I have about 2k rounds through my tikka tac a1 in 6.5 creedmoor. Almost every round shot through it has been hornady american gunner 140g bthp factory loads. I usually just ran clp oil through it with patches every 200 or so rounds until recently. I started adding copper solvent into my cleaning regiment recently and I've spent a shit ton of patches running that stuff through it. I also bought a magnetospeed chronograph and my velocity readings are extremely slow. Factory fps readings are 2690 fps on the box and my 10 shot group avg 2515-2550. I also recently bought a hornady coal gage and my maximum length was measured at 2.945. Is it time to find a new barrel or is this something other tikka shooters have seen before? I know the factory barrels are slow and the oal can also be a little long in tikkas but it seems a lot more for me than what I have read recently.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Time for a new barrel??

- Thread starter Bp90

- Start date

Stop cleaning it so much your doing more damage to it than not. Some copper is good copper it fills in the imperfections. I’ll shot until accuracy falls off (1200 rounds or more)and then clean it. But not very much. As for the FPS on the box. It will be different in different barrels.

Tikka barrels are known to be slow. I don't know why, but mine was, and it seems everyone else's are too.

How does it shoot? If it shoots well, leave it alone.

How does it shoot? If it shoots well, leave it alone.

Tikka barrels are known to be slow. I don't know why, but mine was, and it seems everyone else's are too.

How does it shoot? If it shoots well, leave it alone.

I agree with this^^^^

I found an awesome load for my RPR that was in the low 2600s when the sweet spot for almost every 6.5 CM that I hear about is ~2700

If it hits what you aim it at consistently then don't sweat it.

My Tikka T3x TAC A1 shoots the Hornady AG 140's at around 2,611. Always has, and it's super accurate. Not sure FPS is an issue here, unless you're noticing a degradation over time. That said ... 2,550 as a high, is a bit low. I'm reloading now and will take my first handload tests for this rifle to the range on the next acceptable weather day. Testing Berger 153.5 Long-Range Hybrid Target bullets with Accurate 4350 powder and Hornady cases.I have about 2k rounds through my tikka tac a1 in 6.5 creedmoor. Almost every round shot through it has been hornady american gunner 140g bthp factory loads. I usually just ran clp oil through it with patches every 200 or so rounds until recently. I started adding copper solvent into my cleaning regiment recently and I've spent a shit ton of patches running that stuff through it. I also bought a magnetospeed chronograph and my velocity readings are extremely slow. Factory fps readings are 2690 fps on the box and my 10 shot group avg 2515-2550. I also recently bought a hornady coal gage and my maximum length was measured at 2.945. Is it time to find a new barrel or is this something other tikka shooters have seen before? I know the factory barrels are slow and the oal can also be a little long in tikkas but it seems a lot more for me than what I have read recently.

At 2k rounds it may not be time to replace the barrel but it is time to order one. If it is shooting keep shooting it until it doesn't. But it can take a few months to get a replacement barrel so I would get started on that soon.

It’s hard to tell without previous velocity data with that ammo earlier in the barrels life.

I was in a similar situation with my 260 TRG a few years ago. I was somewhere around 2500 rounds through it and decided to replace the barrel because the velocity seamed low for the bullet and powder range I saw others getting in the reloading depot. I was still getting good accuracy, but decided to change it before it could cause a problem.

I keep some factory ammo on hand and keep a velocity tracking log to with my round count log.

I was in a similar situation with my 260 TRG a few years ago. I was somewhere around 2500 rounds through it and decided to replace the barrel because the velocity seamed low for the bullet and powder range I saw others getting in the reloading depot. I was still getting good accuracy, but decided to change it before it could cause a problem.

I keep some factory ammo on hand and keep a velocity tracking log to with my round count log.

Why did you start using copper solvent in the first place? Was your accuracy falling off dramatically? Just didn’t think it was getting clean enough with just clp?

The barrel will likely speed back up if you stop using copper solvent and shoot it dirty again. A couple patches of CLP won’t hurt, but don’t clean the barrel down to bare metal unless your accuracy starts falling off.

I clean my barrels under two conditions only, if the accuracy starts going to hell, or if I took the rifle hunting (just to clean out any water or dirt).

Also, if that solvent is strong enough to eat copper out of the bore, it might be strong enough to eat your barrel also. I stay away from solvents unless absolutely necessary. Just hoppes and clp for me.

The barrel will likely speed back up if you stop using copper solvent and shoot it dirty again. A couple patches of CLP won’t hurt, but don’t clean the barrel down to bare metal unless your accuracy starts falling off.

I clean my barrels under two conditions only, if the accuracy starts going to hell, or if I took the rifle hunting (just to clean out any water or dirt).

Also, if that solvent is strong enough to eat copper out of the bore, it might be strong enough to eat your barrel also. I stay away from solvents unless absolutely necessary. Just hoppes and clp for me.

Stop cleaning it so much your doing more damage to it than not. Some copper is good copper it fills in the imperfections. I’ll shot until accuracy falls off (1200 rounds or more)and then clean it. But not very much. As for the FPS on the box. It will be different in different barrels.

As long as you’re using the proper solvents, you’re not hurting a barrel cleaning it.

This is bad info being perpetuated from 1995.

Y’all are perpetuating myths. You will rarely hurt a barrel cleaning it. And any “good copper” is replaced within a few shots.

“Waiting for accuracy to fall off” has a huge problem. Accuracy falls off. Proper cleaning means accuracy never falls off and you never get a carbon ring/build up.

You wouldn’t wait for your car to “lose accuracy” before changing the oil. Cleaning is preventative maintaining.

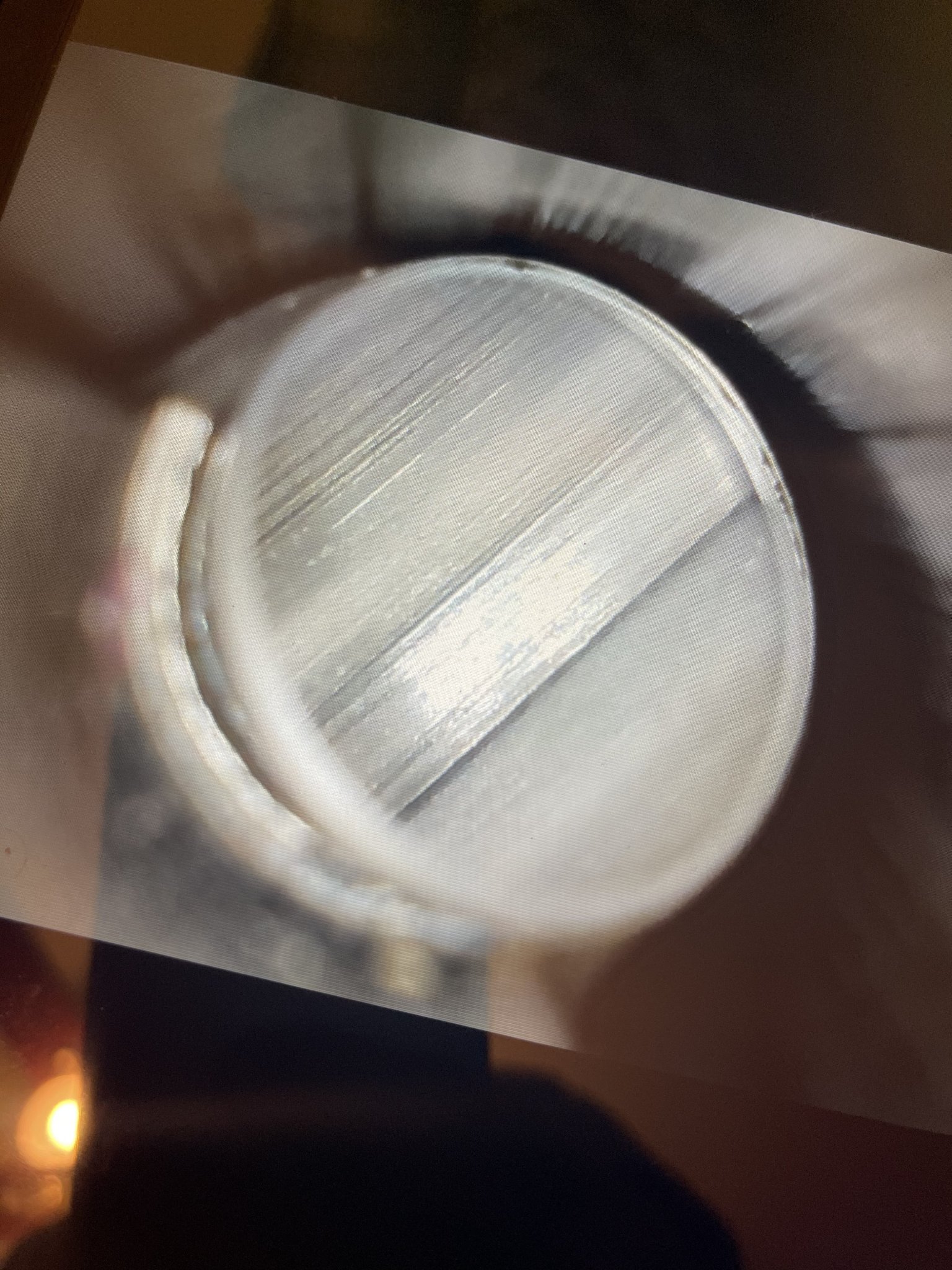

Here’s a 6mm barrel with 1200 rounds, that gets cleaned completely to the steel every 300 or so and this group was less than 10 shots in after cleaning.

“Waiting for accuracy to fall off” has a huge problem. Accuracy falls off. Proper cleaning means accuracy never falls off and you never get a carbon ring/build up.

You wouldn’t wait for your car to “lose accuracy” before changing the oil. Cleaning is preventative maintaining.

Here’s a 6mm barrel with 1200 rounds, that gets cleaned completely to the steel every 300 or so and this group was less than 10 shots in after cleaning.

Last edited:

To the original OP question, you’d need the initial velocity to know if your velocity has taken a dip. Also, there are two definitions some use for a burned out barrel:

1: suffering from velocity loss

2: precision falls below acceptable

If you’re shooting important matches or a hunt, you’ll like either trash or use barrel for practice when it hits #1. You don’t want it to take another velocity loss at the wrong time.

If you just plink, or don’t care when the next velocity loss happens you can use #2.

As mentioned above, at 2,000 I’d definitely be sourcing another barrel.

1: suffering from velocity loss

2: precision falls below acceptable

If you’re shooting important matches or a hunt, you’ll like either trash or use barrel for practice when it hits #1. You don’t want it to take another velocity loss at the wrong time.

If you just plink, or don’t care when the next velocity loss happens you can use #2.

As mentioned above, at 2,000 I’d definitely be sourcing another barrel.

D

Deleted member 10043

Guest

Shoot until barrel is hot to touch. Let it cool. Shoot it again and your bullets are going all over the place. Do you only shoot at 100 yards because you should know over time your MV. Plus, this is factory what is the velocity on the box and the length of your barrel. BTW, I wouldn't have waited so long before adding copper removing solvent to your cleaning regime.

I was much harder on my barrel when it was newer. I would fire off like 20+round strings in maybe 10 minutes and barely let it cool before starting up again. It was my first real bench gun that I bought.

I used to only run clp through it but I started to see copper at the muzzle and brake so I started reading about it hence using the solvent.

So from what I'm reading, using copper solvent after each use or every couple hundred rounds is getting some mixed reviews? Along with cleaning after every use? Why wouldn't everyone want to have a clean gun all the time!?

Also, what's the opinion on here about the longer COAL? Throat erosion? My guage is getting me a maximum length of 2.945. After a couple of tests it seems to shoot the best at a length of 2.900.

Shooting hornady brass with 41.7g h4350 and 140 grain hornady bthp. Velocity is better but still 2700 or so.

I used to only run clp through it but I started to see copper at the muzzle and brake so I started reading about it hence using the solvent.

So from what I'm reading, using copper solvent after each use or every couple hundred rounds is getting some mixed reviews? Along with cleaning after every use? Why wouldn't everyone want to have a clean gun all the time!?

Also, what's the opinion on here about the longer COAL? Throat erosion? My guage is getting me a maximum length of 2.945. After a couple of tests it seems to shoot the best at a length of 2.900.

Shooting hornady brass with 41.7g h4350 and 140 grain hornady bthp. Velocity is better but still 2700 or so.

Ordered a bartlein from bugholesAt 2k rounds it may not be time to replace the barrel but it is time to order one. If it is shooting keep shooting it until it doesn't. But it can take a few months to get a replacement barrel so I would get started on that soon.

I was much harder on my barrel when it was newer. I would fire off like 20+round strings in maybe 10 minutes and barely let it cool before starting up again. It was my first real bench gun that I bought.

I used to only run clp through it but I started to see copper at the muzzle and brake so I started reading about it hence using the solvent.

So from what I'm reading, using copper solvent after each use or every couple hundred rounds is getting some mixed reviews? Along with cleaning after every use? Why wouldn't everyone want to have a clean gun all the time!?

Also, what's the opinion on here about the longer COAL? Throat erosion? My guage is getting me a maximum length of 2.945. After a couple of tests it seems to shoot the best at a length of 2.900.

Shooting hornady brass with 41.7g h4350 and 140 grain hornady bthp. Velocity is better but still 2700 or so.

A borescope really helps with cleaning. The teslong is pretty cheap and does great job.

Let’s you see exactly when you have the barrel cleaned to your liking.

As long as you’re using the proper solvents, you’re not hurting a barrel cleaning it.

This is bad info being perpetuated from 1995.

Really?

Didn't know you had to pay to read posts lol

Old videos are old. Frank has also come around to saying he understands light triggers. You can find videos of him saying they shouldn’t be using light triggers. You can find posts from me from a couple years ago with something different than I believe now. It’s all but impossible to go back and delete or edit this stuff.

People evolve.

According to your theory, the best BR and F class shooters destroy barrels and don’t know what they are doing.

Last edited:

Wipe out won’t hurt your barrel so you can let it sit 24-48 hours and not hurt anything. If I still get blue patches I let it sit again

Old videos are old. Frank has also come around to saying he understands light triggers. You can find videos of him saying they shouldn’t be using light triggers. People evolve.

According to your theory, the best BR and F class shooters destroy barrels and don’t know what they are doing.

This video is from 2017 not 1995 old. Not saying I’m right, just going by what I have learned from others that know more than I do and my experience with my rifles. Looks like I may need to do more research. It all comes down to none of us are as smart as all of us.

This video is from 2017 not 1995 old. Not saying I’m right, just going by what I have learned from others that know more than I do and my experience with my rifles. Looks like I may need to do more research. It all comes down to none of us are as smart as all of us.

That video still perpetuates old theories is my point. We all do it, and will continue as we learn.

We are slowly chipping away, but a very large amount of info out there is old info that was never tested or never testing properly. Or it was true for the materials and things used then, and the knowledge wasn’t updated to reflect new things.

I guess we're going down the rabbit hole lol.

I just don't see or understand how regular cleaning of copper out of a steel barrel can hurt it. Copper is softer than steel, and the solvent is only left on for a short while before removing it and applying some more oil. I always use nylon brushes too and never metal.

I just don't see or understand how regular cleaning of copper out of a steel barrel can hurt it. Copper is softer than steel, and the solvent is only left on for a short while before removing it and applying some more oil. I always use nylon brushes too and never metal.

Didn't know you had to pay to read posts lol

It really pays to become a supporter.. That also gives you the ability to watch the online trainings. I highly recommend Franks book also. Definitely the best book I have read on precision shooting. Lots of new methods that have made my shooting ability better.

Ask yourself this, if cleaning is not important, then why do bench-rest and f-class shooters do it so often.

Cleaning regimens are caliber/barrel dependent. A .308 might go 2000 rounds without needing cleaning. But I’ll give you an example of where listening to the “don’t clean till accuracy drops” crowd got me in a jam.

i shoot 6mm creed. I barely cleaned the gun over the first 400 rounds. At 400 I suddenly jumped 150fps, blew primers, sticky bolt lift and got ejector swipes. Along with a loss of accuracy. (From a .3moa gun to a 1.5moa gun. ) The reason? A had a major carbon ring formed from not cleaning along with more copper than I believed I had. A bit of preventative maintenance would have eliminated the nightmare I went through figuring this out.

A full copper strip and carbon cleaning brought he gun back in line. It took about 10 rounds for velocity to get back to normal and now it’s running great again.

cleaning your barrel will not harm it. The only thing stripping copper will do is change your poi till it settles back in. Cleaning carbon only will maintain POI. And as others have mentioned, most F class shooters who are running the most accurate barrels out there strip their barrels regularly. As in after a few hundred rounds. I believe most of this “dont clean” business is more about people parroting what they have read in the forums which is just more perpetuating of bad info. As long as you follow sound practices, you will not hurt your barrel. You may affect your cold/clean bore shot requiring a scope adjustment if you strip copper but you won’t hurt a thing. And in the case of smaller “barrel burner” calibers you may be preventing some big issues with some simple maintenance.

i shoot 6mm creed. I barely cleaned the gun over the first 400 rounds. At 400 I suddenly jumped 150fps, blew primers, sticky bolt lift and got ejector swipes. Along with a loss of accuracy. (From a .3moa gun to a 1.5moa gun. ) The reason? A had a major carbon ring formed from not cleaning along with more copper than I believed I had. A bit of preventative maintenance would have eliminated the nightmare I went through figuring this out.

A full copper strip and carbon cleaning brought he gun back in line. It took about 10 rounds for velocity to get back to normal and now it’s running great again.

cleaning your barrel will not harm it. The only thing stripping copper will do is change your poi till it settles back in. Cleaning carbon only will maintain POI. And as others have mentioned, most F class shooters who are running the most accurate barrels out there strip their barrels regularly. As in after a few hundred rounds. I believe most of this “dont clean” business is more about people parroting what they have read in the forums which is just more perpetuating of bad info. As long as you follow sound practices, you will not hurt your barrel. You may affect your cold/clean bore shot requiring a scope adjustment if you strip copper but you won’t hurt a thing. And in the case of smaller “barrel burner” calibers you may be preventing some big issues with some simple maintenance.

I clean carbon every 100-200 rds. Would 6.5cm fall more on the 308 side of extensive copper fouling or more on the magnum side? Or is that even the right question?

I clean carbon every 100-200 rds. Would 6.5cm fall more on the 308 side of extensive copper fouling or more on the magnum side? Or is that even the right question?

The quality of the bore machining (rough vs hand lapped) has more effect on copper fouling than caliber. That and bullet jacket quality.

Edited to add: Forgot about bullet design and bearing surfaces, that affects fouling too.

Last edited:

Factory fps readings are 2690 fps on the box and my 10 shot group avg 2515-2550.

Take what you see on the box as a reference only. Ammo loaded and tested in a ammunition test barrel vs a factory barrel can give you night and day different numbers.

Unless you know the bore and groove size of your barrel to the 4th decimal place and what chamber was used can cause huge variances. Our ammunition test barrels and our bolt gun barrels etc...are held to min spec. etc...

I've seen factory barrels with dimensions .002" tighter as well as .002" bigger on sizes. Also the chambers could be min spec and or production spec.

Also you said you have 2k rounds on the barrel? Correct? If so as the barrel wears you will lose velocity because the throat is wearing. No way around it and shooting box ammo vs handloads you can not chase the wear etc...just a given.

Later, Frank

Bartlein Barrels

Stop cleaning it so much your doing more damage to it than not. Some copper is good copper it fills in the imperfections. I’ll shot until accuracy falls off (1200 rounds or more)and then clean it. But not very much. As for the FPS on the box. It will be different in different barrels.

Be careful here....some calibers you can get away with not cleaning as much...others you have to stay on top of. You start getting to much carbon build up in the barrel and it will drive up pressures to the point that guns can become dangerous. Not to mention effect accuracy.

Just two months ago....both guns 338 Lapua caliber. One gun with our barrel was only being cleaned every 500 rounds of firing. There was an accuracy spec that the guns have to hold for the testing. At 2800+ rounds it wouldn't hold accuracy at all. Just quite shooting one day. After a lengthy conversation they went and inspected the bore of the barrel. Portions of the barrel you couldn't see any rifling in it. That's how much carbon was built up. 338 Lapua about every 75 rounds fired you are dumping a 1# of powder down the bore vs a 308 Win. gets about 1# of powder down it for every 170ish rounds fired.

Another gun in 338 Lapua (not our barrel) wasn't cleaned for 1k rounds or so. They blew up the gun! Might have other contributing factors involved....but....clean the guns.

Later, Frank

Bartlein Barrels

Wouldnt higher pressures also be a factor?? For comparisons sake, why would a 6mm cm barrel last half as long as a .308The quality of the bore machining (rough vs hand lapped) has more effect on copper fouling than caliber. That and bullet jacket quality.

Edited to add: Forgot about bullet design and bearing surfaces, that affects fouling too.

I guess that would probably affect carbon fouling more than copper though

It lasts half as long because you’re shoving the same amount of burning powder down a hole that’s 40% smaller.Wouldnt higher pressures also be a factor?? For comparisons sake, why would a 6mm cm barrel last half as long as a .308

I guess that would probably affect carbon fouling more than copper though

Wouldnt higher pressures also be a factor?? For comparisons sake, why would a 6mm cm barrel last half as long as a .308

I guess that would probably affect carbon fouling more than copper though

Last half as long in terms of overall usable accuracy barrel life or did you mean something else? In terms of barrel life, higher pressure cartridges (relative to bore diameter) will exhibit more throat erosion. The amount of gas (and the particulates within) pushed through a smaller orifice can be thought of as a sort of blow torch and sand paper where it literally erodes the steel of the barrel. The problem is compounded by how fast your firing schedule is. Mag dump = faster throat erosion, regardless of caliber. Easy to burn out even a 308 in under 1k rounds (constant mag dumps in Arizona summer for example). Barrel replacement is a case by case basis. Some barrels can still be used by loading longer COAL cartridge. You could be at a point in time that you need to replace if the loaded COAL would require you to single feed only.

The issue of copper fouling (which @Newbie2020 was asking about) is separate from barrel life (I would put carbon fouling also as separate from copper fouling or barrel life). You can easily have a rough finished 308 barrel that copper fouls heavily and one that doesn't, both could have a sub-moa barrel life of 5,000rds. You can also foul a barrel with a polished to mirror finish bore using bullets with longer bearing surfaces, thinner or softer copper jackets.

In terms of cleaning copper in general - think of it like a bumpy gravel road where the holes are slowly filled with sand or dirt (the representation of copper). The road doesn't fill evenly. Eventually there is gonna be portions of the road with more sand/dirt build up than others. Before that though it reaches a point where it's fairly smooth overall before it gets starts getting bumpy again. You want to stay in that smooth portion where the space between gravel is filled just enough.

You won't really hurt your barrel by cleaning so often, what you're basically doing is resetting the amount of copper fill either by a little or a lot. That depends on how smooth your bore is to begin with. Good barrel = less shots necessary "foul", even if you strip 100% of the copper out. Rough bore surface will require more shots to "foul" the barrel to achieve max accuracy. Stripping the copper completely on a barrel with a rough bore finish is in my opinion a waste of money and time.

Any barrel cleaning should be done on a case by case basis. The often subjective numbers of you have to clean in "X" many rounds is often times simply arbitrary

Last edited:

D

Deleted member 10043

Guest

I've learned so much from this thread.

D

Deleted member 10043

Guest

Wouldnt higher pressures also be a factor?? For comparisons sake, why would a 6mm cm barrel last half as long as a .308

Fucking overbore. That is why we burn out barrels. 22-250 and 25-06 are my favorites. You can trace most barrel burners to a parent case that is not considered overbore. Example, my .244 Remington parent case is the 7mm Mauser. If I had any sense I would be shooting only parents, lol.

Hello BP90,

I have been shooting a Tikka T3X for about 2 years. It does have a long throat and this rifle has a fast barrel. After about 1,000 rounds of AG, ELD Match and reloads w RL16, AG 140 chronos 2640 fps, ELD Match 140 at 2710 and 147 ELD MAtch at 2690. So Id say its time for a new barrel or maybe take all that brass and reload some 140 ELD's w RL 16 to 2,650-2,700 fps.

I recently retired a 308 barrel at +5,000 rounds that opened up from 1/2 inch groups with just about anything to 3/4 inch w best reloads I could tune. You will know when to retire a barrel but a 140 at 2,550 fps is not why you bought a 6.5 CM.

I have been shooting a Tikka T3X for about 2 years. It does have a long throat and this rifle has a fast barrel. After about 1,000 rounds of AG, ELD Match and reloads w RL16, AG 140 chronos 2640 fps, ELD Match 140 at 2710 and 147 ELD MAtch at 2690. So Id say its time for a new barrel or maybe take all that brass and reload some 140 ELD's w RL 16 to 2,650-2,700 fps.

I recently retired a 308 barrel at +5,000 rounds that opened up from 1/2 inch groups with just about anything to 3/4 inch w best reloads I could tune. You will know when to retire a barrel but a 140 at 2,550 fps is not why you bought a 6.5 CM.

I have about 2k rounds through my tikka tac a1 in 6.5 creedmoor. Almost every round shot through it has been hornady american gunner 140g bthp factory loads. I usually just ran clp oil through it with patches every 200 or so rounds until recently. I started adding copper solvent into my cleaning regiment recently and I've spent a shit ton of patches running that stuff through it. I also bought a magnetospeed chronograph and my velocity readings are extremely slow. Factory fps readings are 2690 fps on the box and my 10 shot group avg 2515-2550. I also recently bought a hornady coal gage and my maximum length was measured at 2.945. Is it time to find a new barrel or is this something other tikka shooters have seen before? I know the factory barrels are slow and the oal can also be a little long in tikkas but it seems a lot more for me than what I have read recently.

New barrel/rifle gets cleaned, lubed and inspected thoroughly when unboxed.

Shoot one round. Run a wet patch of Butch's Bore Shine, let it sit 10 minutes, run another wet patch (look for green/blue). Follow immediately with dry patches until there is no residue. Follow with a wet patch of Naptha (Zippo lighter fluid was once regularly available) to be sure you got all that BBS out and then more dry patches until not much/nothing is showing on a patch.

If there was copper found (green/blue), you have a not very smooth bore that you need to polish with bullets. Shoot, clean, shoot, clean. Or you might try some of those abrasive bullets but I would not recommend that. A friend even uses 1500 grit compound on a patched jag, but I'd rather wear out my barrels by shooting them.

If there was no copper found, move right to shooting 10 rounds. Repeat the above process until you are no longer seeing copper after 100 rounds.

If you have a custom barrel, usually you won't find much copper at all and are good for a day of shooting. I ALWAYS clean after my day is done...old habits die hard. I leave the barrel and bare metal parts coated with WD40 Long Term Corrosion stuff and make sure my desiccant bags are dry and the dehumidifier is working. Run an oil or Naptha patch then a dry patch before I go out again. I only have one rifle that has a severe cold bore first round deviation.

No brushes, ever, unless badly fouled and even then, the brush is wrapped with a patch. Otis stuff in the field (home, too on my Garand and M1A1) and coated rods with guides at home, breech to muzzle always.

Shoot one round. Run a wet patch of Butch's Bore Shine, let it sit 10 minutes, run another wet patch (look for green/blue). Follow immediately with dry patches until there is no residue. Follow with a wet patch of Naptha (Zippo lighter fluid was once regularly available) to be sure you got all that BBS out and then more dry patches until not much/nothing is showing on a patch.

If there was copper found (green/blue), you have a not very smooth bore that you need to polish with bullets. Shoot, clean, shoot, clean. Or you might try some of those abrasive bullets but I would not recommend that. A friend even uses 1500 grit compound on a patched jag, but I'd rather wear out my barrels by shooting them.

If there was no copper found, move right to shooting 10 rounds. Repeat the above process until you are no longer seeing copper after 100 rounds.

If you have a custom barrel, usually you won't find much copper at all and are good for a day of shooting. I ALWAYS clean after my day is done...old habits die hard. I leave the barrel and bare metal parts coated with WD40 Long Term Corrosion stuff and make sure my desiccant bags are dry and the dehumidifier is working. Run an oil or Naptha patch then a dry patch before I go out again. I only have one rifle that has a severe cold bore first round deviation.

No brushes, ever, unless badly fouled and even then, the brush is wrapped with a patch. Otis stuff in the field (home, too on my Garand and M1A1) and coated rods with guides at home, breech to muzzle always.

Please explain a little more.Rule of thumb is your seating depth should not be less the one caliber. So, rather than COAL look at seating depth in the neck. 6.5 is a .264.

I measure with a hornady OAL guage to see when the bullet first contacts the lands which gives me a maximum COAL of 2.945. Your saying I should seat the bullet 2.945-.264?? I must not be understanding correctly because that seems a little crazy when factory ammo is loaded to 2.800

if your still shooting really good groups why change your 2k seems arbitrary to say its dead , unless you really can't get groups we have 4500 through ours and , yea its showing signs of wear but have not had problems with group size or hitting targets either at 600 or at 1k I may have problems just not the gun at least not yet .like you said maybe its because you have a factory barrel we are also using factory 140 gr ammo . I don't know unless you just burnt it up but again I don't know . what ever you decide to do good luck and may your gun last you for many years to come .

I measure with a hornady OAL guage to see when the bullet first contacts the lands which gives me a maximum COAL of 2.945. Your saying I should seat the bullet 2.945-.264?? I must not be understanding correctly because that seems a little crazy when factory ammo is loaded to 2.800

Right.

You are looking for minus thousandths of an inch from the lands. I start load development just kissing the lands and back away, looking for a sweet spot with a tight group...some bullets like to jump, others not so much. I load powder in increasing increments, looking for a sweet spot of a tight group or signs of pressure. It can take a couple hundred rounds to find that sweet combination of powder charge and seating depth for one particular rifle.

There are several methods of determining these sweet spots.

Right.

You are looking for minus thousandths of an inch from the lands. I start load development just kissing the lands and back away, looking for a sweet spot with a tight group...some bullets like to jump, others not so much. I load powder in increasing increments, looking for a sweet spot of a tight group or signs of pressure. It can take a couple hundred rounds to find that sweet combination of powder charge and seating depth for one particular rifle.

There are several methods of determining these sweet spots.

That is how I understand it also but from the previous post it sounded like he was saying to have a jump of .264 which sounds like way too big of a jump to me.

Im sort of in the same boat with deciding on changing my barrel though I only shoot reloads and track my velocity.

6br with 3500 rnds has been losing velocity quicker and fouling more since about 3000 rnds and Ive been chasing the lands and adjusting my charge weight to keep in my velocity/accuracy node , barrel is cleaned every 200 rnds and checked with a borescope.

now Im no pro but I feel its time to come off while others say keep shooting it , so in the end only you can decide , me Im going down stairs and stripping my rifle down and swapping out my barrel, Im content with my round count and the accuracy Ive gotten out of my Bartlien time to spin on another Bughole Bartlien prefit

6br with 3500 rnds has been losing velocity quicker and fouling more since about 3000 rnds and Ive been chasing the lands and adjusting my charge weight to keep in my velocity/accuracy node , barrel is cleaned every 200 rnds and checked with a borescope.

now Im no pro but I feel its time to come off while others say keep shooting it , so in the end only you can decide , me Im going down stairs and stripping my rifle down and swapping out my barrel, Im content with my round count and the accuracy Ive gotten out of my Bartlien time to spin on another Bughole Bartlien prefit

Tikka barrels do run slower than others.

Yet whatever pagan majik the Finns use, it seems to work.

I field clean my rifle after each session, do a big scrub as required.

But that's just habit.

I tried 140gr and above, consistent mediocrity.

Now I run 95gr Vmax for close ferals,

and 129gr SST for longer ranges, and steel.

Seems to really hum along, and good groups with lighter pills.

You should get more than 2000 rounds out of it, depending on hot loads and maintenance.

Yet whatever pagan majik the Finns use, it seems to work.

I field clean my rifle after each session, do a big scrub as required.

But that's just habit.

I tried 140gr and above, consistent mediocrity.

Now I run 95gr Vmax for close ferals,

and 129gr SST for longer ranges, and steel.

Seems to really hum along, and good groups with lighter pills.

You should get more than 2000 rounds out of it, depending on hot loads and maintenance.

D

Deleted member 10043

Guest

Please explain a little more.

I measure with a hornady OAL guage to see when the bullet first contacts the lands which gives me a maximum COAL of 2.945. Your saying I should seat the bullet 2.945-.264?? I must not be understanding correctly because that seems a little crazy when factory ammo is loaded to 2.800

You were asking if 2.9 was too long for COAL. At 2.9 what is the seating depth of the bullet in the case? Is it +/- .264"? Same for 2.945. Plus, if you are using the Hornady guages than the correct term is CBTO and not COAL, though it doesn't really matter in the context of your question. Like I mentioned the "rule of thumb" is seating depth should not be less than one caliber. So, at 2.9 if the seating depth is not less than .264" than COAL is not too long.

D

Deleted member 10043

Guest

We're making this more complicated than it has to be. Change the barrel when accuracy degrades to + 1 moa for general shooting. For serious competition it will be less and you won't be having to ask this question because you already know the answer. Same thing goes for max overall COAL. And we haven't even discussed being limited to mag length if that is a factor.

Similar threads

- Replies

- 34

- Views

- 1K

- Replies

- 119

- Views

- 4K