OK, I've posted this on a couple other threads before, but I'll do it again here as I've got your solution.

First, let me point out the "jump" simply is not very important as seating depth is (seating depth being how far the base of the bullet is into the case, which changes the volume that the powder can reside in and that has a big influence on the pressure curve that effects the bullet timing in relation your barrel's harmonics for consistent POI's). So, don't focus on jump, but focus on seating depth. Measuring to the lands is only important to find out the space you have to work in. After that, seating depth is what you want to adjust after you've found a decent powder load that's at you're starting seating depth.

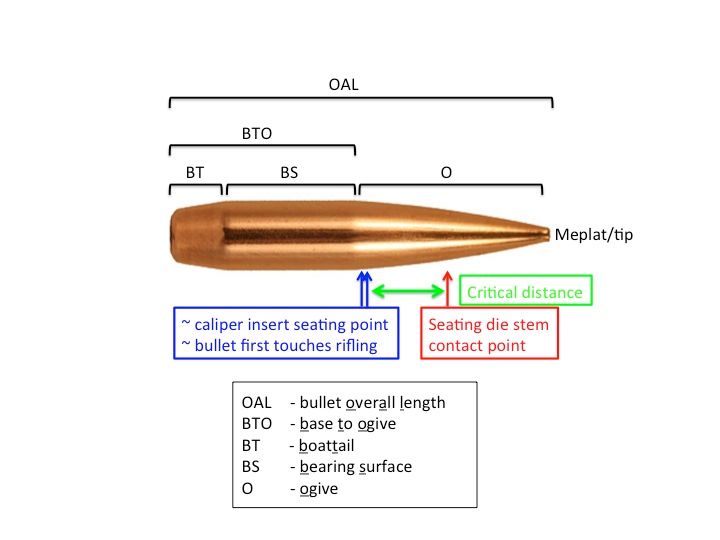

The issue you're talking about is one that confounded me for a while as no one else seems to have a good solution for the variation between the seating stem contact point and the contact point of one's caliper insert for the ogive. . . which is what tends to produce those seating depth variances, even when the bullets are sorted by BTO's. To solve this, I decided to sort my bullets by the distance from the base to the seating stem contact point (for me, that's the point as you've pointed out in your picture for an LE Wilson seating stem). Now that I sort bullets this way, I have very little variance in seating depth, even though the CBTO (Cartridge Base To Ogive) can vary, which is not important (the jump variance).

For my 6.5 bullets, I found Sinclair 17mm comparator insert contact point to be very close to the con Wilson seating stem contact point. So that's what I use to sort my .264 bullets with. I do use Berger's and find they often don't need sorting as the variances are often very small. For other brands, they almost always need sorting to get the kind of consistency I want.

So, the key is in sorting your bullets and sort with a comparator insert that has the same diameter at the contact point as your seating stem does.

Keep in mind that comparator inserts for the same caliber vary and the one you have probably won't give you the same measurement as mine even though it's the same brand. It's a "comparator", not a precision measurement. Always use the same CBTO comparator insert to keep tract of the distance to your lands. That distance changes over time and you don't have to try and keep that distance (the jump) the same. Just keep your seating depth the same for the one that gives you the good results.