Will do tomorrow morning.It could be a headspace issue where you're getting more springback than you thing with some cases (especially if you're not annealing). Take measurements of everything (like at the diameter at the .200 line above the base; the diameter just below the shoulder/body junction, the cases headspace measurements) on your fired cases and your sized cases to see what's really going on. Then report back with the numbers.

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

.308 Winchester

- Thread starter Two Shoes

- Start date

Ok that explains it. Using what you have is something we have all done. The Small Base should work and if the brass is not chambering then there is something going on with the size after it goes through the die and the brass isn’t properly sized. You really should know how much you are bumping the shoulder as if it’s being oversized then it can lead to premature case head separations. Not enough and you get what I think you are getting now. That simple tool will really help.

Yeah I'd bet the small base is pushing the shoulder forward past what it was fired since the small base is moving more metal.Ok that explains it. Using what you have is something we have all done. The Small Base should work and if the brass is not chambering then there is something going on with the size after it goes through the die and the brass isn’t properly sized. You really should know how much you are bumping the shoulder as if it’s being oversized then it can lead to premature case head separations. Not enough and you get what I think you are getting now. That simple tool will really help.

The HS comparator is really a must have.

Yes +1 on what rob01 said.I’m using a small base die because it’s all I have. I screwed up my FL die trying to get a stuck case out, then Amazon sent me the wrong die so I just rolled with it. I was and still am brand new to reloading so I just don’t know what I don’t know. There’s so many opinions out there and I’m trying to learn what’s best for different applications.

I’ll get those and a bushing die soon. For not I’ve got a Lee FL die that works. It allows my reloads to chamber at least.

I recommend keeping the lee die for now, it is not holding you back.

I use Lee fls dies in 308 and 223 and can get sub 1/2 moa loads in both.

Without a comparitor you are driving while blind. You can go old school and bump back till bolt drops but I will leave that for someone else to explain.

I like numbers I can enter into my reloading book I keep so I use the comparitor.

I take the expander out of my Lee dies and measure it. It will normally be two thousand under bullet diameter. I put it in a drill and polish it with 800 grit cloth till it is slick and .004 under bullet diameter.

It runs smoothly, puts less stress on brass while sizing. I then run it through a Sinclair mandrell for the consistant 0.002 neck tension.

It is about 35$ for the die and a pin and extra pins for other calibers are about 6$ .

A Lee fls die, a Sinclair mandrell and the Hornady comparitor will get your brass right.

The only other major tools I use are a bullet (ogive) comparitor for bto measurements and a digital scale at least +/- 0.1gr resolution.

The ogive comparitor will keep you out of trouble when changing bullets since you can't rely on the cartridge over all lenght.

(308 going from 168 smk to 169 smk was a good example, they moved the ogive forward 0.040)

Not trying to spend your money on fancy things, just the basics .

Dies are made to slightly different dimensions. Just grind .002" to .004" off the bottom of the FL die or machine it off with a carbide tool on the lathe. It will then allow easy chambering of the cartridge. I modify & make many dies for forming wildcat cartridges and using existing brass to make other unavailable brass.I’m using a small base die because it’s all I have. I screwed up my FL die trying to get a stuck case out, then Amazon sent me the wrong die so I just rolled with it. I was and still am brand new to reloading so I just don’t know what I don’t know. There’s so many opinions out there and I’m trying to learn what’s best for different applications.

I’ll get those and a bushing die soon. For not I’ve got a Lee FL die that works. It allows my reloads to chamber at least.

Thanks to everyone! I’ve gotten several different 308 loads done for now. I just dropped a lot of money on a thermal, but after I get my savings to a good spot I’ll get the comparator. (I understand it’s cheap but I made a deal with my wife, so purchases are done for now. Lol)

Lapua 155gr

50.2 gr. N 550

2995 fps

Cz 557

25" barrel

Muzzle brake

Vortex 6x24 dimondback tactical.

50.2 gr. N 550

2995 fps

Cz 557

25" barrel

Muzzle brake

Vortex 6x24 dimondback tactical.

47.7F, 84%H, 29.44inHg

Savage 110 Ultralite 22” 1:10” Proof Carbon with 7.5” suppressor.

Virgin Lapua SR primer brass, Rem 7 1/2, Win StaBALL Match @ 46.6, 168 TMK @ 2.900” OAL, 2.185” CBTO 0.035” jump, 2717avg; 1/2moa

The photo was a primer test today 02NOV2023 38.3F, 99%H, 29.41inHg

I also bumped charges to 47.0. Left was Murom KVB-223, middle CCI-450, right Rem 7 1/2. The far right shot was a fouler after cleaning the bore. I may have to make more using the Russian primers to see if they can continue to print smaller groups.

Savage 110 Ultralite 22” 1:10” Proof Carbon with 7.5” suppressor.

Virgin Lapua SR primer brass, Rem 7 1/2, Win StaBALL Match @ 46.6, 168 TMK @ 2.900” OAL, 2.185” CBTO 0.035” jump, 2717avg; 1/2moa

The photo was a primer test today 02NOV2023 38.3F, 99%H, 29.41inHg

I also bumped charges to 47.0. Left was Murom KVB-223, middle CCI-450, right Rem 7 1/2. The far right shot was a fouler after cleaning the bore. I may have to make more using the Russian primers to see if they can continue to print smaller groups.

Attachments

Last edited:

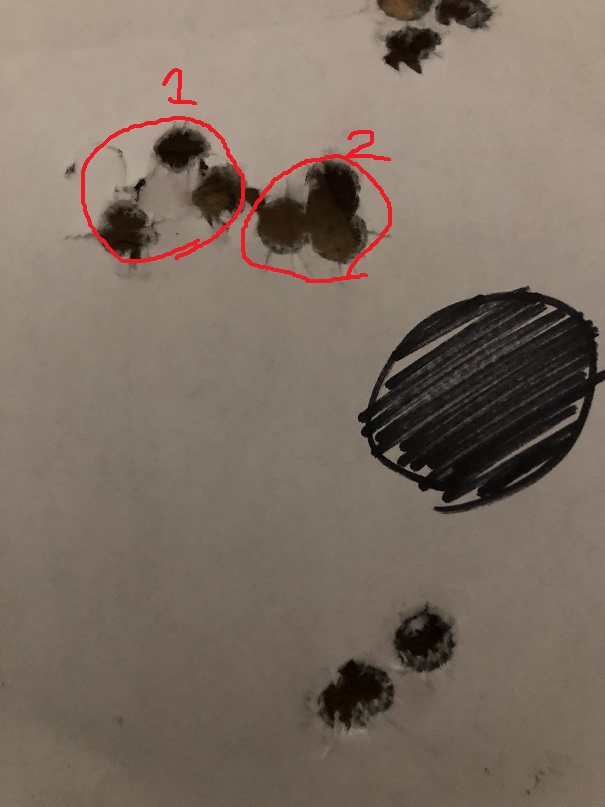

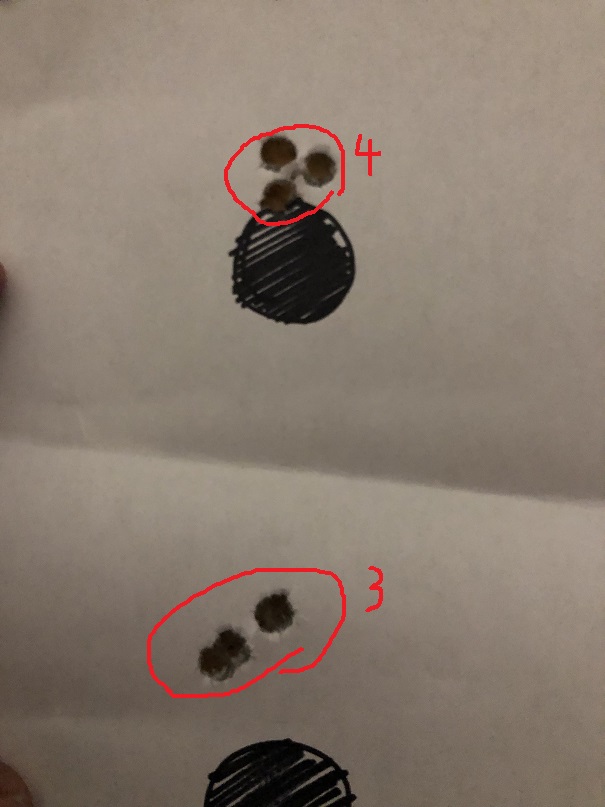

Loading some 168 midway seconds win brass varget 2.80 nominal:

1=42gr

2=Control load

3=42.5gr

4=42.8gr

This was with my SSG3000 and 10X optic at 115yards lasered

1=42gr

2=Control load

3=42.5gr

4=42.8gr

This was with my SSG3000 and 10X optic at 115yards lasered

Tested some Midway factory 2nd 169smk. It turns out surprisingly good. 15rds SD of 8. Group about 0.44moa

Fgm brass /imr 4895 41.8gr

Avg 2720 fps (28”bbl)

Fgm brass /imr 4895 41.8gr

Avg 2720 fps (28”bbl)

Well ,I have them loaded started 10% low and worked up to full charge of vv 550 .Lapua 155gr

50.2 gr. N 550

2995 fps

Cz 557

25" barrel

Muzzle brake

Vortex 6x24 dimondback tactical.

My CZ likes the 146 gr. M 80 pulls one hole at 100 yards 5 shot group. That surprised me,because I was using them just to sight in. Then I switched to 168gr v-max and 42 gr.3031 and got a 1 inch group. Have not had it out since.

Going back out for some confirmations this morning, but here are some results with my Savage 110 Elite Precision that I chopped to 18” and run exclusively with a YHM Resonator K. These are the 2 that shot the best for me out of 8 different loads I tested. Loaded 20 of each to see how they do. Also just for shits and grins I loaded 5 rounds of the N540 load at 41.8 to see if it holds together. Since 41.2 didn’t shoot too hot, 41.5 may be the start of the node or an anomaly. Really grown to love N540. It is super versatile and usually has pretty tiny SD’s. It has worked in every caliber I have tried it in but really seems to shine in 223, 308, and 6.5x47.

All Lapua 1x fired with a 210 primer and a 175RDF at 2.288BTO

Varget 43.5

Average 2595

ES 15.2

SD 6.5

Shot a .141 but only a 3 shot group

N540 41.5

Average 2512

ES 7.3

SD 3.3

Shot a .207 but only a 3 shot group

All Lapua 1x fired with a 210 primer and a 175RDF at 2.288BTO

Varget 43.5

Average 2595

ES 15.2

SD 6.5

Shot a .141 but only a 3 shot group

N540 41.5

Average 2512

ES 7.3

SD 3.3

Shot a .207 but only a 3 shot group

Let me guess controll was fgmm ?Loading some 168 midway seconds win brass varget 2.80 nominal:

1=42gr

2=Control load

3=42.5gr

4=42.8gr

This was with my SSG3000 and 10X optic at 115yards lasered

View attachment 8264064View attachment 8264065

#4 looks promising.

According to Hodgdon you have room for more powder if running SMK's.

My son has the 308 and current data card out at the ranch and forgot to update computer.

Ranch has a major gas leak on the property line so can't get data card right now.

I tried with several powders and only thing I could get to run with that combo was Varget. I hear there are others but not touching anything that has 3/8 moa groups.

I really thought I wouldn't need to bother anybody with help, trying to do my homework... But I'm a little lost. I was following along a set of instructions I saw Erik Cortina post on another forum. But I'm having trouble extrapolating much from my target. Is there an obvious starting point?

I thought 44.5 looked good, but the ES/SD were higher than other groups. I shot off a lead sled and didn't feel like any shot was pulled, pretty confident. Lasered at 100yrds.

Tikka T3X CTR 20"

178gr ELD-M

IMR 4064

Alpha Brass SRP

CCI 450's

CBTO: 2.233"

The three numbers are:

Average Velocity

Extreme Spread

Standard Deviation

I thought 44.5 looked good, but the ES/SD were higher than other groups. I shot off a lead sled and didn't feel like any shot was pulled, pretty confident. Lasered at 100yrds.

Tikka T3X CTR 20"

178gr ELD-M

IMR 4064

Alpha Brass SRP

CCI 450's

CBTO: 2.233"

The three numbers are:

Average Velocity

Extreme Spread

Standard Deviation

I agree with @Rimfire Jesus mostly.

I have a lead sled laying around somewhere not been used in 15 years or more.

IMHO they will not have the same impact point or produce the same groups as your shoulder.

A pair of heavy bags are also a good alternative.

His advice to dump the Hornady bullets is also sound and I have found they are hard to get running well.

Quality bullets will group with less hassle and be more consistant.

Sierra 168g or 169g are both easy to get running, well worth the price difference. Just be aware the ogive on the two of those are different lengths from base and tip.

I have improved my load development by using Eric Cortina's methods and agree with his premise that if 2 shots don't group 5 certainly won't.

In fact the only reason I use 3 with initial ladder tests is to see the shape of the 3 shots to help eliminate stringing.

I have a lead sled laying around somewhere not been used in 15 years or more.

IMHO they will not have the same impact point or produce the same groups as your shoulder.

A pair of heavy bags are also a good alternative.

His advice to dump the Hornady bullets is also sound and I have found they are hard to get running well.

Quality bullets will group with less hassle and be more consistant.

Sierra 168g or 169g are both easy to get running, well worth the price difference. Just be aware the ogive on the two of those are different lengths from base and tip.

I have improved my load development by using Eric Cortina's methods and agree with his premise that if 2 shots don't group 5 certainly won't.

In fact the only reason I use 3 with initial ladder tests is to see the shape of the 3 shots to help eliminate stringing.

Hey guys, thanks for the responses. I actually haven't had any trouble with ELD's... I was shooting LRP Alpha Brass with them, but it's too damn hard to find those primers, so I was working up a round with SRPs. My last round was 41.5gr 4064, LRP Alpha Brass, and the 178 ELD-M, shot less than half MOA, .384" group at 200 was it's best, but they were generally quarter MOA (Bipod and rear bags). I hadn't tried beyond 300 yards yet.I agree with @Rimfire Jesus mostly.

I have a lead sled laying around somewhere not been used in 15 years or more.

IMHO they will not have the same impact point or produce the same groups as your shoulder.

A pair of heavy bags are also a good alternative.

His advice to dump the Hornady bullets is also sound and I have found they are hard to get running well.

Quality bullets will group with less hassle and be more consistant.

Sierra 168g or 169g are both easy to get running, well worth the price difference. Just be aware the ogive on the two of those are different lengths from base and tip.

I have improved my load development by using Eric Cortina's methods and agree with his premise that if 2 shots don't group 5 certainly won't.

In fact the only reason I use 3 with initial ladder tests is to see the shape of the 3 shots to help eliminate stringing.

So I have about 800 ELD-M sitting on my shelf. To be fair, when I had been looking to buy relaxing supplies, the matchkings were impossible to find, so I never gave them a go.

Reloading Equipment - 308 Brass For Sale

This is all 1x fired 308 brass out of various rifle systems and will be noted by each photo. Price includes shipping to the lower 48. I accept PayPal “gift” or personal check. Funds clear and I ship. Thanks for looking. 200 count Federal Gold Medal Match Lot #621A289 out of Accuracy...

Hey guys, thanks for the responses. I actually haven't had any trouble with ELD's... I was shooting LRP Alpha Brass with them, but it's too damn hard to find those primers, so I was working up a round with SRPs. My last round was 41.5gr 4064, LRP Alpha Brass, and the 178 ELD-M, shot less than half MOA, .384" group at 200 was it's best, but they were generally quarter MOA (Bipod and rear bags). I hadn't tried beyond 300 yards yet.

So I have about 800 ELD-M sitting on my shelf. To be fair, when I had been looking to buy relaxing supplies, the matchkings were impossible to find, so I never gave them a go.

Never had any problems with ELDs in any caliber either. The 168 ELDs I loaded for my .308 were easy to get a load for and get an accurate load. They have almost the same BC as the Sierra 169. The 178 ELD-M has a better BC than the 169 SMK also.

You won't be gaining a ton of velocity between those two especially in a 20" barrel but if worried about velocity then use a 168 ELD with a .524 BC instead of the 178.Barely. For all intent and purposes it is basically the same. If a person factors in the additional velocity you'll get out of a 169 grain bullet the 178 with its .020 BC increase will fall behind.

I picked up 175 feet per second going from 178s to Sierra 169s. Granted part of that is because the ELDMs would only shoot halfway decent at a slower velocity. Generally, when shooting short-barreled guns, the lighter bullets at a higher velocity most of the time outperform the super slow, heavy bullet combo.

Sounds like the biggest part as in my 20" I can get the 178s going almost as fast as the 168s.

Would anyone here consider 45 grains of varget too much for a 168 in a properly executed standard saami chamber? I'm having some issues with my bolt lift after 50 of this load this weekend. Peterson srp brass, 45 of varget, cci br4, 168 match, 2.8 coal l. Bolt is now difficult to lift, rough on empty chamber. Only with FP forward

What do you think when looking at this (note the psi pressures and temperature):Would anyone here consider 45 grains of varget too much for a 168 in a properly executed standard saami chamber? I'm having some issues with my bolt lift after 50 of this load this weekend. Peterson srp brass, 45 of varget, cci br4, 168 match, 2.8 coal l. Bolt is now difficult to lift, rough on empty chamber. Only with FP forward

Your bolt lift is hard on an empty chamber?Would anyone here consider 45 grains of varget too much for a 168 in a properly executed standard saami chamber? I'm having some issues with my bolt lift after 50 of this load this weekend. Peterson srp brass, 45 of varget, cci br4, 168 match, 2.8 coal l. Bolt is now difficult to lift, rough on empty chamber. Only with FP forward

Yes. When cocking only though.Your bolt lift is hard on an empty chamber?

It was about 50 degrees outWhat do you think when looking at this (note the psi pressures and temperature):

View attachment 8266205

I havent got quickload so thank you

Perhaps a little warm then.

Hodgedon lists 46gr as a safe max. Brass has no signs of pressure. Tikka action. And now the bolt is super hard to open. Both of my bolts. With the barrel off too

If you go with a longer seating (like a COAL of 2.866 that I've used in my Krieger barrel for my RPR) that would reduce pressure and help alleviate that stiff bolt lift. Of course, that'd depend on how much freebore you've got to work with.It was about 50 degrees out

I havent got quickload so thank you

Perhaps a little warm then.

Hodgedon lists 46gr as a safe max. Brass has no signs of pressure. Tikka action. And now the bolt is super hard to open. Both of my bolts. With the barrel off too

So all you guys running the 178 eldm's I guess are not limmited by magazine length dimensions and short chambers.

Some spr / tactical rifles were forged around fgmm 168's.

Driven by departmental specifications.

I suppose there are many rifles out there with those specs still in departments being used.

Some spr / tactical rifles were forged around fgmm 168's.

Driven by departmental specifications.

I suppose there are many rifles out there with those specs still in departments being used.

So all you guys running the 178 eldm's I guess are not limmited by magazine length dimensions and short chambers.

Some spr / tactical rifles were forged around fgmm 168's.

Driven by departmental specifications.

I suppose there are many rifles out there with those specs still in departments being used.

Departments aren't handloading ammo. The factory loaded 178s will fit in those rifle.

It was about 50 degrees out

I havent got quickload so thank you

Perhaps a little warm then.

Hodgedon lists 46gr as a safe max. Brass has no signs of pressure. Tikka action. And now the bolt is super hard to open. Both of my bolts. With the barrel off too

The difference is Hodgdon is using Winchester brass which has a larger internal capacity. You need to adjust accordingly when changing from anything on the Hodgdon site. I used to use 45grns with Winchester brass and 178 AMAX/175SMK/178 BTHP but when going to Hornady brass I am at 44grns.

Would anyone here consider 45 grains of varget too much for a 168 in a properly executed standard saami chamber? I'm having some issues with my bolt lift after 50 of this load this weekend. Peterson srp brass, 45 of varget, cci br4, 168 match, 2.8 coal l. Bolt is now difficult to lift, rough on empty chamber. Only with FP forward

Do you mean you have an empty chamber, cock it, dry fire it, then open the bolt? And it feels stiff?

I mean I have an empty chamber, uncocked, go to lift the bolt to cock it and its not just stiff it takes significant force to lift the bolt. I can hear and feel metal chattering somewhere. Once open and cocked it operates as normal. This is with my 308 and my 223 bolt body. Tikka t3x action.Do you mean you have an empty chamber, cock it, dry fire it, then open the bolt? And it feels stiff?

So all you guys running the 178 eldm's I guess are not limmited by magazine length dimensions and short chambers.

Some spr / tactical rifles were forged around fgmm 168's.

Driven by departmental specifications.

I suppose there are many rifles out there with those specs still in departments being used.

They have a different bullet design so while it might be 2.85 to the tip the bearing surface is actually further back then a regular bullet. Loading the 169smk at 2.83 my seating die would push a reg 168 to around 2.79". Also you can load some of them to saami length, my 169smk load of 42varget was 2.82 MAX so it could run in an AR10 mag too.

It sounds like Tikkas can have a hard bolt lift. https://rokslide.com/forums/threads/heavy-bolt-lift-rough-bolt-on-new-tikka.174725/I mean I have an empty chamber, uncocked, go to lift the bolt to cock it and its not just stiff it takes significant force to lift the bolt. I can hear and feel metal chattering somewhere. Once open and cocked it operates as normal. This is with my 308 and my 223 bolt body. Tikka t3x action.

You might want to take a look at the thread I post from rokslide. There's a post on there to fix possible issues. Since you had the same problem on two tikkas with the barrel removed and only on uncocked actions I'd say you need to lube or grease the cocking cam. Post#19 on the thread.Would anyone here consider 45 grains of varget too much for a 168 in a properly executed standard saami chamber? I'm having some issues with my bolt lift after 50 of this load this weekend. Peterson srp brass, 45 of varget, cci br4, 168 match, 2.8 coal l. Bolt is now difficult to lift, rough on empty chamber. Only with FP forward

So barring changing the bullet, what's my next step? I'm not above changing if I can't get the groups I want, I just have had a good experience with the ELD-M and I've got quite a few.

Do I need to repeat the tests in a different way? I chrono'd each shot if that helps avoid that.

At 44.5gr, there was a slight ejector rub on the brass.

Do I need to repeat the tests in a different way? I chrono'd each shot if that helps avoid that.

At 44.5gr, there was a slight ejector rub on the brass.

So barring changing the bullet, what's my next step? I'm not above changing if I can't get the groups I want, I just have had a good experience with the ELD-M and I've got quite a few.

Do I need to repeat the tests in a different way? I chrono'd each shot if that helps avoid that.

At 44.5gr, there was a slight ejector rub on the brass.

Didn't you say in one post that you got good groups with 41.5 grains? Looking at your target I want to say about 42.5-43 grains and play with seating depth.

Also you might want to try a shorter COAL rather than longer.

I appreciate your advice, Rimfire Jesus, but I'm trying to work through this method, identifying a node to start from. He advocates finding the node and starting at the middle of that node as that should give you the most forgiving load to maintain consistency from your reloads. That's where I start a seating depth test in .003" increments from jam -.005" to -.040".

I know everyone has their own methods, I was just testing this method out to see if it worked for me. I'm really in it to learn what I can from other people. If it doesn't work out, I'm more than happy to go back to the drawing board.

@BCP, yes, I was getting good groups with 41.5, but it was with large rifle primers as opposed to these CCI small rifle magnums in using now, I'm not sure how much of a difference that really makes, though. Are you suggesting 42.5-43 based on matching (sort of) vertical spread? That's what I started thinking should be the node to go from.

Thanks everyone

I know everyone has their own methods, I was just testing this method out to see if it worked for me. I'm really in it to learn what I can from other people. If it doesn't work out, I'm more than happy to go back to the drawing board.

@BCP, yes, I was getting good groups with 41.5, but it was with large rifle primers as opposed to these CCI small rifle magnums in using now, I'm not sure how much of a difference that really makes, though. Are you suggesting 42.5-43 based on matching (sort of) vertical spread? That's what I started thinking should be the node to go from.

Thanks everyone

I was going to say ditch the lead sled and try the 43.0 and 43.5 gr IMR 4064 load again. I had better luck with Fed 210's or 210M's while using IMR 4064. But if you're switching to SRP then I'd say you're changing too many variables to fine tune your loads. IMO I'd go back and reshoot the 43.0 gr-43.5 gr loads on sandbags or a decent front rest and rear bag. Or if you have some Fed 210's start with the 41.5 gr load and work back up.I appreciate your advice, Rimfire Jesus, but I'm trying to work through this method, identifying a node to start from. He advocates finding the node and starting at the middle of that node as that should give you the most forgiving load to maintain consistency from your reloads. That's where I start a seating depth test in .003" increments from jam -.005" to -.040".

I know everyone has their own methods, I was just testing this method out to see if it worked for me. I'm really in it to learn what I can from other people. If it doesn't work out, I'm more than happy to go back to the drawing board.

@BCP, yes, I was getting good groups with 41.5, but it was with large rifle primers as opposed to these CCI small rifle magnums in using now, I'm not sure how much of a difference that really makes, though. Are you suggesting 42.5-43 based on matching (sort of) vertical spread? That's what I started thinking should be the node to go from.

Thanks everyone

Rofl, that just might be the case. I certainly didn't do it this way to find the round using LRPs, but then people were telling me I got lucky doing it that way. I'm not going to repeat the whole test if it doesn't work, that's for sure.Half the world doesn't believe powder/ velocity nodes exist. So you could be on to something or you could be wasting components and barrel. But either way, 3rd groups and velocity nodes are probably going to have you chasing your tail for a while. It's going to be like watching 50 raccoons fighting in a trashcan through a soda straw. Too much chaos with too small a vantage point to make sense of whats going on.

@Rob01 Thanks for that info, I'll keep that in mind!

@xsn10s Maybe a miscommunication, so I apologize. I'm not using ANY data from my LRP rounds. I've started from scratch to work witht he SRPs. So the only variable changing is the charge weights. I'm not going back and forth with brass or primers.

I get the consensus is to drop the lead sled, which I'll do. Can someone explain how the POI differs from shoulder/rear bags? Does the lead sled affect barrel harmonics (No, I'm not resting the barrel on the rest...lol) How I was using the lead sled was resting the forend on the front rest, and resting the rifle stock on my hand to fine tune my point of aim, similar (I thought) to squeezing a rear bag.

It really depends on the lead sled and how it's used. It sounds like you might not be allowing the lead sled to have as much influence or detachment from the shooter as others. IMO the rifle was designed to shoot from a person so it properly held it's more consistent than off a sled. As far as the SRP sorry I misunderstood you. I think if you go back fire those loads I mentioned it might help. Also depending on the range that 41.5 gr load might be just fine. I suggest shooting those loads out to the max distance you want to use them and look at the results.I get the consensus is to drop the lead sled, which I'll do. Can someone explain how the POI differs from shoulder/rear bags? Does the lead sled affect barrel harmonics (No, I'm not resting the barrel on the rest...lol) How I was using the lead sled was resting the forend on the front rest, and resting the rifle stock on my hand to fine tune my point of aim, similar (I thought) to squeezing a rear bag.

I have never used a lead sled, and rarely shoot off a bench, once in the last 40 yrs...pretty rare.

I shoot from prone & shooting mat, with bipod or front rest along with a rear bag. Mostly get on the ARs with hard firm hold, into the shoulder, maybe a lesser extent with bolts...maybe. Use the same hold for everything from 17 Remington to 50 BMG.

I shoot from prone & shooting mat, with bipod or front rest along with a rear bag. Mostly get on the ARs with hard firm hold, into the shoulder, maybe a lesser extent with bolts...maybe. Use the same hold for everything from 17 Remington to 50 BMG.

I see, so just shoot how you're going to shoot. I guess I thought a lead sled would take out my user error.It's all about natural point of aim. Managing recoil is a fairly decent aspect as well. And certain guns shoot better or worse depending on how you load the bipods, shoot with a neutral grip and load, pull back into your shoulder with a reverse load on the bipod, etc. You lose all that nuance and agency as the shooter with the sex doll of a shooting rest.

It's also been demonstrated on this forum that measured velocities change when shooting prone vs sitting at a bench. How consistent is the lead sled backing the gun every shot and what could that be doing to your SDs?

I understood that my setup needed to be as close to exact as I could, so I had drawn circles around the feet of the lead sled to return it if it moved. What you're saying makes sense, though, now that I think about it, because I would find I might need to raise or lower the front rest just a tad between some shots.

I also don't have a great bipod, so I guess I'll have to look into that

There's nothing wrong with shooting from the bench while doing load development. Heck if all you want to do is shoot from the bench that's perfectly fine. I shoot from the bench using a bipod and rear bag when during load development. Sand bags or a good Eagle front rest is my preferred method. After that it's mostly field positions in tall grass where prone isn't practical most of the time.I see, so just shoot how you're going to shoot. I guess I thought a lead sled would take out my user error.

I understood that my setup needed to be as close to exact as I could, so I had drawn circles around the feet of the lead sled to return it if it moved. What you're saying makes sense, though, now that I think about it, because I would find I might need to raise or lower the front rest just a tad between some shots.

I also don't have a great bipod, so I guess I'll have to look into that

The old lead sled I have somware around was purchased when I got a Winchester featherweight in 270.

It was a bitch on my skinny shoulder. A nice decelerator pad helped that.

Then I started to use it to get the scope close and fine tune from the shoulder.

I found my poi would shift with / without the sled.

I don't buy pencil barrels anymore and use brakes for help with recoil.

There is a wild possibility my recoil management has gotten better but still prefer bag to a bipod (frustrating).

It was a bitch on my skinny shoulder. A nice decelerator pad helped that.

Then I started to use it to get the scope close and fine tune from the shoulder.

I found my poi would shift with / without the sled.

I don't buy pencil barrels anymore and use brakes for help with recoil.

There is a wild possibility my recoil management has gotten better but still prefer bag to a bipod (frustrating).

This is prob mentioned somewhere so apologies, I’m on my phone. Newish to reloading and worked up 39 through 42 varget on 178 ELDM’s. I grouped best at 42. Hornady considers it hot at 42.4. At 42 I’m getting about a 2400 average. Can I push this at all safely? Yes, I get it; Hornady publishes X numbers for a reason, but I venture to guess they really error on the low side to not subject themselves to liability. I’ve read a few ppl going up to 45 no problems, but wanted to get input. Tikka UPR 24” barrel. Thx

Similar threads

- Replies

- 35

- Views

- 2K

- Replies

- 8

- Views

- 670

- Replies

- 20

- Views

- 1K

- Replies

- 0

- Views

- 2K