Just popping in with my build specs and results. If you were like me, you were apprehensive because there just aren't enough reports of success and plenty of videos out there trying to attribute Fuddlore theories to their shortfalls. Things like longer barrel=less accuracy, throat too long, and no-go pressure zones with less accuracy at higher speeds. If a barrel performs to a certain standard early enough, It gives me great confidence and I will advocate for it. So here's what I got:

22" Ballistic advantage with VG 6.5 brake

AR Stoner side charge upper, with left side milled as well

Aero 6.5 Grendel bolt (this is a "high pressure" bolt by the way. Small firing pin hole)

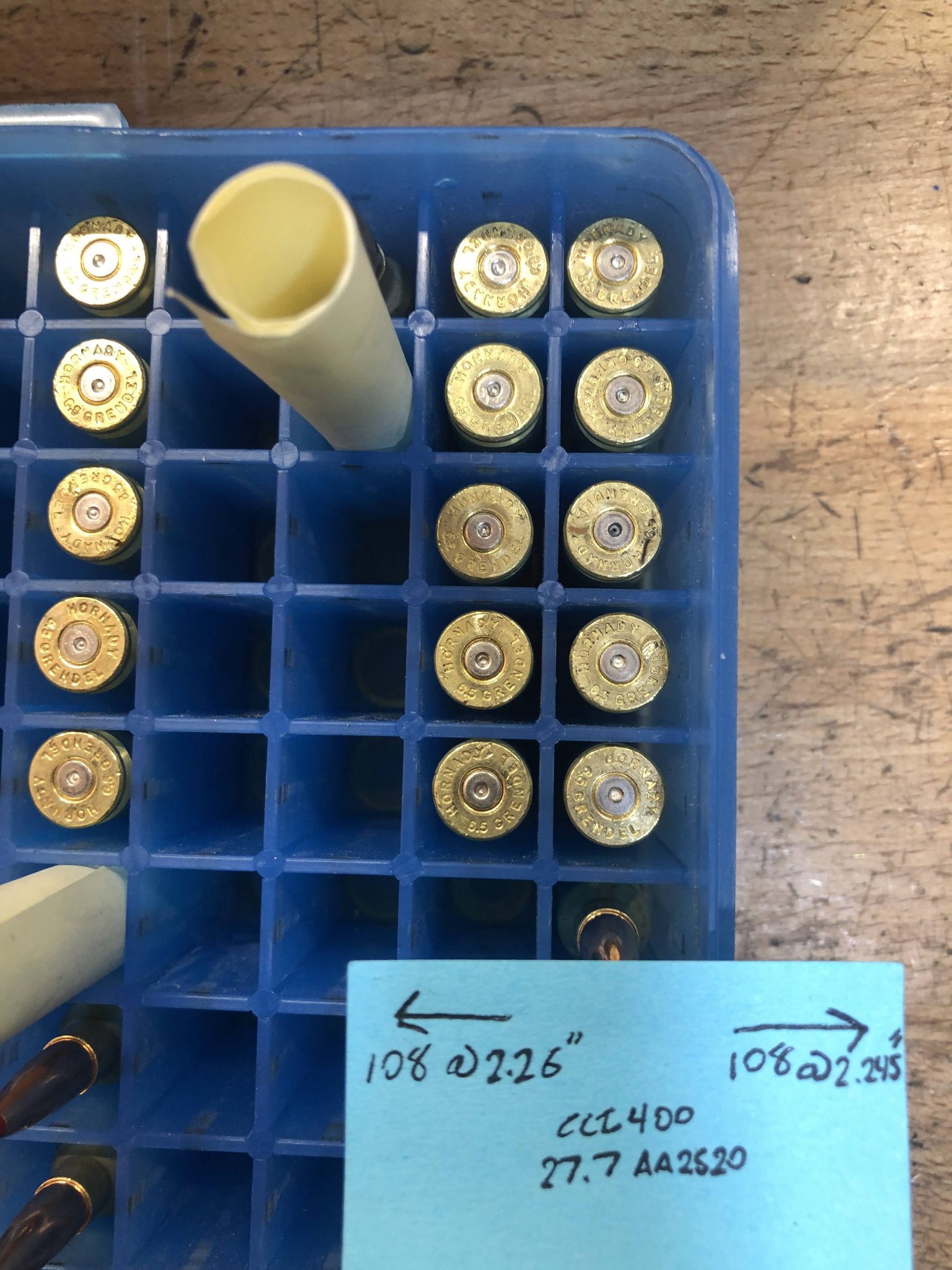

108 ELDM and Varget, AA2520 and CFE 223 tested, CCI400, Hornady 6.5 Grendel brass, first firing after conversion

Summary:

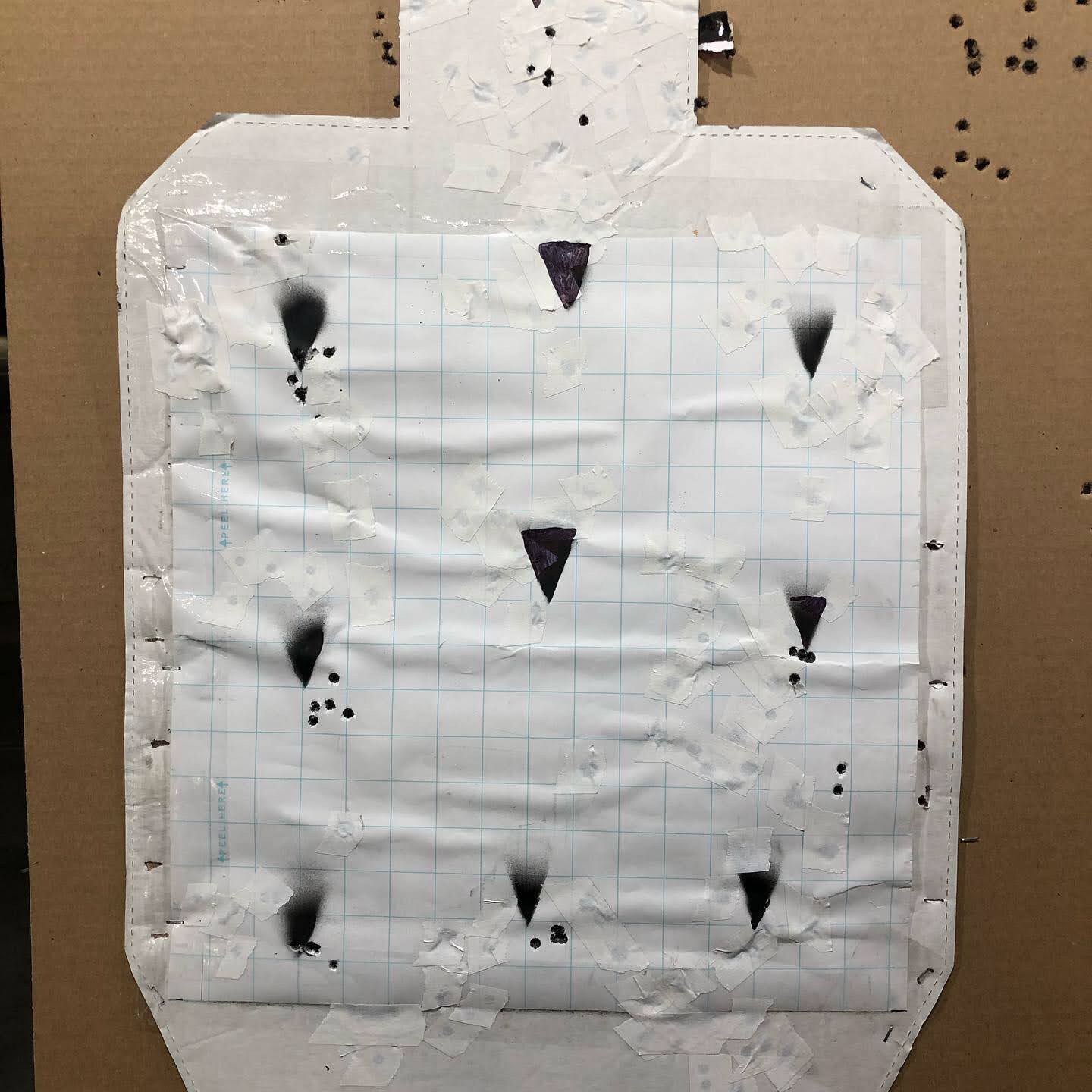

1. Ignore the published data stating 2.245" COAL... There was an obvious dispersion increase and huge pressure increase vs. 2.26"

2. The cartridge can handle 62,000 PSI just like thin bolt head 308 WIn semi autos. I have not seen many (if any) posts talking about early breakage. I am going to load as hot as this rifle can take (still below max "bolt loads") and if it breaks, I'll post about it.

3. The 108 in the Ballistic advantage wanted to make bug holes. This range session was just cruising through and seeing what works, with the first shot of each new powder falling outside the main group.

4. This build was hard to justify because I have a great 85 RDF load for my 18" 5.56... Wind and drop are not much different, but this gun will win because the groups will be less than half the size. If this was printing 1.5ish MOA groups, it would essentially be a failure. This is a super budget entry build where I really only needed a barrel, bolt, dies, and components.

The target is as follows (50m): mid left is [email protected]”/27.7 AA2520; bottom left is [email protected]”/29.2 CFE223; bottom middle is [email protected]”/27 Varget; middle right is [email protected]”/27.7 AA2520

22" Ballistic advantage with VG 6.5 brake

AR Stoner side charge upper, with left side milled as well

Aero 6.5 Grendel bolt (this is a "high pressure" bolt by the way. Small firing pin hole)

108 ELDM and Varget, AA2520 and CFE 223 tested, CCI400, Hornady 6.5 Grendel brass, first firing after conversion

Summary:

1. Ignore the published data stating 2.245" COAL... There was an obvious dispersion increase and huge pressure increase vs. 2.26"

2. The cartridge can handle 62,000 PSI just like thin bolt head 308 WIn semi autos. I have not seen many (if any) posts talking about early breakage. I am going to load as hot as this rifle can take (still below max "bolt loads") and if it breaks, I'll post about it.

3. The 108 in the Ballistic advantage wanted to make bug holes. This range session was just cruising through and seeing what works, with the first shot of each new powder falling outside the main group.

4. This build was hard to justify because I have a great 85 RDF load for my 18" 5.56... Wind and drop are not much different, but this gun will win because the groups will be less than half the size. If this was printing 1.5ish MOA groups, it would essentially be a failure. This is a super budget entry build where I really only needed a barrel, bolt, dies, and components.

The target is as follows (50m): mid left is [email protected]”/27.7 AA2520; bottom left is [email protected]”/29.2 CFE223; bottom middle is [email protected]”/27 Varget; middle right is [email protected]”/27.7 AA2520