I have recently picked up a lot of once fired Lake City Brass and a new CMMG AR in 7.62x51. Resized the cases using small base dies, trimmed the cases, etc. The first trip to the range I released the bolt, pulled the trigger and only heard a click. When I tried to pull the bolt back the round was stuck, and it took a lot of persuasion to get the bolt opened. I did notice the bolt did not close fully after this happened. After a couple tries I have determined there is a problem, I am assuming with the brass. I am not new to reloading, but am new to loading 7.762x51 for the AR. Never a problem with 5.56. Does the shoulder need to be bumped down on this brass, or is there other tricks with loading for this platform?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Loading Issues 7.62x51 Lake City Brass

- Thread starter jimbuck

- Start date

A few questions:

- Just to confirm, are you talking once-fired milsurp (ie NATO headstamp), possibly M60 fired?

- to what length did you trim?

- did you run any of your resized/trimmed brass thru a case gage?

- have you been able to run any other ammo thru your CMMG?

BTW-problems are often not unique, search is your friend:

http://www.snipershide.com/shooting/showthread.php?t=182747

I cannot confirm or deny that I have had an issue with this brass myself

- Just to confirm, are you talking once-fired milsurp (ie NATO headstamp), possibly M60 fired?

- to what length did you trim?

- did you run any of your resized/trimmed brass thru a case gage?

- have you been able to run any other ammo thru your CMMG?

BTW-problems are often not unique, search is your friend:

http://www.snipershide.com/shooting/showthread.php?t=182747

I cannot confirm or deny that I have had an issue with this brass myself

Last edited:

Sounds like you are firing LC brass that was fired in an MG. In my experience many of the head of the cases were swelled so much that the FL seizing die would resize the head back to specs and the rounds would not chamber the same way yours wouldn't. One way you can check to verify this is to insert the round in a Wilson (what I use) or Dillion case length gauge backwards. If properly resized it will go ~ half way into the case length gauge. The swollen head cases barely go in at all. Some have had luck using small base dies to resize the swollen heads. Now when I get LC brass I always check that the FL die touches the shell holder when resizing. If it doesn't the case will not go into the CLG as I described.

Last edited:

Sounds like you are firing LC brass that was fired in an MG. In my experience many of the head of the cases were swelled so much that the FL seizing die would resize the head back to specs and the rounds would not chamber the same way yours wouldn't. One way you can check to verify this is to insert the round in a Wilson (what I use) or Dillion case length gauge backwards. If properly resized it will go ~ half way into the case length gauge. The swollen head cases barely go in at all. Some have had luck using small base dies to resize the swollen heads. Now when I get LC brass I always check that the FL die touches the shell holder when resizing. If it doesn't the case will not go into the CLG as I described.

The OP stated he used a small base die to resize... I'm gunna guess it's a headspace issue... Didn't bump the shoulders back far enough.

As I said some have had luck with small base dies but others have not. It depended on how swollen the case heads were. I've dealt with this LC brass problem for over 30 years and it was always caused by swollen case heads. It takes a few seconds to check it out if the problem is the case heads. If not the OP can move on to the question if he bumped the shoulder back enough.

Like everyone else has said, It's either the case web not being resized down enough with the Small based die or you're not bumping the shoulders back far enough. Do some measuring to find out what it is.

Measure the web of the case after F/L resizing, it should be around .468"-.469". What sometimes helps is to run the cases twice, slowly through the F/L die.

How do you measure your shoulder bump? You should have a gauge to measure it. If you don't have a gauge, you can try turning your F/L die in another 1/8-1/4 turn and try a couple of dummy rounds (no powder or primer) and see if they chamber and extract smoothly.

You should be bumping the shoulders back to about SAAMI minimum with that once fired M/G brass when sizing it for the first time.

Measure the web of the case after F/L resizing, it should be around .468"-.469". What sometimes helps is to run the cases twice, slowly through the F/L die.

How do you measure your shoulder bump? You should have a gauge to measure it. If you don't have a gauge, you can try turning your F/L die in another 1/8-1/4 turn and try a couple of dummy rounds (no powder or primer) and see if they chamber and extract smoothly.

You should be bumping the shoulders back to about SAAMI minimum with that once fired M/G brass when sizing it for the first time.

That's great info gentlemen. The trim to length is 2.005, the web is .467. I don't have a gauge to measure the shoulder. I think turning the die deeper to bump the shoulder will be the answer.

jimbuck

You need a Hornady cartridge case headspace gauge to measure your fired rounds "from your rifle" and to set up your dies for the proper amount of shoulder bump.

In the meantime just adjust the press and die to cam over with maximum shoulder bump, these Lake City case were fired in a machine gun with a larger diameter and a much longer headspace chamber setting. Even after you size this way with the die making hard contact with the shell holder the case shoulder will "spring back" after sizing.

Then after the brass is brought back to "normal" dimensions you can adjust the die for minimum shoulder bump.

What you are seeing happens to any brass fired in a machine gun and "larger" military chambers and once you bring the brass back to minimum dimensions you can adjust your dies upward for the correct shoulder bump.

Lake City 7.62 brass is thicker and harder than commercial brass and its spring back rate after full length sizing is more because of this.

You need a Hornady cartridge case headspace gauge to measure your fired rounds "from your rifle" and to set up your dies for the proper amount of shoulder bump.

In the meantime just adjust the press and die to cam over with maximum shoulder bump, these Lake City case were fired in a machine gun with a larger diameter and a much longer headspace chamber setting. Even after you size this way with the die making hard contact with the shell holder the case shoulder will "spring back" after sizing.

Then after the brass is brought back to "normal" dimensions you can adjust the die for minimum shoulder bump.

What you are seeing happens to any brass fired in a machine gun and "larger" military chambers and once you bring the brass back to minimum dimensions you can adjust your dies upward for the correct shoulder bump.

Lake City 7.62 brass is thicker and harder than commercial brass and its spring back rate after full length sizing is more because of this.

Can you chamber a piece of brass after you size it? Your sizing die may not be set right. If you can chamber your brass try a couple of dummies, brass and bullet.

My first run of LC M118LR had the same problem. Reset the sizing die to fix the problem and borrowed a body die to correct the rest of the first run.

My first run of LC M118LR had the same problem. Reset the sizing die to fix the problem and borrowed a body die to correct the rest of the first run.

bigedp51's answer above is your most likely best advice.

Are you sizing on a Dillon or a standard single-stage press? Sometimes the Dillon's shell plate won't let you size low enough on the case diameter.

Use your mic to see how large your case dimensions are above the extractor groove and compare with a case fired from your chamber and dimensions for an unfired case. A cartridge headspace comparator will help you mic for proper shoulder bump.

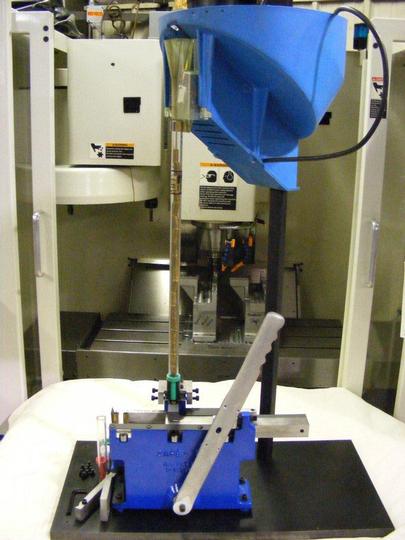

Check the lower pic to see why machinegun brass may be stretched longer. Fewer GI issued 7.62mm rifles out there.

Are you sizing on a Dillon or a standard single-stage press? Sometimes the Dillon's shell plate won't let you size low enough on the case diameter.

Use your mic to see how large your case dimensions are above the extractor groove and compare with a case fired from your chamber and dimensions for an unfired case. A cartridge headspace comparator will help you mic for proper shoulder bump.

Check the lower pic to see why machinegun brass may be stretched longer. Fewer GI issued 7.62mm rifles out there.

Last edited:

jimbuck

You need a Hornady cartridge case headspace gauge to measure your fired rounds "from your rifle" and to set up your dies for the proper amount of shoulder bump.

In the meantime just adjust the press and die to cam over with maximum shoulder bump, these Lake City case were fired in a machine gun with a larger diameter and a much longer headspace chamber setting. Even after you size this way with the die making hard contact with the shell holder the case shoulder will "spring back" after sizing.

Then after the brass is brought back to "normal" dimensions you can adjust the die for minimum shoulder bump.

What you are seeing happens to any brass fired in a machine gun and "larger" military chambers and once you bring the brass back to minimum dimensions you can adjust your dies upward for the correct shoulder bump.

Lake City 7.62 brass is thicker and harder than commercial brass and its spring back rate after full length sizing is more because of this.

Shat he said^^^^. But 1 additional thing I do when first resizing LC brass is to smoke the case before resizing and see if the smoke is rubbed off the full length of the case. Then I insert it backward into a Wilson case length gauge. If it doesn't go in at least half way the brass has sprung back. LC is great brass but sometime can really be a pain to resize it properly.

Sometimes when resizing .. It helps to hold the tam up in the upstroke to help prevent some of the spring back. I usually hold for 5 sec, then turn 180 deg then hold for another 5.. It def helps

Like Pinecone, I've found that the use of a Redding small base body die straightened out problems that I had with a FAL after reloading LC MG fired brass that I had resized using a small base RCBS FL sizer. Usually the FAL will eat just about anything, but for some reason didn't like a batch of my LC reloads until after the use of the Redding small base body die.

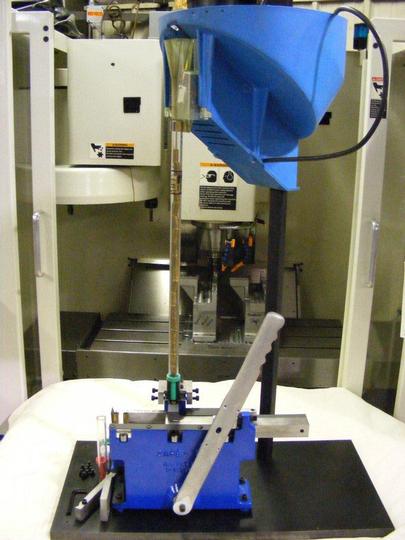

Best way to size MG fired brass is with one of these:

Only $700 or so for the basic machine. ~$1100 for one including .308 and .223 "dies".

Case-Pro 100 - Case-Pro 100

This machine "roll forms" the case right down to taking "dings" out of he extractor grooves. No lube required either so that's a plus. Also, no more stuck cases.

Order now and you can get in the production que for 2015

Only $700 or so for the basic machine. ~$1100 for one including .308 and .223 "dies".

Case-Pro 100 - Case-Pro 100

This machine "roll forms" the case right down to taking "dings" out of he extractor grooves. No lube required either so that's a plus. Also, no more stuck cases.

Order now and you can get in the production que for 2015

Last edited:

That's great info gentlemen. The trim to length is 2.005, the web is .467. I don't have a gauge to measure the shoulder. I think turning the die deeper to bump the shoulder will be the answer.

You are on right track. Bump shoulder a bit more and see if brass will chamber. Bet that is ALL you need to do at this time. KISS.

Similar threads

- Replies

- 15

- Views

- 675