Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ultrasonic cleaners

- Thread starter BurtG

- Start date

Some folks use a mixture of "Simple Green" & dish soap. Infante sells a solution for ultrasonic cleaning. Most steel & plastic parts are fine, be careful with "anodized" parts, always test them & limit there time in the tank to 10-15 minutes or less. Heat works well, something below "boiling" so 140-170, you will need to experiment with what works for you. Don't leave the parts in too long, 30 minutes is a good average, I use a small scrub or toothbrush on these parts, like the frame & slide. Heavier carboned parts like AR BCG, bolts, will require more time & more creative cleaning tools etc. Good luck & your cleaning life just got alot easier. Cheers

No odor, they are a bit noisy though, so the garage is a good place. I clean the tank , once the carbon build up is sufficient.Do they put off odor etc ? So they should be in garage or not

I'm a bit early along with my ultrasonic cleaner experience (see "recomendations" thread here). I bought mine for suppressor cleaning. Experience so far:

- A friend gave me a jug of Hornady One Shot Sonic Clean Solution Gun Parts Formula. It is toxic - contains dipropylene glycol n-propyl ether, with jug warnings to avoid breathing vapor and skin irritation may occur with contact. A quick google search showed that such cleaning products, after use, shoulf be disposed of as toxic waste.

Did it clean my suppressor, which had maybe 300ish rounds through it? Meh. I ran the can through three 30-minute cycles. Some of the carbon came out for sure, but certainly not shiny clean.

I really prefer not to use this stuff because I've seen what effect of pouring this sort of thing on the ground can have. I have a heavy plastic jug in which I store the used solution; it will go to county dump when we make the occasional trip.

- I haven't tried Simple Green yet.

- I definitely learned not to simply lay my suppressor in the basket and run the machine. Everyplace the can contacted the basket has finish worn off. I made a hanger out of stiff wire; I run this through the can and hang the wire on the basket's little handles. No more finish wear.

- The noise is irritating but tolerable... but my Apple Watch 90+ db noise alert goes off withing 30 seconds of turning the machine on in my garage.

- I have a lot of learning to do.

I use Simple Green in mine. It doesn't smell very strong, but it's obnoxiously noisy. I either put it in the garage or on the back porch.Do they put off odor etc ? So they should be in garage or not

I got mine specifically for cleaning my suppressor. It didn't do nearly as well as some have claimed it does for them. Not on heavy carbon, anyway.

It's a good parts cleaner though, and got my girlfriends jewelry looking like new.

I tried simple green and then the purple simple green. I'd just offer a word of caution. Many post that heat is a must and many also reported that simple green purple was the stuff to use; so, that what I got and that's what I did. After the fact, I happened to read the small print on the simple green purple. It turns out that if you heat it over 100 degrees or so, it becomes unstable and is no longer safe for all metals. It also took a good bit of the finish off of my suppressor.

My point is, read the small print before hitting the on button. The ultrasonic cleaner isn't going to make whatever you put into as a solvent into something that it wouldn't do with my time, a brush and elbow grease.

Im still happy that I got it. I hate doing deep cleans on slides and bolt carrier groups. The slides come out pretty much squeaky clean. The bolt carrier groups come out mostly clean, save for the carbon that you still have to scrape.

I'm just gonna bite the bullet and get a gallon of breakthrough. At the rate I shoot, that should last ne a good 6 months.

It's a good parts cleaner though, and got my girlfriends jewelry looking like new.

I tried simple green and then the purple simple green. I'd just offer a word of caution. Many post that heat is a must and many also reported that simple green purple was the stuff to use; so, that what I got and that's what I did. After the fact, I happened to read the small print on the simple green purple. It turns out that if you heat it over 100 degrees or so, it becomes unstable and is no longer safe for all metals. It also took a good bit of the finish off of my suppressor.

My point is, read the small print before hitting the on button. The ultrasonic cleaner isn't going to make whatever you put into as a solvent into something that it wouldn't do with my time, a brush and elbow grease.

Im still happy that I got it. I hate doing deep cleans on slides and bolt carrier groups. The slides come out pretty much squeaky clean. The bolt carrier groups come out mostly clean, save for the carbon that you still have to scrape.

I'm just gonna bite the bullet and get a gallon of breakthrough. At the rate I shoot, that should last ne a good 6 months.

We have a large US Cleaner at work, so I use a glass bread loaf pan to hold the cleaning solution and small parts including AR-10 BCG's.

Then add water to about 1/2" below the rim of the loaf pan.

This makes clean up easy and you're not wasting a large amount of cleaning solution for a few small parts.

Currently, I'm using aluminum safe Simple Green, but have used Purple Power and regular Simple Green as well.

I had the NiBo coating become damaged on an AR-15 BCG with Simple Green and a long cleaning period, but Toolcraft warrantied the BCG - Kudos to them for standing behind their product.

Then add water to about 1/2" below the rim of the loaf pan.

This makes clean up easy and you're not wasting a large amount of cleaning solution for a few small parts.

Currently, I'm using aluminum safe Simple Green, but have used Purple Power and regular Simple Green as well.

I had the NiBo coating become damaged on an AR-15 BCG with Simple Green and a long cleaning period, but Toolcraft warrantied the BCG - Kudos to them for standing behind their product.

At $40 a jug, I’d maybe just use ZEP brand CLR (the CLR branded stuff is more $).I'm just gonna bite the bullet and get a gallon of breakthrough. At the rate I shoot, that should last ne a good 6 months.

I used a whole jug of Breakthrough trying to break open and clean my damn Banish 30 and it didn’t seem to do any better than CLR. In fact, the only thing that finally unstuck it was 50% diesel/ 50% acetone mix.

And beware, Breakthrough isn’t simply DMSO, in which butyl rubber gloves supposedly protect you. The unlisted trade secret chems in Breakthrough attacked the $45 gloves and started breaking them down. Emailed the company and they said that nitrile or neoprene MAY afford protection. MAY.

But nitrile isn’t good against DMSO, which opens your skin barrier and lets whatever is around go straight into your bloodstream…

Kinda went into a deep dive on that one. Maybe I’m wrong, but?

Suppressors - Best way to clean heavily fouled TBAC can ?

Time + temperature + mechanical agitation are a bitch. Things get worse if there's any contamination remaining from machining operations (such as ferrous deposits that act as a site for initial corrosion). On the other hand, chemical passivation via exposure to strong acids post-machining can...

Last edited:

Man, it just looks like there's no short cut. Back when I shot a lot of uspsa open and had to clean comps and stuff on my supers, I used a concoction of 1 gallon of mineral spirits, 1 quart of motor oil and 1 quart of marvel mystery oil. Dump everything in, let it sit for an hour and come back and hit it with a brush. Take it out, shake it off, the mineral spirits would evaporate and leave a film of oil on the parts. I wonder if I can put this concoction into thr ultrasonic cleaner.At $40 a jug, I’d maybe just use ZEP brand CLR (the CLR branded stuff is more $).

I used a whole jug of Breakthrough trying to break open and clean my damn Banish 30 and it didn’t seem to do any better than CLR. In fact, the only thing that finally unstuck it was 50% diesel/ 50% acetone mix.

And beware, Breakthrough isn’t simply DMSO, in which butyl rubber gloves supposedly protect you. The unlisted trade secret chems in Breakthrough attacked the $45 gloves and started breaking them down. Emailed the company and they said that nitrile or neoprene MAY afford protection. MAY.

But nitrile isn’t good against DMSO, which opens your skin barrier and lets whatever is around go straight into your bloodstream…

Kinda went into a deep dive on that one. Maybe I’m wrong, but?

Suppressors - Best way to clean heavily fouled TBAC can ?

Time + temperature + mechanical agitation are a bitch. Things get worse if there's any contamination remaining from machining operations (such as ferrous deposits that act as a site for initial corrosion). On the other hand, chemical passivation via exposure to strong acids post-machining can...www.snipershide.com

I was gonna give clr a try, but I saw a couple of videos where clr etched stainless after just an hour of soaking. After extensive soaking, a ridge developed between the portion of the cylinder that was submerged and the part that wasn't. Like the clr was eating the stainless.

Maybe I'll try using diesel instead of mineral spirits. The mystery oil should help. If you're unfamiliar, it's a top cylinder oil that is supposed to get rid of carbon buildup in engines.

Yeah, I’ve read the same. But I discovered CLR concoctions (CLR brand, ZEP brand) have different formulations. I made a post on SH somewhere on that. Not sure how that factors in.I was gonna give clr a try, but I saw a couple of videos where clr etched stainless after just an hour of soaking. After extensive soaking, a ridge developed between the portion of the cylinder that was submerged and the part that wasn't. Like the clr was eating the stainless.

Regardless, I don’t soak the SS threads, and as you prob know, CLR is harmless on titanium.

You can buy pure DMSO off of Amazon for about $15, and I guess DMSO eats carbon. Not sure how that compares to the secret formula of Breakthrough. I might try that at some point.

But my real plan is to buy cans from manufacturers that’ll clean them free once a year. Lol

What worked for me on the suppressors, trial and error.

Small Hornady US cleaner, tall glass jar, water in tank, water in jar to nearly cover suppressor, rubber plug in suppressor end cap and suppressor filled with CLR.

Remove the mount/adapter, etc.

I ran 3 cycles of about 20 minutes, water hose rinse with cold water in between. The trial and error, first run on the Sandman S with jar filled with CLR resulted in softening the finish a tad on the second cycle. Some minor smudge marks but nothing more than normal wear and tear scratches. I think the third cycle would've removed the cerakote. One option is to do the same above in regards to the plug and simply soak overnight, insuring the plug doesn't leak. The plug does give about 3/8" offset fro the jar bottom, you could add a spacer in case the CLR leaked so it would not contact the suppressor. Of course with the soak, no water in the jar.

Small Hornady US cleaner, tall glass jar, water in tank, water in jar to nearly cover suppressor, rubber plug in suppressor end cap and suppressor filled with CLR.

Remove the mount/adapter, etc.

I ran 3 cycles of about 20 minutes, water hose rinse with cold water in between. The trial and error, first run on the Sandman S with jar filled with CLR resulted in softening the finish a tad on the second cycle. Some minor smudge marks but nothing more than normal wear and tear scratches. I think the third cycle would've removed the cerakote. One option is to do the same above in regards to the plug and simply soak overnight, insuring the plug doesn't leak. The plug does give about 3/8" offset fro the jar bottom, you could add a spacer in case the CLR leaked so it would not contact the suppressor. Of course with the soak, no water in the jar.

I would suggest that you do some research on the effects of a long term soak using CLR. The downside to using it on the inside of the can only is that damage cannot be observed.What worked for me on the suppressors, trial and error.

Small Hornady US cleaner, tall glass jar, water in tank, water in jar to nearly cover suppressor, rubber plug in suppressor end cap and suppressor filled with CLR.

Remove the mount/adapter, etc.

I ran 3 cycles of about 20 minutes, water hose rinse with cold water in between. The trial and error, first run on the Sandman S with jar filled with CLR resulted in softening the finish a tad on the second cycle. Some minor smudge marks but nothing more than normal wear and tear scratches. I think the third cycle would've removed the cerakote. One option is to do the same above in regards to the plug and simply soak overnight, insuring the plug doesn't leak. The plug does give about 3/8" offset fro the jar bottom, you could add a spacer in case the CLR leaked so it would not contact the suppressor. Of course with the soak, no water in the jar.

What’s it do to Ti?I would suggest that you do some research on the effects of a long term soak using CLR. The downside to using it on the inside of the can only is that damage cannot be observed.

What materials?I would suggest that you do some research on the effects of a long term soak using CLR. The downside to using it on the inside of the can only is that damage cannot be observed.

I have no idea. I was only looking for info on stainless.What’s it do to Ti?

Stainless barrel material.What materials?

This is a Snipershide we all run 100% Ti cansI have no idea. I was only looking for info on stainless.

Stainless barrel material.

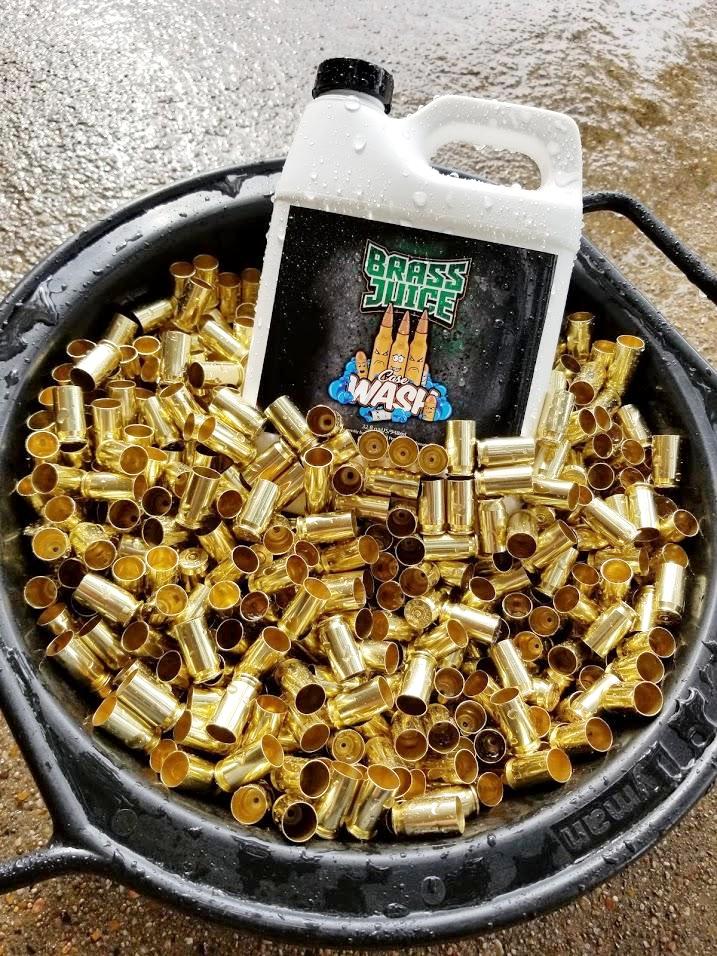

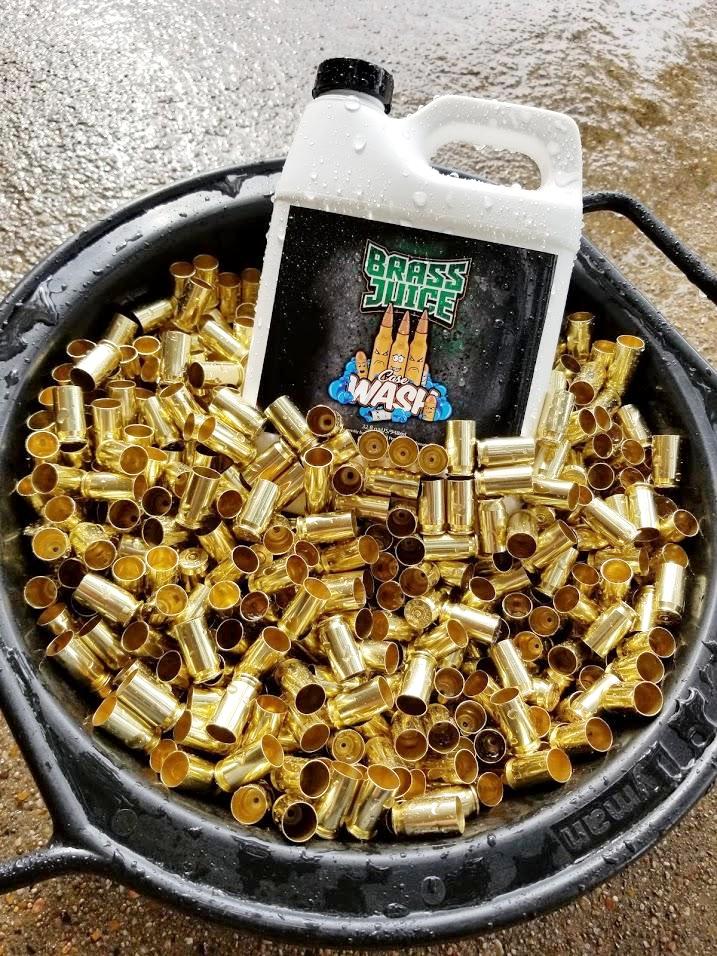

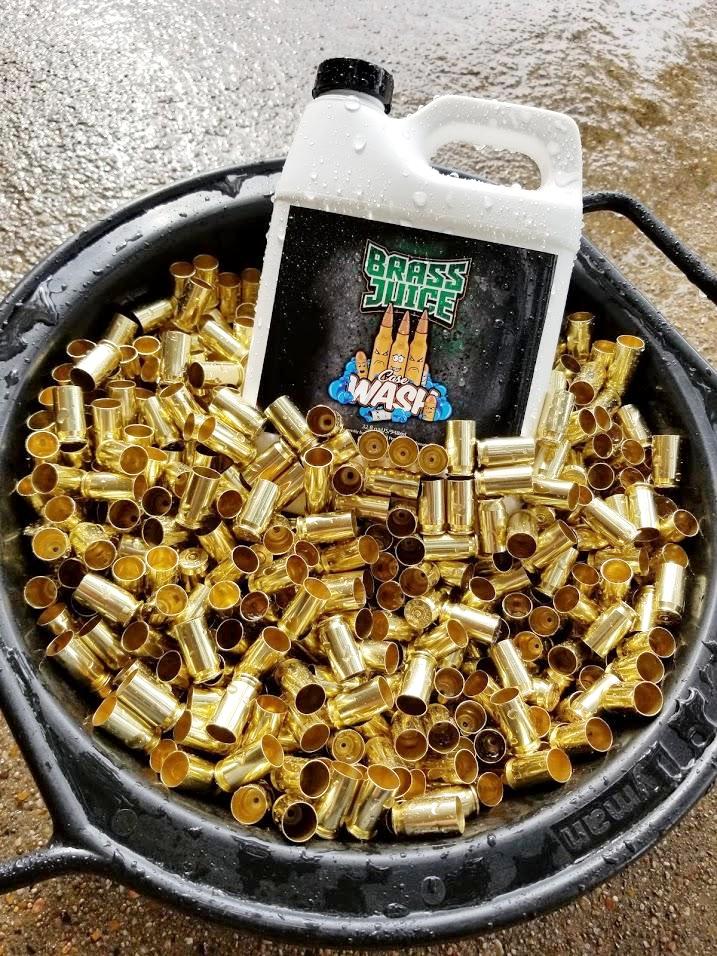

I use brass juice, doesn't take much and I get a couple washings before I replace it.

www.thereloadingstation.com

www.thereloadingstation.com

BRASS JUICE CASE WASH

No Stainless Steel Media Required Designed for use with sonic cleaner and rotary tumblers Removes fouling, tarnish and oxidation from brass cases Cleans cases inside and out including primer pockets Made in the USA Brass Juice Case Wash is formulated to remove carbon buildup, tarnish and...

www.thereloadingstation.com

www.thereloadingstation.com

I clean my brass with an ultrasonic. I've used simple green, dish soap, lemishhine and car wash soap and they all work fine. I've been sticking with an Armorall car wash soap recently because it's easy to rinse off and cheap. Simple green is difficult to rinse off and when I dry the cases I've gotten purple, green and blue colored brass from the dried residue which doesn't hurt anything but just looks odd.

I've tried cleaning suppressors with a CLR soak and time in the ultrasonic but found it slow and moderately effective. For suppressors I've been CLR soaking then power washing.

I've tried cleaning suppressors with a CLR soak and time in the ultrasonic but found it slow and moderately effective. For suppressors I've been CLR soaking then power washing.

Bore Tech US cleaners work well, but they are relatively expensive compared to household cleaners.

I was looking at that Vevor one also. Have you had a chance to use it yet? I definitely could have used this when I cleaned some fuel injectors last week

It works well. There's a few of us here that own it as well.I was looking at that Vevor one also. Have you had a chance to use it yet? I definitely could have used this when I cleaned some fuel injectors last week

I use brass juice, doesn't take much and I get a couple washings before I replace it.

BRASS JUICE CASE WASH

No Stainless Steel Media Required Designed for use with sonic cleaner and rotary tumblers Removes fouling, tarnish and oxidation from brass cases Cleans cases inside and out including primer pockets Made in the USA Brass Juice Case Wash is formulated to remove carbon buildup, tarnish and...www.thereloadingstation.com

Are they still in Business? I ordered some a couple years ago. Took my money and never sent a thing. Reached out via every form of contact and never got a reply. Ended up doing a chargeback. Saw god reviews but it was an odd experience.

I picked up a 5 gallon jug of the Purple Power concentrate from Walmart ($24) for the ultra sonic cleaner. I ran a 5/1 water/PP solution mix and it did awesome job on some .308 brass.

I ordered so much in 2020, and haven't needed any in a while. That sucks if they shut down (and took your money)Are they still in Business? I ordered some a couple years ago. Took my money and never sent a thing. Reached out via every form of contact and never got a reply. Ended up doing a chargeback. Saw god reviews but it was an odd experience.

Similar threads

- Replies

- 1

- Views

- 324

- Replies

- 27

- Views

- 2K

- Replies

- 0

- Views

- 394

Reloading Equipment

Ultrasonic Cleaner SOLD

- Replies

- 4

- Views

- 553

- Replies

- 123

- Views

- 4K