Hey all,

I'm trying to bed my Savage 93 into a Boyds stock and I'm running into an issue with the pillars.

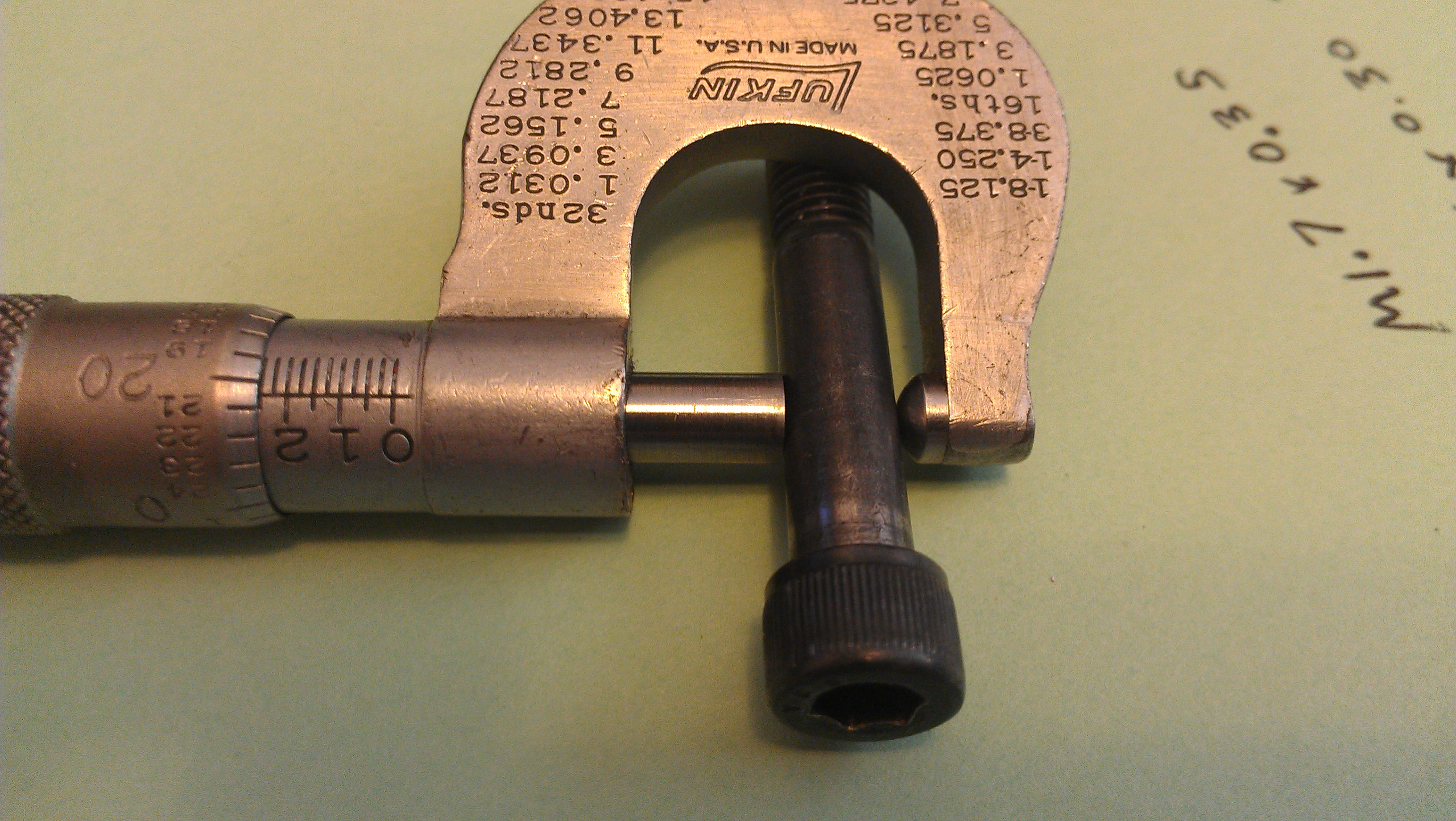

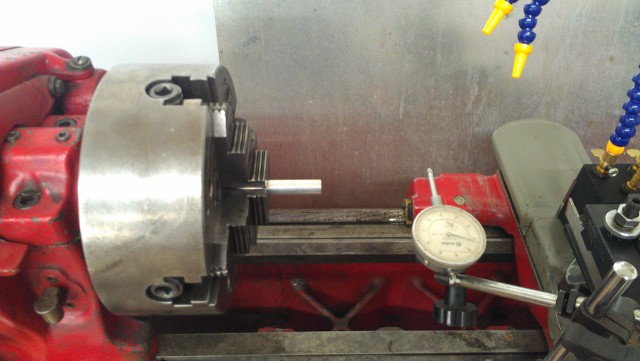

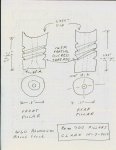

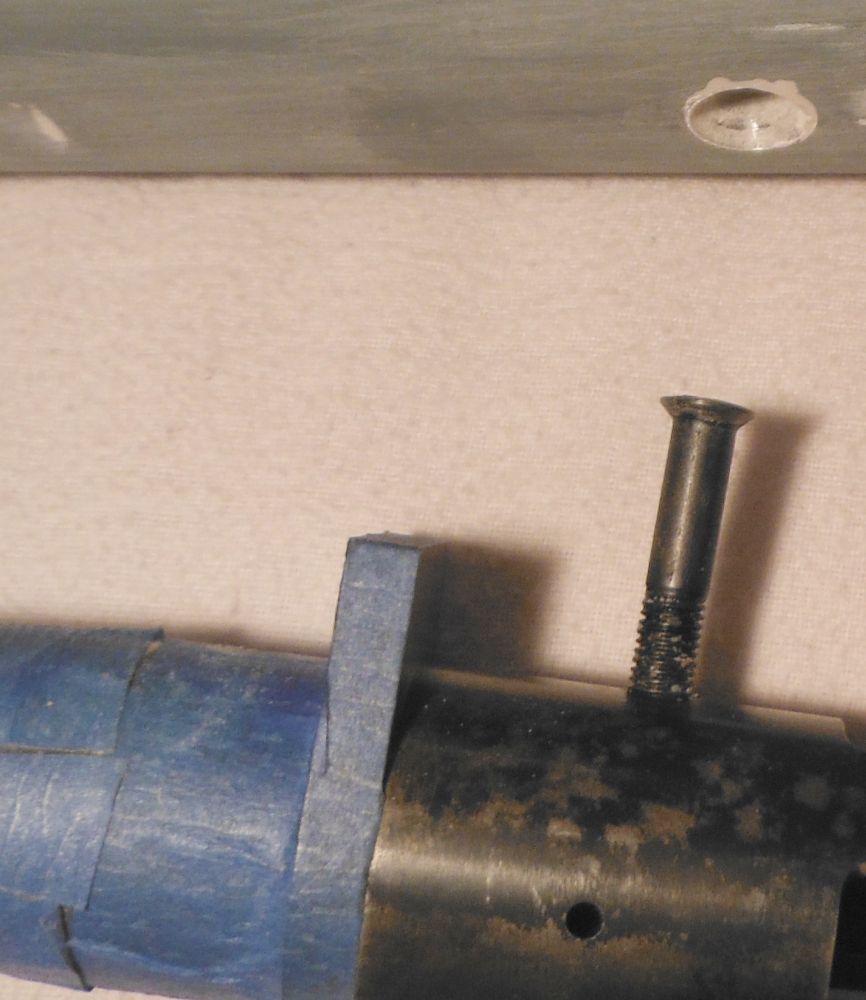

I can't use .5"+ pillars due to it being a Rimfire, there just isn't enough real estate in the stock for the rear pillar so I'm going to be using 3/8" pillars instead. The problem is, I can't seem to find 3/8 / .375 pillars anywhere. I did find these Mauser 98 stock ferrules that will work but it's not grooved to hold the bedding and I dont have a lathe.

It may be worth noting that I'll be using Remington 700 action screws cut down to length for the Savage action. I believe they are .250 1/4x28 threaded so the pillars must accept them.

http://www.brownells.com/gunsmith-t...ixtures/mauser-98-stock-ferrules-prod983.aspx

If any of you guys make your own pillars and can make me a set (I'll pay of course) or get me pointed in the right direction it would be a great help.

I'm trying to bed my Savage 93 into a Boyds stock and I'm running into an issue with the pillars.

I can't use .5"+ pillars due to it being a Rimfire, there just isn't enough real estate in the stock for the rear pillar so I'm going to be using 3/8" pillars instead. The problem is, I can't seem to find 3/8 / .375 pillars anywhere. I did find these Mauser 98 stock ferrules that will work but it's not grooved to hold the bedding and I dont have a lathe.

It may be worth noting that I'll be using Remington 700 action screws cut down to length for the Savage action. I believe they are .250 1/4x28 threaded so the pillars must accept them.

http://www.brownells.com/gunsmith-t...ixtures/mauser-98-stock-ferrules-prod983.aspx

If any of you guys make your own pillars and can make me a set (I'll pay of course) or get me pointed in the right direction it would be a great help.