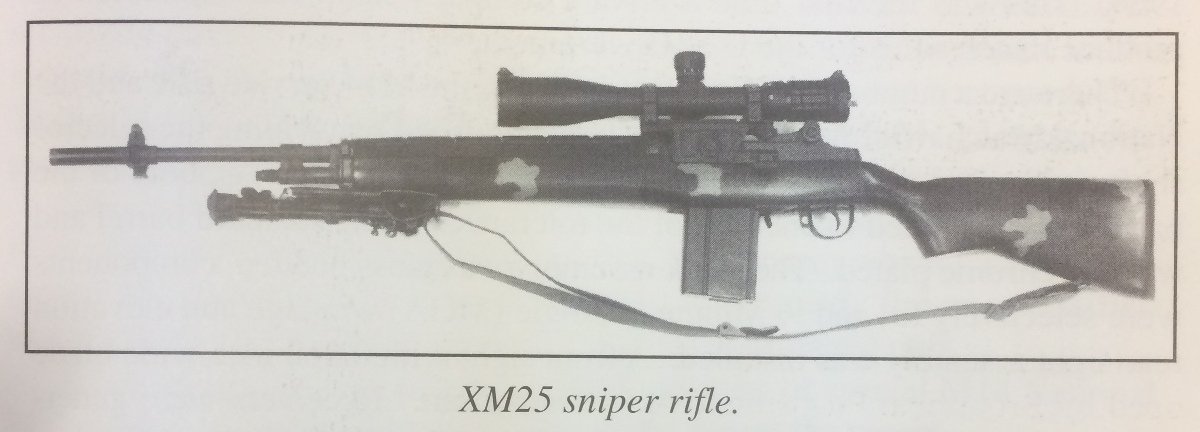

My replica of a U.S. Army XM25 sniper rifle project that began in the summer of 2017 is now basically complete. I just got it back from the builder, so I don’t have a range report yet, but here are some pictures and info for those interested in this type of retro-project.

BRIEF HISTORY: From 1986 to 1988 the U.S. Army 10th Special Forces Group at Ft. Devens, MA developed a ‘Product Improved’ sniper rifle that was internally designated as an XM25 (1988) and subsequently as the M25 (1991) for SF-specific M14 sniper rifles. National Stock Numbers (NSNs) were not developed for these rifles or the special parts used, as they were more or less an unofficial sniper system originally built at Ft. Devens, and possibly other units (5th SFG?). Here's a vintage picture where you can see the unique Pachmyer buttpad that was used on these rifles instead of the standard M14 steel buttplate. (The scope shown is the old B&L 10X Tactical scope from the late 1980s-1990s era).

The XM25 rifles were unique in that they employed a steel stock liner made by Brookfield Precision Tool (BPT) that was permanently epoxy-bedded inside a black or forest camo McMillan M1A (and later an M3A) fiberglass stock that ensured a solid steel-to-steel mating surface between the receiver and XM25 stock liner. Unlike the traditional M21 rifle, the XM25 stock liner permanently secured with Bisonite or MarineTex epoxy, effectively prevented ‘bedding break down’, and also allowed the operator to repeatedly remove the action from the stock for cleaning and maintenance without any degradation of accuracy over time. The McMillan M1A stock specified for the XM-25 rifle by its co-developer, SOTIC instructor Sfc. Thomas Kapp (RIP) was unique in that it utilized a Pachmayr rubber buttpad, instead of the traditional M14 buttplate.

Only 250 BPT stock liners were manufactured, and one source states that only 200 XM25 rifles were likely assembled by US Army Special Force units. They were reportedly first used in Panama in December 1989 and apparently some were still in use during the early parts of the Afghanistan war circa 2002 or so. Not much official history exists, as they were not a 'Program of Record' and were built at the unit level. Thus I am always interested in seeing any pictures of these rifles when they were in service, or any anecdotals from those familiar with these rifles.

Anyhow, here’s my latest project.

Here's the BPT stock liner, which was a unicorm part until the BPT owner came out of retirement and made a few dozen in 2017 for the collector community.

Here's a picture of the BPT stock liner before it was bedded into this stock:

I’m glad it is finally complete. I'll take it to range in a few weeks.

BRIEF HISTORY: From 1986 to 1988 the U.S. Army 10th Special Forces Group at Ft. Devens, MA developed a ‘Product Improved’ sniper rifle that was internally designated as an XM25 (1988) and subsequently as the M25 (1991) for SF-specific M14 sniper rifles. National Stock Numbers (NSNs) were not developed for these rifles or the special parts used, as they were more or less an unofficial sniper system originally built at Ft. Devens, and possibly other units (5th SFG?). Here's a vintage picture where you can see the unique Pachmyer buttpad that was used on these rifles instead of the standard M14 steel buttplate. (The scope shown is the old B&L 10X Tactical scope from the late 1980s-1990s era).

The XM25 rifles were unique in that they employed a steel stock liner made by Brookfield Precision Tool (BPT) that was permanently epoxy-bedded inside a black or forest camo McMillan M1A (and later an M3A) fiberglass stock that ensured a solid steel-to-steel mating surface between the receiver and XM25 stock liner. Unlike the traditional M21 rifle, the XM25 stock liner permanently secured with Bisonite or MarineTex epoxy, effectively prevented ‘bedding break down’, and also allowed the operator to repeatedly remove the action from the stock for cleaning and maintenance without any degradation of accuracy over time. The McMillan M1A stock specified for the XM-25 rifle by its co-developer, SOTIC instructor Sfc. Thomas Kapp (RIP) was unique in that it utilized a Pachmayr rubber buttpad, instead of the traditional M14 buttplate.

Only 250 BPT stock liners were manufactured, and one source states that only 200 XM25 rifles were likely assembled by US Army Special Force units. They were reportedly first used in Panama in December 1989 and apparently some were still in use during the early parts of the Afghanistan war circa 2002 or so. Not much official history exists, as they were not a 'Program of Record' and were built at the unit level. Thus I am always interested in seeing any pictures of these rifles when they were in service, or any anecdotals from those familiar with these rifles.

Anyhow, here’s my latest project.

Here's the BPT stock liner, which was a unicorm part until the BPT owner came out of retirement and made a few dozen in 2017 for the collector community.

Here's a picture of the BPT stock liner before it was bedded into this stock:

I’m glad it is finally complete. I'll take it to range in a few weeks.

Last edited: