Too hot to touch is 140F. Grab is 130F.I have no idea how hot a heat gun will get it but I would think just to the point of too hot to touch would be, what, 200f max?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

-

Quick Shot Challenge: What’s the most underrated gear you never leave home without?

Contest ends Wednesday, join now for the chance to win free Hide merch!

Join contest

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is bedding the AR barrel a myth? What's the best way?

- Thread starter KCode

- Start date

Armorer's school ...now I understand whats behind that keyboard .In armorer's school the instructor said if the aluminum turns white, you are too hot! This might be the only case in the known universe where white isn't always right!

Personal attack and trolling.Armorer's school ...now I understand whats behind that keyboard .

@MarinePMI

I'm not someone well-known or claim to be hot shit, but I have learned a lot of metrology doing QC, and I think the biggest step that you can do if you want to make sure the upper and the barrel are true facing together is to set up a V-block for the barrel and a dial gauge on a surface plate or other known flat (and I mean actual measured, not "I know its flat") or in a lathe if you happen to be lucky enough to have one capable of handling the piece. The dial gauge will tell you what your actual surface issues are, if any on the barrel extension, and then you can repeat a similar technique using a reaction rod to spin the receiver.

file or cut as necessary.

tbh AR building and Gunsmithing as a whole share one fundamental thing with precision machining: if your setup is shit, your results will be shit. the more care you put into the front end, the easier everything gets downstream. Bedding/Truing is just part of that set up

file or cut as necessary.

tbh AR building and Gunsmithing as a whole share one fundamental thing with precision machining: if your setup is shit, your results will be shit. the more care you put into the front end, the easier everything gets downstream. Bedding/Truing is just part of that set up

Heat guns get way way hotter than that. I heat stuff up with them and melt red loctite. I’m pretty sure a hair dryer will approach or pass 200 degrees.I have no idea how hot a heat gun will get it but I would think just to the point of too hot to touch would be, what, 200f max?

thanks guys im going to try to glue on a shim and stuff it in the enhanced upper, wish me luck.

Don’t glue the shim, your just asking for a raised spot in it which will do nothing for accuracy.

Find the right size shim by mocking it up and then clean everything good with acetone and slide it in coated with 620 above and below the shim.

@Haney and @FredHammer go to your neutral corners as another post by either against the other and both are banned for a while. This shit is getting old. And neither of you PM me as I don't want to hear it.Personal attack and trolling.

As the industry moved more into slimmer and Keymod, then MLOK aluminum handguards, dudes looking to conform with trends scoffed at the AA handguards. I saw a guy tell Bill A. to his face at SHOT once, “I like your rifles, but your handguards are sh*t.” Bill remained very cordial, didn’t argue with the guy.

Looking at everything now, those cut-rifled GDRMs and GSRs are collector’s items. They just shot. If you went with the lower price-point rifles, you weren’t going to see that kind of precision and consistency, but they still were good.

The first person who made me aware of 6.5 Grendel was an instructor at SOTIC/SFARTAETC at Bragg in 2003. He was an early adopter, bought the best 24” AA Grendel he could get out of the gate. The guy had to bring in an assessor to count his safes and rifles for insurance purposes, and was a long-time long-gunner from CIF out of Okinawa, then at the School House. He said that rifle was the most accurate rifle he owned. He wasn’t prone to hype, more of a low-key, softer-spoken guy, so it didn’t make any sense what he was saying because he had a lot of laser bolt guns. He loved that Grendel.

I waited at least 5 years for the bugs to get ironed out with what I always see as beta testers, then I ordered a barrel/bolt combo from Midway in 2009. In hindsight, I wish I had bought one of the full-up billet Mega monolithic upper GDMRs or GSRs with a cut-rifled Satern pipe when they were available.

I Cerakoted a 20” one for a friend with the G10 handguard. I didn’t want to let it go back to him.

The problem with stiff handguards is they deflect the front of the receiver when you load them. Standard AR receivers deflect a lot unless you tie the receiver rail to the handguard.

I just can't resist commenting in another discussion on bedding

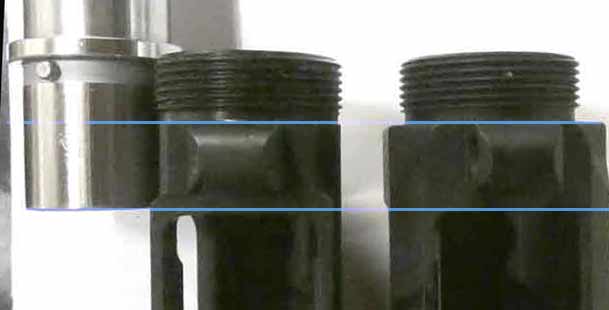

First off: Measure receiver nose I.D. for the first inch.

Unless it was machined poorly the bore will be smooth, shiny and straight for the inch that the extension fits in.

If it's at the upper end of the spec, maybe consider another upper.

Next measure extension O.D.

I've found that the end diameter being a little small. Maybe to help getting it started without dinging up the front edge of the receiver.

Now you have just enough info to decide how much heat, or shimming is needed to get a true thermal fit.

If you can slip most of the extension into the receiver, having to tap the last 1/4", this is NOT a thermal fit.

Most likely the extension is fitting tight ONLY at the thin threaded end of the receiver.

The rest of the extension, the part that just slipped in, is likely LOOSE in the bore.

Also note that most of the strength of the joint is NOT the nose but the body of the receiver.

A heavy walled receiver helps. The extension flange clamped against the receiver nose helps a LITTLE BIT in keeping things straight.

Figuring the heat/cold needed to slip the parts together requires just a little arithmetic (no algebra).

Expansion coefficients for 7075 aluminum, and barrel steel are easy to find. I'll leave that to you.

Receiver in your oven @ 200-220F, and barrel in freezer @ 4-10F should give you about 0.002" extra room to fit up

by the time you get them together and add a hand tight nut as the temperatures equalize.

I think having a "thermal fit" for the expected temperature in use, maybe 120 to 130F at the extension/chamber, not just thermal fit at room temperature will keep things tight in use. I think the upper and barrel measurements shown above could benefit from a little bit of shim stock, goop, or spray-on.

First off: Measure receiver nose I.D. for the first inch.

Unless it was machined poorly the bore will be smooth, shiny and straight for the inch that the extension fits in.

If it's at the upper end of the spec, maybe consider another upper.

Next measure extension O.D.

I've found that the end diameter being a little small. Maybe to help getting it started without dinging up the front edge of the receiver.

Now you have just enough info to decide how much heat, or shimming is needed to get a true thermal fit.

If you can slip most of the extension into the receiver, having to tap the last 1/4", this is NOT a thermal fit.

Most likely the extension is fitting tight ONLY at the thin threaded end of the receiver.

The rest of the extension, the part that just slipped in, is likely LOOSE in the bore.

Also note that most of the strength of the joint is NOT the nose but the body of the receiver.

A heavy walled receiver helps. The extension flange clamped against the receiver nose helps a LITTLE BIT in keeping things straight.

Figuring the heat/cold needed to slip the parts together requires just a little arithmetic (no algebra).

Expansion coefficients for 7075 aluminum, and barrel steel are easy to find. I'll leave that to you.

Receiver in your oven @ 200-220F, and barrel in freezer @ 4-10F should give you about 0.002" extra room to fit up

by the time you get them together and add a hand tight nut as the temperatures equalize.

I think having a "thermal fit" for the expected temperature in use, maybe 120 to 130F at the extension/chamber, not just thermal fit at room temperature will keep things tight in use. I think the upper and barrel measurements shown above could benefit from a little bit of shim stock, goop, or spray-on.

Last edited:

Intriguing! Nice postI just can't resist commenting in another discussion on bedding

First off: Measure receiver nose I.D. for the first inch.

Unless it was machined poorly the bore will be smooth, shiny and straight for the inch that the extension fits in.

If it's at the upper end of the spec, maybe consider another upper.

View attachment 8276810

Next measure extension O.D.

I've found that the end diameter being a little small. Maybe to help getting it started without dinging up the front edge of the receiver.

View attachment 8276814

Now you have just enough info to decide how much heat, or shimming is needed to get a true thermal fit.

If you can slip most of the extension into the receiver, having to tap the last 1/4", this is NOT a thermal fit.

Most likely the extension is fitting tight ONLY at the thin threaded end of the receiver.

View attachment 8276824

Also note that most of the strength of the joint is NOT the nose but the body of the receiver.

A heavy walled receiver helps.

View attachment 8276829

Do you shim, use gap filler, or both?After 20 years of pretty intense study and regular hands-on experience with AR-15s, M16s, and M4s, I thought I knew most of what there was to know about the design and its history, assembly, function, and troubleshooting. I could name every part from memory, assemble, do some general fixing, and seemed highly-competent to myself and those with less experience.

The me today would tell that me, “You don’t know jack or squat about this, but if you stay hungry and don’t stop learning, you’ll be so much farther ahead in another 20 years."

When I approach an AR-15 build now, it doesn’t even feel like I’m working on the same design. It feels like literally different lifetimes between that me and me now.

One main thing that’s different, besides all the tools and techniques I’ve acquired along the way, are the availability of parts I personally have on-hand. I keep as many uppers and barrels around, so when I go to assemble once the barrel specs have met what I’m looking for, I can closely match the OD of the extension to the ID of the tunnel in the upper by checking several different uppers.

I don’t have to be pigeonholed into one upper that I ordered, so that starts off the tight fitment however I want. The tightest one I ever did took me at least 45 minutes to get the extension seated in the upper. That was a 12” Grendel pipe in a 2A Armament Balios Lite upper. It shot great right out the gate with 123gr ELD-M, 5rd groups into .75 to .9 MOA, which is hard to do with a lightweight build pushing that projectile weight.

There is a whole different world in the material science and processes side of things with the AR-15 that is the separator between serious manufacturing and amateur assembly. I try to take it as serious as an aerospace project, since the materials and components that are core to the AR-10 and AR-15 came from Stoner’s experiences in the aerospace sector. Aircraft aluminum (receivers) and hydraulic lines (gas tube). It’s a genius design that nobody has been able to best when looking at weight, balance, accuracy, and reliability for self-loaders.

Much of the industry is actually going backwards in time away from it, not forwards.

How would you go a out shimming a Seekins or Aero upper that has the internal threads instead of a conventional external threads. There is no way to hold the shim in place otherwise. The reinforced receiver covers the extension before it enters the housing. I think gluing the shims would be the only way to even have a chance or just avoid shimming altogether on those.Don’t glue the shim, your just asking for a raised spot in it which will do nothing for accuracy.

Find the right size shim by mocking it up and then clean everything good with acetone and slide it in coated with 620 above and below the shim.

I know my Seekins SP10 uppers have a sloppy fit to any barrel I’ve tried so far.

Barrel removal bedded with goop;

Try it like the golf guys do when changing out a golf head, hot water.

Almost ALL glues will have reduced strength when hot.

Boil a pot of water, dip receiver, grab with an oven mitt , yank with a steady pressure.

May start to move slowly.

Don't worry, excess water will evaporate quickly.

Try it like the golf guys do when changing out a golf head, hot water.

Almost ALL glues will have reduced strength when hot.

Boil a pot of water, dip receiver, grab with an oven mitt , yank with a steady pressure.

May start to move slowly.

Don't worry, excess water will evaporate quickly.

that's one of the reasons I like the Athena Chassis, the handguard is part of the lower, so none of the force applied to the handguard ever gets transferred to the upper at all.The problem with stiff handguards is they deflect the front of the receiver when you load them. Standard AR receivers deflect a lot unless you tie the receiver rail to the handguard.

One thing I have noticed with literally every build since I started squaring faces and bedding is that it’s so much easier to zero optics and iron sights. Mounting a scope involves very minimal adjustments to be made when bore-sighting and confirming zero.I'm not someone well-known or claim to be hot shit, but I have learned a lot of metrology doing QC, and I think the biggest step that you can do if you want to make sure the upper and the barrel are true facing together is to set up a V-block for the barrel and a dial gauge on a surface plate or other known flat (and I mean actual measured, not "I know its flat") or in a lathe if you happen to be lucky enough to have one capable of handling the piece. The dial gauge will tell you what your actual surface issues are, if any on the barrel extension, and then you can repeat a similar technique using a reaction rod to spin the receiver.

file or cut as necessary.

tbh AR building and Gunsmithing as a whole share one fundamental thing with precision machining: if your setup is shit, your results will be shit. the more care you put into the front end, the easier everything gets downstream. Bedding/Truing is just part of that set up

For the last several builds, I have Cerakote applied in the extension tunnel, but the raceway foamed off so it doesn’t get any ID closing into the clearances required for carrier articulation.Do you shim, use gap filler, or both?

I personally haven’t shimmed yet, but I parts-fit with uppers so there isn’t much gap from the start. One thing that gives me pause with thermo-fit is that I can’t troubleshoot the feed ramp alignment between the extended ramps in the upper and the barrel extension ramps.

If you get overhang, you then have to blend with the two components already assembled, which means a higher likelihood of removing anodizing from the upper receiver extended ramps. I normally test-fit, take hollow point dummy cartridges and manually check to see if there is any lip catching the meplats.

I color those spots and then remove them using my advanced degree in dremology

So, either the stability is addressed top down with reinforced fontal lug/barrel nut area, or it is addressed here in a bottom approach. This is intriguing. Of what material is the lower here pictured comprised?that's one of the reasons I like the Athena Chassis, the handguard is part of the lower, so none of the force applied to the handguard ever gets transferred to the upper at all.

Yes but that thing is hideous looking!!that's one of the reasons I like the Athena Chassis, the handguard is part of the lower, so none of the force applied to the handguard ever gets transferred to the upper at all.

standard machined aluminum, it's not as heavy as you'd think, and I personally like the look so I enjoy it twice overSo, either the stability is addressed top down with reinforced fontal lug/barrel nut area, or it is addressed here in a bottom approach. This is intriguing. Of what material is the lower here pictured comprised?

I expect that with all the previously mentioned steps taken, plus the full barrel isolation it will be quite a shooter.

standard machined aluminum, it's not as heavy as you'd think, and I personally like the look so I enjoy it twice over

I expect that with all the previously mentioned steps taken, plus the full barrel isolation it will be quite a shooter.

I’ve heard the Springfield version was less than impressive in precision. But, that was Springfield.

I'm in love!standard machined aluminum, it's not as heavy as you'd think, and I personally like the look so I enjoy it twice over

I expect that with all the previously mentioned steps taken, plus the full barrel isolation it will be quite a shooter.

I’ve heard the Springfield version was less than impressive in precision. But, that was Springfield.

Leave it to Springfield Armory to advertise something as a "precision rifle" then turn around and build it with a Ballistic Advantage barrel.

And I’d be curious if the barrel has an interference fit. Certainly wasn’t bedded.Leave it to Springfield Armory to advertise something as a "precision rifle" then turn around and build it with a Ballistic Advantage barrel.

I’m late, didn’t read all of this. If the upper isn’t thermo fit I use shim stock sizes until I find an interference fit. Cut to size, add shim stock with 620 loctite and done. My ideas, not that it’s correct, shim stock makes a solid thermal fit, the 620 will fill any slight void. Done.

I used just 620 and it worked, but then it had my mind thinking, what if the barrel isn’t perfectly centered when cured. So shim stock it is.

I mean there are so many possible variables to a gun shooting/not shooting. Why not just completely take one out with very little time or money wasted to do it.

I used just 620 and it worked, but then it had my mind thinking, what if the barrel isn’t perfectly centered when cured. So shim stock it is.

I mean there are so many possible variables to a gun shooting/not shooting. Why not just completely take one out with very little time or money wasted to do it.

I've personally never shimmed and used Loctite. I measure the OD and ID and then heat the upper while measuring the expansion. I usually need a couple thousandths for a smooth seat. Maybe a couple taps with a soft hammer. I usually leave a 1/16" to 1/8" gap on the bolt release side. I will use a dab of brake grease smeared in the ID to help. All of the polishing/light grinding is done beforehand obviously.

Like LRRPF52 mentioned, I find I need minimal windage when zeroing after shimming.

Like LRRPF52 mentioned, I find I need minimal windage when zeroing after shimming.

Worse still is the "modular match trigger" that they put in the base model because there's nothing "modular" or "match" about it, it's the same flat faced NiB trigger that they put in their other rifles, in all its 7+ lb glory. I think the only thing modular about is that you can take it out and put something more practical in it its place.Leave it to Springfield Armory to advertise something as a "precision rifle" then turn around and build it with a Ballistic Advantage barrel.

The ATC happens when you let the advertising department build a rifle.

Springfield armory. What do you expect from a company that has “since 1794” in their logo. Flat out lie there. So go figure.

it did not out of the box, but it did shoot reasonably well, certainly acceptable for the billing (MoA with 77gr HPBT)And I’d be curious if the barrel has an interference fit. Certainly wasn’t bedded.

Actually the Edge ATC used the LaRue MBT-2S, the regular Edge that did not use the ATC was the standard trigger. Most of your points still stand, but lets at least be accurate with the criticismsWorse still is the "modular match trigger" that they put in the base model because there's nothing "modular" or "match" about it, it's the same flat faced NiB trigger that they put in their other rifles, in all its 7+ lb glory. I think the only thing modular about is that you can take it out and put something more practical in it its place.

The ATC happens when you let the advertising department build a rifle.

Unfortunately springfield stopped making them, so you'll have to get lucky and find one on the seconadry market or still floating in a store's inventoryI'm in love!

Last edited:

I'm entirely accurate in my criticisms, there are two models of Edge ATC, the black anodized base model and tan Edge ATC Elite. The Elite received the LaRue trigger upgrade, I was referring to the black anodized base model, which does have the standard flat faced trigger.Actually the Edge ATC used the LaRue MBT-2S, the regular Edge that did not use the ATC was the standard trigger. Most of your points still stand, but lets at least be accurate with the criticisms

ah right, forgot they had 3 modelsI'm entirely accurate in my criticisms, there are two models of Edge ATC, the black anodized base model and tan Edge ATC Elite. The Elite received the LaRue trigger upgrade, I was referring to the black anodized base model, which does have the standard flat faced trigger.

So you shim for an interference fit, use heat, but no retention compound?I've personally never shimmed and used Loctite. I measure the OD and ID and then heat the upper while measuring the expansion. I usually need a couple thousandths for a smooth seat. Maybe a couple taps with a soft hammer. I usually leave a 1/16" to 1/8" gap on the bolt release side. I will use a dab of brake grease smeared in the ID to help. All of the polishing/light grinding is done beforehand obviously.

Like LRRPF52 mentioned, I find I need minimal windage when zeroing after shimming.

Correct. I cut the shim stock so there is no allowable overhang from the barrel extension, and I use a small piece of masking tape to hold the shim on the extension as I slide the barrel into the expanded upper. To help keep the whole thing together and not crunch up, I'll make sure the shim is as flat to the surface of extension as possible. That SS stock bends when you cut it and is also about as sharp as a razor and it can and will crunch up (my wording) if the upper isn't expanded enough. About 90% of the time it slides right in but occasionally I'll have to do it again with another piece of shim (that's why I have a box of the stuff) . I notch out the SS shim for the index pin too.So you shim for an interference fit, use heat, but no retention compound?

When I started shimming, I bought some from a seller on Fleabay but have done it enough that I didn't want to depend on anyone else and need more at the worst possible minute.

I use a heat gun and the upper is in a Odin Works upper vice block. The reason I don't use Loctite is because I doubt it would work with the heat retained by the upper and I don't want to smell it cooking. Having pulled a couple shimmed uppers apart, I cannot think some extra Loctite would make it any tighter and rigid. They are TIGHT.

Every upper receiver I have has been shimmed now (and a pile of others). I know how my rifles shot before and after (for the older guns I had built before I started shimming) and none have shot worse and with the side benefit of the barrel sitting straight with the upper. Almost no windage correction with a centered scope.

If you start out with a thermal fit upper (undersized ID that is) all of my novel is unnecessary but I prefer a certain configuration and that leaves me having to shim more often than not. It's not hard and just part of the assemby process for me.

it did not out of the box, but it did shoot reasonably well, certainly acceptable for the billing (MoA with 77gr HPBT)

…

Which you can get with all sorts of normal free floated ARs. The crazy lower-integrated-handguard did nothing for it. That is my point.

I maintain the concept has merit. If you had an "MDT ACC" AR-15 lower, you'd isolate the bipod from the upper completely and remove the outside influence on shifting POI.

Springfield had a great idea there with potential then used 30% of it.

Springfield had a great idea there with potential then used 30% of it.

Thanks.Correct. I cut the shim stock so there is no allowable overhang from the barrel extension, and I use a small piece of masking tape to hold the shim on the extension as I slide the barrel into the expanded upper. To help keep the whole thing together and not crunch up, I'll make sure the shim is as flat to the surface of extension as possible. That SS stock bends when you cut it and is also about as sharp as a razor and it can and will crunch up (my wording) if the upper isn't expanded enough. About 90% of the time it slides right in but occasionally I'll have to do it again with another piece of shim (that's why I have a box of the stuff) . I notch out the SS shim for the index pin too.

When I started shimming, I bought some from a seller on Fleabay but have done it enough that I didn't want to depend on anyone else and need more at the worst possible minute.

I use a heat gun and the upper is in a Odin Works upper vice block. The reason I don't use Loctite is because I doubt it would work with the heat retained by the upper and I don't want to smell it cooking. Having pulled a couple shimmed uppers apart, I cannot think some extra Loctite would make it any tighter and rigid. They are TIGHT.

Every upper receiver I have has been shimmed now (and a pile of others). I know how my rifles shot before and after (for the older guns I had built before I started shimming) and none have shot worse and with the side benefit of the barrel sitting straight with the upper. Almost no windage correction with a centered scope.

If you start out with a thermal fit upper (undersized ID that is) all of my novel is unnecessary but I prefer a certain configuration and that leaves me having to shim more often than not. It's not hard and just part of the assemby process for me.

I have lots of shim, but none of the Loctite 620.

I maintain the concept has merit. If you had an "MDT ACC" AR-15 lower, you'd isolate the bipod from the upper completely and remove the outside influence on shifting POI.

Springfield had a great idea there with potential then used 30% of it.

I agree. It would have been better if Chris Drake had manufactured the other variant of the chassis in his patent, the one with a long ACC-style M-lok forend and integrated Arca rail.

https://patents.google.com/patent/US20200284535A1/en

Last edited:

I'd cut a couple pieces of shim for my first time if I were you. Notch for the index pin so the shim doesn't crunch up at the last 3/16" and make you want to use foul language.Thanks.

I have lots of shim, but none of the Loctite 620.

In my earlier post where I mentioned using masking tape, I pull it off as soon as the barrel starts to slide in smoothly without any crunching up. The only hiccup I've really ran into is not expanding the upper enough and having to start over. Only once have I had to use a thinner shim because it just wouldn't fit. The .0015" shim stock is definitely easier to handle but sometimes it won't fit. In an Aero M4E1 upper, the .0015" is more times than not the correct size.

Having shimmed with and without the high temp brake grease, I don't even consider doing it without.

Which you can get with all sorts of normal free floated ARs. The crazy lower-integrated-handguard did nothing for it. That is my point.

I maintain the concept has merit. If you had an "MDT ACC" AR-15 lower, you'd isolate the bipod from the upper completely and remove the outside influence on shifting POI.

Springfield had a great idea there with potential then used 30% of it.

That's basically why I started this project, I know the idea has legs, but it would take a high attention to detail build to really get the most out of it. Still trying to decide what stock I want to put on the thing, everything else is more or less set in stone and just waiting on lead times.

I’d be very curious of results from testing with specific lbs of force applied at specific distances from the barrel nut, especially if you can reuse the upper with a different handguard attached and repeat the testing.That's basically why I started this project, I know the idea has legs, but it would take a high attention to detail build to really get the most out of it. Still trying to decide what stock I want to put on the thing, everything else is more or less set in stone and just waiting on lead times.

Can confirm. Upper you sold me is about tack driver.Old dudes response to lapping the receiver face… “ohh dear”. That’s about how I feel about it. I trust a $250K+ CNC to make the receiver face straight more than I trust a $30 lapping tool in a Milwaukee.

He makes a point about tightening the barrel nut down gripping the extension, but that’s putting more stress on the receiver and also deforming it to the barrel extension. Whether it’s enough to make a difference I don’t know but I do know that reducing stress on precision rifle components is generally a good thing.

The fact that right in the beginning of the video the dweeb admits it’s “personal” because people do it a way opposite of how he’s always done it with grease instead tells me about all I need to know.

I believe that bedding the extension and shimming it if the gap is large enough makes a difference and the results I’ve gotten supports it. I’ve taken accurate factory uppers apart and bedded them and they’ve gotten more accurate and consistent so it’s pretty apparent to me that it works.

The 620 fills everything and gets hard AF for a perfect fit. I let it cure for two days with the barrel nut just snug enough to seat everything well and then come back and torque it down. I don’t know how much PSI the extension to receiver surfaces see when it’s tightened down but I’d bet it’s not as much as the compression strength of the 620.

The one builds I’ve done used the BCM uppers. I have to deep freeze barrels and heat up the upper to get them to slide in.

Factory PSA shit is loosey goosey hot dog down a hallway.

I'll see what I can do, my 'home range' is very safety conscious so I'll need to find someplace a bit less restrictive for this and other experimental setups for other projectsI’d be very curious of results from testing with specific lbs of force applied at specific distances from the barrel nut, especially if you can reuse the upper with a different handguard attached and repeat the testing.

You may have already read it but Carlos mentioned barrel nut tightness in at least 1 of his articles about AR-15 accuracy. There was a lot of information in those articles and he went so much deeper than I ever want to go as I will never sling up for the 600 yard line.I’d be very curious of results from testing with specific lbs of force applied at specific distances from the barrel nut, especially if you can reuse the upper with a different handguard attached and repeat the testing.

Alright, done. The tape came in handy, since I was using oven mitts.

I got about 80% wrap on the extension with .0015” shim stock. This fit was already very good. I had to pummel the upper with my heat gun pretty good.

What’s everyone’s thought on barrel nut torque? I don’t have to worry about indexing for the gas tube. I went 70lbs.

I got about 80% wrap on the extension with .0015” shim stock. This fit was already very good. I had to pummel the upper with my heat gun pretty good.

What’s everyone’s thought on barrel nut torque? I don’t have to worry about indexing for the gas tube. I went 70lbs.

I like to stay under 50 ft lbs. but honestly I don’t don’t think it matters much as long you stay under the max recommended, which I think is 85 or 90. I haven’t seen any convincing data to back up the claims that less is more. Is your 80% wrap width wise or length wise concerning the shim stock?Alright, done. The tape came in handy, since I was using oven mitts.

I got about 80% wrap on the extension with .0015” shim stock. This fit was already very good. I had to pummel the upper with my heat gun pretty good.

What’s everyone’s thought on barrel nut torque? I don’t have to worry about indexing for the gas tube. I went 70lbs.

I trimmed the shim to but up against the barrel shoulder, and be just behind the feed ramps. The 80% is around the diameter.I like to stay under 50 ft lbs. but honestly I don’t don’t think it matters much as long you stay under the max recommended, which I think is 85 or 90. I haven’t seen any convincing data to back up the claims that less is more. Is your 80% wrap width wise or length wise concerning the shim stock?

Should be fine since you didn’t use and loctite, my concern doing that with loctite is if does become malleable the barrel would displace in that gap when it’s hot, and then the loctite would not return when cooled. Pure speculation though.I trimmed the shim to but up against the barrel shoulder, and be just behind the feed ramps. The 80% is around the diameter.

Should be fine since you didn’t use and loctite, my concern doing that with loctite is if does become malleable the barrel would displace in that gap when it’s hot, and then the loctite would not return when cooled. Pure speculation though.

I removed green loctite off of a barrel extension last night. It took a MAP gas torch and flat edge razor.

That’s reassuring. I’d think anyone who’s going thru this trouble would be going on the precision side of AR building and would probably never get the extension and chamber that hot anyway.I removed green loctite off of a barrel extension last night. It took a MAP gas torch and flat edge razor.

Similar threads

- Replies

- 28

- Views

- 2K

- Replies

- 8

- Views

- 510