before you do anything drastic, seat a bullet out so that the case headspaces on it. You could be having 2 very small problems both add to make a larger problem. I have deprimed many live primers without incident. Can also pull the bullets partially out then seat them as a jam fit. I probably wouldn't change the primer, just give it a restrike.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6gt

- Thread starter Dthomas3523

- Start date

@CK1.0 with 5k on the action when was the last time you have changed your striker spring?

I just changed it ~300rds ago, it's fresh.

old vs new:

Last edited:

before you do anything drastic, seat a bullet out so that the case headspaces on it. You could be having 2 very small problems both add to make a larger problem. I have deprimed many live primers without incident. Can also pull the bullets partially out then seat them as a jam fit. I probably wouldn't change the primer, just give it a restrike.

Yeah, my plan is to re-load the ones that didn't go off long enough to be jammed

*After further thought, since the problematic brass is 9 thou below the fired brass that went bang, I'll load them 10 thou into the lands to account for that, plus anything wonky between the firing-pin protrusion and my primer depth (paranoia, thanks @Cascade Hemi lol) and as long as the primers aren't duds, I should be good. I'll see lol.

BTW, firing-pin protrusion is a fun thing to try and measure using calipers lol. Mine is somewhere between .007" and .017"? IDK, getting a legit measurement seems beyond the envelope of my skill lol.

Last edited:

Your measurements are spot on. My impact precision proof prefit was exactly the same as yours, as was my alpha brass measurements. I was concerned myself initially. My gunsmith allows for about .005 runout on headspace, where as I'm assuming proof does the max allowable for any slop between actions. So basically I had about .009 runout on my brass after 1st firing. I did not have any ftf though. Cci 450 primersJust an FYI/PSA…

I’ve had 11 FTFs over my first 200rds with some brand new Alpha OCD “Gay Tiger” head-stamped brass purchased through GAP.

Not a huge deal, but it was annoying until I figured it out (with the help of another experienced shooter because at first I didn’t think of it and was starting to think I was going crazy). I've bumped some shoulders back a little too much and learned that lesson before, but never expected to see it with new brass. There's a first time for everything though lol.

Apparently, the virgin brass’ headspace is too short (6 thou below SAAMI minimum which is 1.357"). The shoulder datum on the ones that fired is now 1.360", while the still-virgin ones that didn't go off measure 1.351".

I guess I’ll have to disassemble them and then put them back together long to jam them a little in order to blow them out.

Just something to look out for if you purchased some of this stuff or ever run into this… I'm glad I didn't have to learn this lesson at a match or I'd be pissed lol.

ETA: FWIW, I did some more measuring detective work, and looks like my Origin/Proof SS prefit combo (checked with Go/No-Go gauges) will still light off cases that are ~4 thou below SAAMI minimum (~1.353", which is what most of the new brass measures), but seems the ~2 thou difference between those and the ones that are ~1.351" is enough to make them not go bang.

View attachment 8086510View attachment 8086511View attachment 8086513View attachment 8086512

Your measurements are spot on. My impact precision proof prefit was exactly the same as yours, as was my alpha brass measurements. I was concerned myself initially. My gunsmith allows for about .005 runout on headspace, where as I'm assuming proof does the max allowable for any slop between actions. So basically I had about .009 runout on my brass after 1st firing. I did not have any ftf though. Cci 450 primers

Thanks for confirming that you've seen the same problem.

After doing some more measuring of things, I don't think the issue is with Proof allowing more headspace than is needed though, and I think the cause of the "headspace headache" falls squarely on Alpha.

Post-firing my cases are 1.360", SAAMI spec is 1.357" - 1.364". Proof has their headspace parked right in the middle, 3 thou over the minimum (in my case anyway). I don't think that's so bad.

Good thing brass is malleable.

Thanks500 count brass in stock at Alpha (19 as of writing this)

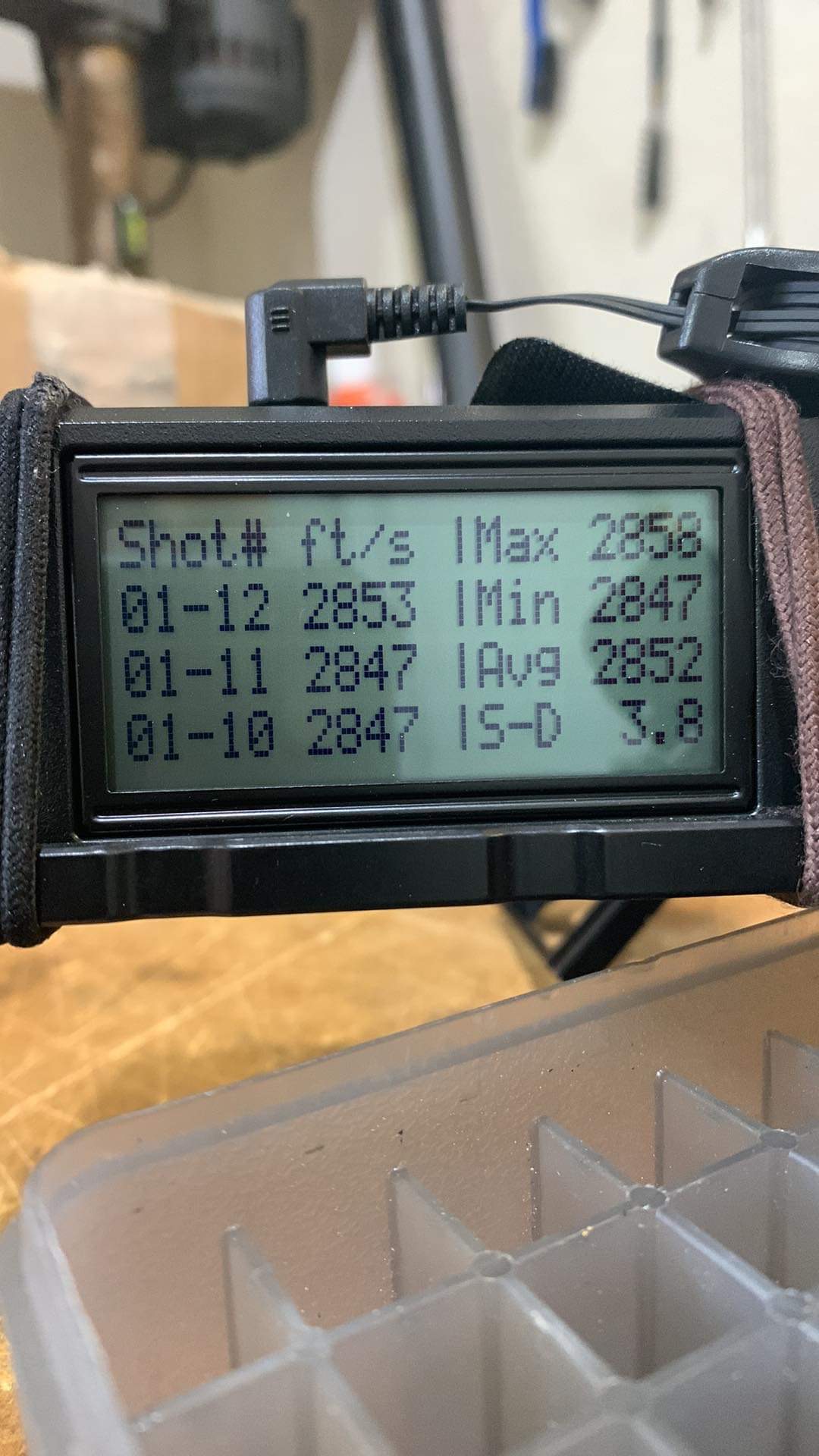

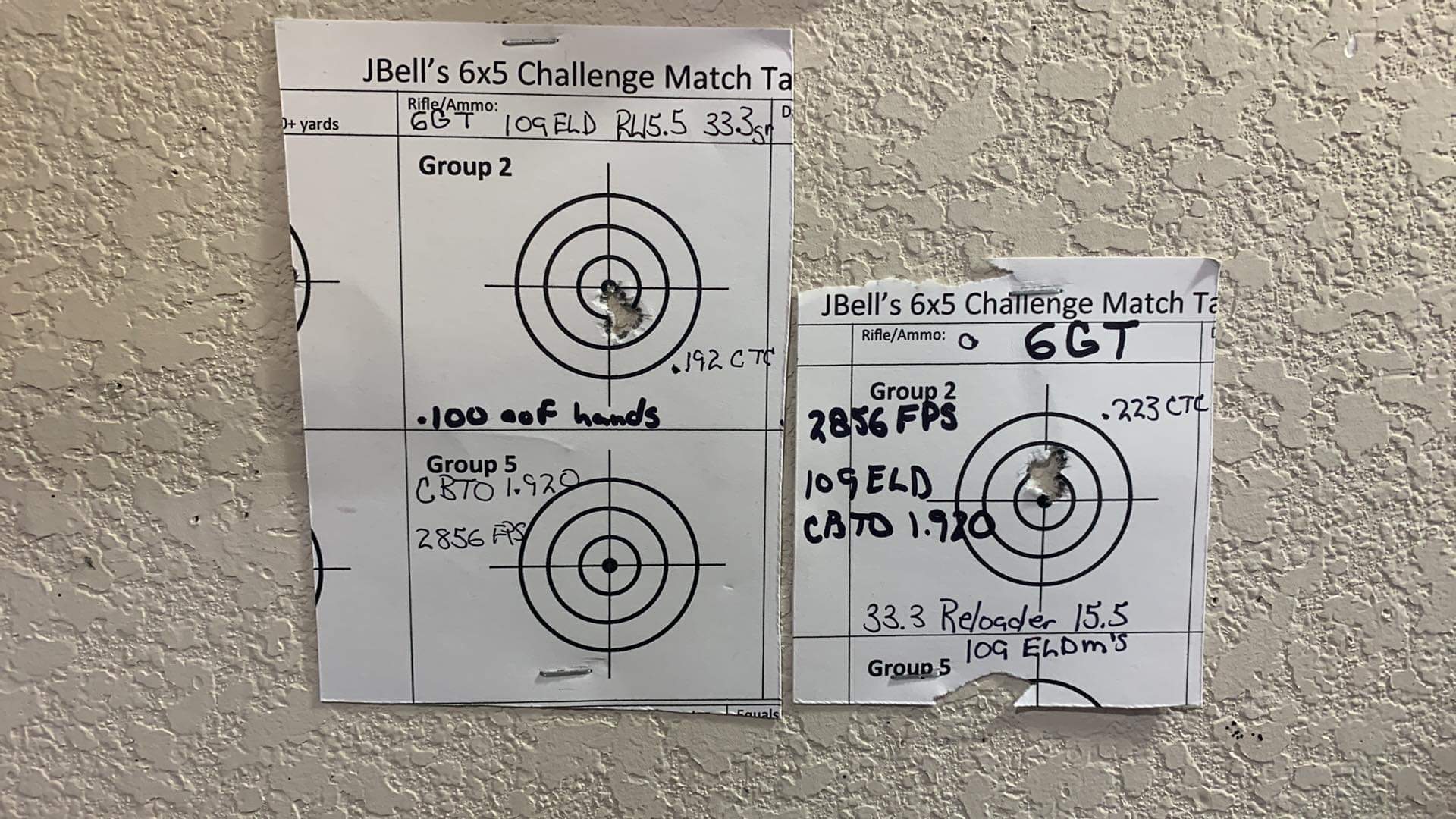

Had a few sticky bolts in a match so I tuned my load down a tad. Bolt throw is lot smoother now with the new load and will see how it is in a match coming up. Two groups from different days to affirm it.

Impact 737

Proof Comp contour 26” 1-7

109 ELDM’s

RL 15.5 33.3grs

CCI 450

Alpha brass

CBTO 1.920

.002 Neck tension

Checking data at 501yds 5 shots

Impact 737

Proof Comp contour 26” 1-7

109 ELDM’s

RL 15.5 33.3grs

CCI 450

Alpha brass

CBTO 1.920

.002 Neck tension

Checking data at 501yds 5 shots

Last edited:

Earlier, when I said the Alpha Gay Tiger brass was giving me a problem due to having short shoulders, ~6 thou under (1.351") SAAMI minimum (1.357"), it was, and still is, but I thought my brass was growing post-firing to 1.360"... I was wrong about that last part.

The brass is still giving me headaches with 16 still unfired out of 300 over 3 different range trips trying to get it fire-formed...

Turns out I was getting a bad measurement due to the primers being puckered outward slightly (another side-effect of the shoulders being too short and resulting loose/bad fit in the chamber).

I figured this out when I discovered that, even with my sizing die touching the shell plate, it still wasn't bumping the shoulder back, duh, probably because the post-fired cases are actually ~1.356" at the shoulder (not 1.360"). As most of you reading this know, usually, most times, touching the shell plate with a FL die results in ~5-6 thou of bump (around SAAMI minimum) and you have to back dies off to get the usual 1.5-2 thou of bump most of us are looking for... well, my shoulders aren't being bumped because they aren't even SAAMI minimum yet.

The good news is, the gun is a f'ing laser and hammers, so at least there's that, but this Alpha brass is giving me a terrible first impression of their product. I'd honestly rather shoot Hornady brass at this point, 6-7 thou below SAAMI minimum isn't due to it being special or Gucci, it's BS, and when I paid more money for fancy brass I thought I was paying for them not letting shit like this get out the door, and make no mistake, this shit shouldn't have made it out into the world.

For the third time, I pulled/disassembled the ones that wouldn't go off and then purposely upped the neck tension by skipping the mandrel step in my process and will be jamming these next ones 20 thou into jam (normal neck tension and 10 thou of jam wasn't enough). I'm also using a different brand/batch of primers just to rule out me having a bad batch of CCI 450s. Hopefully, with these extra measures taken in order to make sure the case is wedged in there enough to allow for a successful primer whack, they will finally go bang.

I'm going to load 100 more rounds at my usual/preferred .100" off to try, because they should go bang like that without me having to lend a helping hand jamming them, but that's it, I don't have enough confidence in this brass to burn any more primers and bullets on it. If I get any more FTF's with this shit or any brass-related shit at all with it on the second load cycle/firing... it goes in the trash can.

Dear Lapua,

Please make 6GT brass so I can buy it.

Thanks.

The brass is still giving me headaches with 16 still unfired out of 300 over 3 different range trips trying to get it fire-formed...

Turns out I was getting a bad measurement due to the primers being puckered outward slightly (another side-effect of the shoulders being too short and resulting loose/bad fit in the chamber).

I figured this out when I discovered that, even with my sizing die touching the shell plate, it still wasn't bumping the shoulder back, duh, probably because the post-fired cases are actually ~1.356" at the shoulder (not 1.360"). As most of you reading this know, usually, most times, touching the shell plate with a FL die results in ~5-6 thou of bump (around SAAMI minimum) and you have to back dies off to get the usual 1.5-2 thou of bump most of us are looking for... well, my shoulders aren't being bumped because they aren't even SAAMI minimum yet.

The good news is, the gun is a f'ing laser and hammers, so at least there's that, but this Alpha brass is giving me a terrible first impression of their product. I'd honestly rather shoot Hornady brass at this point, 6-7 thou below SAAMI minimum isn't due to it being special or Gucci, it's BS, and when I paid more money for fancy brass I thought I was paying for them not letting shit like this get out the door, and make no mistake, this shit shouldn't have made it out into the world.

For the third time, I pulled/disassembled the ones that wouldn't go off and then purposely upped the neck tension by skipping the mandrel step in my process and will be jamming these next ones 20 thou into jam (normal neck tension and 10 thou of jam wasn't enough). I'm also using a different brand/batch of primers just to rule out me having a bad batch of CCI 450s. Hopefully, with these extra measures taken in order to make sure the case is wedged in there enough to allow for a successful primer whack, they will finally go bang.

I'm going to load 100 more rounds at my usual/preferred .100" off to try, because they should go bang like that without me having to lend a helping hand jamming them, but that's it, I don't have enough confidence in this brass to burn any more primers and bullets on it. If I get any more FTF's with this shit or any brass-related shit at all with it on the second load cycle/firing... it goes in the trash can.

Dear Lapua,

Please make 6GT brass so I can buy it.

Thanks.

Turns out I was getting a bad measurement due to the primers being puckered outward slightly (another side-effect of the shoulders being too short and resulting loose/bad fit in the chamber).

Always deprime brass that you’re using for shoulder bump measurements!!! It ensures that you’re really measure the head and not a primer standing slightly proud or something.

Sounds like your smith may have did a crap job on headspace. I have had 4 6gt and a 22gt barrel(s). All have been chambered to go plus 001 and new alpha brass grows 003 from new, I bump it back 002. Easy easy.Earlier, when I said the Alpha Gay Tiger brass was giving me a problem due to having short shoulders, ~6 thou under (1.351") SAAMI minimum (1.357"), it was, and still is, but I thought my brass was growing post-firing to 1.360"... I was wrong about that last part.

The brass is still giving me headaches with 16 still unfired out of 300 over 3 different range trips trying to get it fire-formed...

Turns out I was getting a bad measurement due to the primers being puckered outward slightly (another side-effect of the shoulders being too short and resulting loose/bad fit in the chamber).

I figured this out when I discovered that, even with my sizing die touching the shell plate, it still wasn't bumping the shoulder back, duh, probably because the post-fired cases are actually ~1.356" at the shoulder (not 1.360"). As most of you reading this know, usually, most times, touching the shell plate with a FL die results in ~5-6 thou of bump (around SAAMI minimum) and you have to back dies off to get the usual 1.5-2 thou of bump most of us are looking for... well, my shoulders aren't being bumped because they aren't even SAAMI minimum yet.

The good news is, the gun is a f'ing laser and hammers, so at least there's that, but this Alpha brass is giving me a terrible first impression of their product. I'd honestly rather shoot Hornady brass at this point, 6-7 thou below SAAMI minimum isn't due to it being special or Gucci, it's BS, and when I paid more money for fancy brass I thought I was paying for them not letting shit like this get out the door, and make no mistake, this shit shouldn't have made it out into the world.

For the third time, I pulled/disassembled the ones that wouldn't go off and then purposely upped the neck tension by skipping the mandrel step in my process and will be jamming these next ones 20 thou into jam (normal neck tension and 10 thou of jam wasn't enough). I'm also using a different brand/batch of primers just to rule out me having a bad batch of CCI 450s. Hopefully, with these extra measures taken in order to make sure the case is wedged in there enough to allow for a successful primer whack, they will finally go bang.

I'm going to load 100 more rounds at my usual/preferred .100" off to try, because they should go bang like that without me having to lend a helping hand jamming them, but that's it, I don't have enough confidence in this brass to burn any more primers and bullets on it. If I get any more FTF's with this shit or any brass-related shit at all with it on the second load cycle/firing... it goes in the trash can.

Dear Lapua,

Please make 6GT brass so I can buy it.

Thanks.

Sounds like your smith may have did a crap job on headspace. I have had 4 6gt and a 22gt barrel(s). All have been chambered to go plus 001 and new alpha brass grows 003 from new, I bump it back 002. Easy easy.

Nope, no Gunsmith needed, Origin/Proof prefit, checked with Go/No-Go gauges, spun on in my garage (just like my last 4 barrels). The headspace on my action/barrel is not the problem.

The Alpha brass I have is short and out of spec, period. I know I'm not the only one dealing with this since another guy had already mentioned he had the same problem earlier in the thread, and I've already talked to 2 guys at my club that have had issues with 6GT Alpha brass.

I'm not losing sleep over it or anything, but I'm a fairly experienced reloader, I've loaded tens of thousands of rounds and I'm still having a hard time getting all of this brass fire-formed since it's so short. A new reloader would likely have no idea how to deal with this and would definitely be bothering/blaming their Gunsmith.

6GT isn't a wildcat, it's a SAAMI cartridge, so really there shouldn't be any fire-forming of anything at all in order to make it work. That's kind of the whole point.

FWIW, I do have some virgin Hornady brass on hand, just 50 pieces I figured I might need as I lost some of the "good stuff" at matches, and for comparison, the .375 datum on the Hornady brass measures 1.355", ~5 thou taller than the Alpha stuff and within 2 thou of SAAMI minimum. No doubt the Hornady stuff is close enough that it would all go bang on the first try.

I just hope it doesn't give me any more problems, and for my OCD's sake, I hope I can get the 16 to go bang that haven't yet.

Last edited:

Always deprime brass that you’re using for shoulder bump measurements!!! It ensures that you’re really measure the head and not a primer standing slightly proud or something.

I know, that's how I figured out the number I had gotten earlier when I made my first hasty measurement was bad. Not being able to bump the shoulder just reminded me that I needed to decap some of the brass and get a "real" measurement to figure out what was going on...

Contact alpha, they'll do you right. Hopefully you have some new unfired for them to measure. Your 375 bump gauge(depending on type) is a mass produced tool, just used as a reference, not a certified measure. Check your go and no go gauge with your 375 comperator, what do they measure vs your brass? Gauges aren't always full spec either. Just shoot and don't bump till you have to I guess. ADGs last lot of 65prc brass had necks so think I had to turn off over a full though per side to have 4k nk clearance. I've been using a lot of alpha brass lately, 22,6,6.5cm, 22 and 6gt,6bra, none has been short but the bra, it was 006 under go, but traditionally a 6bra is cut go -004, so made sense. I've seen a few proof tikka prefits well out of spec, but that could been the action vs chamber. I've got ocd 6gt and 22gt from 5 total lots, and all have been close. They're releasing a lot of 6gt right now and will be buying another 300pcs for another project, I'll see if it's considerably shorter. I have noticed newer lots have had less consistent neck thickness vs older lots, their qc has slipped some, I can attest to that.Nope, no Gunsmith needed, Origin/Proof prefit, checked with Go/No-Go gauges, spun on in my garage (just like my last 4 barrels). The headspace on my action/barrel is not the problem.

The Alpha brass I have is out of spec, period.

The minimum the shoulder should measure, using the .375 shoulder datum per the SAAMI print, is 1.357" (SAAMI spec is 1.364" - .007"). The Alpha Gay Tiger brass that I have all measures/measured 1.350" - 1.352", 5-7 thou less than SAAMI minimum.

I'm not losing sleep over it or anything, but I'm a fairly experienced reloader, I've loaded tens of thousands of rounds and I'm still having a hard time getting all of this brass fire-formed since it's so short. A new reloader would likely have no idea how to deal with this and would definitely be bothering their Gunsmith.

What is annoying is this isn't the first time Alpha has sent bad brass out into the world. One doesn't have to search too hard to find multiple instances over the last couple of years of them putting out jacked-up stuff in all sorts of cartridges like Dasher, 6BRA, 6.5CM, etc. Someone should have measured it and caught it before they put it in the fancy plastic box.

The brass being this far out of spec would be annoying with almost any wildcat, except, 6GT isn't a wildcat, it's a SAAMI cartridge, which means there's a universally recognized specification for manufacturers to adhere to, so really there shouldn't be any fire-forming of anything at all in order to make it work. That's kind of the whole point.

I just hope it doesn't give me any more problems, and for my OCD's sake, I hope I can get the 16 to go bang that haven't yet.

What really sucks is, considering how short the fired cases are after the first firing, it's probably going to take 2-3 more firings before they're fully fire-formed to my chamber... that's ~900-1200 rounds, maybe half of the barrel's useable life, just to get the brass fully fire-formed.

Shit, after typing that last part, I don't know why I'm still even bothering with it honestly. Maybe they don't even know it's f'ed up? I may contact Alpha and see what they can do, maybe they'll exchange this shit for stuff that's actually in spec?

Contact alpha, they'll do you right. Hopefully you have some new unfired for them to measure. Your 375 bump gauge(depending on type) is a mass produced tool, just used as a reference, not a certified measure. Check your go and no go gauge with your 375 comperator, what do they measure vs your brass? Gauges aren't always full spec either. Just shoot and don't bump till you have to I guess. ADGs last lot of 65prc brass had necks so think I had to turn off over a full though per side to have 4k nk clearance. I've been using a lot of alpha brass lately, 22,6,6.5cm, 22 and 6gt,6bra, none has been short but the bra, it was 006 under go, but traditionally a 6bra is cut go -004, so made sense. I've seen a few proof tikka prefits well out of spec, but that could been the action vs chamber. I've got ocd 6gt and 22gt from 5 total lots, and all have been close. They're releasing a lot of 6gt right now and will be buying another 300pcs for another project, I'll see if it's considerably shorter. I have noticed newer lots have had less consistent neck thickness vs older lots, their qc has slipped some, I can attest to that.

I'm going to try and get it sussed out on my own if I can, if I can't, I'll contact Alpha and see what they say.

I loaded 100 tonight out of the ones that went off on the first firing, and as long as those don't give me any further problems, I'll call things good.

The 16 that refuse to go off are annoying, but sooner or later I'll figure out how to set them off and then I will finally have peace again lol.

Run a 6.5mm mandrel into the neck, then neck the case back down to where your bolt closes with slightest resistance to fireform against a false shoulder. Or seat a bullet to jam 10k into lands to keep the case from coming forward upon pin striking primer. Should get it to go bang.I'm going to try and get it sussed out on my own if I can, if I can't, I'll contact Alpha and see what they say.

I loaded 100 tonight out of the ones that went off on the first firing, and as long as those don't give me any further problems, I'll call things good.

The 16 that refuse to go off are annoying, but sooner or later I'll figure out how to set them off and then I will finally have peace again lol.

If that’s an accurate measurement, it’s a problem.BTW, firing-pin protrusion is a fun thing to try and measure using calipers lol. Mine is somewhere between .007" and .017"? IDK, getting a legit measurement seems beyond the envelope of my skill lol.

Should be able to use back end of caliper to get close & protrusion should be .030 - .035 For ARC actions or double what you stated.

What action is this? Never mind found it, Origin. The protrusion numbers I've seen in threads on here for Origin are .045-.055. Seems like a lot to me, but .017 is definitely not enough. They are supposedly adjustable for protrusion & I've seen at least one thread where the guy had the pin come loose from the cocking piece. Might have loosened and backed up??

If it were me I'd call Zermat and get the correct protrusion from them, set it & try again without changing the load. Maybe just fresh primers.

Last edited:

If that’s an accurate measurement, it’s a problem.

Should be able to use back end of caliper to get close & protrusion should be .030 - .035 For ARC actions or double what you stated.

What action is this? Never mind found it, Origin. The protrusion numbers I've seen in threads on here for Origin are .045-.055. Seems like a lot to me, but .017 is definitely not enough. They are supposedly adjustable for protrusion & I've seen at least one thread where the guy had the pin come loose from the cocking piece. Might have loosened and backed up??

If it were me I'd call Zermat and get the correct protrusion from them, set it & try again without changing the load. Maybe just fresh primers.

How do you recommend measuring for firing-pin protrusion..?

I can measure the back end when it’s cocked when I get home, and I know it’s a lot more than 17 thou, but trying to measure how much it protrudes through the bolt face when the firing-pin gets let loose was a PITA in my first attempt lol…

you can also just used the back of the caliper and measure to the bolt face and then the firing pin, the difference is the protrusion.

Pull bolt, decock bolt/cocking piece. Use ass end of caliper, slide stem out at least 0.060, seat stem against bolt face next to protruded firing pin, slide caliper body down to make contact with firing pin while maintaiging as close to parallel angles with bolt face. Pretty sure that's how most folks check fp protrusion. Since you're using and origin, you can measure depth from. Front of lug face, to bolt face, then measure from lug face to tip of protruded firing pin and subtract the two, also gives same measurement as other method. I'd position the caliper body on the bolt in reference of the two arrows, then offset it a lil to get the stem to sit atop the firing pin.

Last edited:

Ok, it looks like I was measuring the firing-pin protrusion correctly, it just wasn't protruding enough for me to grab a measurement that I thought was accurate, but it turns out that my initial number of ~0.017" was correct at the time.

I spent a good chunk of the day waiting on MF'ers while running errands today and pretty sure I searched out everything that is available online on bolt-action firing-pin protrusion, and especially any info if it had anything to do with Zermatt actions in particular.

I also decided to take up Ray at Zermatt's offer on getting a new/fresh firing-pin-assembly sent my way for just in case.

I found a few things related to Zermatt/Big Horn actions, and everything pointed toward my firing-pin-assembly having been reassembled correctly after changing out the spring. I even found an old thread where Ray from Zermatt chimed in about a TL3 and said that the firing pin needed to be screwed all the way into the cocking piece before setting the set screws, not backed off at all, screwed all the way until it stopped against the cocking-piece and where it wouldn't go any further, just like I had done with my Origin. There are a couple of things out there that describe the process of reassembling a Zermatt firing pin assembly and none of them mention backing off the firing-pin from the cocking piece before locking it down.

Well, I don't know if the design has changed or what, but it appears that backing the firing pin off 3-4 turns from stopped against the cocking-piece is exactly what it needed to give the firing-pin the extra protrusion I needed. I played with it a bit and set the protrusion to ~0.045" which from what I could find is considered correct, and is roughly 3-times the amount of protrusion I had before.

So, sorry Alpha, I may have been coming for your neck too soon.

I won't know for sure until I can check my assembly against the new/fresh assembly, but I think I may have it finally figured out (hopefully anyways). Thing is, I didn't find anything anywhere that mentioned backing off the firing pin and "setting" the protrusion, but that's what seemed obvious and appears to have worked. IDK if that's how it's supposed to be, but it sure looks right, and if I end up breaking the firing pin, at least there's a replacement already in the mail lol.

Thanks for the help Hide peeps, reinforces my opinion that no one person has seen everything, but the collective may have lol!

I spent a good chunk of the day waiting on MF'ers while running errands today and pretty sure I searched out everything that is available online on bolt-action firing-pin protrusion, and especially any info if it had anything to do with Zermatt actions in particular.

I also decided to take up Ray at Zermatt's offer on getting a new/fresh firing-pin-assembly sent my way for just in case.

I found a few things related to Zermatt/Big Horn actions, and everything pointed toward my firing-pin-assembly having been reassembled correctly after changing out the spring. I even found an old thread where Ray from Zermatt chimed in about a TL3 and said that the firing pin needed to be screwed all the way into the cocking piece before setting the set screws, not backed off at all, screwed all the way until it stopped against the cocking-piece and where it wouldn't go any further, just like I had done with my Origin. There are a couple of things out there that describe the process of reassembling a Zermatt firing pin assembly and none of them mention backing off the firing-pin from the cocking piece before locking it down.

Well, I don't know if the design has changed or what, but it appears that backing the firing pin off 3-4 turns from stopped against the cocking-piece is exactly what it needed to give the firing-pin the extra protrusion I needed. I played with it a bit and set the protrusion to ~0.045" which from what I could find is considered correct, and is roughly 3-times the amount of protrusion I had before.

So, sorry Alpha, I may have been coming for your neck too soon.

I won't know for sure until I can check my assembly against the new/fresh assembly, but I think I may have it finally figured out (hopefully anyways). Thing is, I didn't find anything anywhere that mentioned backing off the firing pin and "setting" the protrusion, but that's what seemed obvious and appears to have worked. IDK if that's how it's supposed to be, but it sure looks right, and if I end up breaking the firing pin, at least there's a replacement already in the mail lol.

Thanks for the help Hide peeps, reinforces my opinion that no one person has seen everything, but the collective may have lol!

Last edited:

With .045" of protrusion you should be able to set off cases with .025" of travel. I think my new AR Grendel cases expand .020" without any issues. .006" just isn't very much, certainly not enough to require jamming or false shoulders. There's a point where the extractor holds the case and doesn't allow it to travel further into the chamber, probably less than .006".

With .045" of protrusion you should be able to set off cases with .025" of travel. I think my new AR Grendel cases expand .020" without any issues. .006" just isn't very much, certainly not enough to require jamming or false shoulders. There's a point where the extractor holds the case and doesn't allow it to travel further into the chamber, probably less than .006".

Yeah, from the looks of it, I should be able to set off anything now. I'll find out at the range tomorrow, but the lack of firing pin protrusion is most likely the culprit.

Before leaving for the range this morning, I did one final search on "Origin firing pin" and found this:

Ray from Zermatt references a "detent" on the firing pin, which was the first time I'd heard it mentioned...

Well, sure enough, there is a detent/notch/hole located within the threading of the firing pin that I had no idea existed. Once I locked the set screws down inside the detent, I rechecked the firing pin protrusion and it was great (~.050").

So it was that all along.

I went to the range and all the rounds went bang (just as I thought they would).

While trying to suss this out over a few range trips I'd shot rounds seated .100" off, and rounds that were .010" into jam... both shot great.

So, using a completely unscientific method of determining seating depth, I decided to just load them all at .050" off and see what I got?

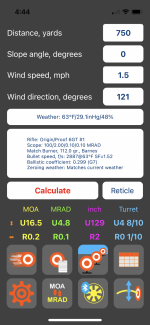

I shot a quick, semi-rapid fire group of 5 shots at 100 and another 5 at 750 off a cattle gate and shmedium bag, and saw pretty much everything I need to see:

Alpha Gay Tiger

Barnes Match Burner 112gn

SWPR 34gn

CBTO 1.925 (.050" off the lands)

= 2887fps

Ray from Zermatt references a "detent" on the firing pin, which was the first time I'd heard it mentioned...

Well, sure enough, there is a detent/notch/hole located within the threading of the firing pin that I had no idea existed. Once I locked the set screws down inside the detent, I rechecked the firing pin protrusion and it was great (~.050").

So it was that all along.

I went to the range and all the rounds went bang (just as I thought they would).

While trying to suss this out over a few range trips I'd shot rounds seated .100" off, and rounds that were .010" into jam... both shot great.

So, using a completely unscientific method of determining seating depth, I decided to just load them all at .050" off and see what I got?

I shot a quick, semi-rapid fire group of 5 shots at 100 and another 5 at 750 off a cattle gate and shmedium bag, and saw pretty much everything I need to see:

Alpha Gay Tiger

Barnes Match Burner 112gn

SWPR 34gn

CBTO 1.925 (.050" off the lands)

= 2887fps

Last edited:

Alright. When you guys say you found a node what’s it look like. On paper my average speed per group with a ladder test just shows a linear line no dips or anything traditional

Alright. When you guys say you found a node what’s it look like. On paper my average speed per group with a ladder test just shows a linear line no dips or anything traditional

That's accurate. I see a cluster of low ES samples. Every .2gr still shows a net change in velocity with enough recorded shots in the sample. "Nodes" is largely untrue when you fire enough shots for a relevant sample.

Got it. I thought you guys were seeing the old school nodes where there is a dip etc. yeah. I see some that yield good es/sd. Thanks

I was talking to a guy today at the range today and when I said I didn't believe in nodes I think he got offended.

He then said something to the effect of "you're wrong, yes, they exist" and then asked me "how do you explain it when something doesn't shoot then?"... and I said, "most of the time it's me, not the ammo, I don't think I've ever loaded a single batch that was ever bad enough to blame it all on".

The modern thinking is that if loads with small incremental changes in speed/depth appear drastically better than others in a similar range, it doesn't mean you've found a "node". It is more than likely just that you haven't shot enough rounds, and had a chance to observe a large enough sample size to see that they're actually performing relatively the same.

He then said something to the effect of "you're wrong, yes, they exist" and then asked me "how do you explain it when something doesn't shoot then?"... and I said, "most of the time it's me, not the ammo, I don't think I've ever loaded a single batch that was ever bad enough to blame it all on".

The modern thinking is that if loads with small incremental changes in speed/depth appear drastically better than others in a similar range, it doesn't mean you've found a "node". It is more than likely just that you haven't shot enough rounds, and had a chance to observe a large enough sample size to see that they're actually performing relatively the same.

I personally feel the "nodes" are bs, until you actually repeat the same test 3 times and it repeats. I've tried it that way, and it'll repeat only half the time or less. I prefer to shoot 2 or 3 shots at same charge weight ascending 0.2-0.3gr steps at 500-600y, you'll find velocity ranges with very tight vertical spread usually 0.4 or 0.6gr wide depending on case size that hold tight water line. This is where I load at. If the rifle shoots tight vert from 2880-2920 I'll pick a charge in the middle of there, and even if my es is 25, it's still going to shoot well at distance. This is referred to as ladder testing, but I have modified it a bit for my methods. Once the speed with tight vertical is found, and accuracy is sufficient(half moa at 500y)I'll stop. If not, I'll start with seating depth, adjusting in our out 0.010 steps. Has worked pretty well for me.

Agreed. I started doing 10 shot zeros after that podcast. Luckily my match rifles are all still 0.3Xmoa guns with 10 shot groups at 100y from a modified prone bag/bipod combo. But it gives you a really good idea of the true center of your cone of fire.That goes back to the Hornady podcast about sample sizes

The only thing that appears to be certain is: if you can make the same round over and over again, like a clone of the last one, and just like the next... your ES and SD numbers will look good.

If you can do that, then chances are your shit will shoot lol.

If you can do that, then chances are your shit will shoot lol.

Small cases, absolutely. 6br, bra, gt, dasher 100% spot on. Magnums require testing. I could take a 300 norma and drop exact same charge of H1000 in perfectly prepped brass and seat a 215hyb at exactly 50k off lands, and it might shoot over an inch at 100y, seating depth in or out 25k, could shrink it dramatically, may need another 1.5 grain or 2 of powder to get it up another 60-70fps to get bug holes.The only thing that appears to be certain is: if you can make the same round over and over again, like a clone of the last one, and just like the next... your ES and SD numbers will look good.

If you can do that, then chances are your shit will shoot lol.

Small cases, absolutely. 6br, bra, gt, dasher 100% spot on. Magnums require testing. I could take a 300 norma and drop exact same charge of H1000 in perfectly prepped brass and seat a 215hyb at exactly 50k off lands, and it might shoot over an inch at 100y, seating depth in or out 25k, could shrink it dramatically, may need another 1.5 grain or 2 of powder to get it up another 60-70fps to get bug holes.

This 6GT is my first go around using "Varget" (Varget-clone Shooter's World Precision Rifle anyways) and it's magic sauce for sure. Stupid consistent. I don't have to break out the chronograph to know I'm in single digits with my SDs and my ES is good, just by looking at targets.

After ~2 years of using Sta-Ball 6.5 in 6CM, which can be hard and does one no favors... the magic sauce is stupid easy.

Varget, N150, TS15.5, H4350, RL16, it don't matter, the gt shoots as long your reloading practices are sound. 4166 works too but only if you're content with speeds mid 2800s and lower, but in that case you should be shooting a br based case.This 6GT is my first go around using "Varget" (Varget-clone Shooter's World Precision Rifle anyways) and it's magic sauce for sure. Stupid consistent. I don't have to break out the chronograph to know I'm in single digits with my SDs and my ES is good, just by looking at targets.

After ~2 years of using Sta-Ball 6.5 in 6CM, which can be hard and does one no favors... the magic sauce is stupid easy.

Varget, N150, TS15.5, H4350, RL16, it don't matter, the gt shoots as long your reloading practices are sound. 4166 works too but only if you're content with speeds mid 2800s and lower, but in that case you should be shooting a br based case.

I'm not really concerned with speed. IMHO once above ~2800fps, more speed doesn't really matter much as long as the accuracy looks good. A 6mm is never going to be a great "heavy wind gun" choice and that's the only reason I might even want to flirt with pushing one for speed...

I mean, it's not like any of us are going to run out of elevation in our scopes lol, 1000 yards was only 8mils at only 2820fps.

I'm digging the 6GT though, so far everything I've tried shoots, feeds perfectly, recoils less, hammers.

Last edited:

Agreed. My 2920fps load in a 28" barrel is likely similar chamber pressure to a 26" with varget at lower 2800s. The GT will shoot very well 2820-2840, 2880-2920 and then again up near 3000 in experience with 5 barrels. Burn rate determines it a bit. I love the accuracy and repeatability so much I'm building a hunting rifle in 6gt for deer/antelope. Bat bumblebee action and a 22" 3B hawkhill 7tw to run supressed. Gonna be a fun lil toy.I'm not really concerned with speed. IMHO once above ~2800fps, more speed doesn't really matter much as long as the accuracy looks good. A 6mm is never going to be a great "heavy wind gun" choice and that's the only reason I might even want to flirt with pushing one for speed...

I mean, it's not like any of us are going to run out of elevation in our scopes lol, 1000 yards was only 8mils today at only 2820fps.

SD 3.0?Today’s results

What brass, bullet, powder, primer . . . ?

Can you tell us a little about how you reload, dies, neck tension, etc? I promise I will take the time to read carefully whatever you decide to share.

I am sure that has nothing to do with the recoil difference of a 300 norma vs a 6BR.

its almost like these smaller calibers are just easier to shoot small groups more often..........hrm

its almost like these smaller calibers are just easier to shoot small groups more often..........hrm

Alpha brass, cci450s, 109eldm, 35.9g h4350. Base to ogive using SAC tool-1.851”SD 3.0?

What brass, bullet, powder, primer . . . ?

Can you tell us a little about how you reload, dies, neck tension, etc? I promise I will take the time to read carefully whatever you decide to share.

These where annealed on a flame annealer, sized with a SAC sizing die(first gen) on a coax press, no mandrel, .266 bushing. Trimmed on a giraud trimmer, then cleaned, primed on primal rights, powder poured with a AutoTrickler and bullet seated with a sac die

I can’t tell you how far I’m off the lands as this was a load for another rifle. I shot it through this rifle when I got it and decided not to touch anything

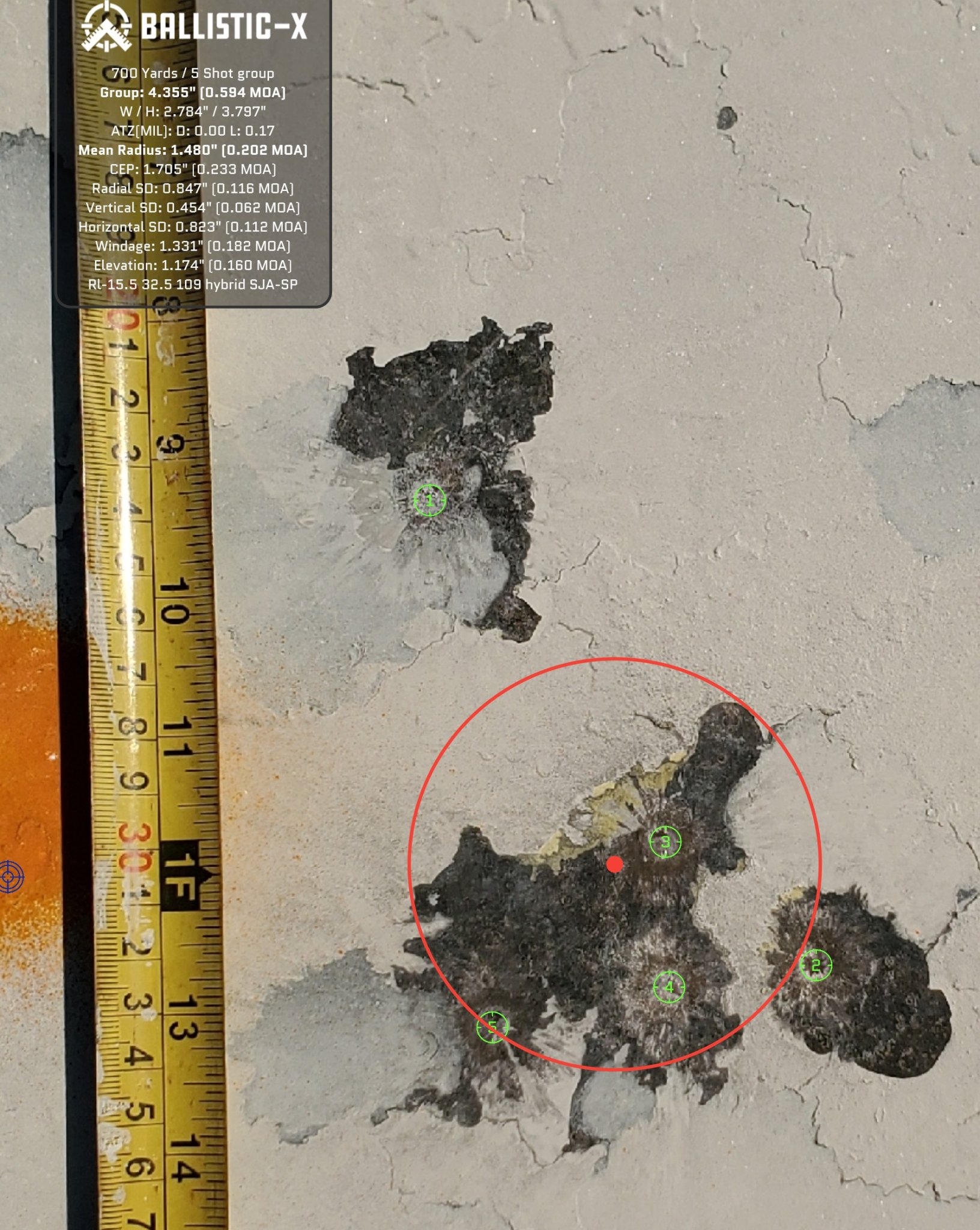

Nice conditions on the range yesterday morning 19.7 degrees, barely discernable wind around a mph made for a good day on the range verifying 4DOF data. Load is Alpha brass 5th firing, FGMM primers, 32.5gr of RL-15.5 and 109 Hybrid's jumping .065" Barrel is a PROOF cut to 26" and chambered with a .170 Alpha reamer by Straight Jacket Armory, velocity 2857fps SD 7.

Nice conditions on the range yesterday morning 19.7 degrees, barely discernable wind around a mph made for a good day on the range verifying 4DOF data. Load is Alpha brass 5th firing, FGMM primers, 32.5gr of RL-15.5 and 109 Hybrid's jumping .065" Barrel is a PROOF cut to 26" and chambered with a .170 Alpha reamer by Straight Jacket Armory, velocity 2857fps SD 7.

How’s the temp stability on the 15.5 compare to RL-16?

Curious what you guys are seeing for loaded neck diameter with Hornady brass? Barrel is on the big brown truck and trying to get everything needed.

Hickswr, hard to say, RL15.5 is very stable IME in the 6gt and I have been running it from the low teens this winter to 101 in last summer's heat at the positional punisher match in Kansas, but I can't compare it to RL16 as I have not used it enough to know. I can say that RL16 was very stable in my creedmoor loads.

Mine average about 0.269" on the second loading.Curious what you guys are seeing for loaded neck diameter with Hornady brass? Barrel is on the big brown truck and trying to get everything needed.

Thank you Mike!Mine average about 0.269" on the second loading.

Similar threads

- Replies

- 14

- Views

- 1K

- Replies

- 19

- Views

- 1K