Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rifle Scopes Nightforce told me to use 100in/lbs on ring clamps - it broke

- Thread starter hkmp5ks

- Start date

Yes.Some of us learn our lessons the hard way.

yes indeed!

I’ve learned many painfully.

Good example of how torque wrenches used blindly can be more trouble than just tightening by feel.

It pays to think about what you are doing when using a torque wrench. If it feels like you are going tighter than what you feel is right theres a good chance something is wrong.

60 in/lbs is more than enough for the cross bolts for most rings.

It pays to think about what you are doing when using a torque wrench. If it feels like you are going tighter than what you feel is right theres a good chance something is wrong.

60 in/lbs is more than enough for the cross bolts for most rings.

I read the manual on a set of 6 screw NF rings I had. They specify 100 inch pounds for the rail clamp nuts. I never tightened them that tight, it didn't seem like a good idea. I bet if more people followed that torque rating we would hear about a lot more broken NF rings.Yeah one of them did fine at 100in/lbs the other one snapped at probably 90ish

For MOA yes, Mil you don't have to.Wait... you guys torque your scope rings?

I’m not going to pile on but get yourself some fix it sticks. And learn by your mistakes, owe by the way you might not want to announce them around here the sharks like fresh blood lol. Good luck!

Just to defend the OP a little since I'm not sure whats going on with some of the replies. He followed the Nightforce recommendation for the crossbolt and it broke. I did the same thing and if you search for about 30sec on Google this is not an uncommon thing with the 6 screw rings that call for 100 in/lbs on the cross bolt.

Just to defend the OP a little since I'm not sure whats going on with some of the replies. He followed the Nightforce recommendation for the crossbolt and it broke. I did the same thing and if you search for about 30sec on Google this is not an uncommon thing with the 6 screw rings that call for 100 in/lbs on the cross bolt.

A lot of the problem has to do with knowing how to properly apply that much torque on something with multiple bolts, you don't just go bolt by bolt and go to 100inlb in a single operation, you need to gradually tighten them in a pattern (try to stagger, so you aren't tightening adjacent bolts) to lower torque values and step your way up (say 30 on all bolts/60 on all bolts/90 on all bolts/100 on all bolts if your target is 100). Additionally, a lot of people don't know how to properly hold a torque wrench and apply even steady pressure, so they significantly over-torque bolts.

Finally, some people make the mistake of using thread locker then torquing to max specification, which leads to a significantly different outcome. You need to reduce torque by ~20% if using thread-locker, and 25% for other types of lubricants, if not more.

Either way, helicoils to the rescue for OP.

There is only one cross bolt per ring, can't really rotate from bolt to bolt when there is just one but I do agree with almost everything else.

There is only one cross bolt per ring, can't really rotate from bolt to bolt when there is just one but I do agree with almost everything else.

I should have paid more attention, I assumed this was a solid mount, not individual rings. The rest of the advice still applies aside from staggering the torque across multiple bolts! Sorry OP for the slightly off-topic info, but maybe it'll help someone else.

Holy shit, the reading comprehension around here gets worse and worse every day.

For future reference, the crossbolts on anything probably shouldn't ever see more than 65 in/lbs and the ring clamps 20-25 in/lbs unless they're ARC rings.

I ain't even mad... If it blows up, that's a Darwin award. If not, color me impressed lolThat’s ok guys, thanks for all the great advice! Definitely looking forward to setting up the Nightforce rings on my new build! Here’s a pic. Not to brag but I built a lot of it myself

I agree buff Tom SelleckI hope this is real.

I use an impact 1/2in drive. Isn’t that what everyone uses

What?For MOA yes, Mil you don't have to.

I use an impact 1/2in drive. Isn’t that what everyone uses

Yep. Ingersoll Rand 1/2” Drive Impact Wrench, 400ft-lbs of torque. Makes removing bolts a “snap”!

You don't use an iron roughneck? Weird.1” drive impact plugged into a torque multiplier then stepped down to 1/4” drive for scope ring bolts and action screws.

Fucking basement-dwelling amateurs and wanna be operators. You don’t need torque wrenches and fancy tools to mount shit. Just tighten the caps until there isn’t a gap between the caps and base. For the crossbolts, just tighten them hand-tight + 1 full wrench turn. There’s a recoil/set lug on the bottom so it won’t go anywhere. If you’re running MIL/MIL, this is all you need to do. MIL stands for military so it’s military grade and can handle these specs. If it’s MOA/MOA, it’s fucked. If MIL/MOA, it’s gender-confused and shouldn’t be used for anything.

OP,

Accidents happen and while it sucks, it’s a learning experience. Obviously you meant in/lb and not ft/lb. NF customer service will take care of ya.

Happy turkey day you disgusting children.

OP,

Accidents happen and while it sucks, it’s a learning experience. Obviously you meant in/lb and not ft/lb. NF customer service will take care of ya.

Happy turkey day you disgusting children.

350 for safety, 250 if you’re one of those peopleHow many ft/lbs for trigger adjustment screw?

unless it is a Honda Accord... warp rotors quick...ask me how I know

RTFM

Honda spec is 80 ft-lbs for all of their passenger cars

RTFM

Honda spec is 80 ft-lbs for all of their passenger cars

You're right, the fucking Honda tech should have RTFM!

^1” drive impact plugged into a torque multiplier then stepped down to 1/4” drive for scope ring bolts and action screws.

Amateur

You're right, the fucking Honda tech should have RTFM!

He should have been fired

This thread did not fail to entertain!

agreed. I enjoyed reading every single response.

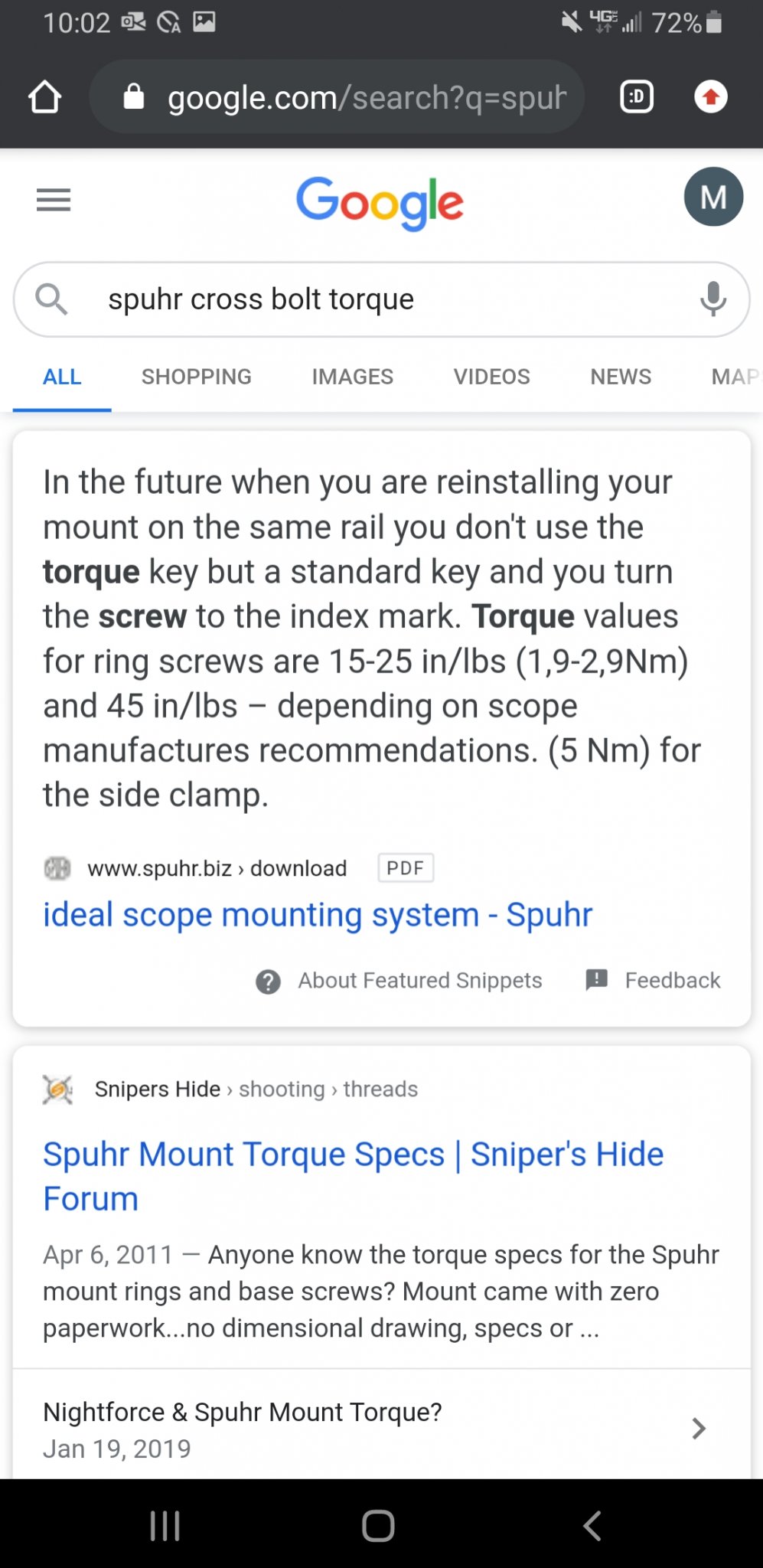

Suspicious.....just my thought but suspiciousThis is why I only buy Spuhr. Cranked my cross bolts to 150ftlbs no issues at all. Cranked the scope caps to 50ftlbs. Also no issues

I know some people go higher on big calibers like 30-06 and stuff, but I figured 50ftlb and 150ftlb should be sufficient for a 22lrSuspicious.....just my thought but suspicious

They call for in/lbs not ft/lbs he clearly stated he tighten to ft/lbs.....Just to defend the OP a little since I'm not sure whats going on with some of the replies. He followed the Nightforce recommendation for the crossbolt and it broke. I did the same thing and if you search for about 30sec on Google this is not an uncommon thing with the 6 screw rings that call for 100 in/lbs on the cross bolt.

Many people hear in/lbs but think ft/lbs because they dont deal in these things often or assume its the same thing as the torque bar they buy at lowes... its not the same

What???? You said 150ftlbs!!!!! Im sorry but I think you are digging a hole.I know some people go higher on big calibers like 30-06 and stuff, but I figured 50ftlb and 150ftlb should be sufficient for a 22lr

I highly doubt a sphur would survive 150ftlbs... trust me i use torque wrenches on machinery alot

Issa joke. Obviously not torquing anything gun related in ft lbs. Except barrels. Barrels get the ft-lb treatment. I don’t even own a ft lb torque wrench currently as I’ve never needed it. But I am very familiar with them and what 150 to 600+ ft-lbs of torque feels like (worked in a mechanic shop and now the oilfield).What???? You said 150ftlbs!!!!! Im sorry but I think you are digging a hole.

Jokes sometimes don’t translate well over the internet, sorry bout that.

They call for in/lbs not ft/lbs he clearly stated he tighten to ft/lbs.....

Many people hear in/lbs but think ft/lbs because they dont deal in these things often or assume its the same thing as the torque bar they buy at lowes... its not the same

Shit I meant in/lbs... my torque wrench doesn't do ft/lbs it's not that big. Sorry, I can see how you're all confused. Seems like the nut was problematic because the other one didn't care and it got to 100in/lbs without a problem

Gotta read past the first post sometimes. I get the obviously funny responses but there are some straight up dumb post in this thread. It is entertaining though!

I use a breaker bar when tightening anything on s gun, the only way to be sure.

Similar threads

- Replies

- 30

- Views

- 2K

Rifle Scopes

Mounting Help: Scope Rotates w/ XTR Signature Rings

- Replies

- 32

- Views

- 2K

- Replies

- 26

- Views

- 3K

- Replies

- 141

- Views

- 14K