ooo this means we're getting closer to getting cuddle riflesHi,

That receiver size is not even on the stove yet to be honest. It is sitting over on the counter.

Priority list Hoplite Arms:

PRODUCTION versions of the Kopis and Apsis with the new chassis.

Finalize T&E period on the Phalanx.

PRODUCTION version of the Phalanx with the new recoil mitigating chassis.

Launch the Training Division of Hoplite Arms.

Finalize T&E period of the High Pressure Cartridges for Kopis, Aspis and Phalanx models.

PRODUCTION versions of the High Pressure Cartridges.

Enter T&E phase for the 223 platform.

Sincerely,

Theis

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hoplite Arms

- Thread starter THEIS

- Start date

- Status

- Not open for further replies.

Hi,

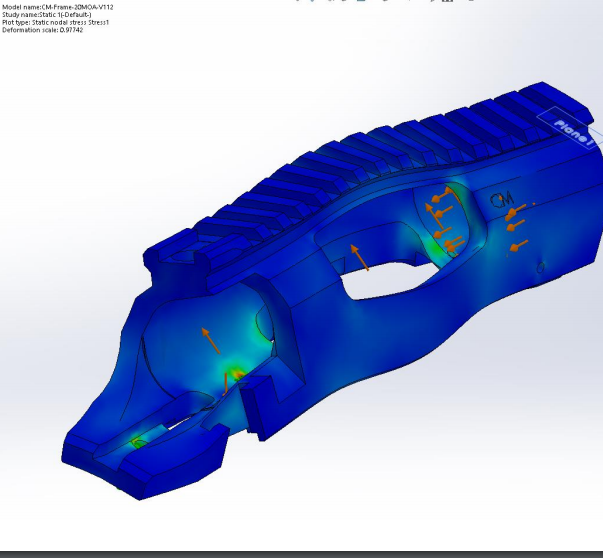

So while we are busy running all different FEA simulations....

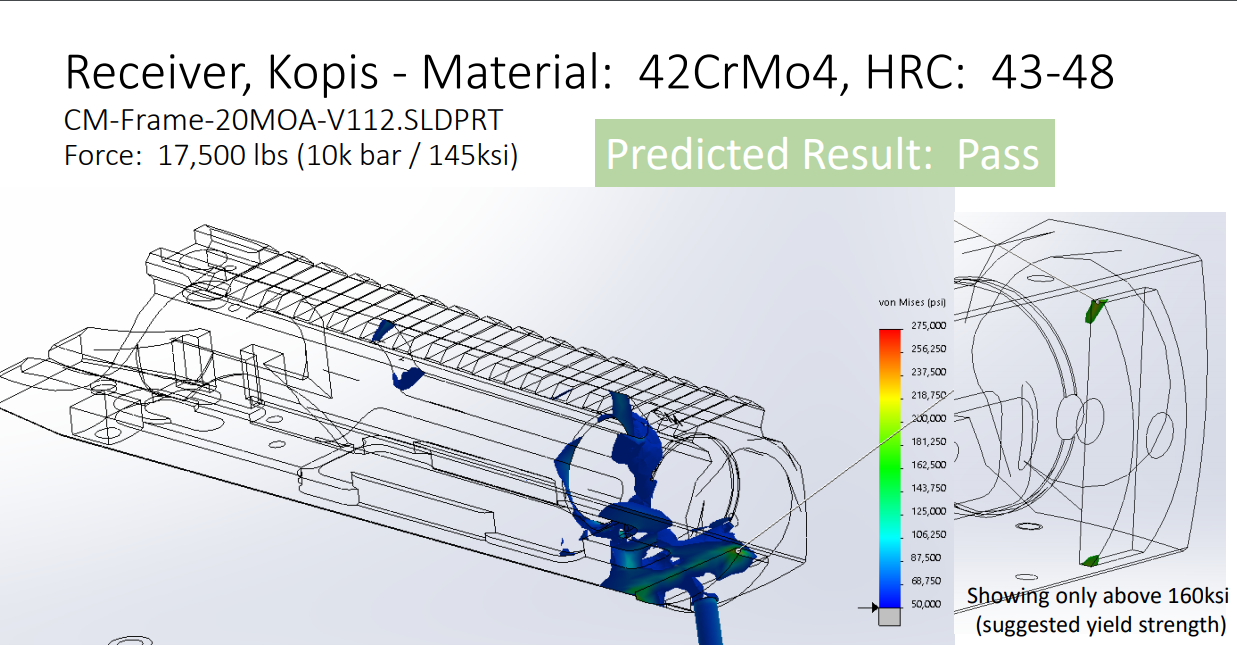

Here is the receiver body with 145k PSI (Real pressure, not cartridge pressure) put on it as a single plane static model stress.

The deformation is an exaggeration of the software. Scale is in top left corner.

Sincerely,

Theis

So while we are busy running all different FEA simulations....

Here is the receiver body with 145k PSI (Real pressure, not cartridge pressure) put on it as a single plane static model stress.

The deformation is an exaggeration of the software. Scale is in top left corner.

Sincerely,

Theis

Hi,

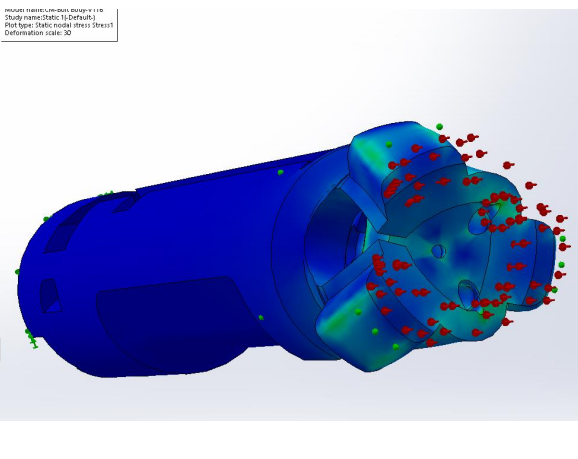

We suggest that nobody let anything much larger than an M1 Abrams run over their Hoplite Arms bolt, lolol

Here is the bolt with 145k PSI (Real pressure, not cartridge pressure) put on the entire front area as a single plane static model stress.

The deformation is an exaggeration of the software. Scale is in top left corner.

Sincerely,

Theis

We suggest that nobody let anything much larger than an M1 Abrams run over their Hoplite Arms bolt, lolol

Here is the bolt with 145k PSI (Real pressure, not cartridge pressure) put on the entire front area as a single plane static model stress.

The deformation is an exaggeration of the software. Scale is in top left corner.

Sincerely,

Theis

You're ruining all my T&E ideas hereHi,

We suggest that nobody let anything much larger than an M1 Abrams run over their Hoplite Arms bolt, lolol

Here is the bolt with 145k PSI (Real pressure, not cartridge pressure) put on the entire front area as a single plane static model stress.

The deformation is an exaggeration of the software. Scale is in top left corner.

View attachment 7344352

Sincerely,

Theis

If I ever see a receiver in person that streched out oafter a shot, I might pee myself a little. I got that it was exaggerated, but daaaaaaammmmmnn

If I remember single plane static stress transposed to a rifle rifle action would be like taking shaft the size of the bolt face (I’m guessing this is a regular short action sized bolt face 308 win) and pressing 145000psi strait down its throat.

On one linear direction, no expansion

So quick math .473” bolt face has about .178 square inches of surface area.

.178 x 145000 = 25800 pounds of force more or less.

So pretty much it looks like the bolt and receiver can handle a SHIT ton of pressure and still not fail (i don’t see any deep red colors which would usually mean material failure) or in a action catastrophic events.

Since this is a static model and doesn’t seem to have any dynamic stress or “shock” like a rifle action would when firing.

With all the dark blue throughout it pretty much means the action laughed at it.

Only stress points at the bolt lugs and even they look to not permanently deform (again if I remember the color scales). Which I would expect because they take the brunt of the reward force.

That’s ridiculously strong.

Pile up a couple of pick up trucks on a 1/2” shaft ...balance that on the bolt face and this action laughs at it.

On one linear direction, no expansion

So quick math .473” bolt face has about .178 square inches of surface area.

.178 x 145000 = 25800 pounds of force more or less.

So pretty much it looks like the bolt and receiver can handle a SHIT ton of pressure and still not fail (i don’t see any deep red colors which would usually mean material failure) or in a action catastrophic events.

Since this is a static model and doesn’t seem to have any dynamic stress or “shock” like a rifle action would when firing.

With all the dark blue throughout it pretty much means the action laughed at it.

Only stress points at the bolt lugs and even they look to not permanently deform (again if I remember the color scales). Which I would expect because they take the brunt of the reward force.

That’s ridiculously strong.

Pile up a couple of pick up trucks on a 1/2” shaft ...balance that on the bolt face and this action laughs at it.

Hi,

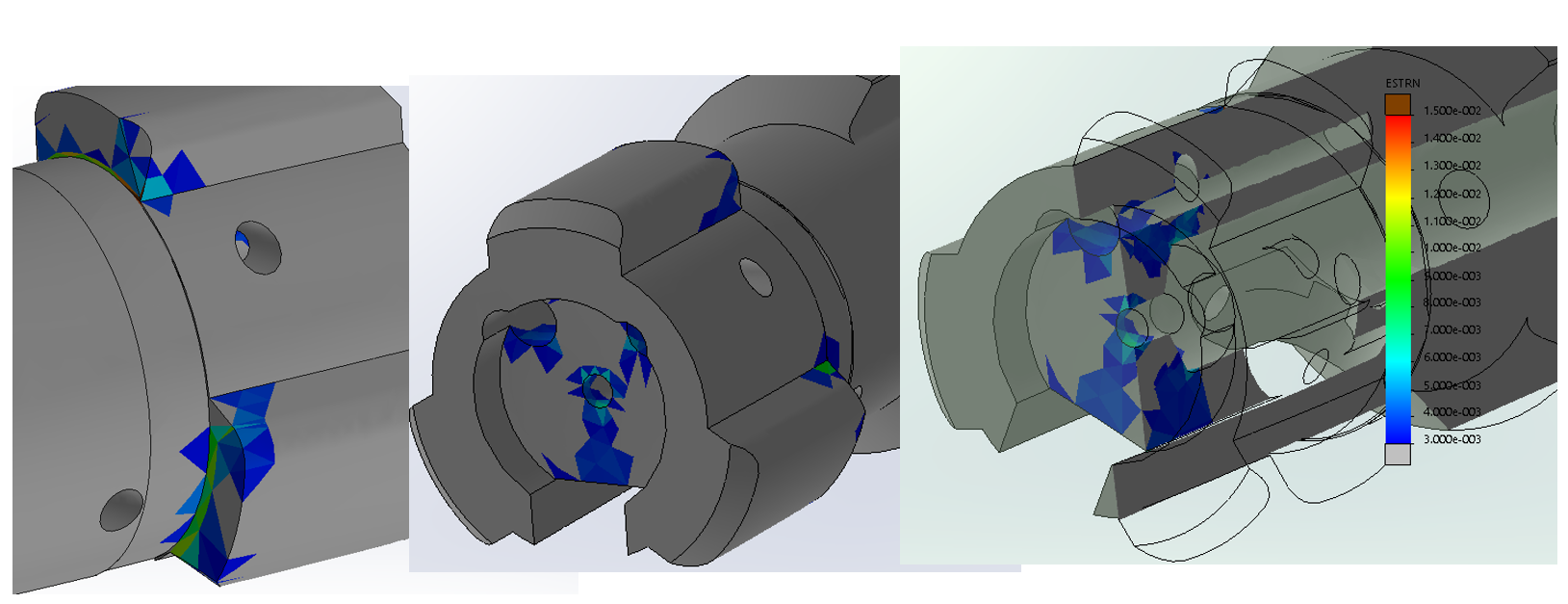

So we are running and running and running some more, lolol....

The below bolt pic is from running predicted cartridge pressure of 10k bar (145,037psi).

Kopis Bolt Strain Plot

Sincerely,

Theis

So we are running and running and running some more, lolol....

The below bolt pic is from running predicted cartridge pressure of 10k bar (145,037psi).

Kopis Bolt Strain Plot

Sincerely,

Theis

How's it feel when your creation laughs at you Theis?? It's currently saying, "That's all you got, gimme more!!" Awesome to see it holding up so wellHi,

So we are running and running and running some more, lolol....

The below bolt pic is from running predicted cartridge pressure of 10k bar (145,037psi).

Kopis Bolt Strain Plot

View attachment 7347526

Sincerely,

Theis

I’m guessing..

Gray is almost untouched / way below max

Blue/green is showing up on the scale

Orange/ red would be getting up there (I don’t see any)

Looks like the last set, those pressures aren’t even waking it up from its nap.

Correct me if I read the scale wrong.

Gray is almost untouched / way below max

Blue/green is showing up on the scale

Orange/ red would be getting up there (I don’t see any)

Looks like the last set, those pressures aren’t even waking it up from its nap.

Correct me if I read the scale wrong.

How's it feel when your creation laughs at you Theis?? It's currently saying, "That's all you got, gimme more!!" Awesome to see it holding up so well

Hi,

Thanks!!

Luckily (or unlucky, depending on how you view it, lol) for us there is not a cartridge case that can function at 145k pressures; so for right now that pressure is off limits in regards to operating pressures, hahahaha....not to mention you damn sure do not want that recoil very much.

Sincerely,

Theis

I’m guessing..

Gray is almost untouched / way below max

Blue/green is showing up on the scale

Orange/ red would be getting up there (I don’t see any)

Looks like the last set, those pressures aren’t even waking it up from its nap.

Correct me if I read the scale wrong.

Hi,

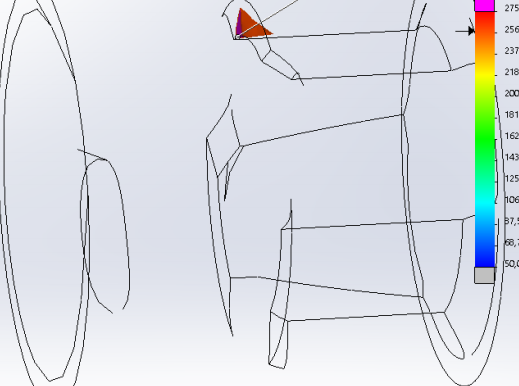

Pretty much and now for something we do not hardly ever see in the firearms industry......a company showing the "Red", lol

Here is the Kopis Bolt Stress Plot at 10k bar cartridge pressures. The red areas are above 200KSI from such cartridge pressures.

Sincerely,

Theis

With that kind of ceiling it should run those 80-90k high pressure cartridges no problem, the conventional chamberings would barely be a warm up. Very well doneHi,

Thanks!!

Luckily (or unlucky, depending on how you view it, lol) for us there is not a cartridge case that can function at 145k pressures; so for right now that pressure is off limits in regards to operating pressures, hahahaha....not to mention you damn sure do not want that recoil very much.

Sincerely,

Theis

Hi,

That receiver is one of the original birdsong coated ones.

If anyone cares to throw up videos of DLC'd receiver please do. I am really am interested to see what it holds up to.

Sincerely,

Theis

@THEIS - As I'm sure you are aware, not all DLC is created equal. There are differing application processes that can produce very different results.

For automotive racing applications only the best will live on wrist pins, valves, cams etc.

Might want to check with Industrial Hard Carbon in NC.

They were early adopters of DLC and pioneered DLC application to some of the most challenging racing parts. I can personally vouch for their quality DLC work. My experience pre dates DLC's use in firearms, but I've been to their plant in NC back when they used to call themselves Extremion.

A large percentage of Wrist pins, valves, flat tappet/billet cams, and lifters used in Nascar and NHRA were done by them back in 2007-2010 when I was last involved. It's pretty amazing to see a side by side comparison of a DLC wrist pin next to an uncoated & larger pin from a Cup car after 500 miles + with minimal oiling due to high vac dry sump. DLC looked brand new. Uncoated & larger O.D. pin galled to holly hell.

I've seen it first hand in cup shops and in Marine race engines I built after 500 plus supercharged hrs.

Firearms Suppliers: Increase RIO by Coating in DLC - Industrial Hard Carbon

When it comes to firearms, suppliers are missing an opportunity to generate ROI by coating firearms in diamond-like carbon coating. In a nutshell, by coating parts of a gun in DLC, dealers are able to guarantee a longer lifespan and less maintenance on the firearm. This then allows the firearm...

https://industrialhardcarbon.com/

For an even more cutting edge coating baliq-carbos from Balzers is worth a look.

Oerlikon Balzers unveils latest innovation: BALIQ CARBOS - beyond Diamond-Like-Carbon (DLC)

Oerlikon Balzers, Liechtenstein, August 29, 2019 – Oerlikon Balzers, a leading supplier of surface technologies, has developed new amorphous hydrogen-free carbon (a-C) coatings, BALIQ CARBOS and BALIQ CARBOS STAR, which deliver an exceptional combination of high hardness, low friction and low...

Hi,

@357Max

Do you have a POC for Oerlikon Balzers? I emailed them this past week to see if any of their USA locations were capable of processing firearm parts with the Barliq Carbos but have not heard back.

Sincerely,

Theis

Also--For those that may not have noticed; I will be updating our Genesis Ballistics Solutions thread here https://www.snipershide.com/shootin...esires-request-must-have-cannot-have.6999683/ as I have been doing this one. Some of you may not have even noticed that we have formed a separate but yet synergistic company in partnership with Patagonia Ballistics

Sincerely,

Theis

@357Max

Do you have a POC for Oerlikon Balzers? I emailed them this past week to see if any of their USA locations were capable of processing firearm parts with the Barliq Carbos but have not heard back.

Sincerely,

Theis

Also--For those that may not have noticed; I will be updating our Genesis Ballistics Solutions thread here https://www.snipershide.com/shootin...esires-request-must-have-cannot-have.6999683/ as I have been doing this one. Some of you may not have even noticed that we have formed a separate but yet synergistic company in partnership with Patagonia Ballistics

Sincerely,

Theis

Enjoying watching the progression of this...SH is proud of you, keep it up!

I'll cut the grass if I get a rifle now!Hi,

Well, no...lol

Genesis Ballistics Solutions has its' own list.

ANN (Ares News Network) has its' own list.

International and National exhibitions, demos and meetings have their own list.

Oh Ohh, and taking care of the newly seeded grass at Hoplite office facility has its' own list.

Sincerely,

Theis

The hoplite army of indentured servants.I'll cut the grass if I get a rifle now!

patiently waiting for snuggle rifles!The hoplite army of indentured servants.

View attachment 7352447

Hi,

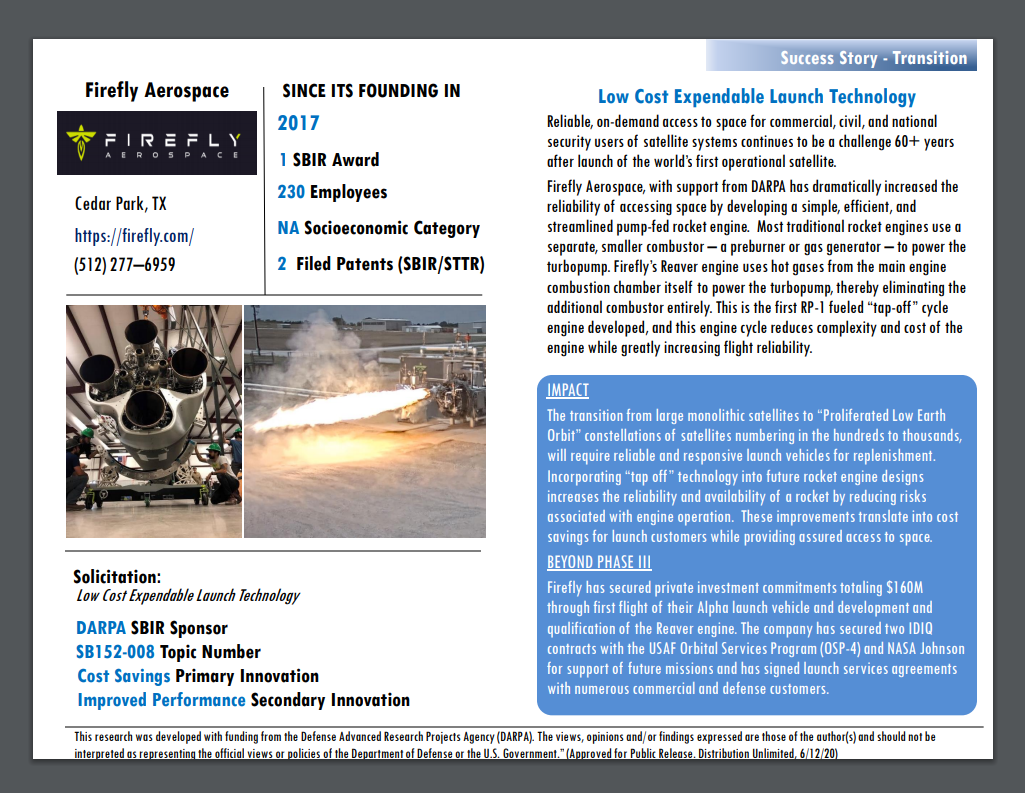

Advance Notice of OT kind of post, lol...

Just wanted to say Congrats to my friends and colleagues over a FireFly Aerospace on their DARPA program.

Now if we can just Mr. Rocketman to finish up the internal dimension specifications of a few cartridge designs to increase the ignition/combustion/burn process I will be even more excited for FireFly, haha.

Sincerely,

Theis

Advance Notice of OT kind of post, lol...

Just wanted to say Congrats to my friends and colleagues over a FireFly Aerospace on their DARPA program.

Now if we can just Mr. Rocketman to finish up the internal dimension specifications of a few cartridge designs to increase the ignition/combustion/burn process I will be even more excited for FireFly, haha.

Sincerely,

Theis

I love this idea!!!Hi,

There are 2 rifles in each case...so snug and tight is what they looked like, lolol.

Sincerely,

Theis

Hi,

Soft goods.......

Sounds like I need to get some shirts with serial numbers to match rifles and include in the purchase.

Standalone shirts would not have serial numbers

Sincerely,

Theis

Hi,

OK guys and gal, lol...

I want to take a minute to Thank and Congratulate a few more friends and Hoplite Arms family members.

I also want to take this time to introduce you all to someone that will be part of the customer journey and business brand you sometimes read me talking about.

So without further delay...

Please welcome @Jamie C to this thread, the forum and the industry in general.

She is the newly appointed (since we did not have any until her) Social Media Manager for Hoplite Arms. She handles all the business branding of the social media accounts and customer interactions on instagram and facebook right now. I will be transitioning her to SH slowly but I will be here too.

So this past weekend her and her husband attended and took part of the Spearpoint Ranch ELR match and it was a great time to see how she liked the ELR side of shooting since IIRC she had never shot past 300-600yds.

Long story short.....she made it onto the 2203yd target and liked ELR so much that she told me she was going to need a bigger gun, lolol.

Congrats on your 2203yd accomplishment and THANK YOU for taking on the social media roles.

Also Thanks to @Geno C. for talking his wife into this side of the industry for me along with that crazy long drive to show how what ELR comp was like.

Sincerely,

Theis

OK guys and gal, lol...

I want to take a minute to Thank and Congratulate a few more friends and Hoplite Arms family members.

I also want to take this time to introduce you all to someone that will be part of the customer journey and business brand you sometimes read me talking about.

So without further delay...

Please welcome @Jamie C to this thread, the forum and the industry in general.

She is the newly appointed (since we did not have any until her) Social Media Manager for Hoplite Arms. She handles all the business branding of the social media accounts and customer interactions on instagram and facebook right now. I will be transitioning her to SH slowly but I will be here too.

So this past weekend her and her husband attended and took part of the Spearpoint Ranch ELR match and it was a great time to see how she liked the ELR side of shooting since IIRC she had never shot past 300-600yds.

Long story short.....she made it onto the 2203yd target and liked ELR so much that she told me she was going to need a bigger gun, lolol.

Congrats on your 2203yd accomplishment and THANK YOU for taking on the social media roles.

Also Thanks to @Geno C. for talking his wife into this side of the industry for me along with that crazy long drive to show how what ELR comp was like.

Sincerely,

Theis

Last edited:

Thank you @THEIS! I’ve been with @Geno C. (I hope I tagged the right Geno C)  for 20 years and have been very much behind the scenes. I have attend many shoots as a spectator, and the last few years have participated. My good friend @northern50 borrowed me his 300 Norma and loaded ammo for me. I was “bullied” into shooting this weekend (thank you @duramaxman08 ). I’m so happy that they did. I had a blast! I’m hooked ❤ I’m so excited for this opportunity, and yes, I’m excited for a larger rifle

for 20 years and have been very much behind the scenes. I have attend many shoots as a spectator, and the last few years have participated. My good friend @northern50 borrowed me his 300 Norma and loaded ammo for me. I was “bullied” into shooting this weekend (thank you @duramaxman08 ). I’m so happy that they did. I had a blast! I’m hooked ❤ I’m so excited for this opportunity, and yes, I’m excited for a larger rifle

Last edited:

Sorry for late reply. For some reason I'm not getting notifications for this thread?Hi,

@357Max

Do you have a POC for Oerlikon Balzers? I emailed them this past week to see if any of their USA locations were capable of processing firearm parts with the Barliq Carbos but have not heard back.

Sincerely,

Theis

Also--For those that may not have noticed; I will be updating our Genesis Ballistics Solutions thread here https://www.snipershide.com/shootin...esires-request-must-have-cannot-have.6999683/ as I have been doing this one. Some of you may not have even noticed that we have formed a separate but yet synergistic company in partnership with Patagonia Ballistics

Sincerely,

Theis

I do not have a POC for Oerlikon Balzers. I worked with Industrial Hard Carbon in NC when they were called Extremion. At that time they did a lot of the the coating for the top Cup teams & NHRA pro stock. Coating was top shelf for sure. There was a lot of emphasis on cleanlyness of parts to be coated, they had a special cleaning procedure that left zero residue prior to coating. It was White glove lab level. I never saw a coating failure on valves, lash caps, wrist pins etc. & those parts get hammered literally!

Hi,

Almost makes me want to do a pre order group buy on stuff so I can acquire this, lolol

Sincerely,

Theis

Almost makes me want to do a pre order group buy on stuff so I can acquire this, lolol

Textron Defense | eBay

Find many great new & used options and get the best deals for Textron Defense at the best online prices at eBay! Free shipping for many products!

www.ebay.com

Sincerely,

Theis

Hi,

Almost makes me want to do a pre order group buy on stuff so I can acquire this, lolol

Textron Defense | eBay

Find many great new & used options and get the best deals for Textron Defense at the best online prices at eBay! Free shipping for many products!www.ebay.com

Sincerely,

Theis

Hoplite team mobile OAF center?

Hi,

And now back to our regular scheduled technical programming...

Sincerely,

Theis

And now back to our regular scheduled technical programming...

Sincerely,

Theis

I want one of these with the KMW Sentinel even though I cannot justify a bolt gun. The sheer quality of this product, design, and overall durability (though unfielded) writes its own justification.

A standard Rmag without SCIF certification would probably be a shit ton cheaper. But I'm just guessing. Haven't priced-shopped TSCIFs on eBay lately..

Hi,

Me neither, lol... I was searching for the MRAP Prototypes that Blackwater had built years ago because some company has acquired all the different versions Blackwater had built and selling them on Ebay, hahahaha

Sincerely,

Theis

I can build a 40 container armory etc.Hi,

Almost makes me want to do a pre order group buy on stuff so I can acquire this, lolol

Textron Defense | eBay

Find many great new & used options and get the best deals for Textron Defense at the best online prices at eBay! Free shipping for many products!www.ebay.com

Sincerely,

Theis

Ps will trade for many many rifles

Hi,

Just in case some of you do not venture into the ballistic calculator subforum very often.

Comments requested.

www.snipershide.com

www.snipershide.com

Sincerely,

Theis

Just in case some of you do not venture into the ballistic calculator subforum very often.

Comments requested.

Bullet Library----Useful or Mute Point

Hi, So we have been having some round table meetings and would like to get comments, feedback, opinions, etc etc on the topic of bullet libraries in modern ballistic application. So in order to not "sway" the direction of the conversation I am purposely withholding our internal comments...

Sincerely,

Theis

Sorry for late reply. For some reason I'm not getting notifications for this thread?

I do not have a POC for Oerlikon Balzers. I worked with Industrial Hard Carbon in NC when they were called Extremion. At that time they did a lot of the the coating for the top Cup teams & NHRA pro stock. Coating was top shelf for sure. There was a lot of emphasis on cleanlyness of parts to be coated, they had a special cleaning procedure that left zero residue prior to coating. It was White glove lab level. I never saw a coating failure on valves, lash caps, wrist pins etc. & those parts get hammered literally!

Hi,

Talked with Oerlikon and found out the Baliq-Carbos is not available in the USA.

Sincerely,

Theis

Hi,

OK, so figured it is time to play a little information game

For all the internal to external ballistic geeks.

Download the free alternative to quickload IF you do not have QL already --- Gordons Reloading Tool

Manipulate your favorite loaded cartridge (Or next closest one that the software has available to choose from) to the following pressures and post the screenshots of:

Standard Load

Load manipulated to 60k pressures

Load manipulated to 70k pressures

Load manipulated to 80k pressures

Load manipulated to 90k pressures

Sincerely,

Theis

OK, so figured it is time to play a little information game

For all the internal to external ballistic geeks.

Download the free alternative to quickload IF you do not have QL already --- Gordons Reloading Tool

Manipulate your favorite loaded cartridge (Or next closest one that the software has available to choose from) to the following pressures and post the screenshots of:

Standard Load

Load manipulated to 60k pressures

Load manipulated to 70k pressures

Load manipulated to 80k pressures

Load manipulated to 90k pressures

Sincerely,

Theis

Last edited:

It would be cool if such a thing existed.I got that. All my technology is phone based. I haven’t touched a computer in over 10 years so I was searching for an app that would do something similar to Quickload

I very rarely am using a PC any more.

I guess for some people the mobile only lifestyle works.

In my case I find it annoying every time I have to do something on a mobile style device, productivity is so much less and forget about decent multi tasking.

Even something as simple as chats / texting / group chats, I can do so much faster with an actual PC.

In my case I find it annoying every time I have to do something on a mobile style device, productivity is so much less and forget about decent multi tasking.

Even something as simple as chats / texting / group chats, I can do so much faster with an actual PC.

Download the free alternative to quickload IF you do not have QL already --- Gordons Reloading Tool

Just as an informational note, Gordon's Reloading Tool has a Linux version available for download.

I tested it on Linux Mint 20 x64 Cinnamon edition & it works fine, you just need to make sure to read the manual where it has the install instructions and do the whole long string of sudo commands and then it works.

Hi,

Almost makes me want to do a pre order group buy on stuff so I can acquire this, lolol

Textron Defense | eBay

Find many great new & used options and get the best deals for Textron Defense at the best online prices at eBay! Free shipping for many products!www.ebay.com

Sincerely,

Theis

You need that. And a driver.

Okay Boomer

So, are you an ass to people in person or just over the internet?

Hi,

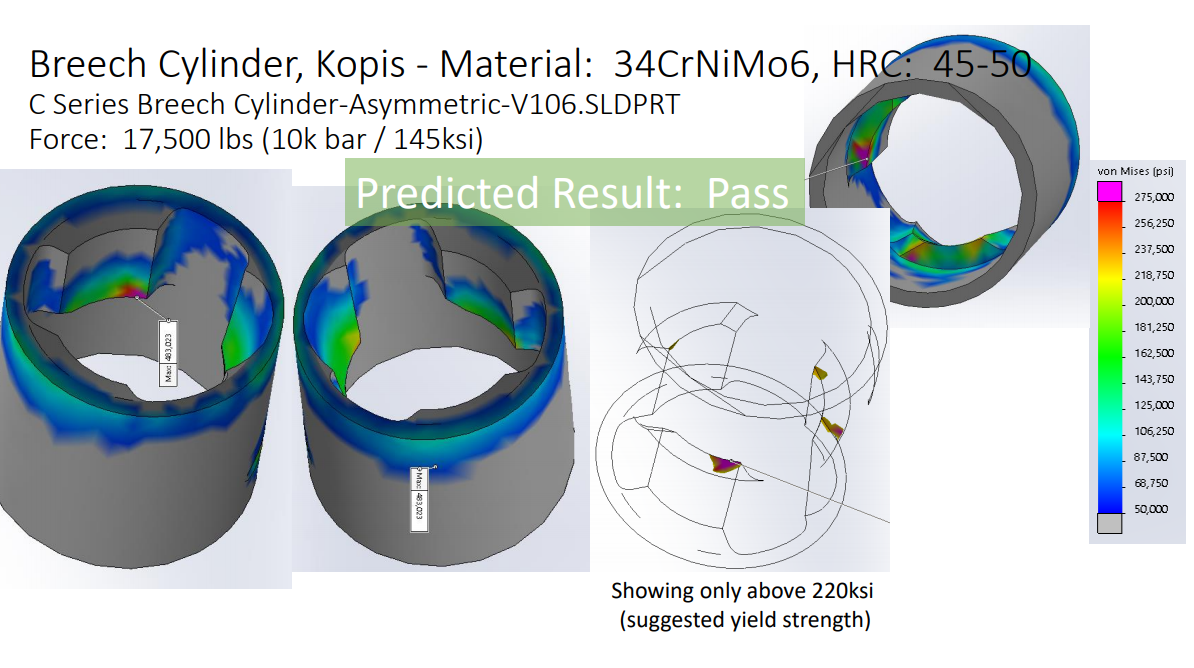

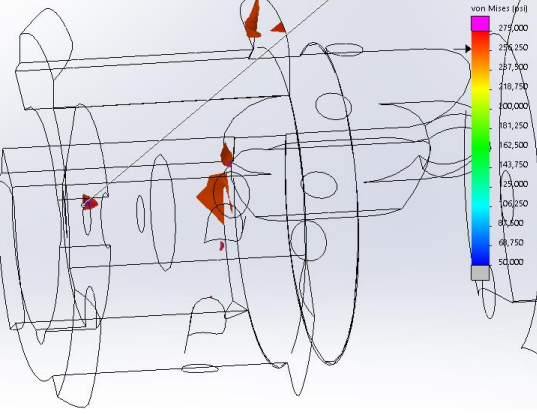

Breech cylinder and bolt FEA at 145k cartridge pressure.

That is good safety margin for the insurance company while operating at 80-85k cartridge pressures.

Sincerely,

Theis

Breech cylinder and bolt FEA at 145k cartridge pressure.

That is good safety margin for the insurance company while operating at 80-85k cartridge pressures.

Sincerely,

Theis

So how does that work for insurance?

I'd assume they require actual proof firings in a test barrel to validate FEA predictions. Do they hire 3rd party engineering consultant to evaluate FEA and test data?

Please for our entertainment, fire a solid over a crono when you do your destructive proof loads

So it looks like 256,250 psi. Is that the failure threshold? If so, 3 x safety margin over 85K, assuming FEA pressure closley correlates to actual chamber pressure.

I'd assume they require actual proof firings in a test barrel to validate FEA predictions. Do they hire 3rd party engineering consultant to evaluate FEA and test data?

Please for our entertainment, fire a solid over a crono when you do your destructive proof loads

So it looks like 256,250 psi. Is that the failure threshold? If so, 3 x safety margin over 85K, assuming FEA pressure closley correlates to actual chamber pressure.

- Status

- Not open for further replies.

Similar threads

- Replies

- 2

- Views

- 213