Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

L3i New "Stinger" Barreled action

- Thread starter wizit247

- Start date

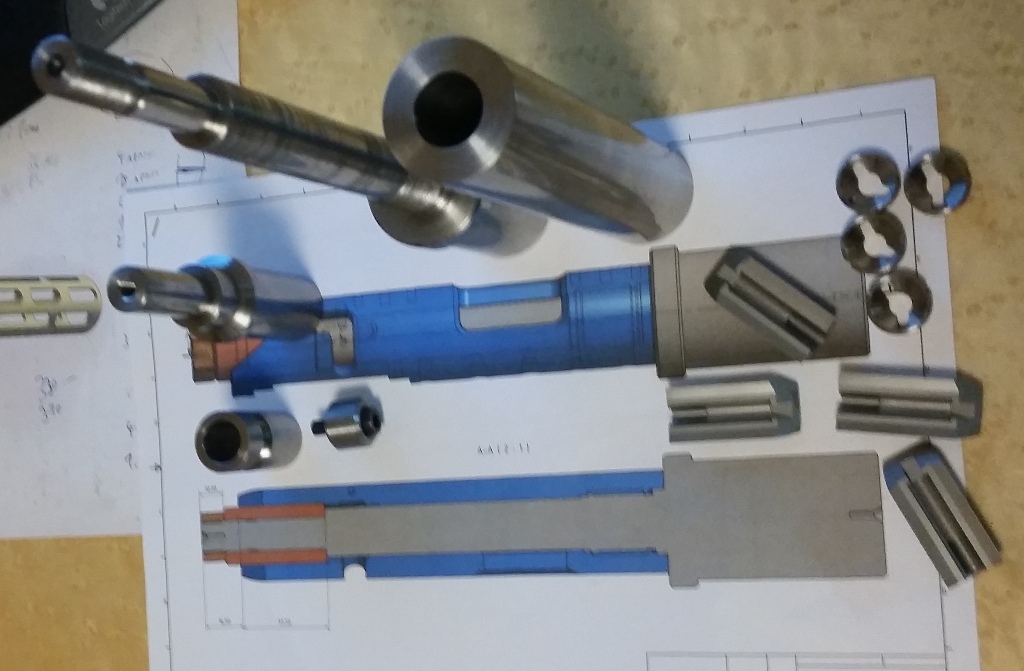

Really liking the full-sized ejection port (it's a pain to single load my Bergara), and the straightforward, classy aesthetic. I would be very interested in a 1/2-28 threaded, 24" MTU contour. Faster twist would be neat too, I'm playing with a 1:12 right now and so far it's pretty promising. Not big on coned breeches, but not super opinionated on them either.Also a teaser for the current action design

We have two tenon designs we are testing.

The second one is a really interesting tenon design. I don't think I've seen that before. Thanks for sharing the teasers!

The widened extractor cuts seem like a no-brainer to me, these cuts are always the reason people say a Vudoo can't take prefits. I always thought they could just be cut wider, or eliminated entirely with a coned breech a la RimX, with no compromise in function, but I also don't make actions or cut barrels.We have two tenon designs we are testing.

Either way, glad to see the innovation! Would be interested in the barrel torque specs and a review of bolt stripping/cleaning/adjustment when the design locks in.

PS: +1 vote for offering a threaded version, even at a $100 markup, but I also understand that SKU minimization is important.

Might be something to those coned breeches, I stole this pic from a thread over on RFC. Barrel is from the new Springfield 2020, I’ve got one and have been very impressed with how it has held up thus far. I just assumed the edge would wear or get damaged during high round counts, but so far it’s been fine.

If this new rifle is adjusted to feed correctly, with little chance for bubba to screw something up, I’m sure it’ll sell.

We have two tenon designs we are testing.

The cone breach as I’m sure you know can be dinged when dry fired. This design I wouldn’t even consider unless it’s a benchrest rifle with a shooter that is careful. The top design imo is ideal or a V style breach can be done like below. I’ve done many V breaches and it has always been my favorite.

Attachments

The Lithgow LA101 has had a similar style breach face since its inception:

Went back to reread the finer details and just noticed this - why 5/16-18 instead of 5/16-24?L3i released their new barreled action at Shot Show. Anyone have any more info?

From their Site:

- One Piece Rear Bolt Threaded 5/16-18 for Interchangeable Bolt Knobs

I'd sure buy one. Especially if it was compatible with standard Remington 700 bases and had a Remington-style bolt handle. Would love to build a really nice rimfire sporter.Sporter profile plus threaded. You'll sell plenty of those as well.

Really like this design, can't think of any real downsides to it.

Is it Fall 2024 yet? When can I place my order?

Went back to reread the finer details and just noticed this - why 5/16-18 instead of 5/16-24?

It is 5/16-24 that was a mistake in the spec sheet!

I'd sure buy one. Especially if it was compatible with standard Remington 700 bases and had a Remington-style bolt handle. Would love to build a really nice rimfire sporter.

It has a full 1.350 diameter body so it cant use standard Rem 700 bases. It is currently compatible with Stiller/Savage pattern bases.

Really like this design, can't think of any real downsides to it.

I like it too, we might pursue this route

Is it Fall 2024 yet? When can I place my order?

Still looking at Fall, getting all the manufacturing lined out still!

Gotcha, so (thinking specifically about a potential sporter) these bases would likely work? Received holes 6-48 or (preferably) 8-40?It is 5/16-24 that was a mistake in the spec sheet! Awesome!

It has a full 1.350 diameter body so it cant use standard Rem 700 bases. It is currently compatible with Stiller/Savage pattern bases.

If additional barrel contours are a long ways off, I'd be down to purchase a standalone action or two if you have enough capacity to offer those as well.

Gotcha, so (thinking specifically about a potential sporter) these bases would likely work? Received holes 6-48 or (preferably) 8-40?

If additional barrel contours are a long ways off, I'd be down to purchase a standalone action or two if you have enough capacity to offer those as well.

The base holes are 8-40 with 1/8” dowel pins as well. We are talking about selling actions by themselves as well. Our main concern is rifles built off of them with the excessively tight chambers that cause reliability issues and that effecting the reputation of our action, this is why many other rimfire actions are not available as just an action.

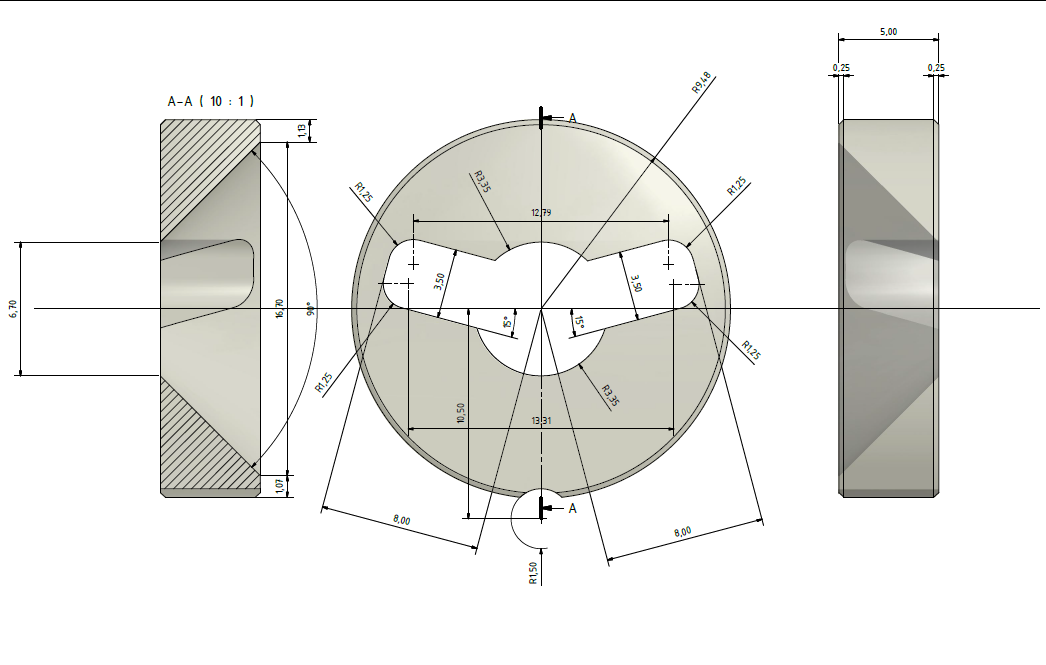

Some years ago when i dabled in a rimfire action design , i used a breech face insert , which enables you to use prefits with simple cone breech while protecting the chamber rim from the firing pin damage. If you want easy use of prefit barrels i would consider using a this kind of a cone insert

You can index it with a set screw or a pin could even be front scope base screw or pin

In modern positional single shoot rimifres these breech inserts are now even larger ,some basically forming near whole .22lr chamber , and barrel only having a freebore cut.

*Note in regards to dimensions this was for a single shot action , with tenon smaller than rem700 as folk in BR long ago figured out you do not want a tennon larger than the typical barrel diameter in rimfires as not to choke the barrel at the chamber end.

You can index it with a set screw or a pin could even be front scope base screw or pin

In modern positional single shoot rimifres these breech inserts are now even larger ,some basically forming near whole .22lr chamber , and barrel only having a freebore cut.

*Note in regards to dimensions this was for a single shot action , with tenon smaller than rem700 as folk in BR long ago figured out you do not want a tennon larger than the typical barrel diameter in rimfires as not to choke the barrel at the chamber end.

Last edited:

Protecting the chamber edge on a conical breech from dry fire damage is important for a field comp rifle, we are currently using a partially shielded cone with success however the machining is more labor intensive. I like the insert idea for simplicity of manufacturing!

Attachments

That is the whole idea Inserts are cheap and easy to make vs non lathe turned part to the breech , can also be hardened steel vs barrel steel that is basically in annealed stateProtecting the chamber edge on a conical breech from dry fire damage is important for a field comp rifle, we are currently using a partially shielded cone with success however the machining is more labor intensive. I like the insert idea for simplicity of manufacturing!

Mockup . the insert is shouldered and tightened with the barrel , it just needs an indexing point somewhere

Last edited:

We are working with our manufacturing partners to get them released by our original late Fall estimate. Realistically we see the release falling back to winter time frame though. We want to ensure that the best product possible is sent out to the early adopters!Any news on possible release date?

That would be so coolMy understanding is that the B14R is a carbon sleeve, not an epoxied carbon wrap? And carbon seems like a gimmick in a .22 where rigidity and/or heat characteristics don't seem like a concern. If you think you need carbon, you are probably looking at Proof/Bartlein and the associated $500+ jump in price. Plenty of us like shooting nice .22s, love to be able to build trainers around the R700, without wanting some crazy axle of a barrel on a rifle that is instantly only useful for a very specific type of competition. Unpopular opinion, but I think all of PRS and NRL is eventually going to get nudged toward unsupported stages, because the idea of guns heavier than the heaviest benchrest class being used in a "sporting" competition is laughable, and twising the whole industry around itself. It's just speed benchrest at this point.

Anyway, Bergara barreled actions have been relatively unavailable outside of a few vendors (Brownells, etc), and their default (factory) stock choices suck. For the life of me I can't figure out why they didn't come in a KRG Bravo, for example. Maybe they are selling as many Rimfires as they make, but it feels like they could have eaten up a lot of market share and didn't.

I still think you are competing with 1500 barreled action versus around 2000 for the Vudoo, and they have a ton of barrel profiles ready to go. It also seems like lots of folks are running the EC tuners, so the "no threading" seems like a non-starter, for some folks, and doing it after often adds $150+ to the price if you don't have someone local. I'm excited to see another vendor in the space, and will be pretty tempted if you guys release a more sporting oriented rifle.

Think about releasing one in 9mm!!!! No one is doing it (yet), cheap 9mm costs the same amount, or less, than match .22, hits on steel are way more responsive, etc, etc. I love rimfire but I would kill (and have lost some money) trying to find a good R700 in 9mm that I can train with.

Not yet, we are still in the process of getting the manufacturing stood up

I think the initial run will be a standard twist but we actually have some 14 twist blanks we've been testing

@Thesepaperwings how many of the billet stinger magazines will be included with the barreled action?

I'm not sure it will come with one. The original plan was for it to come with two elite mags and if we include billet mags it'll end up raising the price

I would rather have (1 )Stinger Billet Magazine included than (2) Elite mags with the Stinger Barreled Action, even if it raises the price. It would be foolish to not include the namesake magazine with the launch of the barreled action. If you are worried about pricing, then make it an option: 1) barreled action only; 2) included 1 Stinger Billet Magazine; 3) included with 2 Elite magazines.I'm not sure it will come with one. The original plan was for it to come with two elite mags and if we include billet mags it'll end up raising the price

That's a good point. It would be easy to make it selectable for anything through the siteI would rather have (1 )Stinger Billet Magazine included than (2) Elite mags with the Stinger Barreled Action, even if it raises the price. It would be foolish to not include the namesake magazine with the launch of the barreled action. If you are worried about pricing, then make it an option: 1) barreled action only; 2) included 1 Stinger Billet Magazine; 3) included with 2 Elite magazines.

I like this idea, I have plenty of mags and would rather just purchase a barreled action only.I would rather have (1 )Stinger Billet Magazine included than (2) Elite mags with the Stinger Barreled Action, even if it raises the price. It would be foolish to not include the namesake magazine with the launch of the barreled action. If you are worried about pricing, then make it an option: 1) barreled action only; 2) included 1 Stinger Billet Magazine; 3) included with 2 Elite magazines.

I concur, sell the barrelled action alone. I wouldn't be interested in polymer mags personally, too many bad experience with other brand's poly mags. metal for me please, I'll pay extra.

Are your actions going to be able to be single round fed?I think the initial run will be a standard twist but we actually have some 14 twist blanks we've been testing

Any Lefty actions in future?

They can absolutely be single round fed since we based it off the 40X. We know that we won't left-handed actions in the future but it'll come after the right hands are established.Are your actions going to be able to be single round fed?

Any Lefty actions in future?

Awesome,most lefties my age are used to seeing and feeding RH actions from the right side,hard to change that habit.LH Cz 457 and LH B14r action have enough space between scope mount and right side of action to see bullet feed into chamber.

I'll take a RH action when ya get em...............Can ya put the bolt on left side.

I'll take a RH action when ya get em...............Can ya put the bolt on left side.

Anyone get pictures of the Chassis and Action at the PRS Rimfire Nationals this past weekend? They just posted more renderings but would be cool to see photos.

Will the magazines start rolling out again post prs finale ? Very happy with the ones I have so far, in a Vudoo.

We have a batch ready but it's less than 100 so we're waiting till we get a bit more before we list them. We try not to list things until there's enough to fill at least the notification request amount since we all know how much it sucks to get that email that says they're in stock but by the time you look at it they're gone.Will the magazines start rolling out again post prs finale ? Very happy with the ones I have so far, in a Vudoo.

Any update on the action and the barrels?We have a batch ready but it's less than 100 so we're waiting till we get a bit more before we list them. We try not to list things until there's enough to fill at least the notification request amount since we all know how much it sucks to get that email that says they're in stock but by the time you look at it they're gone.

Looks like it evolved further

Different grip panels make it possible. So not adjustable but you can swap what gip panel you want depending on what size of hand you have@Thesepaperwings

Is the grip adjustable fore and aft for trigger finger location

Any further updates on the Stinger Barreled Action or whether it will be released in 2024? Any indications of performance from prototypes (or preproduction) in terms of grouping @ 50yds, @100yds?

it'll group as good as your ammo will allow I'd bet.Any further updates on the Stinger Barreled Action or whether it will be released in 2024? Any indications of performance from prototypes (or preproduction) in terms of grouping @ 50yds, @100yds?

no secret sauce available to make a gun shoot everything into one hole.

Grouping is least of my concern as unless there is something terribly wrong with the ignition , as long as barrels and chambers are up to spec it will shot.

Only reason i never dabled in repeater Rimfire action design is that i am somewhat terrified of making them feed and extract flawlessly . Magazine design is as hard or harder than action design and then there is magazine to action sync.

That is why actions like CZ and Anschutz bolt the magwell and magrelease to the action , makes for much more consistent fit than inlets and bottom metals in 3rd party stocks and chassis , so action and magazine combo can work flawlessly in one chassis or stock and be absolute nightmare in another.

Thesepaperwings and Mechdesigner send me a message if you want brainstorm some things around that insert i see is still not in final form.

Only reason i never dabled in repeater Rimfire action design is that i am somewhat terrified of making them feed and extract flawlessly . Magazine design is as hard or harder than action design and then there is magazine to action sync.

That is why actions like CZ and Anschutz bolt the magwell and magrelease to the action , makes for much more consistent fit than inlets and bottom metals in 3rd party stocks and chassis , so action and magazine combo can work flawlessly in one chassis or stock and be absolute nightmare in another.

Thesepaperwings and Mechdesigner send me a message if you want brainstorm some things around that insert i see is still not in final form.

Last edited:

I beg to differ sir.it'll group as good as your ammo will allow I'd bet.

no secret sauce available to make a gun shoot everything into one hole.

“Match” chamber, rifling and lapping all have huge impact on the grouping, as much or more so than the ammo alone. Other factors such as how well the prefit mates up to the receiver and how deep the grub screw cuts may affect the amount of surrounding chamber steel. Barrel steel, diameter and length affects harmonics, hence why tuners (fact or fiction) are popular (or fad).

I am interested in the performance based on design intent and whether it matches expectations. From very small sampling and sampling size, it is rather bold statements to claim this barrel will hang with the other higher tier prefit barrel offerings.

I am not throwing any shade on L3i, and I have a purchase in that I am waiting for (so I put my money on the line, same as everyone else), and just curious as to performance, as they have not shared any information from their testing (to date). Edit: Sorry, this last comment is with regards to the CZ pre-fit barrel offerings, not on the Stinger Barreled Action, although, one can be a somewhat indicator of the other, maybe.

they use grub screws on a rem40x?I beg to differ sir.

“Match” chamber, rifling and lapping all have huge impact on the grouping, as much or more so than the ammo alone. Other factors such as how well the prefit mates up to the receiver and how deep the grub screw cuts may affect the amount of surrounding chamber steel. Barrel steel, diameter and length affects harmonics, hence why tuners (fact or fiction) are popular (or fad).

I am interested in the performance based on design intent and whether it matches expectations. From very small sampling and sampling size, it is rather bold statements to claim this barrel will hang with the other higher tier prefit barrel offerings.

I am not throwing any shade on L3i, and I have a purchase in that I am waiting for (so I put my money on the line, same as everyone else), and just curious as to performance, as they have not shared any information from their testing (to date). Edit: Sorry, this last comment is with regards to the CZ pre-fit barrel offerings, not on the Stinger Barreled Action, although, one can be a somewhat indicator of the other, maybe.

ive seen some seriously impressive groups from lot tested guns with not what we would call "match" chambers, and they likely weren't finish lapped barrels either, just decent barrels and chamber jobs with lot matched ammos.

a Saturn barrel is a good one from what I've heard, so you just need to be concerned about the chambering. I don't know what they'll use and I forgot the names of them off the top of my head, but I went with the tightest matchiest eley reamer on my latest 22 and I plan on having it lot tested as soon as I beak it in real good. its one a cz that I had threaded and the grub screws removed. now the heart wants a rem40x pattern and ive had such good luck from l3i previously

Last edited:

I errored and mixed up my comments by commenting on the CZ prefit barrel offering that was just released. That is my mistake. I added an edit comment.they use grub screws on a rem40x?

Similar threads

- Replies

- 3

- Views

- 807

- Replies

- 3

- Views

- 429