II have US market Sig Saur SSG 3000 Patrol 308 rifle. The stock that came with it is OK- but I would like something different. The action is right handed- but I shoot left handed. GRS can make left handed blank- and they claim many gunsmiths should be able to "inlet" the blank for my rifle. I would be getting their "laminate hybrid" model. They recommend "glass bedding". Does anyone know of someone that can inlet this blank for my rifle in Los Angeles/Orange County area- someone that does this.... and does it well?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Gunsmithing recommend gunsmith to inlet blank GRS laminate stock for SSG 3000 Patrol 308 please!

- Thread starter kip.duff

- Start date

To be honest, your action isnt a typically inletted action so I couldnt say if it could or not but I know someone you can call and ask if its doable,etc, Brad at XRing Gunworks in Phelan,Ca. Its in san bernadino area. His number is (760)646- 5584 and tell him I sent you. Hope this helps.

-Reagan

-Reagan

Thanks...To be honest, your action isnt a typically inletted action so I couldnt say if it could or not but I know someone you can call and ask if its doable,etc, Brad at XRing Gunworks in Phelan,Ca. Its in san bernadino area. His number is (760)646- 5584 and tell him I sent you. Hope this helps.

-Reagan

We/I (LRI) have the resources and bandwidth to exactly this kind of work. We do it every day because all of our full builds begin life as blank stocks. Wood, composite, alloy, ... it doesn't matter.

Modeled in software first, tested on a sample slug, then we run your piece. I've literally done thousands of these and we have a very, very large archive of receivers on file. The Sig is likely one we don't have, but its no issue at all.

Happy to help.

Here are but a few samples specific to the GRS pieces.

Panda action all ready to go from a month or two ago:

Recent build on a Nesika:

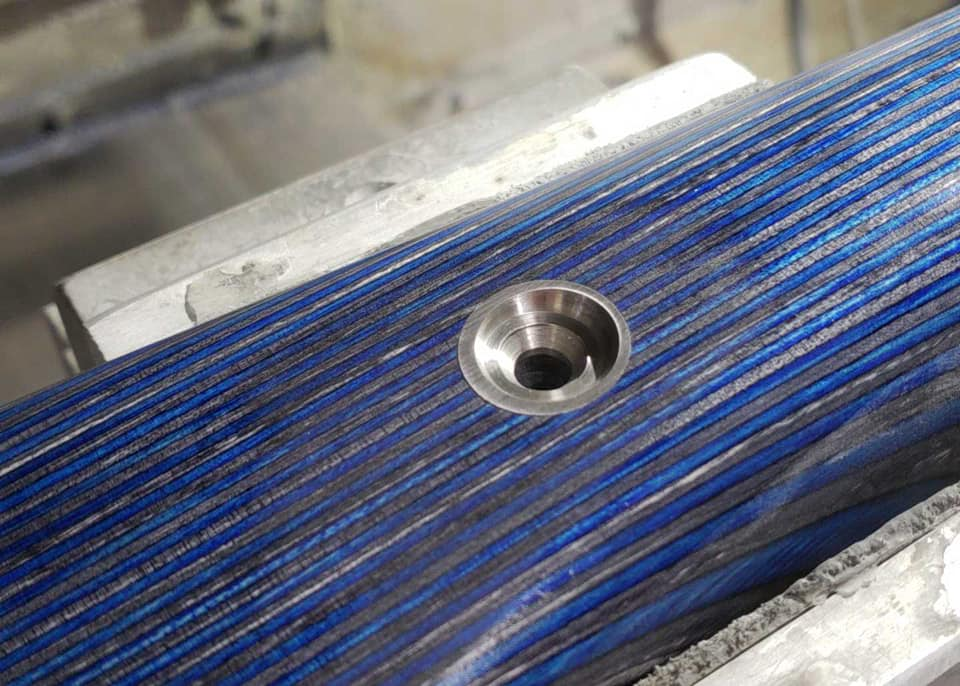

Front screw escutcheon we make:

Anschutz type rail I make fitted:

Where this all gets done:

Modeled in software first, tested on a sample slug, then we run your piece. I've literally done thousands of these and we have a very, very large archive of receivers on file. The Sig is likely one we don't have, but its no issue at all.

Happy to help.

Here are but a few samples specific to the GRS pieces.

Panda action all ready to go from a month or two ago:

Recent build on a Nesika:

Front screw escutcheon we make:

Anschutz type rail I make fitted:

Where this all gets done:

I would second LRI, Chad has done top quality work for me before. I have heard very good things about X Ring Gunworks in Phelan and one of the guys I shoot our local matches at Pala with wins matches with his rifles. But, for what you want, I'd have to give the nod to LRI, your blank stock has to be completely hogged out for the action then glass bedded and I'm pretty sure Chad will have no problem modeling and programming his CNC to mill out your stock prior to bedding. Unless X Ring Gunworks has the computer modeling software they would be doing the job by hand.

Just got back from work.

Thank you guys. And thanks LRI for glimpse into your shop- wow!

I'll be sending some pics to help you get a better idea of details of the job.

Thank you guys. And thanks LRI for glimpse into your shop- wow!

I'll be sending some pics to help you get a better idea of details of the job.

On a related subject of appearance of GRS stocks.

Obviously, in general, GRS likes to make the grain of their birch wood stocks pop, visually. It's pretty extreme, and I don't know how they are able to get those beautiful contrasts and colors. I guessing it's very popular with their customers also. For whatever reason, I think I would prefer a more subtle, typical wood appearance. Their "brown" color scheme for the Hybrid would work for me. And it's possible that if they just used clear rather than color treatment, appearance would be even more monotone and natural. Also, just plain solid semi gloss black (not tint) might be nice as an option if they would offer it. Naturally, I will probably bring this up with them- but I just wondered if anyone had advice or experience with other finishes for GRS stocks.

Also, GRS say their laminate stock finish is "oil"- is this like True Oil?

Thanks, Kip......

Obviously, in general, GRS likes to make the grain of their birch wood stocks pop, visually. It's pretty extreme, and I don't know how they are able to get those beautiful contrasts and colors. I guessing it's very popular with their customers also. For whatever reason, I think I would prefer a more subtle, typical wood appearance. Their "brown" color scheme for the Hybrid would work for me. And it's possible that if they just used clear rather than color treatment, appearance would be even more monotone and natural. Also, just plain solid semi gloss black (not tint) might be nice as an option if they would offer it. Naturally, I will probably bring this up with them- but I just wondered if anyone had advice or experience with other finishes for GRS stocks.

Also, GRS say their laminate stock finish is "oil"- is this like True Oil?

Thanks, Kip......

i found this on the GRS website....it says the oil they sell for the stock is based on Linseed oil and they mention a wax component: https://www.grsriflestocks.com/extras-and-maintenance/grs-maintenance-oil

Last edited:

The individual layers of the laminate are dyed seperately then laminated into 1 blank for the stock. I would also be interested if they could do a black and silver X-Eater.

The individual layers of the laminate are dyed seperately then laminated into 1 blank for the stock. I would also be interested if they could do a black and silver X-Eater.

OK- now makes more sense. So plain laminate like I'm interested in would actually be a simpler process. I built a laminate plinth (base) for my Garrard 301 phonograph turntable out of 8 layers of 1/2" Baltic birch. The natural colors of the wood really pop with just clear oil base or epoxy finish. Attached is a picture of what birch ply laminate can look like (mine is in shop being finished).

Black and silver... would be interesting.

i found this on the GRS website....it says the oil they sell for the stock is based on Linseed oil and they mention a wax component: https://www.grsriflestocks.com/extras-and-maintenance/grs-maintenance-oil

Linseed oil. And in your GRS link, they say it "cures". So apparently it goes from liquid state to solid- didn't know that. Two coats with sanding. Sounds like very simple system.

GBMaryland:

Nice..... I can't tell what actions you have- were you able to buy the stocks pre-inletted? Are those the Hybrid model stocks?

I just looked at the Benchmark website. They make many drop-in barrels for the Sig SSG- cool. One reason I decided to keep my SSG is because of barrel swapping feature. Intend to set up with some 6.5 round.

Nice..... I can't tell what actions you have- were you able to buy the stocks pre-inletted? Are those the Hybrid model stocks?

I just looked at the Benchmark website. They make many drop-in barrels for the Sig SSG- cool. One reason I decided to keep my SSG is because of barrel swapping feature. Intend to set up with some 6.5 round.

Those are the hybrid model stock. They are inletted by GRS, and uncharacteristically they require no bedding.

The benchmark barrels actually shoot pretty damn well and they make all sorts of barrels and magazine related stuff for the SSG 3000.

The actions are both Sig SSG 3000 actions. One of them is an older style without a Picatinny rail and the other is the version where the rail is a part of the receiver.

The SSG actions are different than other actions you would attach the stock to. Due to that unique way of mounting the action into the stock, and due to the components attached to the side of the receiver, you do not need to bed the action to the stock.

I can tell you that in both 308 and 6.5 all the bullets are one ragged hole at 100 yards.

I was planning on taking them out to Vegas and doing some distance shooting but I haven’t had time and everything shut down.

The benchmark barrels actually shoot pretty damn well and they make all sorts of barrels and magazine related stuff for the SSG 3000.

The actions are both Sig SSG 3000 actions. One of them is an older style without a Picatinny rail and the other is the version where the rail is a part of the receiver.

The SSG actions are different than other actions you would attach the stock to. Due to that unique way of mounting the action into the stock, and due to the components attached to the side of the receiver, you do not need to bed the action to the stock.

I can tell you that in both 308 and 6.5 all the bullets are one ragged hole at 100 yards.

I was planning on taking them out to Vegas and doing some distance shooting but I haven’t had time and everything shut down.

II have US market Sig Saur SSG 3000 Patrol 308 rifle. The stock that came with it is OK- but I would like something different. The action is right handed- but I shoot left handed. GRS can make left handed blank- and they claim many gunsmiths should be able to "inlet" the blank for my rifle. I would be getting their "laminate hybrid" model. They recommend "glass bedding". Does anyone know of someone that can inlet this blank for my rifle in Los Angeles/Orange County area- someone that does this.... and does it well?

by the way I have two McMillan stocks for the SSG 3000.... just in case you’re interested in either of those.

by the way I have two McMillan stocks for the SSG 3000.... just in case you’re interested in either of those.

Is this the one?

Now I'm confused. If GRS inlet a right hand Hybrid stock for SSG 3000, why not do the same for left hand Hybrid stock? I know I talked to them about this, but don't remember the exact response.... memory not what it used to be.Those are the hybrid model stock. They are inletted by GRS, and uncharacteristically they require no bedding.

I'm gonna revisit their site and review the Hybrid options.

I have that one and I have the one made for the SSG 3000 originally, which is black.

Last edited:

I have that one and I have the one made for the SSG 3000 originally, which is black.

Thanks for offer- I prefer the GRS.

View attachment 7308812View attachment 7308813

Benchmark drop in barrels, on in 308 and the other in 6.5CM.

I’m enjoying the GRS stocks....

I have separated my SSG 3000 barrel and stock to see how it is mounted. Not a lot of contact area (see pics). How does the Hybrid mount to the action? Did they install metal pillar blocks for front and rear mounting screws? Aluminum or steel? Still use the long 6mm (?) Allen head screw thru the grip? Just curious....

If you choose LRI, you should probably go ahead and have them bed the thing as well.

Laminate is nice, but it is not impervious to moisture and temperature.

Laminate is nice, but it is not impervious to moisture and temperature.

So the primary contact points are the back of the receiver and that ledge that you see on the stock.

Now someone who does this all the time could probably do a pretty good job putting some bedding compound in those key contact areas.

However they’re going to need to take the receiver completely apart, and they might even need to take the barrel out of the action... The instructions from GRS do indicate that this inlet is the only one they don’t tell you to bed.

Now someone who does this all the time could probably do a pretty good job putting some bedding compound in those key contact areas.

However they’re going to need to take the receiver completely apart, and they might even need to take the barrel out of the action... The instructions from GRS do indicate that this inlet is the only one they don’t tell you to bed.

So the primary contact points are the back of the receiver and that ledge that you see on the stock.

Now someone who does this all the time could probably do a pretty good job putting some bedding compound in those key contact areas.

However they’re going to need to take the receiver completely apart, and they might even need to take the barrel out of the action... The instructions from GRS do indicate that this inlet is the only one they don’t tell you to bed.

Truth be told I think bedding a rifle like this is going to be a waste of time. A machined inlet with pillars will be sufficient. We'll paint a layer of thin resin on the exposed material, let it sit overnight, and run the program again to clean it up. The porosity of the material will soak it up and leave a hard "crust" for the metal parts to contact.

Bedding a wood stock that is "hyper-responsive" to ambient weather is kind of a fallacy. A paper thin layer of hard resin, no matter what its made of, is not going to "hold" a stock in place should it decide to grow or shrink from a radical change in humidity. It just won't do that.

On the Anschutz rifles I used to build for the ISSF crowd it was std practice to machine a healthy bathtub around/below the receiver register and quite literally slather on what became a block of pure resin. The idea was to do exactly what your describing. I would add so much atomized aluminum filler that the bedding material behaved more like week old mashed potatoes. Very stiff, very little resin present. It worked, but one has to keep in mind that 22's in that community are very fussy when your in pursuit of a 50 shot group that does not break the circumference of a 10mm circle (50meters). It takes a 12mm gun to get on the podium. A 10mm will get you a silver or gold. 9mm does happen, but its extremely, extremely rare. I'd heard of it once on a Carl Kenyon built rig fitted with a Pat McMillan barrel using Russian Olymp ammo. I got lucky once with a gun that put down a 9.6mm string using Tennex.

The real "trick" here is to get wood that has the appropriate amount of resident moisture to begin with. Around 5-8 percent seems to be the magic number. With a laminate its probably even less as the strips are likely dried long before they are squashed together and glued in the layup. It's typically why laminates are heavier than the parent material. Glue is replacing the sap.

The "surfed" GRS pieces we've done in the past have all been holding together nicely. I have done a few now that reside in some damp places: the Pacific Northwest and the Indonesian Islands. So far so good.

C.

Last edited:

May i ask,

In this scenario there exists some extra space behind the receiver, as well as a bit in front of the receiver as well. I've identified this in my own stock.

I would imagine that the sides are more tightly held/fixed in place by the resin and stock.

If one inlets pillars...then there is a given amount of space around the bolts that secure the receiver to the stock.

Wouldn't this then lend itself to allowing for anterior/posterior movement (albeit fixed laterally) or does the resin take up that extra space as well?

thank you

In this scenario there exists some extra space behind the receiver, as well as a bit in front of the receiver as well. I've identified this in my own stock.

I would imagine that the sides are more tightly held/fixed in place by the resin and stock.

If one inlets pillars...then there is a given amount of space around the bolts that secure the receiver to the stock.

Wouldn't this then lend itself to allowing for anterior/posterior movement (albeit fixed laterally) or does the resin take up that extra space as well?

thank you

Truth be told I think bedding a rifle like this is going to be a waste of time. A machined inlet with pillars will be sufficient. We'll paint a layer of thin resin on the exposed material, let it sit overnight, and run the program again to clean it up. The porosity of the material will soak it up and leave a hard "crust" for the metal parts to contact.

Bedding a wood stock that is "hyper-responsive" to ambient weather is kind of a fallacy. A paper thin layer of hard resin, no matter what its made of, is not going to "hold" a stock in place should it decide to grow or shrink from a radical change in humidity. It just won't do that.

On the Anschutz rifles I used to build for the ISSF crowd it was std practice to machine a healthy bathtub around/below the receiver register and quite literally slather on what became a block of pure resin. The idea was to do exactly what your describing. I would add so much atomized aluminum filler that the bedding material behaved more like week old mashed potatoes. Very stiff, very little resin present. It worked, but one has to keep in mind that 22's in that community are very fussy when your in pursuit of a 50 shot group that does not break the circumference of a 10mm circle (50meters). It takes a 12mm gun to get on the podium. A 10mm will get you a silver or gold. 9mm does happen, but its extremely, extremely rare. I'd heard of it once on a Carl Kenyon built rig fitted with a Pat McMillan barrel using Russian Olymp ammo. I got lucky once with a gun that put down a 9.6mm string using Tennex.

The real "trick" here is to get wood that has the appropriate amount of resident moisture to begin with. Around 5-8 percent seems to be the magic number. With a laminate its probably even less as the strips are likely dried long before they are squashed together and glued in the layup. It's typically why laminates are heavier than the parent material. Glue is replacing the sap.

The "surfed" GRS pieces we've done in the past have all been holding together nicely. I have done a few now that reside in some damp places: the Pacific Northwest and the Indonesian Islands. So far so good.

C.

Thanks.... This would be similar to original set up- with improvement of receiver now resting (entirely?) on two metal pillars, which will mimic position of original mounting screw bores? When the two mounting screws are tightened down, would the receiver be mostly clamping to the pillars (pillars raised- not flush)- or would the contact force be distributed about the newly finished inlet as well?

So the tolerances on the stock are very tight... Picture of the back of the receiver you can see exactly how close they are.

The plastic block in the front is used to hold front of the action, and the rear ~45 degree bolt ensures the stock is properly held into the rear of the action. They do provide specific torque specs for the bolts, as well as replacement bolts / offset nut for the rear.

The SSG 3000 receiver has a pronounced lip on to that literally provides a mating surface for the action... then entire length of the action.

I found that assembly with blue loctite seemed to be all that was needed... and a torque wrench.

The plastic block in the front is used to hold front of the action, and the rear ~45 degree bolt ensures the stock is properly held into the rear of the action. They do provide specific torque specs for the bolts, as well as replacement bolts / offset nut for the rear.

The SSG 3000 receiver has a pronounced lip on to that literally provides a mating surface for the action... then entire length of the action.

I found that assembly with blue loctite seemed to be all that was needed... and a torque wrench.

Thanks. The rear mounting screw sits in the grip like original. Maybe even same length bolt. What I don't get is that black thing in front of the magazine bore. That doesn't exist on my receiver. Is that part of their stock? Front mounting screw situated inside?

thank you for taking the time to take all these photos. perhaps on black friday there will be some good sales on these stocks. i'd like very much to try one, i thought hard about purchasing a new rifle but i should probably just make this one work for me.

So the tolerances on the stock are very tight... Picture of the back of the receiver you can see exactly how close they are.

The plastic block in the front is used to hold front of the action, and the rear ~45 degree bolt ensures the stock is properly held into the rear of the action. They do provide specific torque specs for the bolts, as well as replacement bolts / offset nut for the rear.

The SSG 3000 receiver has a pronounced lip on to that literally provides a mating surface for the action... then entire length of the action.

I found that assembly with blue loctite seemed to be all that was needed... and a torque wrench.

So the plastic block comes with the stock?

Are there metal pillars where mounting screws go thru?

So the plastic block comes with the stock?

Are there metal pillars where mounting screws go thru?

Amazing how close the fit is around the receiver.

Yes, the plastic part is something specific to their stock, and is needed due to the manner in which the magazine release is situated on the SSG 3000.

As such the front bolt goes through that large plastic piece into the OEM steel stud that attaches to the front barrel bolt. The plastic piece provides a significant amount of surface area for the front part of the action, as well as a discreet place for the magazine release.

The rear bolt is not the OEM rear bolt, I think. They provide a special machined offset that attaches to the rear receiver and then the bolt goes through that offset piece of steel. Hence the reason I decided to use blue Loctite on the parts.

if you look underneath the barrel in one of the pictures you’ll note that there is extra space in there to add weight to the stock.

I always shoot with suppressors and haven’t found that necessary for the overall balance of the weapon.

As such the front bolt goes through that large plastic piece into the OEM steel stud that attaches to the front barrel bolt. The plastic piece provides a significant amount of surface area for the front part of the action, as well as a discreet place for the magazine release.

The rear bolt is not the OEM rear bolt, I think. They provide a special machined offset that attaches to the rear receiver and then the bolt goes through that offset piece of steel. Hence the reason I decided to use blue Loctite on the parts.

if you look underneath the barrel in one of the pictures you’ll note that there is extra space in there to add weight to the stock.

I always shoot with suppressors and haven’t found that necessary for the overall balance of the weapon.

Yes, the plastic part is something specific to their stock, and is needed due to the manner in which the magazine release is situated on the SSG 3000.

As such the front bolt goes through that large plastic piece into the OEM steel stud that attaches to the front barrel bolt. The plastic piece provides a significant amount of surface area for the front part of the action, as well as a discreet place for the magazine release.

The rear bolt is not the OEM rear bolt, I think. They provide a special machined offset that attaches to the rear receiver and then the bolt goes through that offset piece of steel. Hence the reason I decided to use blue Loctite on the parts.

if you look underneath the barrel in one of the pictures you’ll note that there is extra space in there to add weight to the stock.

I always shoot with suppressors and haven’t found that necessary for the overall balance of the weapon.

Jeez- this is a bit much. I may ask them if they provide that offset adapter.

They give you everything... except the blue loctite

So you got all the hardware you needed- plastic piece, rear screw adapter, correct screws, instructions?

If so, might be worth trying.

one last question.....with respect to the grip, must you wrap the thumb around the grip or is it possible to maintain your thumb aligned with the outer surface of the grip. thanks

Sorry to hijack the thread. GBMaryland what rail do you have on your older SSG 3000? I’m want to change out the original 0 MOA rail on mine.Instructions too...

grip works perfectly for me, but I have big hands.

I knew this question would come up eventually!

I ordered one from Europe, and I cant Find the name of the company. Keep in mind that the same rail can be used on the SSG 3000 as for the STR 200.

I will tell you that you want the one that I have on my rifle, because it not only uses the screws on the top of the receiver but has additional compression screws on the side of the rail to ensure that it never comes loose.

I have several extras from other manufacturers that I tried and none of them were anywhere near as decent as what I now have

I ordered one from Europe, and I cant Find the name of the company. Keep in mind that the same rail can be used on the SSG 3000 as for the STR 200.

I will tell you that you want the one that I have on my rifle, because it not only uses the screws on the top of the receiver but has additional compression screws on the side of the rail to ensure that it never comes loose.

I have several extras from other manufacturers that I tried and none of them were anywhere near as decent as what I now have

LRD | Sweden | THE LONG RANGE SHOOTING SPECIALIST

LRD Sweden is all about longrangedesign. We do basic and advanced training courses in precision long range shooting and accessories related to shooting.

www.longrangedesign.com

www.longrangedesign.com

Last edited:

i was looking through some posts. I found that Near Mfg, Spuhr and US Optics all made/make a 20MOA rail for the SIG SSG3000. you might want to call them. The posts were from a few years back.

i ended up using rings that had a 20moa slant of which there are several.

i ended up using rings that had a 20moa slant of which there are several.

Similar threads

- Replies

- 14

- Views

- 2K

- Replies

- 8

- Views

- 935

- Replies

- 16

- Views

- 3K

- Replies

- 6

- Views

- 2K