Going to post this over at Practical Machinist, but thought some of the guys here may have some answers……

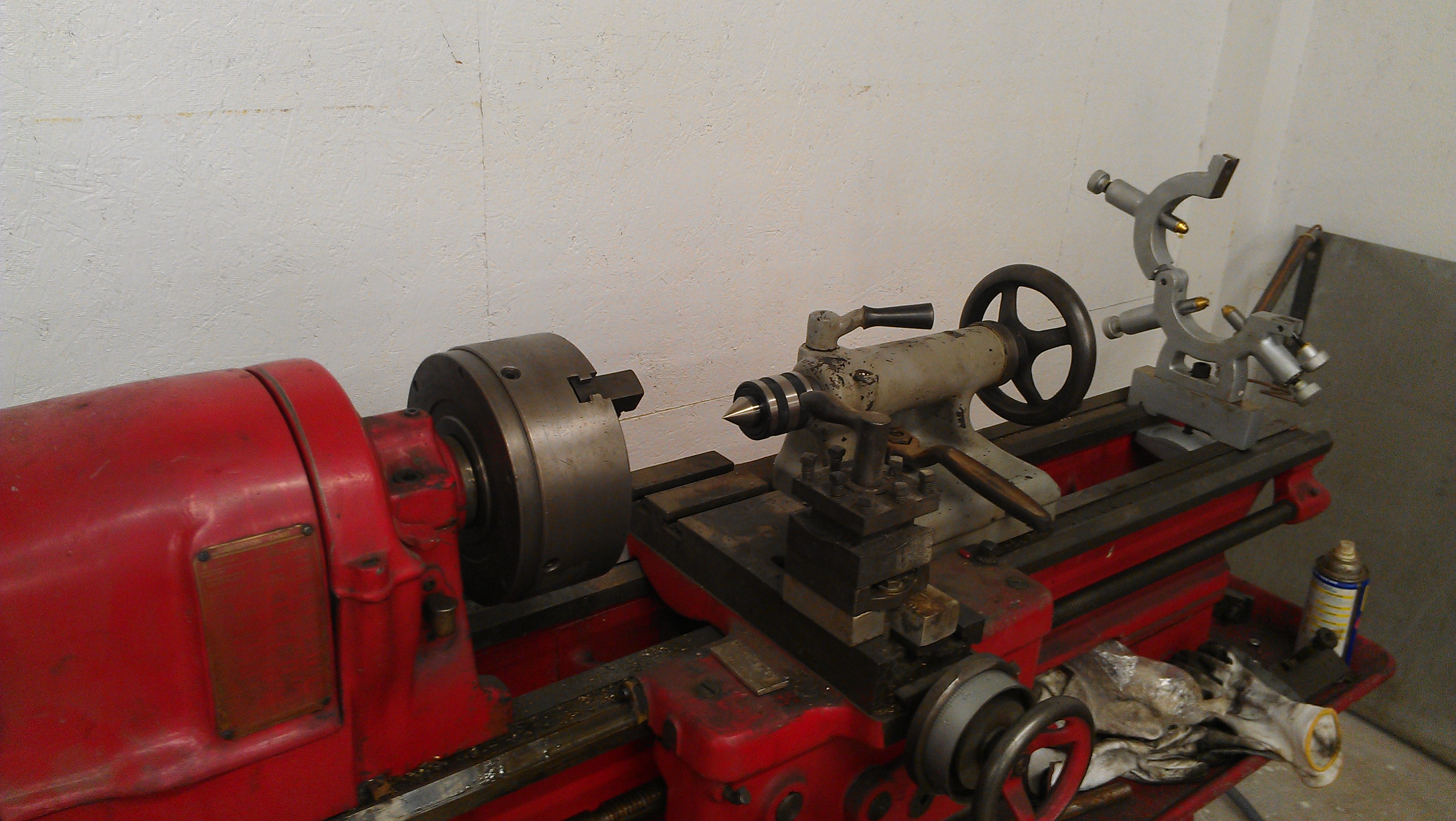

GenePool and I purchased our first lathe over the weekend; trying to gather some info on it. I spoke with South Bend today and gave Mike the serial and catalog number. He didn’t have any reference info on the catalog number, but said he’d pull the serial card and send me the info. What I know so far:

Serial Number 10893TKT14

Catalog CL1BT

Motor 1HP 3 Phase

Bed Length 5

Some questions:

I bought this for gunsmithing and general hobby use. Obviously it’s a collet lathe, can I get a bigger headstock for this?

Its 3 phase, how do these run on a static converter? I know I’ll lose a 1/3 of a horse power, is that a huge deal. Static is about a 1/3 of the cost of a rotary converter.

If it won’t run on a static converter, what about getting a 220V single phase motor for it? Frame size any issue? I was told the controller/switch may not work well single phase or over heat.

Anyone using a VFD for a converter on a lathe?

Is the power turret of any general use? How does it compare to a standard lathe?

What tail stock will fit this, and can it be replaced?

I paid $600 for it delivered, how’s the price?

Any general info you can give me would be greatly appreciated…..

GenePool and I purchased our first lathe over the weekend; trying to gather some info on it. I spoke with South Bend today and gave Mike the serial and catalog number. He didn’t have any reference info on the catalog number, but said he’d pull the serial card and send me the info. What I know so far:

Serial Number 10893TKT14

Catalog CL1BT

Motor 1HP 3 Phase

Bed Length 5

Some questions:

I bought this for gunsmithing and general hobby use. Obviously it’s a collet lathe, can I get a bigger headstock for this?

Its 3 phase, how do these run on a static converter? I know I’ll lose a 1/3 of a horse power, is that a huge deal. Static is about a 1/3 of the cost of a rotary converter.

If it won’t run on a static converter, what about getting a 220V single phase motor for it? Frame size any issue? I was told the controller/switch may not work well single phase or over heat.

Anyone using a VFD for a converter on a lathe?

Is the power turret of any general use? How does it compare to a standard lathe?

What tail stock will fit this, and can it be replaced?

I paid $600 for it delivered, how’s the price?

Any general info you can give me would be greatly appreciated…..