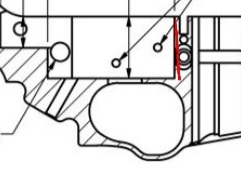

Hey everyone, so ive milled a few lowers with a 5d tactical jig and I'm getting pretty pissed off. This keeps happening. I'm wondering if somthing is out of spec. But is there anyway to fix this? Is it still functional? I was thinking JB weld or trying a tig welder. I keep milling through where the mag release is. Any suggestions?

Join the Hide community

Get access to live stream, lessons, the post exchange, and chat with other snipers.

Register

Download Gravity Ballistics

Get help to accurately calculate and scope your sniper rifle using real shooting data.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

80 percent lower help?

- Thread starter Dildobaggins

- Start date

Not familiar with 5d tactical jig, but have used Broken Arms jig & tooling with great success. Could be the jig is out of spec or cutter not vertical. Probably functional In spite of cut-thru.

OFG

OFG

I've done 4 or 5 with the 80% arms gen 1 jig without any problems. That's definitely fucked up. I'd imagine it'll still work fine, but I'd be making some calls.

Jig or lowers are probably out of spec, or you're using lowers that aren't compatible or something.

Jig or lowers are probably out of spec, or you're using lowers that aren't compatible or something.

it should work. Did you also buy the 80% from 5d tactical? Just wondering if the jig is best used on their own stuff

I have a 5d tactial jig for Ar-15 and its been fine for the few ive done.

I have a 5d tactial jig for Ar-15 and its been fine for the few ive done.

I bought them from right to bear. I also have 2 coming from thunder tactical. I would gladly buy the 5d tactical lowers, but i'm in NY, and they wont ship lowers to me...but they have no problem shipping the jig to make them haha. im just upset. the jig took 10 weeks to get here. Ive looked over everything. guide plates the jig itself. the bits, etc. I wish I could find some measurements from them to see if this thing is within spec. I did one earlier today, and it came out great. looks professionally done. not sure what im doing wrong. also. with me being in NY the mag will be permanently fixed in place anyway so the mag release wont even be functioning.it should work. Did you also buy the 80% from 5d tactical? Just wondering if the jig is best used on their own stuff

I have a 5d tactial jig for Ar-15 and its been fine for the few ive done.

I bought them from right to bear. I also have 2 coming from thunder tactical. I would gladly buy the 5d tactical lowers, but i'm in NY, and they wont ship lowers to me...but they have no problem shipping the jig to make them haha. im just upset. the jig took 10 weeks to get here. Ive looked over everything. guide plates the jig itself. the bits, etc. I wish I could find some measurements from them to see if this thing is within spec. I did one earlier today, and it came out great. looks professionally done. not sure what im doing wrong. also. with me being in NY the mag will be permanently fixed in place anyway so the mag release wont even be functioning.

maybe send them an email with the picture and ask them about it. Also explain that they wont ship you their lowers. i see they have a blemish for sale for 49 in the ar10 size.

one thing is for sure gun businesses like these are owned by gun people (typically) they are usually pretty good to deal with if you can get them on the phone.

Ive tried calling, they arent answering phones, and emails take about a week to get answered. Its rediculous. Maybe I'll go buy an 80 percent arms jig. Or put somthing on the guide plate so the pins that hot the template wont go forward as much as they are. I have a feeling by the time I have it all sorted out they will have completly ban them in NY.I've done 4 or 5 with the 80% arms gen 1 jig without any problems. That's definitely fucked up. I'd imagine it'll still work fine, but I'd be making some calls.

Jig or lowers are probably out of spec, or you're using lowers that aren't compatible or something.

Was the good one done before or after the problem?I bought them from right to bear. I also have 2 coming from thunder tactical. I would gladly buy the 5d tactical lowers, but i'm in NY, and they wont ship lowers to me...but they have no problem shipping the jig to make them haha. im just upset. the jig took 10 weeks to get here. Ive looked over everything. guide plates the jig itself. the bits, etc. I wish I could find some measurements from them to see if this thing is within spec. I did one earlier today, and it came out great. looks professionally done. not sure what im doing wrong. also. with me being in NY the mag will be permanently fixed in place anyway so the mag release wont even be functioning.

OFG

There are some videos on YouTube about this "mystery hole" I'm not sure if they have gotten answers from the company yet.

This is the first video in the series about the jig and mystery hole. The first video is just him using the jig then there are some followup videos.

So I ordered an 80 percent arms jig. Thing is nasty, works great, zero problems. Sold the other jig to a guy on gun broker. Who said it wasnt the jig, it was me. After bitching to 5d tactical and writing horrible reviews... went out to my mailbox last week, opened it up and a brand new 5d tactical jig was in it. So I'll be selling that one as well. I know for a fact many people have had stellar results with that jig, but I have no faith in it.There are some videos on YouTube about this "mystery hole" I'm not sure if they have gotten answers from the company yet.

This is the first video in the series about the jig and mystery hole. The first video is just him using the jig then there are some followup videos.

Watched that video. Never heard him mention the magwell hole, but I noticed it in the video. Im still interested in why its happening. On the 5D, I built up 4 layers of electrical tape and epoxied it to the front, basically. Made a shim, and they came out fine, but I want better quality than that.

Sorry. I think it isnt mentioned until the second or third video in the series.Watched that video. Never heard him mention the magwell hole, but I noticed it in the video. Im still interested in why its happening. On the 5D, I built up 4 layers of electrical tape and epoxied it to the front, basically. Made a shim, and they came out fine, but I want better quality than that.

Okay, im going to go watch. Maybe I'll finally have an answer. Thanks man!Sorry. I think it isnt mentioned until the second or third video in the series.

I've used the 5d jig numerous times with ar-15 and lr-308 recievers, and never had an issue. I let a friend use it to cut some ar-9 receivers and both of them had a very slight cut-through in the same spot. I believe the problem is in the castings, and not necessarily the jig. With the way the jig is made, unless you monkey up the mounting of the receiver or have an end mill that's bent, I don't know how it would be the jig's fault. With the number of 80% lowers that have been cast and sold, a bad cast would not be out of the question.

My rationale for my post is that, if you look at the front wall of the fcg cavity from the top, the thickness looks right. If the jig was off, that wall should be VERY thin even at the top, and it isn't. If your cutter is concentric and square to the router base, then it's cutting into a cavity that should not exist.

I'm sure they are great. But thats like saying JP has never made a lemon barrel. Its very uncommon but it does happen. Somthing was out of spec with the jig. I had 4 80 lowers from 3 different manufacturers. All had the same problem. Tried different router and endmill. Dissasembled jig, put it back together even tried one 308 lower. Same issues. Got the 80 percent arms jig. Issue gone. I checked every possible variable to the situation. Mathematically the odds of getting a total of 5 lowers from diff manufacturers and haveing them all be out of spec, is astronomical. The only variable left that was,unchecked was jig specs.I've used the 5d jig numerous times with ar-15 and lr-308 recievers, and never had an issue. I let a friend use it to cut some ar-9 receivers and both of them had a very slight cut-through in the same spot. I believe the problem is in the castings, and not necessarily the jig. With the way the jig is made, unless you monkey up the mounting of the receiver or have an end mill that's bent, I don't know how it would be the jig's fault. With the number of 80% lowers that have been cast and sold, a bad cast would not be out of the question.

Are the bits cutting 90° perpendicular to the top of the receiver? That area is pretty thin already and if its off by even aa few thou you can get this.

The top part should be at least .1" but you could get away with more.

The top part should be at least .1" but you could get away with more.

aspecs.also when milling out the hole for the trigger, the front of the hole was spec and the back of the hole was almost triple the thickness. Tried to remedy by using a level. Got ut completly level...same issueMy rationale for my post is that, if you look at the front wall of the fcg cavity from the top, the thickness looks right. If the jig was off, that wall should be VERY thin even at the top, and it isn't. If your cutter is concentric and square to the router base, then it's cutting into a cavity that should not exist.

With the shim i made useing the 5d, i got a thickness of .13 drop in and milspec triggers both fit. Good info. Thanks!Are the bits cutting 90° perpendicular to the top of the receiver? That area is pretty thin already and if its off by even aa few thou you can get this.

The top part should be at least .1" but you could get away with more.

View attachment 7486301

Also on the 5d the top was. .07 and bottom was .07. The same happened with the other endmillAre the bits cutting 90° perpendicular to the top of the receiver? That area is pretty thin already and if its off by even aa few thou you can get this.

The top part should be at least .1" but you could get away with more.

View attachment 7486301

I just bought a 5D jig. Did you use the recommended direct-thread router bit they sell?With the shim i made useing the 5d, i got a thickness of .13 drop in and milspec triggers both fit. Good info. Thanks!

I'm not saying it's not possible, and please don't take this as some sort of personal attack. You said you did one later that came out perfect, correct? The jig didn't change. So what was different? Keep in mind, everyone and their brother is selling 80% lowers, but there are only two or three companies that are manufacturing them (that I know of), and if it is a manufacturer's defect (the casting), there could be untold thousands of them out there.I'm sure they are great. But thats like saying JP has never made a lemon barrel. Its very uncommon but it does happen. Somthing was out of spec with the jig. I had 4 80 lowers from 3 different manufacturers. All had the same problem. Tried different router and endmill. Dissasembled jig, put it back together even tried one 308 lower. Same issues. Got the 80 percent arms jig. Issue gone. I checked every possible variable to the situation. Mathematically the odds of getting a total of 5 lowers from diff manufacturers and haveing them all be out of spec, is astronomical. The only variable left that was,unchecked was jig specs.

I'm not familiar with that jig but I would double check that the receiver is sitting in it correctly and that all horizontal plates are parallel to the top of the receiver.

Fwiw, I exclusively use Juggernaut tactical jig and a mill.

Fwiw, I exclusively use Juggernaut tactical jig and a mill.

aspecs.also when milling out the hole for the trigger, the front of the hole was spec and the back of the hole was almost triple the thickness. Tried to remedy by using a level. Got ut completly level...same issue

If your jig is not square on the receiver this would explain both.

There's a lot of chips flying its easy to get one stuck in the wrong place and tighten everything down.

That would explain it, however, I can't see flying chips or misalignment or the lower to happen so consistently. I expect that it is a tolerance issue with the jig but probably easily solved.If your jig is not square on the receiver this would explain both.

There's a lot of chips flying its easy to get one stuck in the wrong place and tighten everything down.

View attachment 7486347

I'm not saying it's not possible, and please don't take this as some sort of personal attack. You said you did one later that came out perfect, correct? The jig didn't change. So what was different? Keep in mind, everyone and their brother is selling 80% lowers, but there are only two or three companies that are manufacturing them (that I know of), and if it is a manufacturer's defect (the casting), there could be untold thousands of them out there.

[/QUOTE

My bad man. I wasnt trying to sound like a dick. Thats correct though. The one that does not have a hole measures .07 wall thickness from the magwell. It could have been me. Im by no,means a machinist. I used noreen forged and Anderson who I believe is cerro. Thunder tactical? I have no idea who does those.

Yes I did. But I said in a previous comment, ive seen dozens of videos of people milling out excellect lowers with them. In my opinion from what I have seen they are just as good if not better than any other jig out there. It very well could have been my own doing, or perhaps the jig was out of spec. But from what I'm gathering thats pretty unlikely. The new one they sent me looks like a replica of an 80 percent arms jig. They resigned some things. I would use it again, if I didnt already go buy an 80 percent arms jig.I just bought a 5D jig. Did you use the recommended direct-thread router bit they sell?

That picture is exactly what kept happening. Thabks for all the input. Much appriciated.If your jig is not square on the receiver this would explain both.

There's a lot of chips flying its easy to get one stuck in the wrong place and tighten everything down.

View attachment 7486347

Similar threads

- Replies

- 142

- Views

- 17K

- Replies

- 15

- Views

- 4K

- Replies

- 157

- Views

- 31K