Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

.308 Winchester

- Thread starter Two Shoes

- Start date

Alpha is about the only 308 brass I don't have.Anyone have pet loads for alpha SRP brass, 175 SMK’s and Varget? I’m running 42.5gr Varget in LRP Lapua brass getting 2700fps and would like to stay in that range if possible.

I'd knock it down to 41.5 & shoot a few. Then measure fire case H20 to compare to whatever brass you've been using.

Depends a lot on the rifle system also. A SRP will handle a little hotter load If & big if your firing pin fit is small & or a tight fit in the bolt.

AI with large pin will handle less pressure using a SRP than LRP from what I've seen.

virgin SRP alpha brass

CCI 450

42.5gr varget

175 SMK

2.049 CBTO (have to check and will update when I get home, puts me at 20k off)

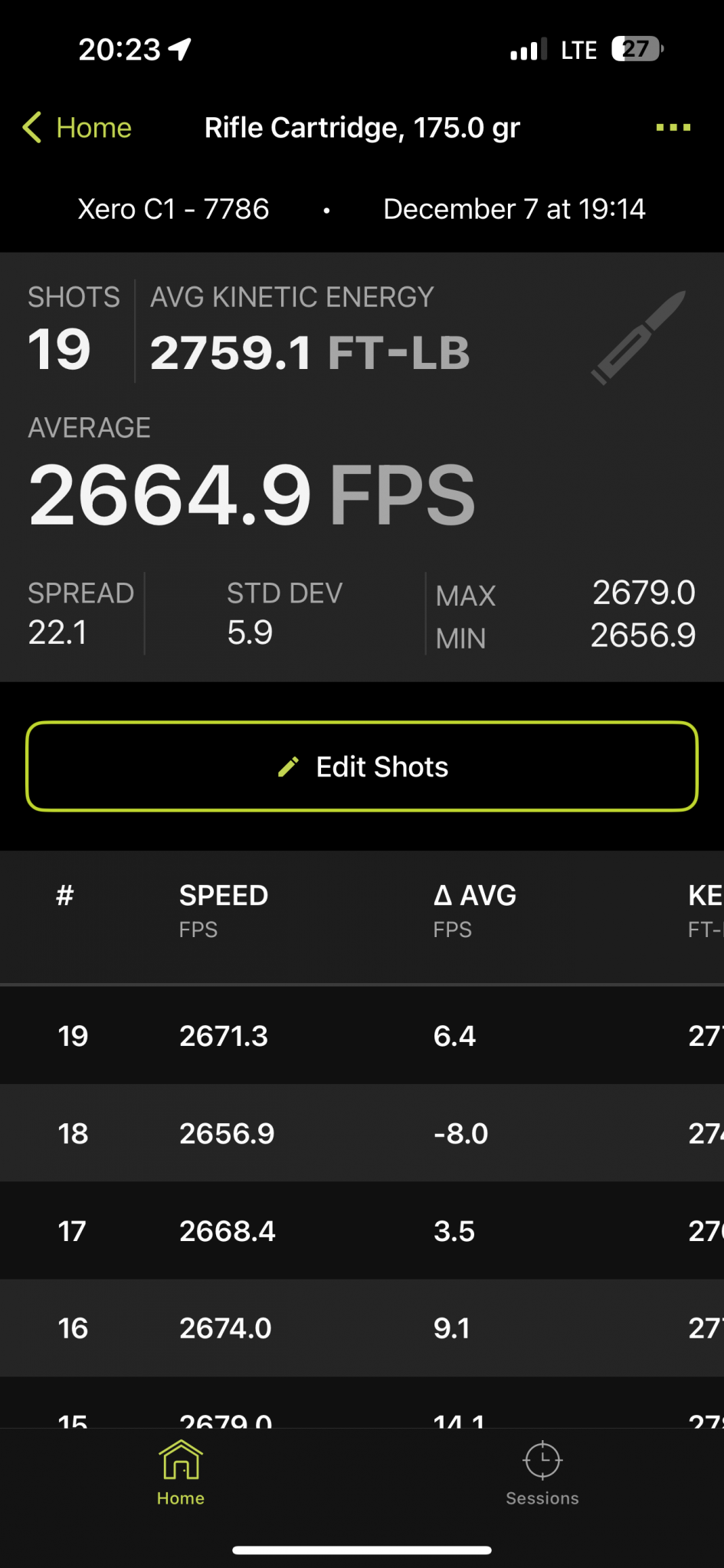

This combo in a 26” lilja 3 groove barrel yields 2665fps with an sd of 5.9 over 19 shots.

CCI 450

42.5gr varget

175 SMK

2.049 CBTO (have to check and will update when I get home, puts me at 20k off)

This combo in a 26” lilja 3 groove barrel yields 2665fps with an sd of 5.9 over 19 shots.

Where are people getting LRPs these days? Also, side note. I haven't been on SH for about 6 years. Let me know if I'm not supposed to be posting certain things.

Look at the "powder in stock" thread, it includes primers.Where are people getting LRPs these days? Also, side note. I haven't been on SH for about 6 years. Let me know if I'm not supposed to be posting certain things.

What has changes in the last few years is that you must have a supporter account to post WTB or for sale items. You can still reply to and purchase items, just can't post your stuff without supporter account.

I picked up 800 at Sportsman's Warehouse about 2 days ago ...they go fast I got the last 1000 box, the lmit, as the other guy only wanted 2 boxes of 100.Where are people getting LRPs these days? Also, side note. I haven't been on SH for about 6 years. Let me know if I'm not supposed to be posting certain things.

Talking about Varget in the 308 win 16" ...the most horrible velocity S/D, I have ever seen with any powder, ...ever, at 49.5 S/D for 5 shots. Happened a few weeks ago. Tried the next 5 after rechecking things, and that string worse at 54.6 S/D with 5 shots of weighed Varget powder. So I shot a 5 shot string with PP 2000 MR and it was 3.7 S/D. I have been noticing bad S/ D strings with my current lot of Varget, but this is the worst. I have used this powder for may years, and never experienced this...has anyone else experienced this problem with current or past lots of Varget? For me it has moved back from the top pick... this is just blasting powder.

Attachments

Talking about Varget in the 308 win 16" ...the most horrible velocity S/D, I have ever seen with any powder, ...ever, at 49.5 S/D for 5 shots. Happened a few weeks ago. Tried the next 5 after rechecking things, and that string worse at 54.6 S/D with 5 shots of weighed Varget powder. So I shot a 5 shot string with PP 2000 MR and it was 3.7 S/D. I have been noticing bad S/ D strings with my current lot of Varget, but this is the worst. I have used this powder for may years, and never experienced this...has anyone else experienced this problem with current or past lots of Varget? For me it has moved back from the top pick... this is just blasting powder.

Cartridge and situation dependent sometimes man. I feel you though.

I have used the same canister of Varget for my 6.5x47 and .223 load development. Got single digit SDs in the x47, and 3 times that in the .223. Using Lapua brass in the x47 and Starline .223 - but before we poo poo the Starline brass, I weighed, measured, and then did H2O capacity on the Starline and it was pretty damn consistent. *For the record though, my .223 Varget loads were pretty accurate at 100...just crap ES and SD.

Sometimes even the most sure thing isn't in a particular barrel.

I would play with seating depth first. Watch Eric Cortinas video on finding the lands. Super cool rifle and welcome.As a newbie to both the Forum and reloading, I would like to consult forum members on a few issues related to reloading the 308.

First of all, I am an amateur shooter, so far shooting rather with calibers: 7.62x54r, 7.62x39, 5.45x39 - using factory ammunition.

By chance, quite fortunately I recently bought a Russian Izhmash Record-1-308 rifle in .308 Win caliber. This is my first encounter with that caliber. Factory ammo is quite expensive ( I live in Europe, EU, Poland ), after shooting I am left with a factory shells, so I thought that I might try to use them and reload .308 for my rifle. Because the scale of reloading was to be rather small – after a net study and watched several YouTube videos on reloading ( I know now, it is not enough, and with a such tiny background I should not take that step – but it is too late ) – I bought a Lee Loader, thinking that it would be an inexpensive way to get a cheaper ammo.

And with a Lee Loader in one hand and a hammer in the other I’m stuck

I did not prepare the classic “ladder” of powder charges – I just focused on one, based on GRT Reloading software callculation. The first attempt to prepare ammunition, with only one powder charge selected, brought me 5-shots group of the size of 0,85 MOA at 100m. Not bad but not very good either. The problem is that having almost no knowledge of reloading, now I don't know if I should increase or decrease the powder load to make the group even tighter.

Working with a Lee Loader is not an easy task, so before I start to use the hammer again I'd like to know at least the direction - incerase or decrease the powder load?

Parameters: bullet : Hornady ELD-M 178gr, powder Lovex 73.6 - an equivalent let's say of Accurate 2520 - load : 41,15 gr, COAL : 72 mm = 2,83 inch. Shooting distance : 100 m, rifle rested on bipod, optics : PS-07 - magnification x7

View attachment 8119661

GRT software data for my "load": pressure : 3200 bar, muzzle velocity : 778 m/s, energy : 3495 J.

The rifle : Izhmash Record-1-308, cal. 308 Win, barrel : 650 mm, barrel twist 320 mm.

View attachment 8119662

My 1st time posting but been following for months. I am doing load development for a new to me 308 build. Defiance Deviant with Benchmark barrel. In process of seating an testing clambering, I am seeing light scoring on the 178 ELDs at 2.88 COL. At 2.80, no scoring. First I thought bolt marks, but it did it on first round from mag, but not when I hand feed. I am guessing just rubbing as it transitions the lift due to longer length. Any thought are appreciated.

Never seen anything like it!...Why are there 2 shoulders on the brass of the reloaded cases?My 1st time posting but been following for months. I am doing load development for a new to me 308 build. Defiance Deviant with Benchmark barrel. In process of seating an testing clambering, I am seeing light scoring on the 178 ELDs at 2.88 COL. At 2.80, no scoring. First I thought bolt marks, but it did it on first round from mag, but not when I hand feed. I am guessing just rubbing as it transitions the lift due to longer length. Any thought are appreciated. View attachment 8301816

You need to stop and investigate.... right dies? bad chamber?

Scratches or striations appear to start near if not on the bullet's tip and graduate beyond the Ogive ,that's chamber defect or something's embedded in your chamber and lands . IMO . I'd investigate that ASAP .

That is what I am thinking. I will give it a thorough cleaning to make sure nothing is lurking in there. Thank you

So ran a bunch of wet patches (Hoppes No9) and brushes, both rifling and in chamber. Before dry patching. Ran another round and marking is almost gone, so you folks were right. I am going to attack it again in the morning. I am now questioning if I cleaned it after last outing.

I am reloading some Sierra match kings in 220 gr. I'm sitting at 2.927 OAL. There is lots of space and the bullet narrows before my 168s. Is there any safety concerns to consider. This is not a compressed load. I'm wanting to run 38 grains of imr 4064. I'd also like to use my 4895. Barrel twist rate os 1 to 10 so it is fast enough to run a 220.

This will be out of a 700 aac SD tactical -20" barrel.

This will be out of a 700 aac SD tactical -20" barrel.

38 grs IMR-4064 behind that 220 gr pill should be plenty safe, even in higher temperatures . . . though it appears in my QL that pressure is very close to max. For H-4895, it looks like you might need 40grs to get an equivalent performance as the 38 grs of IMR-4064.I am reloading some Sierra match kings in 220 gr. I'm sitting at 2.927 OAL. There is lots of space and the bullet narrows before my 168s. Is there any safety concerns to consider. This is not a compressed load. I'm wanting to run 38 grains of imr 4064. I'd also like to use my 4895. Barrel twist rate os 1 to 10 so it is fast enough to run a 220.

This will be out of a 700 aac SD tactical -20" barrel.

I am reloading some Sierra match kings in 220 gr. I'm sitting at 2.927 OAL. There is lots of space and the bullet narrows before my 168s. Is there any safety concerns to consider. This is not a compressed load. I'm wanting to run 38 grains of imr 4064. I'd also like to use my 4895. Barrel twist rate os 1 to 10 so it is fast enough to run a 220.

This will be out of a 700 aac SD tactical -20" barrel.

Why 220s? The only data I've seen is for subsonic loads. Those are what I use in my 300 PRC with I think 78gr of H1000 or some other giant pile of powder.

The heaviest I've gone in 308 was 190smk/208amax using 41-41.5 grains of varget seated long maybe 2.83-2.85 it's been awhile.

I have used everything from 100 gr to 250 Atip in 308 Win.

For LR I prefer 200 gr to 230 gr match, 9 and 8 twist barrels. My barrels are 16" to 30", 12, 11.25, 10, 9, & 8, twists, auto & bolt. A 308 200 can connect at 3000 yds, as seen on video, longer than most will ever try, with 200 gr bullets.

I shoot 208 eldm at 2442 fps in a 16" AR 10, 308. The 18" & 16" AR 10s shoot close to the same speed and have shot 250 Atips out of them for fun at 2219 fps and 225 ELDM around 2450 fps. The twist is too slow for the 250 gr except short range.

I find the in 308 a 22" bolt bolt gun 9 twist to be the most versatile 7.5 lbs shooting 230 SMK 2550 fps with good accuracy, or 200 gr SMK at 2740 fps. The heavy Aluminum chassis Bartleins 30" 8 twist 308 is best suited for LR prone shooting with 200 to 230 gr bullets, velocities 2856 fps for the 200 & 2620 fps for 230, 2675 fps for 225 gr.

To get the velocity up to 2500 fps for the 250 Atip would require even longer throated barrel, but allow too much jump for the lighter bullets. But it will do 2400 now .

Heavy bullets high BC bullets 200 grs and above plus new powders bring new life to the 308 Win...not to mention SS hybrid case can be formed for 80,000 psi experience.

For more standard loads the new 169 gr and 177 gr SMK higher BC and shoot very well in the 6 lb 3 oz 16" barreled 308 AR 10, lighter than most AR 15s, good for about 1200 yds.

For LR I prefer 200 gr to 230 gr match, 9 and 8 twist barrels. My barrels are 16" to 30", 12, 11.25, 10, 9, & 8, twists, auto & bolt. A 308 200 can connect at 3000 yds, as seen on video, longer than most will ever try, with 200 gr bullets.

I shoot 208 eldm at 2442 fps in a 16" AR 10, 308. The 18" & 16" AR 10s shoot close to the same speed and have shot 250 Atips out of them for fun at 2219 fps and 225 ELDM around 2450 fps. The twist is too slow for the 250 gr except short range.

I find the in 308 a 22" bolt bolt gun 9 twist to be the most versatile 7.5 lbs shooting 230 SMK 2550 fps with good accuracy, or 200 gr SMK at 2740 fps. The heavy Aluminum chassis Bartleins 30" 8 twist 308 is best suited for LR prone shooting with 200 to 230 gr bullets, velocities 2856 fps for the 200 & 2620 fps for 230, 2675 fps for 225 gr.

To get the velocity up to 2500 fps for the 250 Atip would require even longer throated barrel, but allow too much jump for the lighter bullets. But it will do 2400 now .

Heavy bullets high BC bullets 200 grs and above plus new powders bring new life to the 308 Win...not to mention SS hybrid case can be formed for 80,000 psi experience.

For more standard loads the new 169 gr and 177 gr SMK higher BC and shoot very well in the 6 lb 3 oz 16" barreled 308 AR 10, lighter than most AR 15s, good for about 1200 yds.

Personally can't see much point in loading anything heavier than 178 gr. in a .308 . Yet I'm not ringing steel at 1200 + yd. either ,so as the saying goes whatever floats one's boat . IF I go for REAL distance for intended purpose , I step up to My 285 gr. .338 LM load .

150, 155, 165,168 and occasionally ELD 178's , feed My 7.62x51mm weapons . IMO 30-06 has it's chamber full with flinging 220 gr. bullets .

150, 155, 165,168 and occasionally ELD 178's , feed My 7.62x51mm weapons . IMO 30-06 has it's chamber full with flinging 220 gr. bullets .

Personally can't see much point in loading anything heavier than 178 gr. in a .308 . Yet I'm not ringing steel at 1200 + yd. either ,so as the saying goes whatever floats one's boat . IF I go for REAL distance for intended purpose , I step up to My 285 gr. .338 LM load .

150, 155, 165,168 and occasionally ELD 178's , feed My 7.62x51mm weapons . IMO 30-06 has it's chamber full with flinging 220 gr. bullets .

Yup I agree. I use the 178 max in my .308s also. You can reach out pretty far even with those with the newer bullets. I have shot the 168 ELD-Ms to 1250 yards in matches. Farther for fun. I just got some 176 ATips I will be working up a load for in a new barrel I got. It's a 28" 10 twist so should be able to get them to good speed and reach out there.

That said if others want to load heavies then have fun.

Yup I agree. I use the 178 max in my .308s also. You can reach out pretty far even with those with the newer bullets. I have shot the 168 ELD-Ms to 1250 yards in matches. Farther for fun. I just got some 176 ATips I will be working up a load for in a new barrel I got. It's a 28" 10 twist so should be able to get them to good speed and reach out there.

That said if others want to load heavies then have fun.

At 3/4 of a century MY eyes aren't what they once were and neither is anything else for that matter . I still ring steel occasionally at 1177 yd. ( the farthest MY personal range allows ) . Which is actually longer than our clubs range which is 1K yd. limit ,yet we have 100- 800 yd. in 100-200 yd. increments ,as well as a drive-able access road . Mine becomes dicey in the winter and strictly Off Road .

Accuracy for ME , is 165, 278 340 and 635 Yards ,as I have target sheds established in which I can place paper targets in . That way I can record loads as to accuracy to particular weapons .

Attachments

I am *very* interested in the CX 150 for a hunting load. Please, circle back and tell us what you have learned!Yes, might be a little bit slow but it's precise and works great on dear and hogs from 30m to 200m. That's my normal shooting distances here in Germany.

Will change to CX 150grains bullets next year. Will be interesting to see how they perform.

I will post an update when tests are done, if possible.I am *very* interested in the CX 150 for a hunting load. Please, circle back and tell us what you have learned!

Missed the deadline to continue my permission for reloading, and now the LUA makes me some trouble. At the moment they are not willing to give me a new permission.

Trying to work out what may ir may not worth with 174-178gr Hornady projectiles.

I will be running 2208 (Varget), 2209 (H4350) powders for 6 NBR and 6.5cm anyway, but I'm curious, the ADI and hogdon websites only list down to 2208/Varget loads in these bullet weights, but they are fastest for pressure, has anyone run 2209/H4350 in ~178gr bullet weights successfully? I'm curious if it may match or slightly exceed the 2208 for velocity or if you run out of case capacity first.

I will be running 2208 (Varget), 2209 (H4350) powders for 6 NBR and 6.5cm anyway, but I'm curious, the ADI and hogdon websites only list down to 2208/Varget loads in these bullet weights, but they are fastest for pressure, has anyone run 2209/H4350 in ~178gr bullet weights successfully? I'm curious if it may match or slightly exceed the 2208 for velocity or if you run out of case capacity first.

Slides,

Never tried H 4350 in a 308 , mainly because I load to 2.80 (+-) "Mag length" . You might see how long you can seat a 178 HP and still chamber the round. That would require single shot reloading though.

Hornady lists Power Pro 2000 MR, along with AA TAC & 2520, as well as WW 748 at 2500 FPS **

You might read the 308 AR section here , as there are several members that list loads, mainly with Varget and the 178 BTHP.

As others have stated here , with the offerings of the ; 168 ELD-M, the 168 TMK and the 169 SMK's with their higher BC might be the way to go IF you are wanting to shoot long distances.

It might help if you told us your intended goals.

** Not sure what powders or their "down under" twins are available to you

Never tried H 4350 in a 308 , mainly because I load to 2.80 (+-) "Mag length" . You might see how long you can seat a 178 HP and still chamber the round. That would require single shot reloading though.

Hornady lists Power Pro 2000 MR, along with AA TAC & 2520, as well as WW 748 at 2500 FPS **

You might read the 308 AR section here , as there are several members that list loads, mainly with Varget and the 178 BTHP.

As others have stated here , with the offerings of the ; 168 ELD-M, the 168 TMK and the 169 SMK's with their higher BC might be the way to go IF you are wanting to shoot long distances.

It might help if you told us your intended goals.

** Not sure what powders or their "down under" twins are available to you

Trying to work out what may ir may not worth with 174-178gr Hornady projectiles.

I will be running 2208 (Varget), 2209 (H4350) powders for 6 NBR and 6.5cm anyway, but I'm curious, the ADI and hogdon websites only list down to 2208/Varget loads in these bullet weights, but they are fastest for pressure, has anyone run 2209/H4350 in ~178gr bullet weights successfully? I'm curious if it may match or slightly exceed the 2208 for velocity or if you run out of case capacity first.

Varget for 308

H4350 is too slow, save it for 6-6.5mm

I should guess Aussie's have access to ADI ,Hodgdon and VV for sure . I've been through the ADI facilities , decades ago .

Reference : H4350 is ADI AR2209 . Used to be a land owner between Glen Innes and Grafton ,spent a fair amount of time down under ( Before the greenies Ruined it ) . Split most of my off hours between Coffs Harbor and Byron Bay aka as Surfers Paradise . Timber purveyor back in them days .

Reference : H4350 is ADI AR2209 . Used to be a land owner between Glen Innes and Grafton ,spent a fair amount of time down under ( Before the greenies Ruined it ) . Split most of my off hours between Coffs Harbor and Byron Bay aka as Surfers Paradise . Timber purveyor back in them days .

Just found this on the net , I'd never even considered looking before now .

http://www.adiworldclass.com.au/powder-equivalents/

http://www.adiworldclass.com.au/powder-equivalents/

Yes it's a good chart, I will stick with ADI (Sold as Hogdon in US) unless nothing works well. Looks like the 2208 is the sensible choice, I think I have a preference for more case fill/slower powder for load generally unless there is a consensus of just use this one as per varget/2208 in BR and 2209 in 6.5cm.

12 twist 26 inch heavy varmint, shooting Sporter/FTR to 900 yards and maybe the odd pig/goat/fox. I bought a heap of ADI loaded with sierra 168s but they don't keep up with the newer ballistic tip stuff. I have some 178ELDX but may try the new 174ELD-VT Ledzep suggested they will stabilise in the 12 under normal conditions. It's still very difficult to get any popular Berger or Sierra bullets here, Hornady is reasonable supply wise. If I get real serious about FTR I will run Atips.

12 twist 26 inch heavy varmint, shooting Sporter/FTR to 900 yards and maybe the odd pig/goat/fox. I bought a heap of ADI loaded with sierra 168s but they don't keep up with the newer ballistic tip stuff. I have some 178ELDX but may try the new 174ELD-VT Ledzep suggested they will stabilise in the 12 under normal conditions. It's still very difficult to get any popular Berger or Sierra bullets here, Hornady is reasonable supply wise. If I get real serious about FTR I will run Atips.

My Lapua brass neck outside diameter loaded is .337. I use a Redding .335 and .334 bushing. That measurement is only for Lapua as the neck thickness of the brass is different for other manufacturers.I'm helping a buddy gear up for precision reloading for his .308 Win, and would appreciate some guidance on which sizes of neck bushings he should order. (My .30 cal. bushings are for turned necks.) We are currently reloading Federal (FC) cases, but he will also be obtaining Lapua brass, which will likely have thicker neck brass. He would like to order three bushings, somewhat towards the looser seating tension range. Any help appreciated.

Back again with another question. I am competing in a 1000 yard 1MOA prone match next week...my first....with my 26" 308. Using info from this site my load development ended up with Nosler case, 43.5 Varget, 178 ELDX at 2720 fps and SD of 7.3. My question is that my AB shows a elevation of 9.7 mils. Most other comments I see are in the 11 to 12 mil range. I have tested the load to 448 yards (2.4 mil) but don't want to show up as the new guy 2 or 3 mil low. Velocity is with Magnetospeed V3. Oh, 100 yard five shot group.

Attachments

You get sighters?Back again with another question. I am competing in a 1000 yard 1MOA prone match next week...my first....with my 26" 308. Using info from this site my load development ended up with Nosler case, 43.5 Varget, 178 ELDX at 2720 fps and SD of 7.3. My question is that my AB shows a elevation of 9.7 mils. Most other comments I see are in the 11 to 12 mil range. I have tested the load to 448 yards (2.4 mil) but don't want to show up as the new guy 2 or 3 mil low. Velocity is with Magnetospeed V3. Oh, 100 yard five shot group.

If so, split the difference and be high, go from there.

No one cares about your target except you, the pit puller and scorer.

Therein lies the rub. No sightseers and on a 10 inch steel plate. As it is a "fun match" fashioned after the recent YouTube Texas 1000 yard 1moa challenge, I am not too concerned, but want to show up prepared.You get sighters?

If so, split the difference and be high, go from there.

No one cares about your target except you, the pit puller and scorer.

Back again with another question. I am competing in a 1000 yard 1MOA prone match next week...my first....with my 26" 308. Using info from this site my load development ended up with Nosler case, 43.5 Varget, 178 ELDX at 2720 fps and SD of 7.3. My question is that my AB shows a elevation of 9.7 mils. Most other comments I see are in the 11 to 12 mil range. I have tested the load to 448 yards (2.4 mil) but don't want to show up as the new guy 2 or 3 mil low. Velocity is with Magnetospeed V3. Oh, 100 yard five shot group.

9.5mils sounds about right. My 18" was 12 and it was 200fps slower.

That makes me feel a bit better. Thanks9.5mils sounds about right. My 18" was 12 and it was 200fps slower.

Therein lies the rub. No sightseers and on a 10 inch steel plate. As it is a "fun match" fashioned after the recent YouTube Texas 1000 yard 1moa challenge, I am not too concerned, but want to show up prepared.

Not being a smart ass but showing up and Not have shot your load at 1K Yd. isn't being prepared , JMO no offense .

Interesting view. Guess that means that a person who doesn't have access to a 1k range except for a match shouldn't show up? Fortunately for me, the organizers are encouraging newbies. No offense taken.Not being a smart ass but showing up and Not have shot your load at 1K Yd. isn't being prepared , JMO no offense .

None taken . There is NO where You are able to fire 1K yd. ? . What about where the match is too be held ?Interesting view. Guess that means that a person who doesn't have access to a 1k range except for a match shouldn't show up? Fortunately for me, the organizers are encouraging newbies. No offense taken.

At least show up with a fouled barrel.Interesting view. Guess that means that a person who doesn't have access to a 1k range except for a match shouldn't show up? Fortunately for me, the organizers are encouraging newbies. No offense taken.

If you know the actual velocity and BC, JBM will get you on paper at 1K, I've done it many times

John

Exactly. I have too and had to do that years back when i only had a 400 yard range and going to matches that shot out to 1000+. Today you get really close with good numbers and a good ballistic program. Actually shooting at 1000is nice but not needed.

If you’re going to use JBM don’t forget to put in the atmospheric data, it affects elevation.

John

John

I am still running Strelok Pro and AB is installed on my Vortex binos. Both gather and apply weather. I noticed significant variations when applying weather. Thanks.

If you’re going to use JBM don’t forget to put in the atmospheric data, it affects elevation.

John

Need to have good environmental info for any ballistic program for it to work well. I use Hornady 4DOF now and put in the correct data as well.

Not surprising. I'm new here, but everywhere I've been on the internet regarding firearms, there seems to be 0 leniency or courtesy. I expect the same here.Scheels.

The mods will let you know with prejudice

Not surprising. I'm new here, but everywhere I've been on the internet regarding firearms, there seems to be 0 leniency or courtesy. I expect the same here.

Not sure where you have been but we are pretty lenient here and give warnings if someone does something they shouldn't be like putting for sale ads anywhere but the PX and not being a supporter or WTB ads other places but the PX. Those are two of the big ones but as long as you are not being an ass in tech forums or any hate speech in the Bear Pit you should be fine.

Similar threads

- Replies

- 37

- Views

- 2K

- Replies

- 8

- Views

- 675

- Replies

- 20

- Views

- 1K

- Replies

- 0

- Views

- 2K