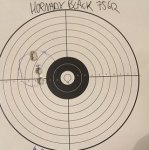

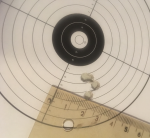

1. Today a buddy of mine shot the rifle- see the targets below. We tried Hornady Match ELD 73gr, Hornady Black 75 gr and GGG SMK 77GR.

2. It seems that the gas block does touch the bottom of the handguard (in fact the piccatiny rail attached to it).

2. It seems that the gas block does touch the bottom of the handguard (in fact the piccatiny rail attached to it).