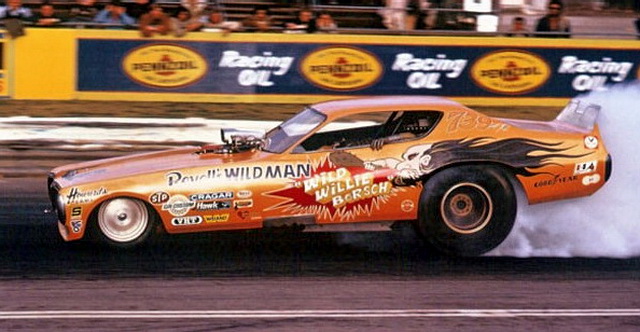

Oh hell, that just beggin' to be restored! I wish I had the money and expertise to restore that.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Maggie’s Motivational Pic Thread v2.0 - - New Rules - See Post #1

- Thread starter Snake-Eyes

- Start date

-

- Tags

- motivational pictures

Engine builder here. Horsepower is measure of how fast an engine can work. So, its a measure of how fast it can move things. Some dynos only measure horsepower. It is figured by how fast they can get the heavy rollers to accelerate.I feel like I need to add this, sorry.

Horsepower will not move a motorized vehicle 1 inch.

It's torque that matters, and it's torque that is measured on a dyno.

Horsepower is nothing but a mathematical equation derived from the torque measurement.

Ask any *real* engine builder.

To make torque, the reciprocating assembly must have inertia.

The more inertia, the more torque.

Ah hell....not much use attempting to explain physics on a gun forum is there ?

Holy shit! I've been driving for 30+ years and could never figure that out!That's also pretty common here in the US, as well. When I was an EMT, our rigs had "AMBULANCE" spelled backwards on the front. This, of course, so that it could be seen as "AMBULANCE" in the rear view mirror of a car in front of us... in the hope that they'd recognize that we were trying to get by them and they should "PULL OVER!"

Chuckle... are we still arguing Torque/HP? Yes, Torque is needed, as it is *part* of the equation. Is it king? No.

I have a car I take to the track (the type with twisty curves, and not just a straight line) and it only produces 145 Foot Pounds of Torque.

None of the big V8 cars stay with me 0-60. Now, the car body is designed to produce downforce, so its CDA (drag) is as bad as a minivan. Once I am over 60 MPH, then overcoming the drag consumes a lot of force/energy... and the V8 cars gain ground. Once we get back into the twisties, they get passed.

You cannot discuss the importance of Torque/HP, unless you includes Mass and Drag. A really light car, needs less Torque/HP to accellerate quickly at low speeds (example Lotus), a car with low drag, requires less Torque/HP to achieve a high rate of speed (example 280z, they had very good top-end speed for their given HP/Torque).

You must consider the whole package, to have a meaningful discussion.

I have a car I take to the track (the type with twisty curves, and not just a straight line) and it only produces 145 Foot Pounds of Torque.

None of the big V8 cars stay with me 0-60. Now, the car body is designed to produce downforce, so its CDA (drag) is as bad as a minivan. Once I am over 60 MPH, then overcoming the drag consumes a lot of force/energy... and the V8 cars gain ground. Once we get back into the twisties, they get passed.

You cannot discuss the importance of Torque/HP, unless you includes Mass and Drag. A really light car, needs less Torque/HP to accellerate quickly at low speeds (example Lotus), a car with low drag, requires less Torque/HP to achieve a high rate of speed (example 280z, they had very good top-end speed for their given HP/Torque).

You must consider the whole package, to have a meaningful discussion.

Does all this drivel really have to be in the MPV thread? Without any pictures or video? Why don’t you all just start a thread about it, on a car forum, where it belongs? Sheesh! Three pages of Dick swinging and braggadocios, along with a little bit of actual good information, interspersed with the occasional attempt by someone with a a clear head trying to get the thread back on track.

For Fucks’ Sake already!

Idiots arguing about model cars and boats in a motivational picture/video thread on a precision rifle forum. See below:

For Fucks’ Sake already!

Idiots arguing about model cars and boats in a motivational picture/video thread on a precision rifle forum. See below:

Quit your belly aching KarenDoes all this drivel really have to be in the MPV thread? Without any pictures or video? Why don’t you all just start a thread about it, on a car forum, where it belongs? Sheesh! Three pages of Dick swinging and braggadocios, along with a little bit of actual good information, interspersed with the occasional attempt by someone with a a clear head trying to get the thread back on track.

For Fucks’ Sake already!

Idiots arguing about model cars and boats in a motivational picture/video thread on a precision rifle forum. See below:

View attachment 7889865

I don’t see kitties, bubbles is out of the deal.

Shut it down for today; you win

She’s pretty cute

It’s not for sale he’s 78 had it 25 years and will work on it one day. Pretty sure that just body with tires propped up under it, rear looks like there’s no studs, sell the fenders we don’t need those were we are goingOh hell, that just beggin' to be restored! I wish I had the money and expertise to restore that.

How about 2 horse power?I feel like I need to add this, sorry.

Horsepower will not move a motorized vehicle 1 inch.

Drift(draft) horses may be 1.5hp each. Long stroke legs and high compression hearts larger air intake.How about 2 horse power?

Last edited:

Some of the members on here that get all butt hurt need to go hang out with Haney

Drift horses may be 1.5hp each. Long stroke legs and high compression hearts larger air intake.

Those are "draft" horses. this is a drift horse.

Those are "draft" horses. this is a drift horse.

Fast and the bi curious 17: Lancaster Drift

If a motor is producing a rotational force, it is producing torque.

Please define how rotational force happens without rotation.This does not require rotation, it is a force.

Such a statement is beyond ludicrous and requires a fully inept mind.

Wait....have you been watching Star Wars again ?

Last edited:

The average horse is around 15 horse power. Go figgure.How about 2 horse power?

But what about unicorns like the one above? Is that horsepower, or do they have a different scale?

Similar threads

- Replies

- 0

- Views

- 44K

- Replies

- 64

- Views

- 21K