If there is a quick answer, I need one.

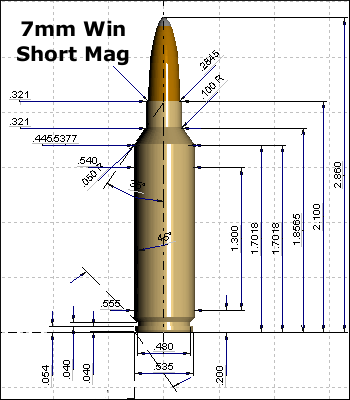

I know there is a difference in the length from the base of the cartridge to the datum line between these cases, and the .270 and 300wsm are the same. The 7wsm is slightly longer. From what I have read, this is to keep a 300wsm from being able to chanber the 7, and the 270wsm from being able to chamber in the 7wsm, because of the datum line of the 7wsm, and the .30cal bullet will not chamber on the .270wsm.

Now, i have been reading about the cream of wheat fire forming method, and it is not creating enough pressure to make the 270 wsm grow to index on the shoulder of the chamber, as new 7wsm brass does. It also smells like burnt hair, which is causing some concern and anxiety from the wife.

Unfortunately I do not have the tool to tell how much it is growing, though I know it is not reaching the shoulder in the chamber yet, by using the "smoke the brass" method taught at hillbilly 101. Judging by the primer, I am reaching some pressure in the chamber where I am not going to go any higher with the powder, because it is protruding, and flat as hell.

Now, my concerns are to load a light to medium load with a bullet into the lands, to create the pressure needed, and to keep the brass against the bolt face, with out having case head separations or gasses leaking back into the action, in return, fucking up my face.

How do I do this safely, or at least as safe as can be done? Fire forming as normal by literally loading up the rounds as usual, but a little lighter, and hope it works out?

I have no experience making brass like this, thanks in advance for the wisdom.

I know there is a difference in the length from the base of the cartridge to the datum line between these cases, and the .270 and 300wsm are the same. The 7wsm is slightly longer. From what I have read, this is to keep a 300wsm from being able to chanber the 7, and the 270wsm from being able to chamber in the 7wsm, because of the datum line of the 7wsm, and the .30cal bullet will not chamber on the .270wsm.

Now, i have been reading about the cream of wheat fire forming method, and it is not creating enough pressure to make the 270 wsm grow to index on the shoulder of the chamber, as new 7wsm brass does. It also smells like burnt hair, which is causing some concern and anxiety from the wife.

Unfortunately I do not have the tool to tell how much it is growing, though I know it is not reaching the shoulder in the chamber yet, by using the "smoke the brass" method taught at hillbilly 101. Judging by the primer, I am reaching some pressure in the chamber where I am not going to go any higher with the powder, because it is protruding, and flat as hell.

Now, my concerns are to load a light to medium load with a bullet into the lands, to create the pressure needed, and to keep the brass against the bolt face, with out having case head separations or gasses leaking back into the action, in return, fucking up my face.

How do I do this safely, or at least as safe as can be done? Fire forming as normal by literally loading up the rounds as usual, but a little lighter, and hope it works out?

I have no experience making brass like this, thanks in advance for the wisdom.