Re: Stainless Steel Media Testimonials

Seawalker, the cases I have tumbled so far with this process are 308 and 280 AI. the necks are thinner on the 280 AI brass, and it definitely shows more peening/deformation than the 308 cases.

As for previous posters, I don't think anybody is misleading anyone, I just don't think most notice or feel it is worth mentioning. As I said before, I expected some of this type of deformation--based on experience--to this type of part (brass case) and don't think it to be unusual, and there are lots of variables that will impact this effect--as an example, age of brass since being annealed, thickness of neck on given cases, and of course length of time in the process.

I will also second what KP has said, if I use my Giraud, I can get a case mouth so f'd up, that I have to retrim,for me just re-chamfering if not enough to remediate the case to my satisfaction.

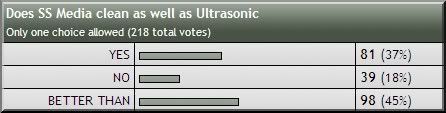

This is a GREAT method for cleaning cases. I remain optimistic for developments in a DRY system that achieves comparable results, and I believe that if truly skilled experts, e.g. industrial process engineeers could specifiy a proper size and type of media that will perform as corn cob or walnut in terms of weight and ease of seperation, as well as achieve the results of removing residue from inside the case and from the primer pockets, we would really have a great option--I think it's doable BTW.

One poster on another forum has indicated to me that he has come upon such a mix of media, but the sizes I have been able to find for the type of media he describes, would not be able to function inside the case and in the primer pockets, so thus far, I have not been able to find a media that will perform to the level of this process in a dry application.

It is interesting how certain things in technology come slowly to the shooting sports community--i.e. affordable remote video target monitoring, simplified case annealing etc. I feel this process is the next level of tech in case cleaning, but think there are more options to come, hopefully utilizing existing 'standard' equipment, like vibratory bowls,and dry media seperators, which are simple, easy to use and readily available at a low cost.

I dislike the amount of case handling needed with this process, but LOVE the results in terms of the actual cleaning of the cases, and getting magnetic media from Mark will help in my SOP--but the amount of case handling is a lot more for me than with ultrasonic or typical vibratory operations. (which again--to me--is really exterior case polishing, not cleaning, as there is no 'real' cleaning of the inside of the case or the primer pockets).

The application of this type of process to brass case cleaning is a good step forward IMO, and may be where economics and practicality stop for some time before there is a better/easier method brought forward, but we will see.