TriggerTech Diamond trigger in it’s shiny package

TriggerTech triggers were one of the many products that I encountered by way of the Mesa Precision Arms Crux rifle review. I vaguely recalled having met the TriggerTech guys a few years before that at SHOT show but the pull weights of the models they had at that time were a bit heavier than I used, I was mostly focused on what optics maker I needed to see next, and the only thing that stuck in my head was the oddity of the rolling sear engagement. Since a TriggerTech primary trigger was included with the Crux rifle, I now needed to look more thoroughly into its technology, understand how it worked, test it, and form an educated opinion. Eventually this would lead to testing the Primary (1.5-4lbs) and Diamond (4-32oz) models as well as TriggerTech sending me their acrylic sided product demonstration trigger. This transparent sided trigger was particularly useful in understanding how their distinct technologies function.

Unique Design Elements

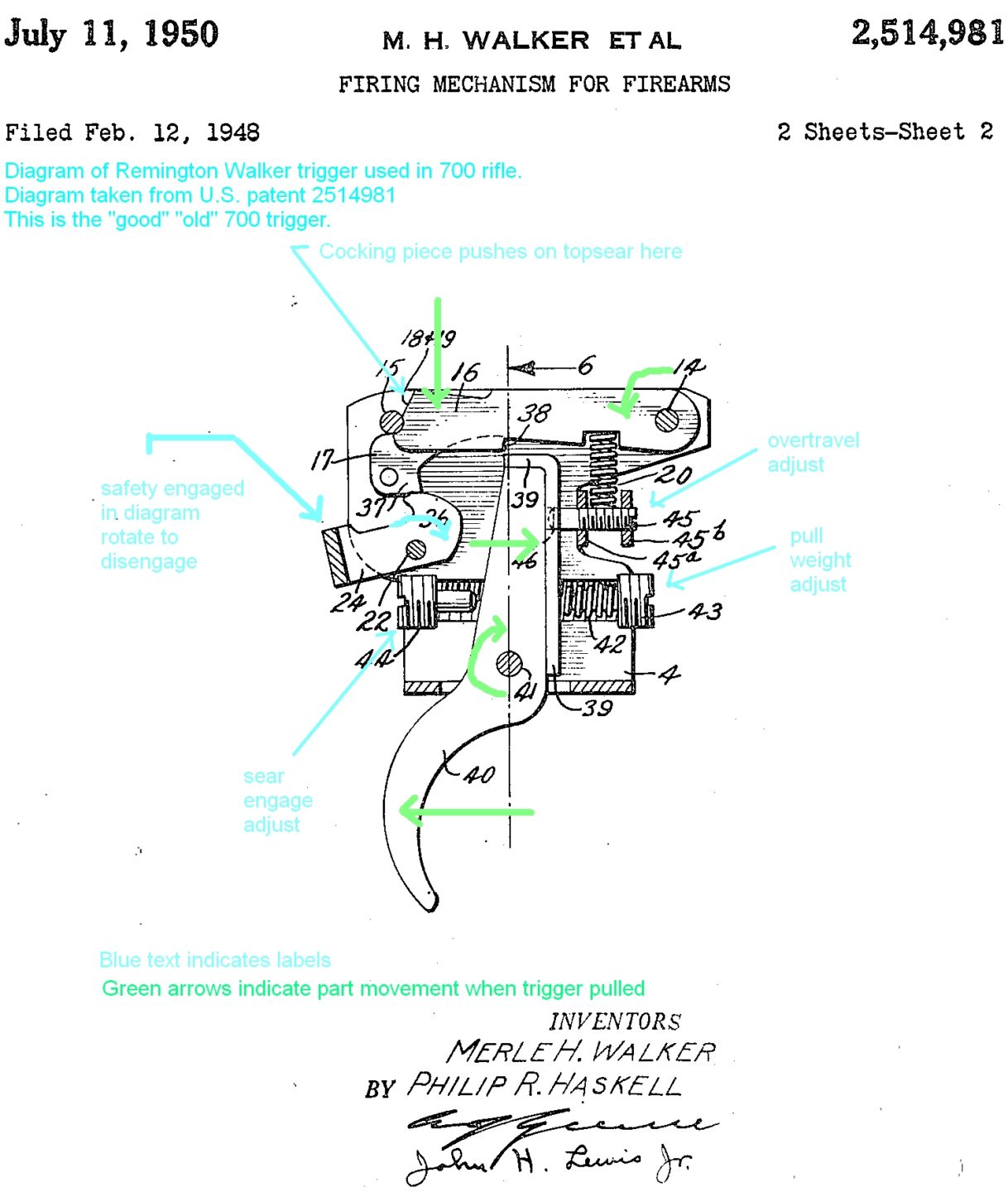

TriggerTech triggers feature FRT, TKR, and CLKR technologies. Acronyms, gross. The CLKR just means that they have put clicks in the pull weight adjustment screw. TriggerTech felt they needed to name, and acronym, clicks in the pull weight screw. Though it’s nice, I’m just not sure it is important enough for both a name and acronym. I mean, just saying you have a click pull weight adjust screw pretty much gets the point across. Despite the seeming profligacy with titles, the TriggerTech guys did not name the double redundant safety cam system they came up with and that certainly seemed to me worth a mention, given the occasional problems trigger safeties have had with immediately firing when the safety is taken off. That tendency has resulted in some unspeakable tragedies as well as some lawsuits for Remington. TriggerTech could have called the system the double redundant safety cam (DRSC) and added to their Acronym Badass Score (ABS). On to the next acronym. TKR refers to TriggerTech’s overtravel stop system. That is how they present it anyway. While it does do that, it is really more integral to the function of the whole system than just an overtravel stop. It also lessens the overall travel necessary for the trigger, a concern when adding a roller to the sear mechanism, and allows for looser tolerances on a few of the parts in the trigger. This is important as differences in real world dimensions from action to action must be accounted for. This brings us to the biggest tech difference, the one that really put TriggerTech on the map: the FRT or Frictionless Release Technology. In simplest terms, FRT is a roller that is interposed between the two sear surfaces to replace the sliding friction with much lower rolling resistance. Doing this basically allows for much greater sear engagement without the feeling of creep that is introduced on a conventional trigger design with greater engagement

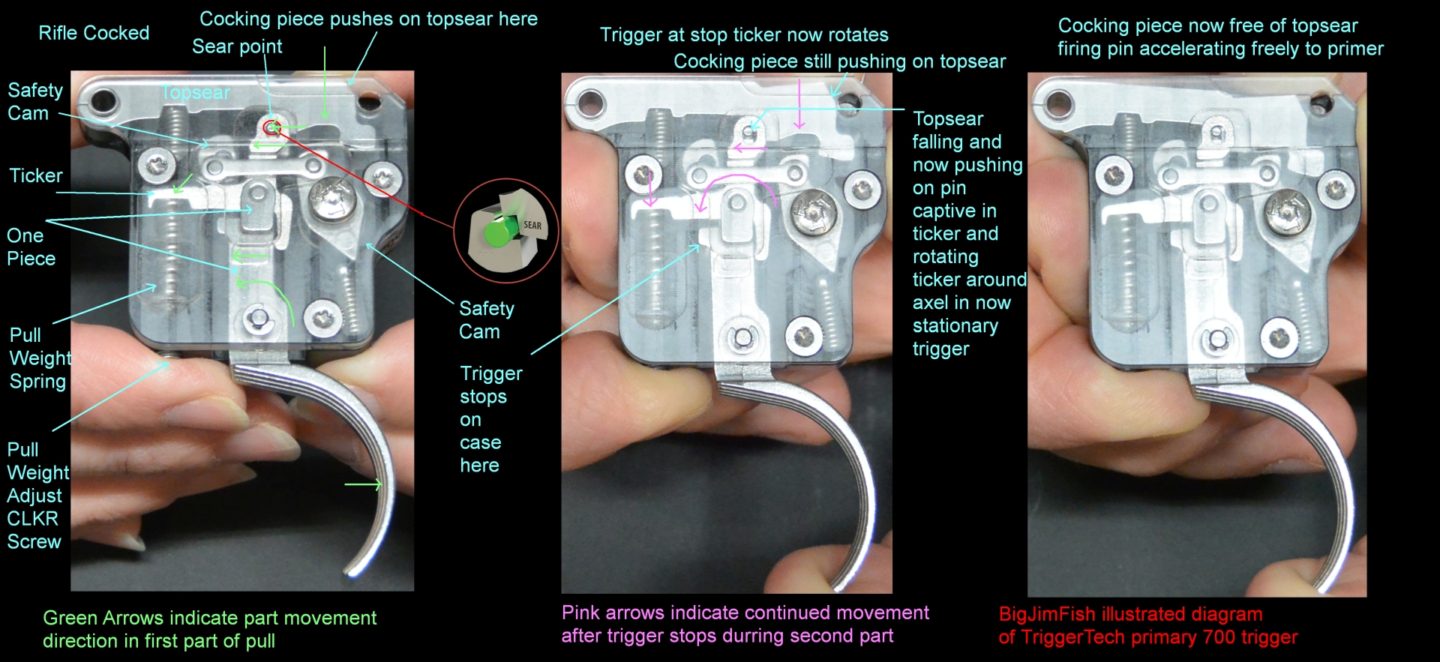

How the Trigger Releases

The combination of the TKR and FRT components of the trigger tech system makes for a little bit of complexity in the release. Basically, the trigger releases in two distinct parts. In the first part, the trigger and ticker move as one. The roller rolls between the stationary topsear and the sear surface on the TKR which is moving forward, with the trigger, underneath the roller. When the roller reaches the edge of the topsear sear surface the topsear starts to fall under force from the cocking piece in the rifle action. Since the roller is between the sear surfaces, the topsear does not simply fall free here: it falls and pushes the roller forward together with the TKR and trigger. At this point, the trigger impinges on the case and stops moving as if is has been stopped by an overtravel adjust screw. However, the ticker continues to move forward, being pushed from behind by the falling topsear’s action on the roller and rotating around the pivot which attaches it to the trigger. This mechanism allows the trigger pull movement to be shorter than it otherwise would have to be to accommodate both a roller in the sear system and a robust sear engagement. It also allows for a lot more slop in the system, such as you might need if it were filthy or to accommodate differences in dimensions from action to action.

My thought on the TriggerTech is that it is a very clever design that has some substantial upsides. The roller and ticker allow for a lot of sear engagement without feeling it in creep. You will not feel any creep in this just as you don’t feel any in an aftermarket trigger tuned to have almost no sear engagement. However, the TriggerTech will be reliable and safe, whereas a conventionally designed trigger set to almost no engagement will not be. With conventional designs, creep is essentially the price you pay for safety and reliability. The roller eliminates that price on the TriggerTech design. A price that would be paid for this is more overall movement of the trigger during firing. By adding the ticker though, the trigger only travels a little more than half of the sear engagement distance, with the ticker traveling the rest of the way with no further trigger movement. Here is where the feel of a TriggerTech differs from others and it took me a while to figure out exactly why. On the heavier, primary model it feels like it has overtravel even though it technically has less than zero overtravel since the sear continues to move after the trigger stops. Furthermore, I do not think the overall travel is probably greater than a typical hunting trigger with substantial sear engagement. This feeling happens because as soon as the trigger starts to move and breaks, the topsear falling actually pushes the trigger backward quicker than your finger. All of this movement is quite minute but the feeling is distinct and is perceived, on the heavier Primary model, as the trigger having overtravel movement after the break. On the lighter Diamond, the same phenomenon happens but, because of the very light pull force necessary, you will more accurately perceive the trigger moving backward, away from your finger, when it breaks. What this really ends up amounting to is that TriggerTech triggers have a distinct, and different, feel from all other triggers at the moment they break. This is not a bad thing. I have played around blindfolding a few folks and having them try the TriggerTech Diamond vs. the Bix’n Andy TacSport set to the same weight and the results have been quite split. I think the driving reason behind this basically comes down to this difference in the feel of the break. Now to talk about the famous dirt tolerance of the TriggerTech. The TKR, being attached to the trigger, rather than the case, allows for less case contact by the internals. TriggerTech also has a couple raised guides on the trigger and case to keep alignment but otherwise leaves a lot of clearance around the parts to prevent dirt from fouling things up. It is really, noticeably, designed to clear dirt even if you ignore the effect the roller has of clearing dirt off of the sear surfaces, an important design aspect of the roller. I have no doubts regarding TriggerTech’s claims that these things are as close to dirt proof as you can get and this is probably the largest driving factor in their takeover of the PRS and NRL series. Not only is dirt tolerance good for safety, but their dual cam safety system is as well. I will never feel great about any trigger safety, but I do feel better about this one than others since it not only holds up the topsear but also keeps the rest of the mechanism engaged when set to safe.

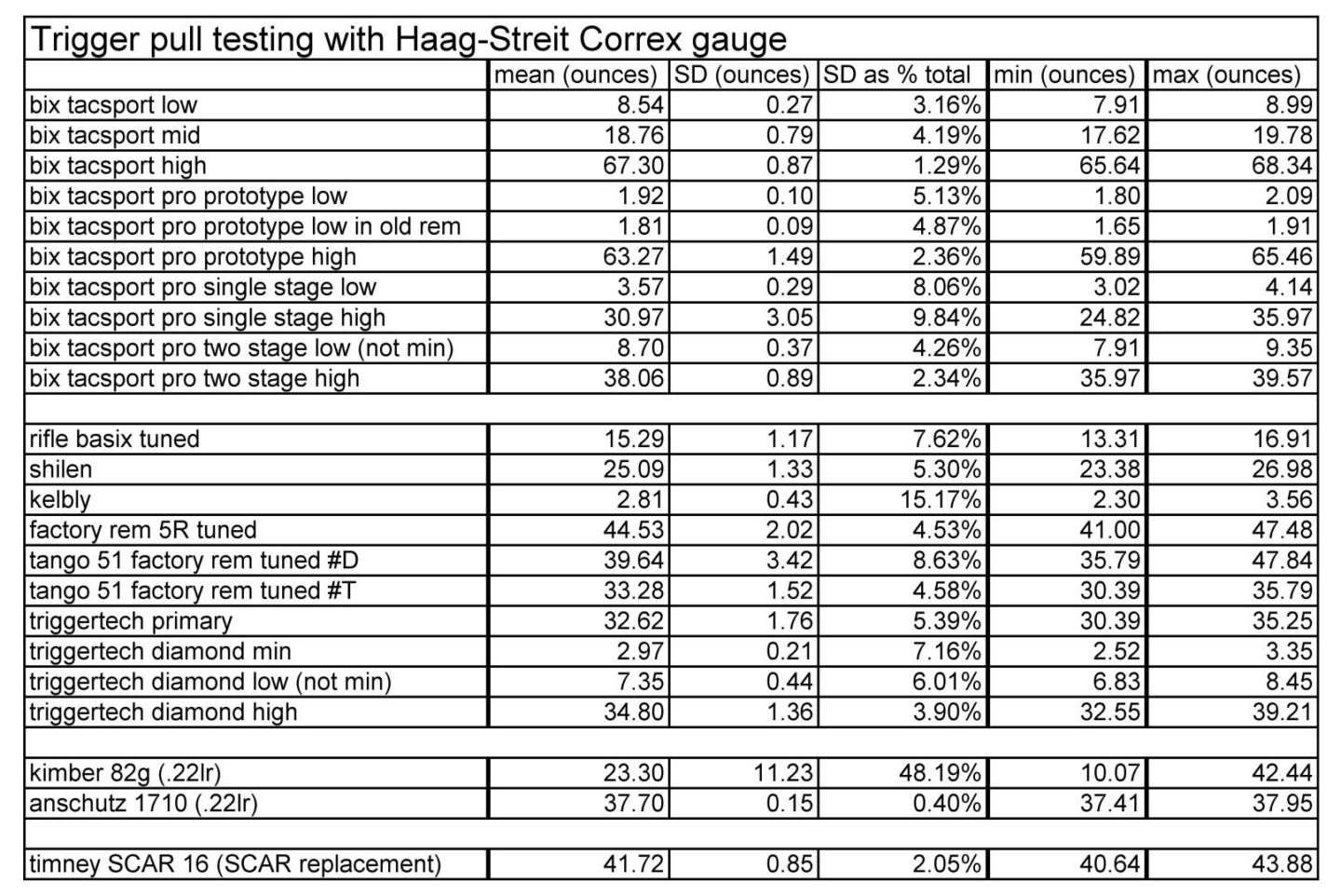

As part of this review and others I did a great deal of pull weight variance testing using some very precise and pricey Correx gauges. I found the pull-to-pull break weight variance on the TriggerTech Primary right in line with conventional technology aftermarket triggers, whereas the Diamond was significantly better than average. Significantly, most of the conventional tech triggers had the advantage of being lubed. This is an advantage in indoor benchtop testing that is decidedly a disadvantage in a dusty field environment.

Trade-offs of the TriggerTech Design

The only potential trade off I have tested in the TriggerTech design is that the topsear reset force is potentially increased, depending on what pull weight you set the trigger to and the specific geometry of your reciever, by the use of the ticker component over potential designs without that innovation. The increase in reset force is because the reset force in the TriggerTech includes both a traditional reset spring and, through the ticker, the much stronger pull weight adjustment spring. Importantly though, this makes the reset force come in stages and the cocking piece will already be moving when it encounters the stronger second stage. Topsear reset force is easy to measure in testing, and both the TriggerTech Primary and Diamond started at about half the topsear reset force of a conventional trigger (Walker units were tested) before the ticker engaged. After the point the ticker engages, the topsear reset force varied from about the same as a conventional trigger at min pull weight to between two and three times the reset force and maximum pull weight. How much this matters, I am unsure of. Firing pin alignment is effected by topsear force and so can be light primer strikes. I have not heard any reports of light primer strikes associated with TriggerTech triggers (whereas some other trigger makers units have a reputation for this), so I don’t think it is a problem to that degree. I am also unsure of the range of force that might actually cause an issue and do not have any triggers that cause light strikes, or any of that other makers triggers known to cause light strikes, to test. On the other end of the testing, all the strikes I have seen on primers of cartridges I have ignited with the TriggerTech were good, solid, strikes though those triggers were both nearer the light than the heavy end of pull weight. So, my thought is that the increased reset force is probably only a thing Benchresters who replace their firing spring regularly because they are worried that old springs get a bit out of concentricity might fret about.

Buyers of the TriggerTech should also be aware that the body of the unit is physically wider than other triggers. The trigger is the same size where it enters the receiver of course but a bit wider below that. This just means that you may need to inlet the trigger area of your stock a little for it to fit without rubbing.

Diamond vs. Primary

TriggerTech 700 pattern triggers vary widely in price between $145 for the Primary and $270 for the Diamond. This is substantially more variance than most trigger makers have between their different models and essentially puts the different TriggerTech models in competition with entirely different competitors. The reason for this comes down to tolerances. Most lightweight triggers (low end of ~2-8oz) have significantly different design than most midweight triggers (low end of ~1-1.5lbs.) With conventionally designed triggers, the differences usually amount to more levers and lighter springs in a lighter weight trigger. With this design approach, the tolerances of the parts don’t have to be a whole lot different on a lighter weight trigger and though the extra lever adds some cost, it is not a whole lot of cost. The TriggerTech Diamond does not add any more levers for mechanical advantage. With its side off, it shows the same layout as the Primary. The spring is obviously lighter, and also 2-stage for greater pull force adjustment range, but the subtle differences in geometry on the major functioning parts are not really noticeable. Because of this, the Diamond has to be exponentially better with regards to tolerances. As such, it has five more machined components than a Primary. Since machining is money, the Diamond ends up landing at a much different price.

The first TriggerTech example I had was a Primary and, at that point, I was not particularly excited about it. It’s not that there was anything particularly bad about it. It certainly broke cleanly with no creep as advertised. It just didn’t feel a whole lot different from the several (admittedly tuned and lubed) Remington Walker factory triggers I have on hand. The TriggerTech’s advantages in functioning when filthy looked interesting, but only academically. Being an Ohioan, large amounts of dust and sand blowing into a trigger and clogging it are not things I spend a lot of time thinking about. On the pull force chart, the Primary also looked a lot like a tuned Remington Walker trigger, both in pull weight and standard deviation, and that is essentially how it felt to me. As such, I just wasn’t excited. This changed when I got the Diamond in to test. The Diamond adjusts quite low. The example I had went down to a Benchrest like 3 oz. At low weights you both feel a lot more and a lot of trigger designs start to have some issues. Many designs start to exhibit pull to pull force variation that is easily observable to the shooter, some can start to feel a little creepy or gritty and some even start to have problems with safety when dropped. The Diamond did not exhibit any of these problems in my testing and, with the Correx gauge on it, produced some more desirable pull to pull weight variation numbers than the Primary had as well. I came away much more impressed. My feeling morphed from “ok, this feels fine like many of these others” with the Primary to “wow, this feels really clean and crisp, not many triggers this light feel this way” with the Diamond. I should note here that the Diamond will adjust all the way up to 2lbs. To my mind, 4oz-2lbs represents a lot greater versatility than the 1.5lbs-4lbs of the Primary. The range of the Diamond has weights I might consider in a Benchrest free recoil set up, a range I commonly use in load development and zeroing, weights I use in competition when my nerves are a little more jittery, all the way up to 2lbs you might use when hunting (I do not carry my rifles with a chambered round when hunting). The Diamond can hit every weight that I personally use and so has complete versatility for my purposes. That is worth a bit of extra cash even if I don’t really have any desire to shoot at 4oz.

Two-Stage Options

I really should have expected to see TriggerTech two stage triggers at SHOT show this year. TriggerTech has been particularly methodical and therefore predictable since they expanded beyond the crossbows they started in to march through the shooting industry. They have basically responded to two things: size of the market and nagging from the competitors and OEMs that use them. Since competitors like two-stage triggers, it is not really surprising that Diamonds and Specials in two-stage was this year’s big announcement at SHOT. As for how the two-stage works, at SHOT I initially thought that the first stage was essentially just tacked on with the addition of a hinge and spring in the trigger piece. After looking back at my pictures, I can see that I was in error and that more significant changes have been made to the mechanism than that. I will get what images I can up as they become available. The examples at SHOT show were not production pieces but rather prototypes, and development is still ongoing with a Q3 release planned.

Conclusion

If you had told me five years ago that the two most popular triggers on PRS series would be ones essentially unheard of at that time and which used designs that were a radical departure in basic function from those used for the 50+ years before that, I would probably not have believed you. In fact, I might even have been willing to lay money against it. Here we are though. The Diamond is the dominant trigger in PRS and NRL and the Special or Primary are found in most custom level production class guns.

I’ll admit not only to not being a very good crystal ball guy, but to also often being wrong when it comes to first impressions. I remember seeing TriggerTech’s stuff when it first came out at SHOT, even examining the core technological innovation, and being neither personally enthused nor expecting a breakout success. I remembered it because I thought it was strange mostly in an ‘answer to a question no one asked’ way. I probably shouldn’t go around picking stocks. I would have shorted Facebook at launch BTW – it just looked like another MySpace but with a worse UI and a jackass at the helm. Good thing I didn’t put money on that.

If nothing else, I do learn. I don’t bet on Facebook (I would still short it if I had to choose) and I get why TriggerTech is having success. Their roller interposed sear mechanism eliminates creep while still allowing substantial sear engagement. TriggerTech cleverly compensates for trade-offs necessary for this and furthermore adds other innovations and improvements such as a secondary safety cam, clicks on the weight adjust, and substantial dirt clearance around key internal components. I have in fact heard that the TriggerTech units now dominating the PRS have never experienced a failure in the series which would be a pretty impressive feat.

My personal experiences with the TriggerTech triggers have been universally good. They have been as crisp as anything else I have tried and although the feel is different than others because of the way the trigger accelerates away from your finger at the break, this difference is more a matter of taste than a plus or minus. I have not been able to effect any malfunctions in my examples regardless of weight setting and I have tried plenty to get them to fail. Also along the lines of safety, I appreciate their dual cam safety system and dirt clearing aspects of the design are appealing. Frankly, it is probably dirt resistance that has most contributed to the success TriggerTech has had. This has given me the perverse desire to dump dirt in my trigger. I’m not sure how you should weigh that in the purchasing decision-making process.