Hey there,

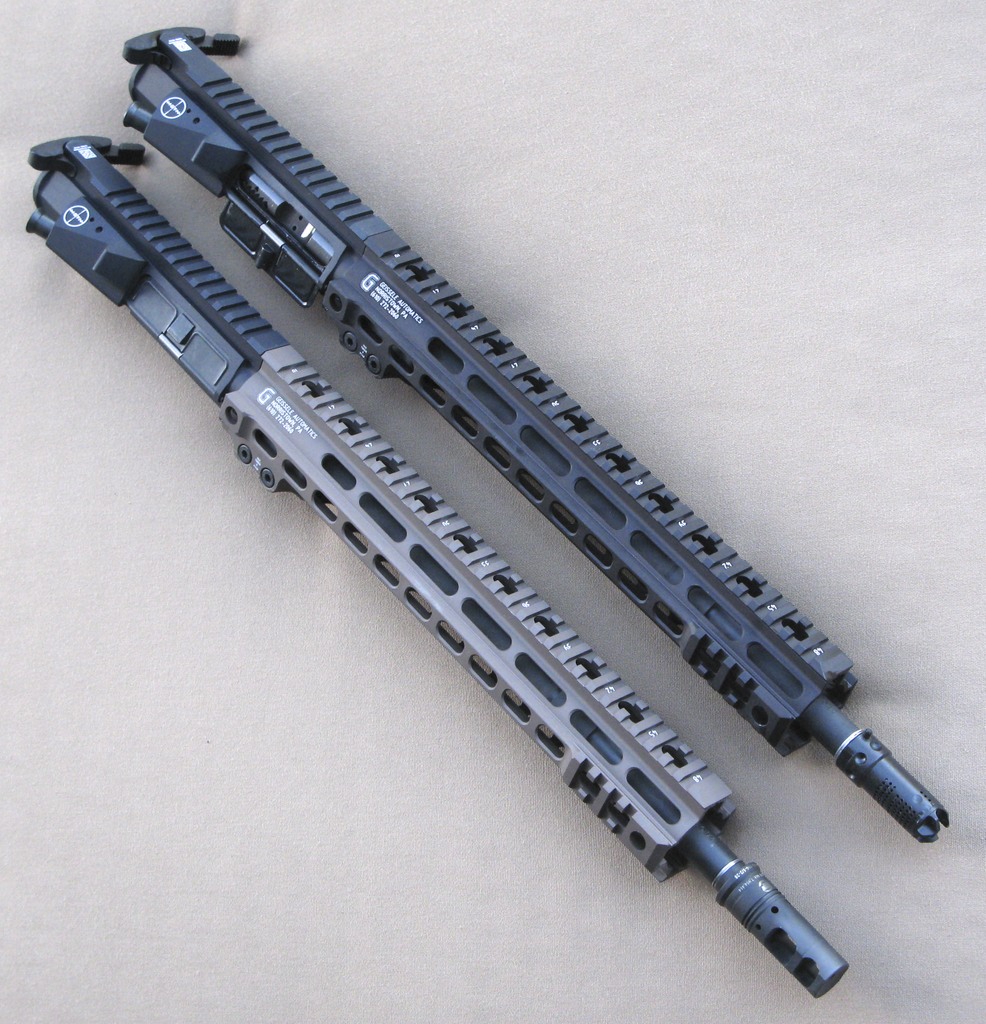

Right now I have a RRA 16" middy barrel with a mid-length fore-end, YHM flip-up front sight/gas block, etc. I've been getting an itch to change something, and thought I'd address two of the issues I have with the current setup - namely, when running suppressed I've broken a cotter pin or two in the BCG and I've managed to reach out and grab onto that front-sight/gas block once too many during a string of fire... ouch! So I was thinking about putting a rifle length tube like a Midwest Industries SSK-Keymod 15" tube or a Seekins MCSR V2 keymod rail, plus a low-profile adjustable gas block. I'm hoping the MI fore-end tube will transition to my Gemtech Trek 5.56 suppressor or a brake without looking too odd. I don't expect to want to adjust the gas block a whole lot, but I do worry about being able to reach it inside the fore-end tube. Optionally, looking into heavy buffers, CWS, that sort of thing.

Sorry if these are silly questions; I've been away from the AR scene for years and never really was that up to speed on the HS/LD stuff in the first place. Just trying to avoid making too many expensive mistakes here.

Thanks,

Monte

Right now I have a RRA 16" middy barrel with a mid-length fore-end, YHM flip-up front sight/gas block, etc. I've been getting an itch to change something, and thought I'd address two of the issues I have with the current setup - namely, when running suppressed I've broken a cotter pin or two in the BCG and I've managed to reach out and grab onto that front-sight/gas block once too many during a string of fire... ouch! So I was thinking about putting a rifle length tube like a Midwest Industries SSK-Keymod 15" tube or a Seekins MCSR V2 keymod rail, plus a low-profile adjustable gas block. I'm hoping the MI fore-end tube will transition to my Gemtech Trek 5.56 suppressor or a brake without looking too odd. I don't expect to want to adjust the gas block a whole lot, but I do worry about being able to reach it inside the fore-end tube. Optionally, looking into heavy buffers, CWS, that sort of thing.

Sorry if these are silly questions; I've been away from the AR scene for years and never really was that up to speed on the HS/LD stuff in the first place. Just trying to avoid making too many expensive mistakes here.

Thanks,

Monte

Last edited: