I was having similar problems last winter.Ask him what he'd charge to do another. I'm struggling with my 120 being very fussy where I put my 419 cup. After about 60 throws it starts to have issues.

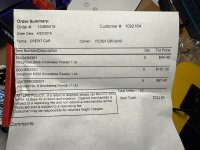

This set up started out as a V2 AutoTrickler, as evidenced by the Stop/Start labels that I put on the scale cover back in 2019. This was before the V3 Bluetooth upgrade that came later.

Anyhow, to make a long story even longer, last fall my scale started acting weird once in awhile, usually in the middle of a long session that involved more than fifty charges being thrown.

It would begin to refuse to go back to zero between throws occasionally. Not plus or minus .02, but sometimes as much as .04 or .06 off of zero.

I’d stop the target weight, make sure there wasn’t powder where it shouldn’t be, fiddle around with the cup, re zero the scale and calibrate it.

Things would return to normal until the next hiccup. Eventually it began to happen more frequently.

I emailed Adam and went back and forth with him and Laura and we decided my power transformer was going bad, as evidenced by the craziness mid session and subsequent return to normal after screwing around with it for 10 minutes or so, allowing the transformer to cool off.

While I waited for the new transformer to get here from Canada, Laura suggested I try the transformer that originally came with the scale and it worked.

They also said they’d recently changed vendors for the transformers.

The original AFX transformer worked well enough until I got my official new vendor transformer from Canada.

You might want to try a transformer.

You’ll get it faster from C&E.

Last edited: