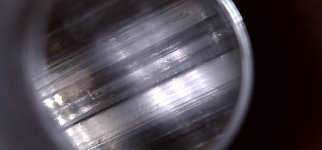

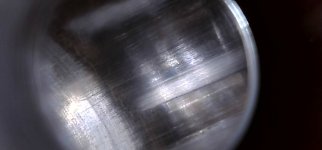

Having a hard time getting my barrel clean even after a little brushing and several cleanings. I don't really care for the sake of being clean, but I am a little worried about the dreaded carbon ring. I am shooting win 6.5 stabal , and it's pretty dang dirty shooting powder. If I were getting my barrel clean each time I wouldn't worry about it but after inspecting my cleaning or lack there of with a borescope, I'm thinking I need to change my system a bit.

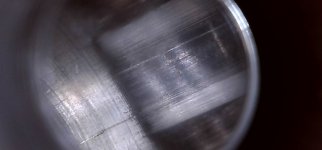

I'm afraid to use any of the abrasive stuff but I may have to if I actually want it clean. Frank's words about using the abrasive stuff like Iosso or something like it has made me not consider anything like that as an option....

Not sure where to go from here or even if I am getting it clean enough to prevent any carbon ring issues or similar issues. Had some weird pressure stuff that went on yesterday and it has me thinking about this. Could have just been the rain though....

I guess my question is "how do I know when it's clean enough" and "how can I get it cleaner without risking my barrel being messed up" ???

I'm afraid to use any of the abrasive stuff but I may have to if I actually want it clean. Frank's words about using the abrasive stuff like Iosso or something like it has made me not consider anything like that as an option....

Not sure where to go from here or even if I am getting it clean enough to prevent any carbon ring issues or similar issues. Had some weird pressure stuff that went on yesterday and it has me thinking about this. Could have just been the rain though....

I guess my question is "how do I know when it's clean enough" and "how can I get it cleaner without risking my barrel being messed up" ???