Guess I'm off to buy me some N550.Here’s some data with N550 and the 162 eldm. 26” barrel, alpha brass, BR4s. Had a couple of errors on my chrono I’ve never had before. View attachment 8146355

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

7mm SAW

- Thread starter Temper

- Start date

I settled in at 41.5gr varget with a 162eldm out at 2.175cbto. 2740fps out of a 24” barrel. Definitely not the fastest but I get single digit ES and I can group them all in a hole as long as I can keep my shit together. I had fast speeds with 550 too but in the end I wanted temperature stability and the double base got too peaky in the warmer months.

I think I’m going to end up right around there when it’s all said and done. What was the COAL with the 162?I settled in at 41.5gr varget with a 162eldm out at 2.175cbto. 2740fps out of a 24” barrel. Definitely not the fastest but I get single digit ES and I can group them all in a hole as long as I can keep my shit together. I had fast speeds with 550 too but in the end I wanted temperature stability and the double base got too peaky in the warmer months.

I’m at 41.1 grs Varget getting 2710 fps with a 162. COAL was 2.88”.

I finally got out to do a ladder test with N550 and never quite made it to pressure. Got all the way up to 43.9 GR of N550 under a Berger 168 hybrid Hunter @ 2773 with room left to push it.

Wide node at 2750 so I may end up there but imma try to reach max velo this weekend.

In related news…

I pushed a 180 Berger out to 2810 fps with the same powder in a 7-08 AI. 2810 was as far as I could push it. It’ll be interesting to see what happens now that it’s cooled down a little here in Texas

Wide node at 2750 so I may end up there but imma try to reach max velo this weekend.

In related news…

I pushed a 180 Berger out to 2810 fps with the same powder in a 7-08 AI. 2810 was as far as I could push it. It’ll be interesting to see what happens now that it’s cooled down a little here in Texas

Last edited:

Anyone? i have a hunt this weekend and would be sweet to take my saw. Alpha will release brass this week but not enough time to get brass to me by friday.Hate to ask but can anyone spare 10 pieces of Alpha brass ? I have a backorder and they haven't released any yet.

Last edited:

After a few setbacks i have a complete rifle. A little ugly but hopefully a good shooter. Thanks to @thegotoguytx for sending some brass to headspace on and to get a load worked up for this weekends aoudad hunt! Will post some groups tomorrow.

Build specs

R700 action

24" Preferred Barrels Remage 1:8 twist

Indain Creek Design Chassis

Riton 3 Primal 3-18x50 30mm FFP

Build specs

R700 action

24" Preferred Barrels Remage 1:8 twist

Indain Creek Design Chassis

Riton 3 Primal 3-18x50 30mm FFP

Good luck on the Aoudad hunt, let us know how it goes and post pics! What bullet you gonna use?After a few setbacks i have a complete rifle. A little ugly but hopefully a good shooter. Thanks to @thegotoguytx for sending some brass to headspace on and to get a load worked up for this weekends aoudad hunt! Will post some groups tomorrow.

Build specs

R700 action

24" Preferred Barrels Remage 1:8 twist

Indain Creek Design Chassis

Riton 3 Primal 3-18x50 30mm FFP

View attachment 8252083

Thanks, Either 168 berger vld hunting or 162 eldm. Havent decided yetGood luck on the Aoudad hunt, let us know how it goes and post pics! What bullet you gonna use?

Good luck, and let us know how it performsI’ll be hunting elk in a week and a half with the 162 ELD-M. Also have a few Nosler ABLR’s for close shots, figured a bonded bullet for within 150 yds would probably be good.

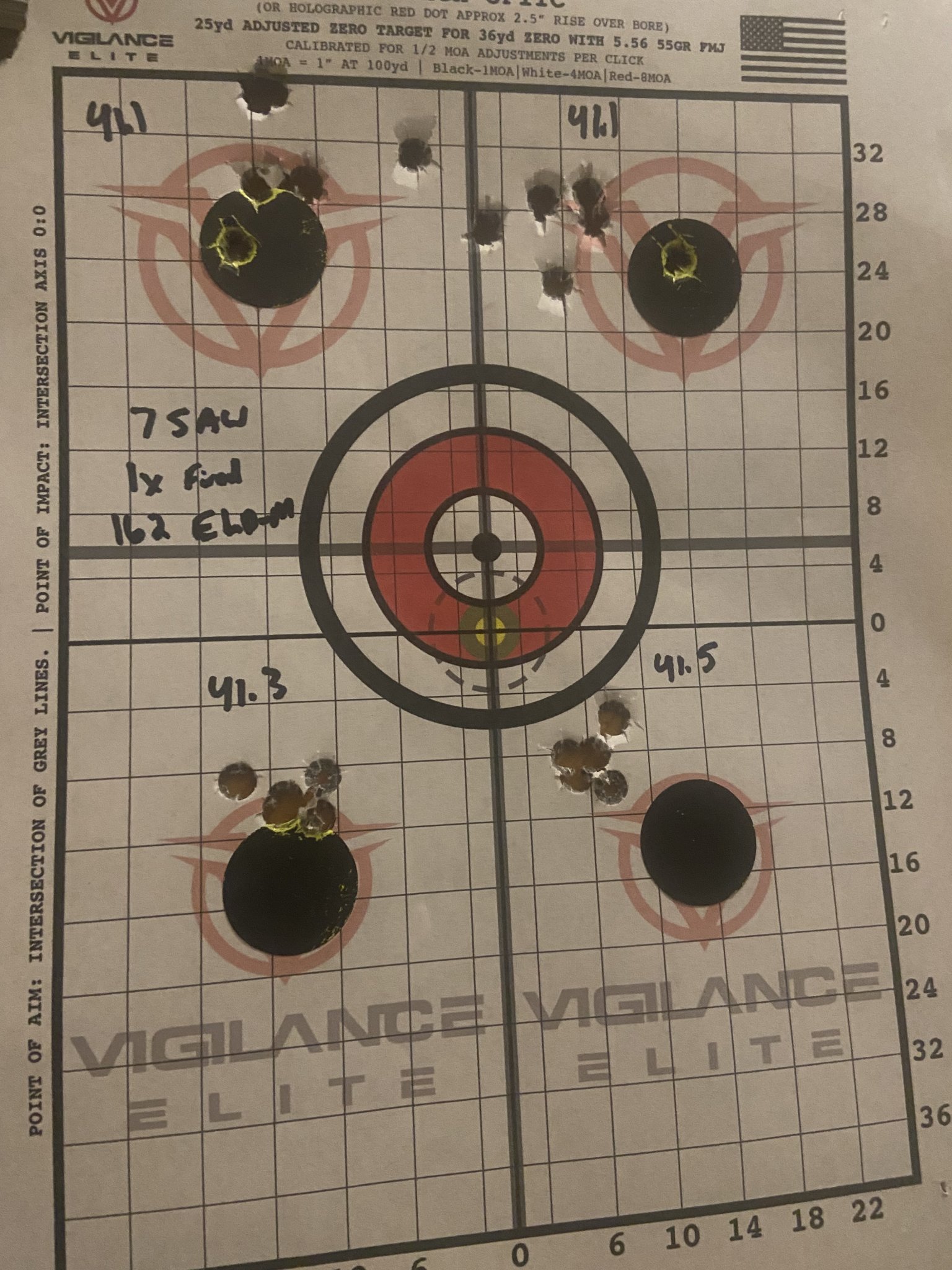

First five shots at 100 yards 162gr eldm 42gr SW Precision loaded to 2.940 oal. This will work for this weekends hunt.

Cleaned my barrel, took off suppressor, put it all back on.

Took a few rounds to settle back in, plus I forgot a rear bag so I was jimmy rigging my bino harness for support, lol.

162 ELD-M is looking good! 41.3-41.5 is definite node, great ES/SD’s.

Will probably do 41.4 grains of Varget and call it good. Gives me 2690 fps with the 162, at my altitude I still have 1500 ft lbs of energy at 625 yards and 1000 ft lbs at over 1000 yards (not that I’m shooting at animals that far).

Took a few rounds to settle back in, plus I forgot a rear bag so I was jimmy rigging my bino harness for support, lol.

162 ELD-M is looking good! 41.3-41.5 is definite node, great ES/SD’s.

Will probably do 41.4 grains of Varget and call it good. Gives me 2690 fps with the 162, at my altitude I still have 1500 ft lbs of energy at 625 yards and 1000 ft lbs at over 1000 yards (not that I’m shooting at animals that far).

Last edited:

My rifle wouldn't mag feed, i set to figure out a solution. Ordered a MDT mag without binder plate. Still had an issue with the Remington 700 action, a quick search i found that others have ground the feed lip to fix the issue. Quick fix and it feeds amazing now. Will work up some other loads and see what speeds im seeing. Deer season opens this weekend here in the Texas panhandle, goodluck everyone.

Attachments

I got you if you havent been sorted out already.Hate to ask but can anyone spare 10 pieces of Alpha brass ? I have a backorder and they haven't released any yet.

I had a fellow member help me out. ThanksI got you if you havent been sorted out already.

Are any of you guys neck sizing at all? Like once you've full length sized from 308 palma doen to SAW and then fired your first batch off, is anyone neck sizing after that? Or is everyone just full length sizing every time?

Full length every time. No sense in not. Just bump it ~.002 and carry on.Are any of you guys neck sizing at all? Like once you've full length sized from 308 palma doen to SAW and then fired your first batch off, is anyone neck sizing after that? Or is everyone just full length sizing every time?

I neck-size almost all my bolt-action brass until I have a chambering issue, then I'll run them through the FL sizer, fire them, and then start neck-sizing again until they get hard to chamber again, repeat the cycle...Are any of you guys neck sizing at all? Like once you've full length sized from 308 palma doen to SAW and then fired your first batch off, is anyone neck sizing after that? Or is everyone just full length sizing every time?

How do you find your accuracy? It's my understanding that you can get better accuracy by letting your brass fire form to your chamber and then neck sizing. I haven't actually done any full length sizing before. I'm still a bit of a rookie at reloading haha. What do you mean by "bump it ~.002"?Full length every time. No sense in not. Just bump it ~.002 and carry on.

Thanks mate! Which brand neck sizing die do you use? The reading and hornady sets for sale on the WTO website both only have FL sizers.I neck-size almost all my bolt-action brass until I have a chambering issue, then I'll run them through the FL sizer, fire them, and then start neck-sizing again until they get hard to chamber again, repeat the cycle...

This is a much longer conversation than what is appropriate for this thread but here is the quick answer:How do you find your accuracy? It's my understanding that you can get better accuracy by letting your brass fire form to your chamber and then neck sizing. I haven't actually done any full length sizing before. I'm still a bit of a rookie at reloading haha. What do you mean by "bump it ~.002"?

Full Length sizing involves moving the shoulder back as well as sizing down the neck. Neck sizing is the same process but without moving the shoulder of the case back as well. You can accomplish neck sizing even with a full length die based on how down you set the die. As the case rams up into the die, if the shoulder of the case doesn't contact the die, it doesn't get full length sized, but the neck will still get reduced in diameter.

Almost all F-Class shooters and other competition shooters full length size their brass every single time. They don't really squeeze the shit out of the brass but they do move the shoulder back a couple thousandths - this is typically refered to as "bumping". The evidence to this theory shows that you get the most repeatable results, firing after firing, if at each point the brass has the same volume every single time making a more uniform pressure. In contrast - if you neck size for 3-4 firings then full length size, your brass is incrementally growing until you shrink it down again after a few firings.

Here is a really good video on how to set up a full length sizing die and also how to use a comparator - an essential tool for reloading. You can see in this video that the difference between full length sizing and neck sizing is really just a matter of how you set your die up.

If you haven't bought one already, order this tonight: https://www.cabelas.com/shop/en/hornady-lock-n-load-headspace-kit

This is a much longer conversation than what is appropriate for this thread but here is the quick answer:

Full Length sizing involves moving the shoulder back as well as sizing down the neck. Neck sizing is the same process but without moving the shoulder of the case back as well. You can accomplish neck sizing even with a full length die based on how down you set the die. As the case rams up into the die, if the shoulder of the case doesn't contact the die, it doesn't get full length sized, but the neck will still get reduced in diameter.

Almost all F-Class shooters and other competition shooters full length size their brass every single time. They don't really squeeze the shit out of the brass but they do move the shoulder back a couple thousandths - this is typically refered to as "bumping". The evidence to this theory shows that you get the most repeatable results, firing after firing, if at each point the brass has the same volume every single time making a more uniform pressure. In contrast - if you neck size for 3-4 firings then full length size, your brass is incrementally growing until you shrink it down again after a few firings.

Here is a really good video on how to set up a full length sizing die and also how to use a comparator - an essential tool for reloading. You can see in this video that the difference between full length sizing and neck sizing is really just a matter of how you set your die up.

If you haven't bought one already, order this tonight: https://www.cabelas.com/shop/en/hornady-lock-n-load-headspace-kit

Thanks Dave, that's really helpful info! I appreciate it!

How important is it to neck turn the 308 palma brass? I'd mainly be shooting hunter class target rifle. (Basically F-class off a bipod with a hunting rifle)

RCBS & Redding. You can find a huge selection of stuff at Midway USA.Thanks mate! Which brand neck sizing die do you use? The reading and hornady sets for sale on the WTO website both only have FL sizers.

I never turn Palma brass (or any brass) unless my chamber calls for it. I have been known to 'skim' necks for uniformity especially during initial brass prep but that's about it. I've found the Lapua brass reasonably consistent with the necks thickening up a little bit near the shoulder. I've found the Alpha version of the 308 Palma brass very good as well (I'm using the WTO / Alpha brass exclusively for this rifle) All of the above statement goes out the door for most other brass manufacturers, it's hit and miss at best (before someone yells at me ADG and Peterson brass are also very good, if I could ever get my hands on ADG brass I'd actually have an opinionHow important is it to neck turn the 308 Palma brass? I'd mainly be shooting hunter class target rifle. (Basically F-class off a bipod with a hunting rifle)

All that being said I haven't really found the sweet spot with the SAW. Found some fast loads, found some accurate but slow loads...haven't found the speed / accuracy combination just yet.

Neck-size only is pretty old school and for good reason...there is no downside to full length sizing every time in terms of accuracy or anything else.Thanks mate! Which brand neck sizing die do you use? The reading and hornady sets for sale on the WTO website both only have FL sizers.

Not the place to get into in this thread but just do your research and learn how to bump the shoulder .002-.003" in a full length size each time. No stuck cases, hard to chamber rounds, etc.

I'm using the Hornady FL 7 Saw die from WTO with good results. The Redding wasn't in stock when I was looking to buy.

Perfect! Thanks, that's what I wanted to hear! I was hoping to avoid neck turning if possible haha. I was under the impression that by necking the brass down to 7mm could cause inconsistent thickness in the wall of the neck.I never turn Palma brass (or any brass) unless my chamber calls for it. I have been known to 'skim' necks for uniformity especially during initial brass prep but that's about it. I've found the Lapua brass reasonably consistent with the necks thickening up a little bit near the shoulder. I've found the Alpha version of the 308 Palma brass very good as well (I'm using the WTO / Alpha brass exclusively for this rifle) All of the above statement goes out the door for most other brass manufacturers, it's hit and miss at best (before someone yells at me ADG and Peterson brass are also very good, if I could ever get my hands on ADG brass I'd actually have an opinion)

All that being said I haven't really found the sweet spot with the SAW. Found some fast loads, found some accurate but slow loads...haven't found the speed / accuracy combination just yet.

Thanks mate, I'm going to start FL sizing. It really does make a lot of sense! I'm leaning towards the Hornady set as wellNeck-size only is pretty old school and for good reason...there is no downside to full length sizing every time in terms of accuracy or anything else.

Not the place to get into in this thread but just do your research and learn how to bump the shoulder .002-.003" in a full length size each time. No stuck cases, hard to chamber rounds, etc.

I'm using the Hornady FL 7 Saw die from WTO with good results. The Redding wasn't in stock when I was looking to buy.

Went out today with the SAW to see what speeds I could get with the 180 ELDMs.

I loaded a small ladder with Varget and H4350.

Unfortunately I could not get enough H4350 in the case to get over 2600 FPS, but with Varget I was able to get 2720 but right on the low side of pressure. (Bolt swipe). Right now I've got it right at 2700 and No pressure sighs whatsoever so I may just shoot this load but wanting a bit more..

I'm thinking I may try some N550 and see if I can get a bit more velocity.

Any suggestions...

28" Hawkhill type II chamber

1-8.25 twist

WTO Alpha brass.

I loaded a small ladder with Varget and H4350.

Unfortunately I could not get enough H4350 in the case to get over 2600 FPS, but with Varget I was able to get 2720 but right on the low side of pressure. (Bolt swipe). Right now I've got it right at 2700 and No pressure sighs whatsoever so I may just shoot this load but wanting a bit more..

I'm thinking I may try some N550 and see if I can get a bit more velocity.

Any suggestions...

28" Hawkhill type II chamber

1-8.25 twist

WTO Alpha brass.

RL26/RL16 seems to be the go-to when people want more velocity in the medium 7mm's like SAW,SAUM, etc. The trick is finding it AND it's more temp sensitive than H4350 supposedly, never messed with it myself. A 180 ELD-M at 2700 is no slouch, especially out of a short action non-magnum. I'd roll with it at 2700 and be happy if your numbers and accuracy are good.Went out today with the SAW to see what speeds I could get with the 180 ELDMs.

I loaded a small ladder with Varget and H4350.

Unfortunately I could not get enough H4350 in the case to get over 2600 FPS, but with Varget I was able to get 2720 but right on the low side of pressure. (Bolt swipe). Right now I've got it right at 2700 and No pressure sighs whatsoever so I may just shoot this load but wanting a bit more..

I'm thinking I may try some N550 and see if I can get a bit more velocity.

Any suggestions...

28" Hawkhill type II chamber

1-8.25 twist

WTO Alpha brass.

Last edited:

IMO, WTOs velocity claims are sensational marketing designed to drive sales similar to how Sherman operates. That doesn’t take away from the real value that these cartridges have but incentivizing guys to push heavies at unrealistic velocities is irresponsible. I still love my 7 saw though just as much as my 7ss, you just won’t see me trying to get full size magnum speeds out of either.

Love my 7 saw, i decided to build a 25 saw. Necked down using 289 and 281 bushing then ran through 25 cal expander. 134gr ELDM just sitting in the case. Preffered Barrel Blanks is making me another Remage barrel 26" 1-7.5 twist heavy palma. Oal should be roughly the same as the 7 and will put the bullet right around the start of the case body. These 134gr ELDM are long

What do you reckon you’ll get for speed? Wondering if this would make power factor for nrlh.Love my 7 saw, i decided to build a 25 saw. Necked down using 289 and 281 bushing then ran through 25 cal expander. 134gr ELDM just sitting in the case. Preffered Barrel Blanks is making me another Remage barrel 26" 1-7.5 twist heavy palma. Oal should be roughly the same as the 7 and will put the bullet right around the start of the case body. These 134gr ELDM are long

View attachment 8277510

What kind of performance are you getting with the 25 SAW?Love my 7 saw, i decided to build a 25 saw. Necked down using 289 and 281 bushing then ran through 25 cal expander. 134gr ELDM just sitting in the case. Preffered Barrel Blanks is making me another Remage barrel 26" 1-7.5 twist heavy palma. Oal should be roughly the same as the 7 and will put the bullet right around the start of the case body. These 134gr ELDM are long

View attachment 8277510

Hoping to see 2800-2900 fpsWhat do you reckon you’ll get for speed? Wondering if this would make power factor for nrlh.

Please let us know how it work out for you.Getting a new barrel. Going with proof comp contour since my last barrel was so slow compared to others using n550. Barrel had a tight bore and led me to pressure earlier. I couldn’t get over 2700 even with a 162.

I am curious if I may be dealing with the same issue.

Will keep the forum updated. I love 7 SAW and it’s become my main cartridge for hunting and PRS. My gunsmith has a 22” that is getting much more fps than my 26” at the same charge weights.Please let us know how it work out for you.

I am curious if I may be dealing with the same issue.

He determined it’s a tight bore, so hope that going to the proof stainless will help. I’ve also went ahead and bought 500 pieces of brand new alpha brass to start anew.

Any of you guys having any trouble with suppressors?

I have a Silencerco Harvester 300 that I had used for a few thousand rounds on everything up to a 300 PRC.

Last winter I got my 7SAW set up on a 18.5” barrel & after ~600 rounds I started getting deformation of the suppressor (little “pimple” towards the end of it). I sent it to Silencerco and they sent me a new one in a jiffy and said the repair was within warranty.

Now I’m only 400 rounds into the new suppressor and I’ve found a new “pimple.”

I’m not doing anything too crazy and have primarily followed reloading guides for the 7-08. (My main load is .1gr above the max Hodgdon rec for Varget and 7-08)

I have a Silencerco Harvester 300 that I had used for a few thousand rounds on everything up to a 300 PRC.

Last winter I got my 7SAW set up on a 18.5” barrel & after ~600 rounds I started getting deformation of the suppressor (little “pimple” towards the end of it). I sent it to Silencerco and they sent me a new one in a jiffy and said the repair was within warranty.

Now I’m only 400 rounds into the new suppressor and I’ve found a new “pimple.”

I’m not doing anything too crazy and have primarily followed reloading guides for the 7-08. (My main load is .1gr above the max Hodgdon rec for Varget and 7-08)

That seems to be a suppressor issue and not the cartridge that you are using. Have any pictures of this issue? I run a hydrogen L on mine pretty much all the time.Any of you guys having any trouble with suppressors?

I have a Silencerco Harvester 300 that I had used for a few thousand rounds on everything up to a 300 PRC.

Last winter I got my 7SAW set up on a 18.5” barrel & after ~600 rounds I started getting deformation of the suppressor (little “pimple” towards the end of it). I sent it to Silencerco and they sent me a new one in a jiffy and said the repair was within warranty.

Now I’m only 400 rounds into the new suppressor and I’ve found a new “pimple.”

I’m not doing anything too crazy and have primarily followed reloading guides for the 7-08. (My main load is .1gr above the max Hodgdon rec for Varget and 7-08)

I have a Harvester 300 that I sent back twice for "baffle failures". It worked flawlessly for approximately 2,000 rounds on a 22" 7-08, a 21.5" .243., and a 22" .280 Ackley. I then put it on an 18" 6.5x47 and started to run into trouble. Both times, the baffle closest to the crown broke/failed. The first time it happened was after about 500 rounds from the 6.5x47. The second time was after a few hundred on the same rifle, fresh from the "re-core". I was pretty anal about not letting it get too hot, cooling down, and only shooting 3 shot strings, but the same exact failure happened again. (Note: these were perfectly safe loads. Primers looked good, no ejector swipe, no heavy bolt lift, brass life was great, etc.) Silencerco fixed it both times in less than a week no questions asked, but I decided that the harvester just doesn't mix well with shorter barrels when paired with rounds that tend to run at higher pressures (SRP like the 6.5x47, 7 saw, etc.).Any of you guys having any trouble with suppressors?

I have a Silencerco Harvester 300 that I had used for a few thousand rounds on everything up to a 300 PRC.

Last winter I got my 7SAW set up on a 18.5” barrel & after ~600 rounds I started getting deformation of the suppressor (little “pimple” towards the end of it). I sent it to Silencerco and they sent me a new one in a jiffy and said the repair was within warranty.

Now I’m only 400 rounds into the new suppressor and I’ve found a new “pimple.”

I’m not doing anything too crazy and have primarily followed reloading guides for the 7-08. (My main load is .1gr above the max Hodgdon rec for Varget and 7-08)

I still have the harvester, but it is dedicated to my longer/standard barreled rigs. I fixed my short barrel suppressor problem by buying a TBAC Ultra 7. Three years later, running the same short barrel "loads", the TBAC has been stellar and worth every penny.

That sounds a lot like my issues. I’m just into hunting, so I let my gun cool between shots because the cold bore shot is the only one that counts.I have a Harvester 300 that I sent back twice for "baffle failures". It worked flawlessly for approximately 2,000 rounds on a 22" 7-08, a 21.5" .243., and a 22" .280 Ackley. I then put it on an 18" 6.5x47 and started to run into trouble. Both times, the baffle closest to the crown broke/failed. The first time it happened was after about 500 rounds from the 6.5x47. The second time was after a few hundred on the same rifle, fresh from the "re-core". I was pretty anal about not letting it get too hot, cooling down, and only shooting 3 shot strings, but the same exact failure happened again. (Note: these were perfectly safe loads. Primers looked good, no ejector swipe, no heavy bolt lift, brass life was great, etc.) Silencerco fixed it both times in less than a week no questions asked, but I decided that the harvester just doesn't mix well with shorter barrels when paired with rounds that tend to run at higher pressures (SRP like the 6.5x47, 7 saw, etc.).

I still have the harvester, but it is dedicated to my longer/standard barreled rigs. I fixed my short barrel suppressor problem by buying a TBAC Ultra 7. Three years later, running the same short barrel "loads", the TBAC has been stellar and worth every penny.

I’m not using the SRP, but converting Alpha 7-08 LRP brass, and getting better speed/performance than I was expecting.

I’ve been looking at getting a second suppressor as my eldest son will start hunting soon, and have been thinking of the TBAC.

Thanks for your response, guys.

Similar threads

- Replies

- 16

- Views

- 816

- Replies

- 18

- Views

- 1K

- Replies

- 37

- Views

- 2K