't use AL on a composite (or wood). AL/glass/carbon are polar opposites on the galvanic table. Introduce an electrolyte such as seawater and it's a breeding ground for corrosion. There's also some adhesion issues. Its not uncommon at all for inletted stocks with AL pillars to pop loose. I've repaired a lot of em.

Whether or not this matters in performance is certainly open for debate. I can say I've never had a bedding job that caused random acts of torture to a target. I know for a fact there's many others who enjoy that same standard, yet they go "thin" on the bedding job.

My opinion has a lot to do with final fit and finish. I genuinely like the way our stuff presents. I like seeing a concentric film of known distance between action and stock. It's become a bit of a hallmark for my shop. For those that really go this "deep" into a gun, it's a big deal. That is the client I'm trying to appeal to with all the extra work.

It's gotten to the point of being a bit absurd at times. Surface modeling the recoil lug for instance. Every radius, everything. Everyone that we do gets that treatment. Same with the inlets afterwards. I now have very accurate CAD solid models on every action we fit for. Not an easy thing to do (reverse engineering other people's stuff just sucks as its very time consuming)

Thanks for asking.

C.

Attachments

Last edited:

It's standard, but there's two different standards.

For the 1:1 inlet I run "to the number". Just meaning there's no additional clearance allowed. For a bedded stock, it's different. I punch out the inlet for the action .05" radially. The idea being a concentric .05" thick film of bedding between stock/action. I never cared for skinned bed jobs when I first started farting around with this stuff. Seemed they always chipped easier, etc. The other reason is if were going to talk about compression tolerance etc, just how realistic is it for a material less than a sheet of paper in thickness in some instances, to deliver all of the prescribed standards?

We wouldn't dare pour a sidewalk like this.

It goes all the way to the pillar design as well. I make those in house also. What I've done is try to make a system of the whole thing. Food/Beverage grade stainless. Never aluminum. I won't use AL on a composite (or wood). AL/glass/carbon are polar opposites on the galvanic table. Introduce an electrolyte such as seawater and it's a breeding ground for corrosion. There's also some adhesion issues. Its not uncommon at all for inletted stocks with AL pillars to pop loose. I've repaired a lot of em.

Whether or not this matters in performance is certainly open for debate. I can say I've never had a bedding job that caused random acts of torture to a target. I know for a fact there's many others who enjoy that same standard, yet they go "thin" on the bedding job.

My opinion has a lot to do with final fit and finish. I genuinely like the way our stuff presents. I like seeing a concentric film of known distance between action and stock. It's become a bit of a hallmark for my shop. For those that really go this "deep" into a gun, it's a big deal. That is the client I'm trying to appeal to with all the extra work.

It's gotten to the point of being a bit absurd at times. Surface modeling the recoil lug for instance. Every radius, everything. Everyone that we do gets that treatment. Same with the inlets afterwards. I now have very accurate CAD solid models on every action we fit for. Not an easy thing to do (reverse engineering other people's stuff just sucks as its very time consuming)

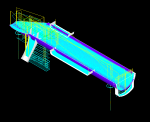

Here's the top of the "absurdosphere" in my world: 1:1 surface inletted chassis I made from 6AL4V titanium. One of One, lol. Quite expensive.. .

Thanks for asking.

C.

So much good information, by brain had an error LOL! That titanium chassis is beautiful. Hopefully the A5 I'm getting will be a shooter. If not, I'll be giving you a call. Thanks again!

I can't speak to the depth that Chad can nor can most people... But here is what I can lend. I had an A5 I got a really good deal on. Put a pre-cut barrel in it and went to shooting (no bedding). Was not happy with how it was shooting so sent it to GAP and had a new barrel put on and it bedded. Shot last week out to 1000 with a blind guess on dope from a different rifle and went 5 for 5 on a silhouette. Would have never been able to do that with the previous version that wasn't bedded, the accuracy just wasn't there. Just my 0.02

I can't speak to the depth that Chad can nor can most people... But here is what I can lend. I had an A5 I got a really good deal on. Put a pre-cut barrel in it and went to shooting (no bedding). Was not happy with how it was shooting so sent it to GAP and had a new barrel put on and it bedded. Shot last week out to 1000 with a blind guess on dope from a different rifle and went 5 for 5 on a silhouette. Would have never been able to do that with the previous version that wasn't bedded, the accuracy just wasn't there. Just my 0.02

I wonder if the accuracy increase had more to do with the barrel rather than bedding?

So its more of a case by case thing then? If I ordered a barreled action and a stock srperate I may not get the accuracy intended, and possible, from the rig with out bedding it?

Context. There's an easy way to put this in perspective.

Pro Stock Drag Racing. If you don't have 1250hp at the flywheel, keep the car on the trailer and buy tickets for the cheap seats. Anything less is a waste of money as you'll just make a bunch of noise with no hopes of ever winning or even placing. If you have 1250 you might spend another 250K to find 15-20 more hp. Numbers that don't mean much. But in a pro class that little bit of power is the difference. A big difference.

The important thing is 1250 to start. Now apply that to a precision. gun. The barrel is your 1250. It just is. The rest is the small gain that when combined with it makes for an exceptionally accurate rifle. By itself however it's little more than the hp rating of a rototiller or garden tractor. . .

If given a choice between all the lapping, buffing, bedding, trigger tuning, whatever. Buy a premium stick and have it installed by someone known to have a good understanding of accurate gunmaking. You'll get much further in the game.

Make sense?

Pro Stock Drag Racing. If you don't have 1250hp at the flywheel, keep the car on the trailer and buy tickets for the cheap seats. Anything less is a waste of money as you'll just make a bunch of noise with no hopes of ever winning or even placing. If you have 1250 you might spend another 250K to find 15-20 more hp. Numbers that don't mean much. But in a pro class that little bit of power is the difference. A big difference.

The important thing is 1250 to start. Now apply that to a precision. gun. The barrel is your 1250. It just is. The rest is the small gain that when combined with it makes for an exceptionally accurate rifle. By itself however it's little more than the hp rating of a rototiller or garden tractor. . .

If given a choice between all the lapping, buffing, bedding, trigger tuning, whatever. Buy a premium stick and have it installed by someone known to have a good understanding of accurate gunmaking. You'll get much further in the game.

Make sense?

I have 3 McMillans, a A4, Game Scout, and a A5. I don't question it, I bed them regardless of the previous performance. I don't question how the stocks are cut, I just have a better peace of mind knowing that it's a perfect fit between action and stock.

Sent from my SM-G930V using Tapatalk

Sent from my SM-G930V using Tapatalk

I have 3 McMillans, a A4, Game Scout, and a A5. I don't question it, I bed them regardless of the previous performance. I don't question how the stocks are cut, I just have a better peace of mind knowing that it's a perfect fit between action and stock.

Sent from my SM-G930V using Tapatalk

It gets down to what is good enough, whether just expectations, or requirements to be competitive at some level. My A5 is a .260 Ackley and McMillian precut it for my BAT Tactical (Wolf) and my MTM sized barrel by BRUX in 8 twist. I deferred to my smith as to skim bedding or not as he strongly recommended it. With approximately 20 shots, taken in 3 shot groups at 100, we fired media fired cases and measured to the best of our ability a .268 group WITH the bullet included. It was a perfect day for sure. 6 weeks later he took a lesser stock he had just lying around, barreled it with a similar extra barrel (.30) and chambered it in WSM to shoot 110 to 125 grains at very high speeds. In approximately the same number of rounds, he shot a .3095 3 shot group across the same course, again WITH the bullet. This does not mean WE are capable of incredible shooting on an ongoing basis, but that the weapon IS capable if we duplicate the level of care we took in testing.

Was the bedding necessary? I shoot past PRS distances and appreciate the special capability this rifle has. If I miss something, I missed it. It was not the rifle, load, poor hand loading, poor optics, etc. and that is what I seek.

I will also add that there are probably MANY more rifles built capable of incredible groups but the users settle for what they see as a fantastic group because it is better than previous rifles and they stop development SHORT, or WAY SHORT, especially with the new breed of bullet offerings, and newer powders.

I suspect you could have someone HURT the capability of a rifle by poor bedding. You should only measure a smith by their work and results, all else walks in my book. I do not accept GOOD ENOUGH when I spend 8 grand for a Precision rifle. If I spend that amount and the SMITH cannot produce a better product than most, he can redo it. I am anal only for the shooting discipline and hope it does not creep into any other aspect of my life.

I'll just have to shoot the stock unbedded and see how it preforms, givin it's already pillar bedded. Really dont wanna spend 3-4 hundred dollars on top of a $900 stock.

Whats the 3-400 extra for? You can easily do it yourself at home for 10% of the cost you listed plus a couple hours of your time. I have used devcon with good results. Acraglass and marine tex are all successfully used by others as well. While I agree that shooting it would be the first thing I do bedding it doesnt have to be a super complicated process either, especially since it already has the pillars.

http://www.brownells.com/gunsmith-tools-supplies/stock-work-finishing/stock-bedding-adhesives/index.htm

Last edited:

Whats the 3-400 extra for? You can easily do it yourself at home for 10% of the cost you listed plus a couple hours of your time. I have used devcon with good results.

+1 to all three

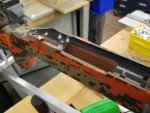

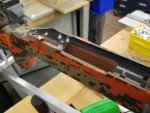

Back around when the A5 was first released, I got hold of one of the first ones shipped, it had a Savage Short Action Inlet. I took my Savage 10FP.260 (Ghost Dancer) Custom out of the McMillan Factory Pillar Bedded A3 stock and simply dropped it into the new A5 with 25in/lb Torque. Accuracy was identical.

Greg

Greg

Been on this site since 2001, never have done pictures.

The Ghost Dancer rifle is nothing special. We concocted the design here at SH back in 2001. It's a 2001 Savage 10FP action in a Ghost Gray McMillan A3 tactical stock, factory pillar bedded. The (current) barrel is a Lothar-Walther 28" 1:8" stainless .260 Rem, exactly as shown on their site as Savage drop-in finished barrels, Savage Varmint Contour. The original 24" Savage barrel was also .260. Been shooting that barrel off and on since about 2003. Ken Farrel 20MOA base, Burris signature Zee rings. Current scope is a temp downgrade, Tasco VAR624X42M 6-24x42 MilDot. Sharpshooter Supply (pre-accutrigger) Trigger Shot it for a couple of years in F Open at Bodines PA.

The original rifles (3) were built by Dan Shumway (Darkeagle Customs), who also did all my barrel swaps up until the last year or two. Except for the scope, D/M, and paint, the rifle on his home page is a ringer for my Ghost Dancer.

I now live in SE Arizona, and will be developing a load for it using the Hornady 143gr ELD-X.

Greg

The Ghost Dancer rifle is nothing special. We concocted the design here at SH back in 2001. It's a 2001 Savage 10FP action in a Ghost Gray McMillan A3 tactical stock, factory pillar bedded. The (current) barrel is a Lothar-Walther 28" 1:8" stainless .260 Rem, exactly as shown on their site as Savage drop-in finished barrels, Savage Varmint Contour. The original 24" Savage barrel was also .260. Been shooting that barrel off and on since about 2003. Ken Farrel 20MOA base, Burris signature Zee rings. Current scope is a temp downgrade, Tasco VAR624X42M 6-24x42 MilDot. Sharpshooter Supply (pre-accutrigger) Trigger Shot it for a couple of years in F Open at Bodines PA.

The original rifles (3) were built by Dan Shumway (Darkeagle Customs), who also did all my barrel swaps up until the last year or two. Except for the scope, D/M, and paint, the rifle on his home page is a ringer for my Ghost Dancer.

I now live in SE Arizona, and will be developing a load for it using the Hornady 143gr ELD-X.

Greg

Last edited:

I wonder if the accuracy increase had more to do with the barrel rather than bedding?

I know that it had some to do with it but not all. The previous barrel shot sub moa I was just being picky.

For me a timely conversation....

My .308 700 SPS Tac in B&C and Magpul stocks was capable of under .5 MOA - occasionally. It was normally more like .75 MOA but with some occasional 1.0 MOA groups as well. In other words, it was anything but consistent.

It is now being rebarreled with a M40 contour Bartlein and the action being trued by well known gunsmith in the bench rest shooting world. I have an A5 inbound (from McMillan's inlet-ready inventory) which has pillars and is being inletted for my specific barreled action. McMillan states that no bedding is required so I will take them at their word see how it shoots. If I don't get the consistent .5 MOA or better that I am hoping for I will bed it.

FWIW, I was considering a chassis too but I've just never warmed up to them aesthetically.

My .308 700 SPS Tac in B&C and Magpul stocks was capable of under .5 MOA - occasionally. It was normally more like .75 MOA but with some occasional 1.0 MOA groups as well. In other words, it was anything but consistent.

It is now being rebarreled with a M40 contour Bartlein and the action being trued by well known gunsmith in the bench rest shooting world. I have an A5 inbound (from McMillan's inlet-ready inventory) which has pillars and is being inletted for my specific barreled action. McMillan states that no bedding is required so I will take them at their word see how it shoots. If I don't get the consistent .5 MOA or better that I am hoping for I will bed it.

FWIW, I was considering a chassis too but I've just never warmed up to them aesthetically.

I own two McMillan stocks (Adjustable A3-5 and Adjustable Game Scout) I asked McMillan about bedding and they answer me that is wasn't necessary but that at the end the decision was up to me. The A3-5 is on a 6.5 CM Tikka T3X with a PVA medium palma barrel nut, the GS is on a 6.5 CM Tikka T3X CTR SS 24' stock barrel. Both rifles shoot 1/2 MOA all day any day and if I do my part they can do 5 shoots group 1/3 MOA at 100 yards easily. I ain't have the necessity for bedding but that doesn't mean that maybe after a bedding job they will shoot better, maybe some day I'll do one of them to compare before and after bedding but my question is, knowing that they surpass my shooting capabilities how better can they shoot?

Last edited:

Similar threads

- Replies

- 8

- Views

- 1K

- Replies

- 5

- Views

- 1K