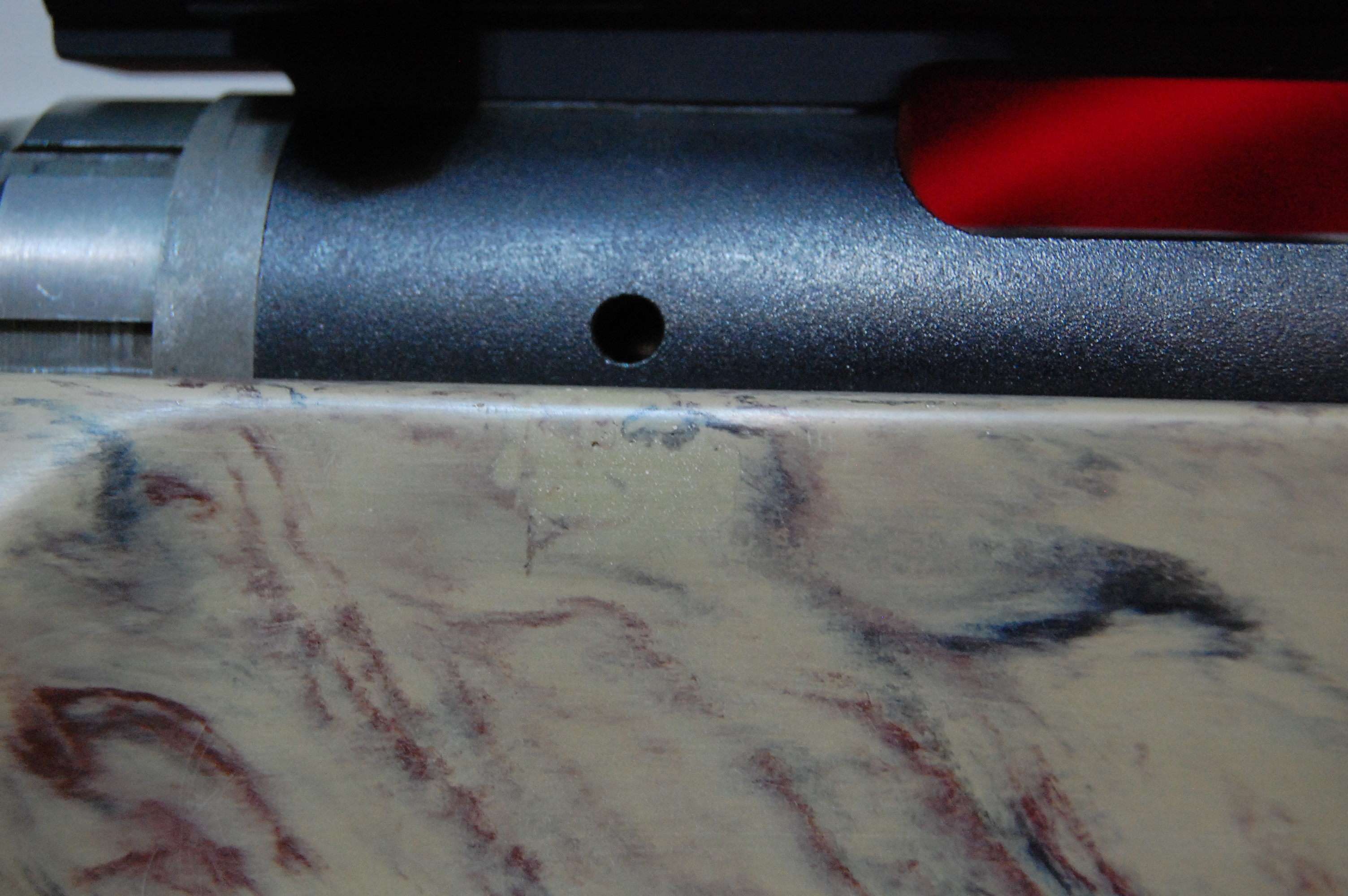

I finally got around to glass bedding my A5 a couple weeks ago. When I tapped the action to get the bedding to release, I must have knocked on the side of the stock a little. To my surprise, this took out a fairly sizable chunk of the stock. It appears this area of the stock was hollow and completely unsupported, hence why it chipped so easily. The chip isn't a big deal (especially since it was my fault), but it seems like this entire hollow area is going to be just as fragile. I don't treat my rifles very gently, which is why I chose the molded in finish to begin with.

My emails to McMillan have gone unanswered thus far. I'll give them a call as soon as I get a chance, but haven't yet, thanks to the fact that I don't even have time for lunch, most days. Anyways, I'm not super well-versed in the manufacturing of these stocks, so what do you guys think? Normal or defective?

My emails to McMillan have gone unanswered thus far. I'll give them a call as soon as I get a chance, but haven't yet, thanks to the fact that I don't even have time for lunch, most days. Anyways, I'm not super well-versed in the manufacturing of these stocks, so what do you guys think? Normal or defective?