I want to make the most of my range time since it is far from home(3 hrs round trip). Is it viable to bring your reloading equipment to the range and adjust the charge, seating depth on spot? Could you share any tips or suggestions that you have found to be helpful if you have done so with success?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Size, prep and prime all your brass in advance then set up a seating press on a platform of some sort and install your seating di. bring your bullets, powder, scooper for the powder, CBTO measuring tools, a small scale, lab radar with you and you can get all your T/E done in one trip.

I use a Harrels press that attaches to a crude but workable platform made out of $8 worth of wood i bought at home depot.

I use a Harrels press that attaches to a crude but workable platform made out of $8 worth of wood i bought at home depot.

What I’ve seen is people pre weigh charges and put them in little capped beakers. That way you don’t have to worry about a scale and wind outside and can just seat what’s needed, the leftovers can go back in the jug when you get home.

Portable load bench. Feet on box to help level. Portable scale. Battery pack with power converter and a Lee hand press.

can't say how true or not it is but we did our load development with only 3 rounds of each load we were trying that day and only 5 warm up /making sure we were centered shots , and came out of it with loads for 8 different powders that pretty closely mimic each other speed wise , and group size wise , as well as sd wise I only made more of the loads ( 20 ) rounds when I had a pretty good idea a particular load was what I was looking for the whole why use 100 rounds if the first 3 or so are not what you want to see either that leads to a lot of pulling of bullets or a lot of wasted bullets . Anyway we saved a lot of powder and primers buy doing that it worked for us but maybe you want to make a ton of rounds up just to find out how it's going to shoot through your gun it's all up to you .

Another idea is to charge and seat very long at home - then seat at the range (if just testing seating that is)

That would be my suggestion. It seems like it would be tough to get accurate results while sitting in the car next to your scale.

Berger suggests finding your OAL first in load development. You could pick an arbitrary charge and load a length test. And long seat a powder test and take press only.

Berger suggests finding your OAL first in load development. You could pick an arbitrary charge and load a length test. And long seat a powder test and take press only.

This is what I've done if I don't need to test charges/pressure. I think it works well enough.Another idea is to charge and seat very long at home - then seat at the range (if just testing seating that is)

What caliber are you trying to optimize? At the range, are you loading outside, under a roof, or inside? Do you have power? Is it warm and sunny or cold and rainy? You said, "charge and seating depth" - so you settled on brass, neck ID, primer, bullet and powder.I want to make the most of my range time since it is far from home(3 hrs round trip). Is it viable to bring your reloading equipment to the range and adjust the charge, seating depth on spot? Could you share any tips or suggestions that you have found to be helpful if you have done so with success?

Make up primed brass in advance.

You will need a seating die and a press, I would use a Wilson hand die and an arbor press. You need a table. If you can throw powder, you need a funnel but you don't need a scale. Adjust the throw for the best groups. Leave the best setting on the thrower. When you get home, throw a charge and weight it.

If you can't throw powder, you need a thrower or a scoop, trickler, scale, power, and you need to be out of the wind. If you are converting 12 volt battery power to AC, test your scale in advance to insure that it likes the AC that you are providing.

If you can't make enough brass in advance, you need to be able to size and prime the brass you just shot. Wipe the grup off the necks then neck size the brass - Wilson dies and the arbor press work for this. If you must bump shoulders then you need a press that can hold a bump die and a way to secure that press to a table.

FWIW, premade brass is better. If you have to full-length size and/or shoulder bump, it is still do-able but it becomes a trial. It takes half an hour to set up and tear down plus all the time to fiddle with the brass between rounds. Add that to your 3-hours of drive time and you don't do much shooting.

You may need to clean the rifle - you need a saddle, cleaning rod(s), patches, and solution. Pick up your used patches.

If you want to see all of this in action, go to a benchrest match. You can see 300 different ways to do this. The motor home guys have the sweetest setups. If you know a friendly welder, he can make a table that slips into a receiver hitch on the back of your pickup.

I really appreciate your suggestions! Now I have a lot of ideas on how to do this.What caliber are you trying to optimize? At the range, are you loading outside, under a roof, or inside? Do you have power? Is it warm and sunny or cold and rainy? You said, "charge and seating depth" - so you settled on brass, neck ID, primer, bullet and powder.

Make up primed brass in advance.

You will need a seating die and a press, I would use a Wilson hand die and an arbor press. You need a table. If you can throw powder, you need a funnel but you don't need a scale. Adjust the throw for the best groups. Leave the best setting on the thrower. When you get home, throw a charge and weight it.

If you can't throw powder, you need a thrower or a scoop, trickler, scale, power, and you need to be out of the wind. If you are converting 12 volt battery power to AC, test your scale in advance to insure that it likes the AC that you are providing.

If you can't make enough brass in advance, you need to be able to size and prime the brass you just shot. Wipe the grup off the necks then neck size the brass - Wilson dies and the arbor press work for this. If you must bump shoulders then you need a press that can hold a bump die and a way to secure that press to a table.

FWIW, premade brass is better. If you have to full-length size and/or shoulder bump, it is still do-able but it becomes a trial. It takes half an hour to set up and tear down plus all the time to fiddle with the brass between rounds. Add that to your 3-hours of drive time and you don't do much shooting.

You may need to clean the rifle - you need a saddle, cleaning rod(s), patches, and solution. Pick up your used patches.

If you want to see all of this in action, go to a benchrest match. You can see 300 different ways to do this. The motor home guys have the sweetest setups. If you know a friendly welder, he can make a table that slips into a receiver hitch on the back of your pickup.

I load 5 rounds of each powder charge at a set seating depth across the board, to find which powder charge produces the best node. If my magazine length allows, I usually seat them 0.010” off the lands. Seating them ALL to 0.010” off will almost always allow you to find both your MAX powder charge, and your barrel’s preferred harmonic velocity node, without having to play duck, duck, goose with your seating depth.

If I’m not able to seat that close due to magazine box length restrictions, then I find the best (longest) seating depth that will allow the ammo to reliably feed from the magazine box, and still be as close as possible to the lands, and seat them all to that depth.

Then, once you find a good powder charge for that load, if you are still not happy with your groups, you can play with seating depth at that same powder charge that produced the best groups.

My methods are a bit unorthodox, but they work very well for me.

If I’m not able to seat that close due to magazine box length restrictions, then I find the best (longest) seating depth that will allow the ammo to reliably feed from the magazine box, and still be as close as possible to the lands, and seat them all to that depth.

Then, once you find a good powder charge for that load, if you are still not happy with your groups, you can play with seating depth at that same powder charge that produced the best groups.

My methods are a bit unorthodox, but they work very well for me.

I want to make the most of my range time since it is far from home(3 hrs round trip). Is it viable to bring your reloading equipment to the range and adjust the charge, seating depth on spot? Could you share any tips or suggestions that you have found to be helpful if you have done so with success?

I’ve been using these for years why would anyone bring their highly sensitive scale to the range to load on their pick up truck tailgate etc. it cannot be accurate. Use your brain set up various charge weights ahead of time. I’ve been using these for years why would anyone bring their highly sensitive scale to the range to load on their pick up truck tailgate etc. it cannot be accurate. Use your brain set up various charge weights ahead of time. A little alcohol on a rag will remove the writing and they are ready for the next time.

You are getting good suggestions here. I have a portable press system I have used for yrs to find seat depth, but dispensing powder at the range is a PIA. I have while in a bind, brought a generator and a chargemaster to the range, not sure if I have ever finalized a load doing so though. But have got close enough to regroup at home.

20 minute drive compared to 3 hrs.

20 minute drive compared to 3 hrs.

I’ve been using these for years why would anyone bring their highly sensitive scale to the range to load on their pick up truck tailgate etc. it cannot be accurate. Use your brain set up various charge weights ahead of time. I’ve been using these for years why would anyone bring their highly sensitive scale to the range to load on their pick up truck tailgate etc. it cannot be accurate. Use your brain set up various charge weights ahead of time. A little alcohol on a rag will remove the writing and they are ready for the next time.

I used to shoot at a range east of Denver, it was an hour drive from my house. The wind always blows in the plains. Behind the 100 yard range, they had a travel trailer up on stands. We would take our gear into the trailer and load there. We did not take nice scales. We were shooting H322 and V133, both of those meter very consistently in a decent thrower. We played with charge and seating depth.

A some match, I saw a nifty loading table that fit into a receiver hitch. If you don't need a scale then you don't much care about wind. You can bolt or clamp a bump press and a thrower to the bench, put a arbor press in the back. All you need is a stool. The biggest risk is sunburn.

I also load to magazine length. If it won't fit the magazine, I won't bother to shoot it. In my case 308 is loaded to about 2.820. The magazine will let me go longer (2.840 I think) but I don't want to risk a feeding issue if a round is too long. At matches, I always load and carry an extra magazine in case I have a problem.I load 5 rounds of each powder charge at a set seating depth across the board, to find which powder charge produces the best node. If my magazine length allows, I usually seat them 0.010” off the lands. Seating them ALL to 0.010” off will almost always allow you to find both your MAX powder charge, and your barrel’s preferred harmonic velocity node, without having to play duck, duck, goose with your seating depth.

If I’m not able to seat that close due to magazine box length restrictions, then I find the best (longest) seating depth that will allow the ammo to reliably feed from the magazine box, and still be as close as possible to the lands, and seat them all to that depth.

Then, once you find a good powder charge for that load, if you are still not happy with your groups, you can play with seating depth at that same powder charge that produced the best groups.

My methods are a bit unorthodox, but they work very well for me.

I only load to mag length in my hunting rifles and potential (maybe in the future) competition rifles, were single-feeding isn't going to win you any timed events. LOLI also load to magazine length. If it won't fit the magazine, I won't bother to shoot it. In my case 308 is loaded to about 2.820. The magazine will let me go longer (2.840 I think) but I don't want to risk a feeding issue if a round is too long. At matches, I always load and carry an extra magazine in case I have a problem.

As far as most of my precision bolt-actions, I load heavies, so I typically run them WAY past the magazine box length, and still single-feed like a single-shot rifle. I might as well remove the box spring, and just put a solid follower in there to make it a single-shot only.

Original Bob Sled Products at MidwayUSA

Shop Original Bob Sled at MidwayUSA! We carry a huge selection of Gun Parts, Ammo Storage, Loading from Original Bob Sled at the best prices!

Powder charges are the most difficult anticipate….

i use glass vials with different charges and if they are not exact you could bring tweezers or use your finger to add a kernel, pre load them

an arbor press with seating die are very easy to bring

load develop at the longest possible distance with low wind

Amazon product ASIN B002JV89OC

i use glass vials with different charges and if they are not exact you could bring tweezers or use your finger to add a kernel, pre load them

an arbor press with seating die are very easy to bring

load develop at the longest possible distance with low wind

Amazon product ASIN B002JV89OC

I bought something similar before seeing your recommendation^^^^^^^^

I use the 4dram. Works great!

I'm a new user of the Wilson seater die. The cartridge tends to get stuck in the die after seating. How to avoid that?

I just use the empty shiny paper my cocaine comes in.

I don’t have that issue, had one stuck once because I didn’t have the bullet set on square. SorryI bought something similar before seeing your recommendation

I'm a new user of the Wilson seater die. The cartridge tends to get stuck in the die after seating. How to avoid that?

View attachment 8039794

I bought something similar before seeing your recommendation

I'm a new user of the Wilson seater die. The cartridge tends to get stuck in the die after seating. How to avoid that?

That usually happens because the Wilson seater has a smaller base than your full-length die - or, if you are neck-sizing, the seater die is smaller than your chamber. A short flat-blade screwdriver will extract the round from the die - pry under the rim.

You want the brass to snugly fit into the seater die. You might ask the Wilson people if they can make the die a little bigger. If you have a chamber reamer you might be able to do it yourself.

It shouldn't get stuck *hard*, but I have had ones that didn't want to drop free or even come out with a fingernail in the extractor groove.I'm a new user of the Wilson seater die. The cartridge tends to get stuck in the die after seating. How to avoid that?

I usually keep a small 1/8" flat blade screwdriver nearby when using the Wilson seater; at this point it's almost second nature to grab the die in one hand, hook the tip of the screwdriver in the extractor groove and give it about a half inch of 'encouragement' to pop it loose from the die. Case slides out into the palm of the hand holding the die, other hand sets down the screwdriver and grabs the case and puts it in the loading block. Probably sounds more complicated than it actually is. Definitely takes longer to describe than to do

One of my most surprising and frustrating experiences was getting custom 21st Century hand die for my match FTR gun. Cases were *so* tight that I couldn't get them out without using the die top and seating stem to air-piston the case out of the die - because it didn't have that conical recess in the bottom like a Wilson. New, but not improved. That recess is there for a reason.

Another option if a person doesn't want to invest in special dies and an arbor press, is to get an el-cheapo Lee hand press. It sounds crazy, but a Redding Comp seater or Forster Ultra BR seater (inline sleeved micrometer styles) in one of those does a surprisingly good job of final seating to length, whether it's match ammo that you loaded well in advance and are bumping to the final dimension, or just doing seating depth testing at the range. Pro-tip: replace the wire clip retainer for the shell holder with an O-ring from the hardware store, to let it float.

Last edited:

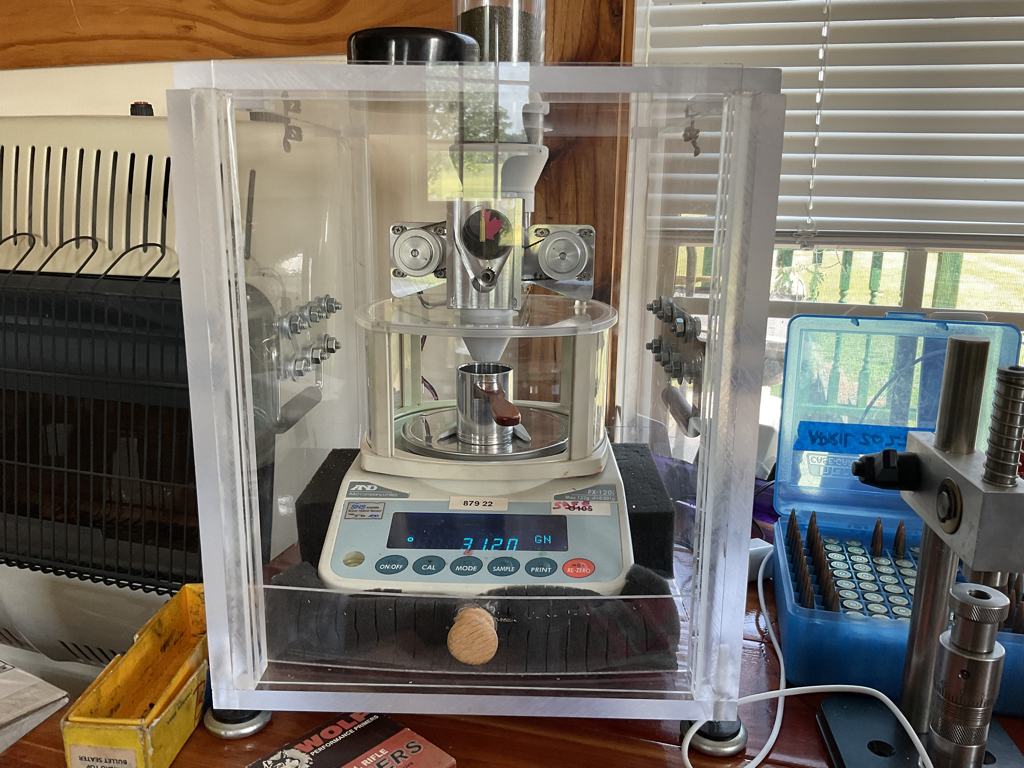

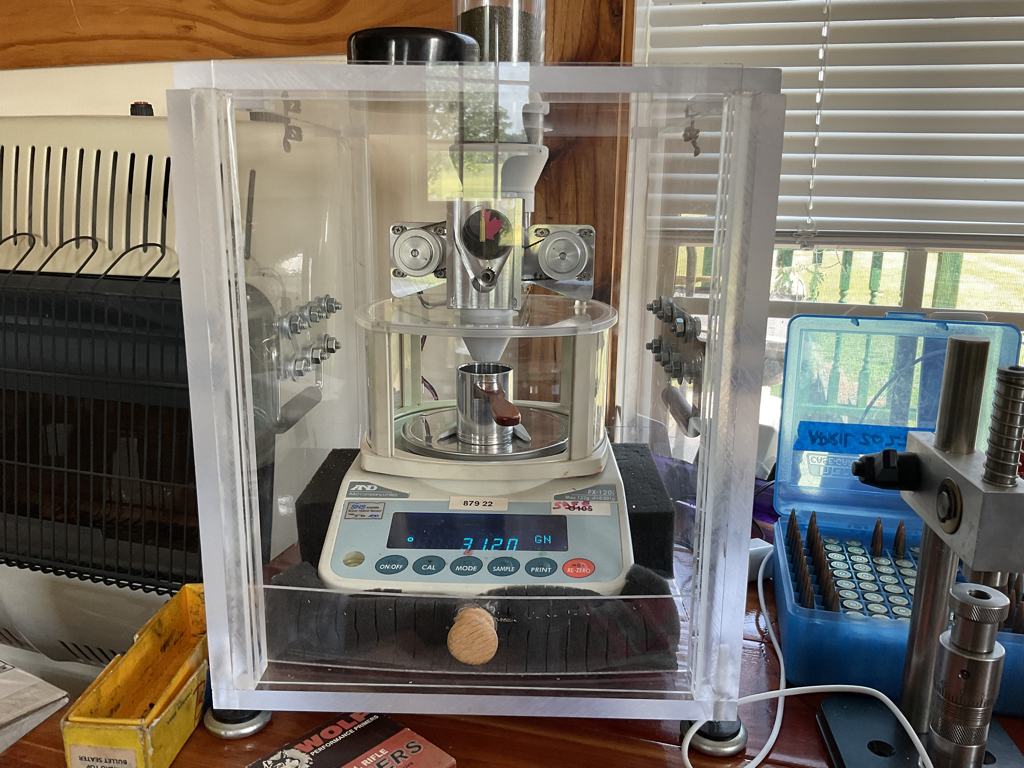

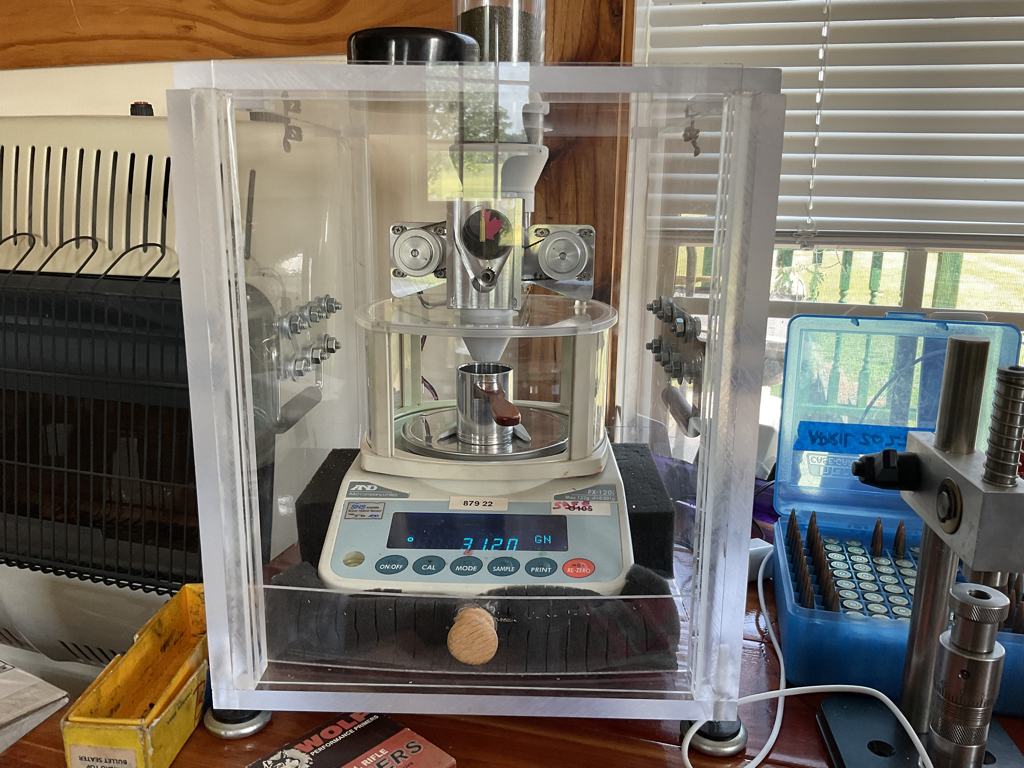

This would work, just add electricity

V4 AutoTrickler Garage

V4 AutoTrickler Garage Great for reloading indoors or out. The V4 Garage protects your scale from drafts to full blown outdoor winds. V4 comes with sliding front and rear doors as well a removable...

bartsbullets.weebly.com

Power is not an issue. I have a solar generator that has 2kwh with 2kw output. The issue is that I am still waiting for my autotrickler.This would work, just add electricity

V4 AutoTrickler Garage

V4 AutoTrickler Garage Great for reloading indoors or out. The V4 Garage protects your scale from drafts to full blown outdoor winds. V4 comes with sliding front and rear doors as well a removable...bartsbullets.weebly.com

This is a low key bragging...My range out to 900yd is at the house its easier that way

It'll be interesting to see what kind of power quality you get off that solar "generator" aka inverter. Whether it's clean enough to use with a precision scale, or if you end up having to put something in between to filter/condition the power.Power is not an issue. I have a solar generator that has 2kwh with 2kw output. The issue is that I am still waiting for my autotrickler.

If you could go DC-DC and skip the inverter step it might be better.

It's a power station that can be recharged with solar panels.It'll be interesting to see what kind of power quality you get off that solar "generator" aka inverter. Whether it's clean enough to use with a precision scale, or if you end up having to put something in between to filter/condition the power.

If you could go DC-DC and skip the inverter step it might be better.

I tried the V4 with a battery pack, It's way too sensitive for outdoor or even in the truck use. Chargemaster was the solution for range loading. My Presses are on a T-track + plywood bases at home so just loosen them up and throw in the truck

Similar threads

- Replies

- 7

- Views

- 854